-

Posts

304 -

Joined

-

Last visited

About Dr PS - Paul Schulze

- Birthday April 11

Contact Methods

-

Website URL

http://www.ClearStarryNights.com

Profile Information

-

Gender

Male

-

Location

North Central Texas

-

Interests

Astrophotography, drones, N-gauge model railroading, and now model ship building. Professor Emeritus.

-

ccoyle reacted to a post in a topic:

New Bedford Whaleboat by Dr PS - FINISHED - Model Shipways MS2033 - Scale 1:16 - Small

ccoyle reacted to a post in a topic:

New Bedford Whaleboat by Dr PS - FINISHED - Model Shipways MS2033 - Scale 1:16 - Small

-

Knocklouder reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

Knocklouder reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

-

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

-

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

-

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

-

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

-

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

Ian_Grant reacted to a post in a topic:

Gokstad Viking Ship by Dr PS - Paul Schulze - FINISHED - Dusek Ship Kits - 1:35 Scale

-

aaronc reacted to a post in a topic:

New Bedford Whaleboat by Dr PS - FINISHED - Model Shipways MS2033 - Scale 1:16 - Small

aaronc reacted to a post in a topic:

New Bedford Whaleboat by Dr PS - FINISHED - Model Shipways MS2033 - Scale 1:16 - Small

-

Ugo Crisponi reacted to a post in a topic:

Guns of HISTORY Civil War Coffee Wagon by Dr PS - FINISHED - Model Shipways - Scale 1:16

Ugo Crisponi reacted to a post in a topic:

Guns of HISTORY Civil War Coffee Wagon by Dr PS - FINISHED - Model Shipways - Scale 1:16

-

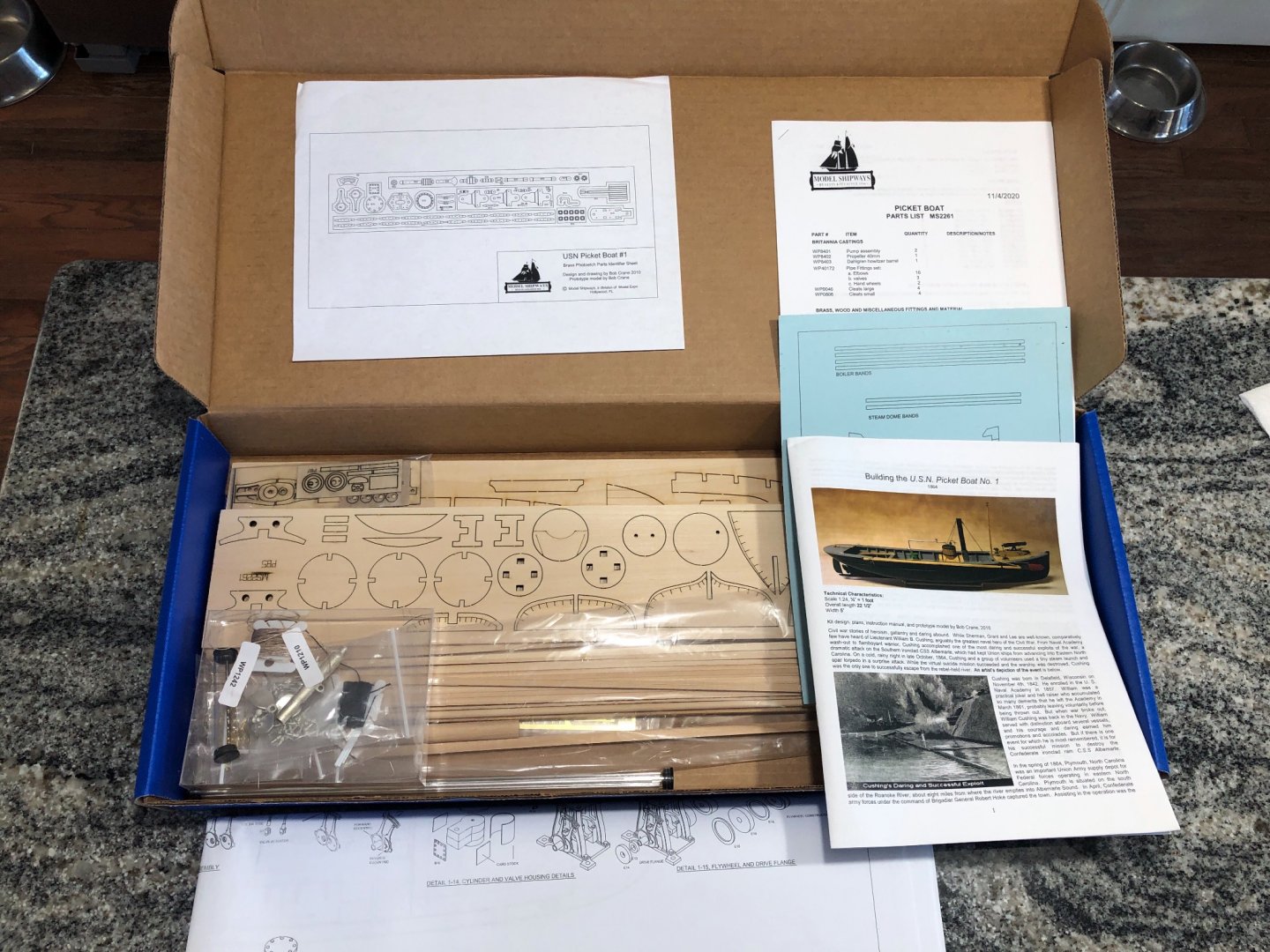

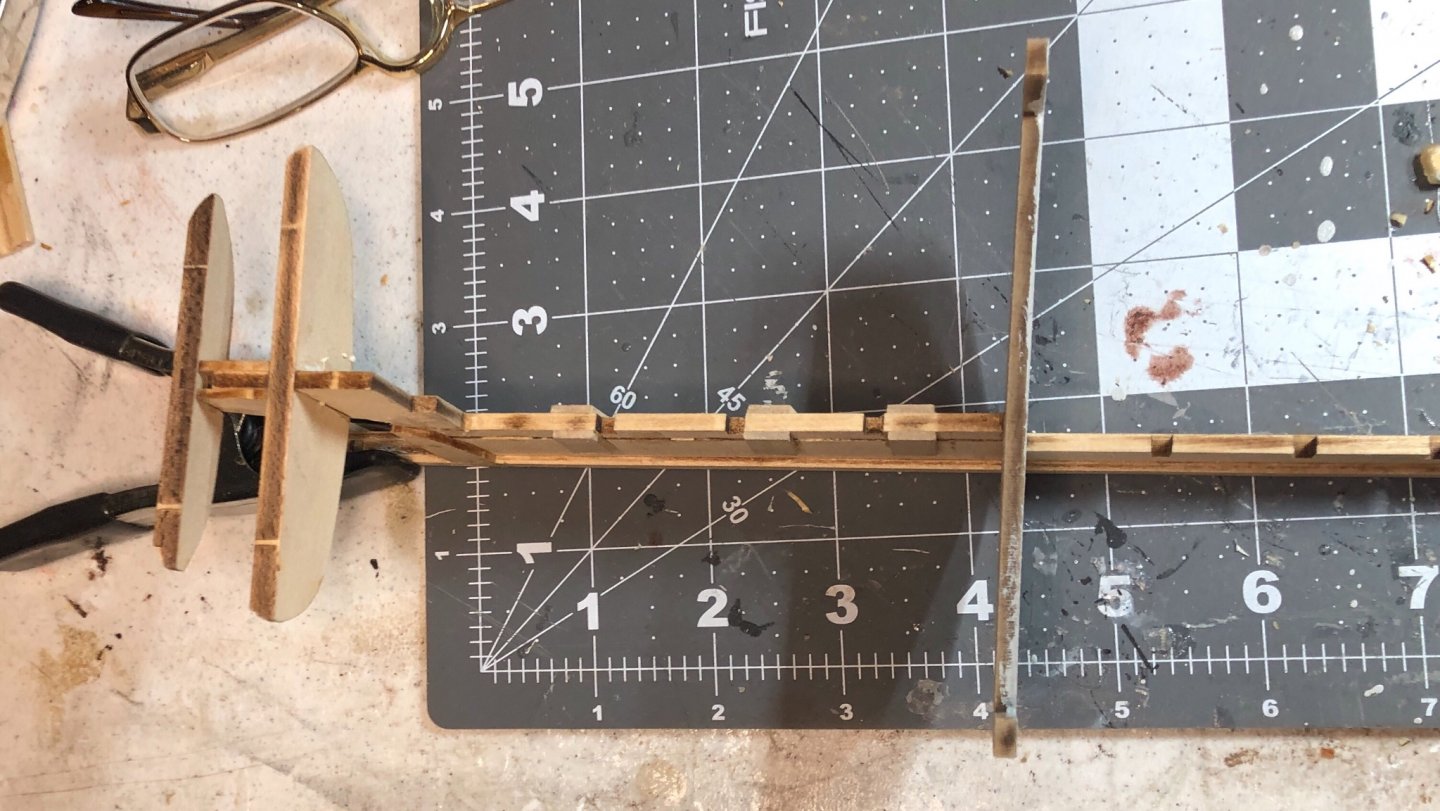

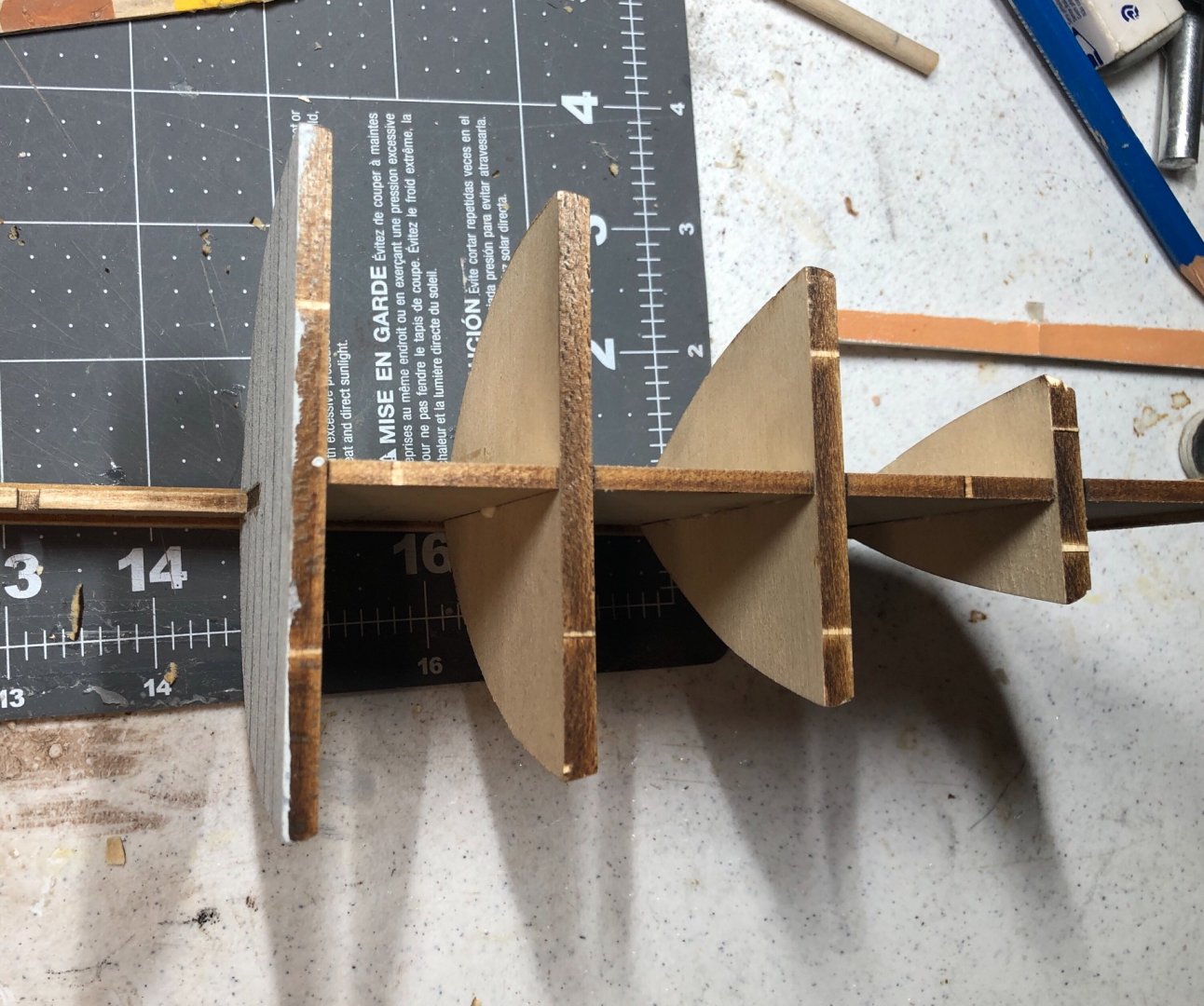

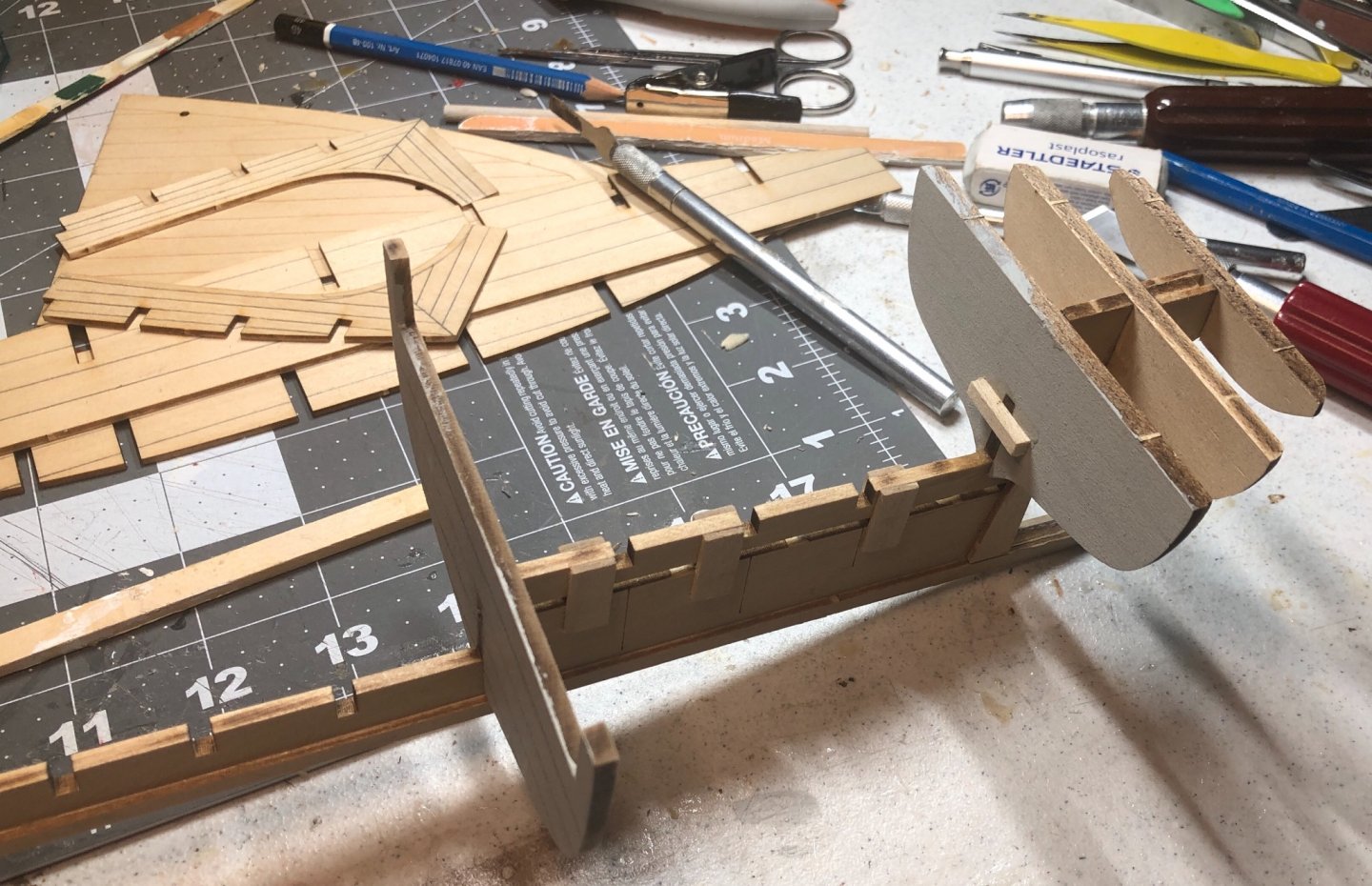

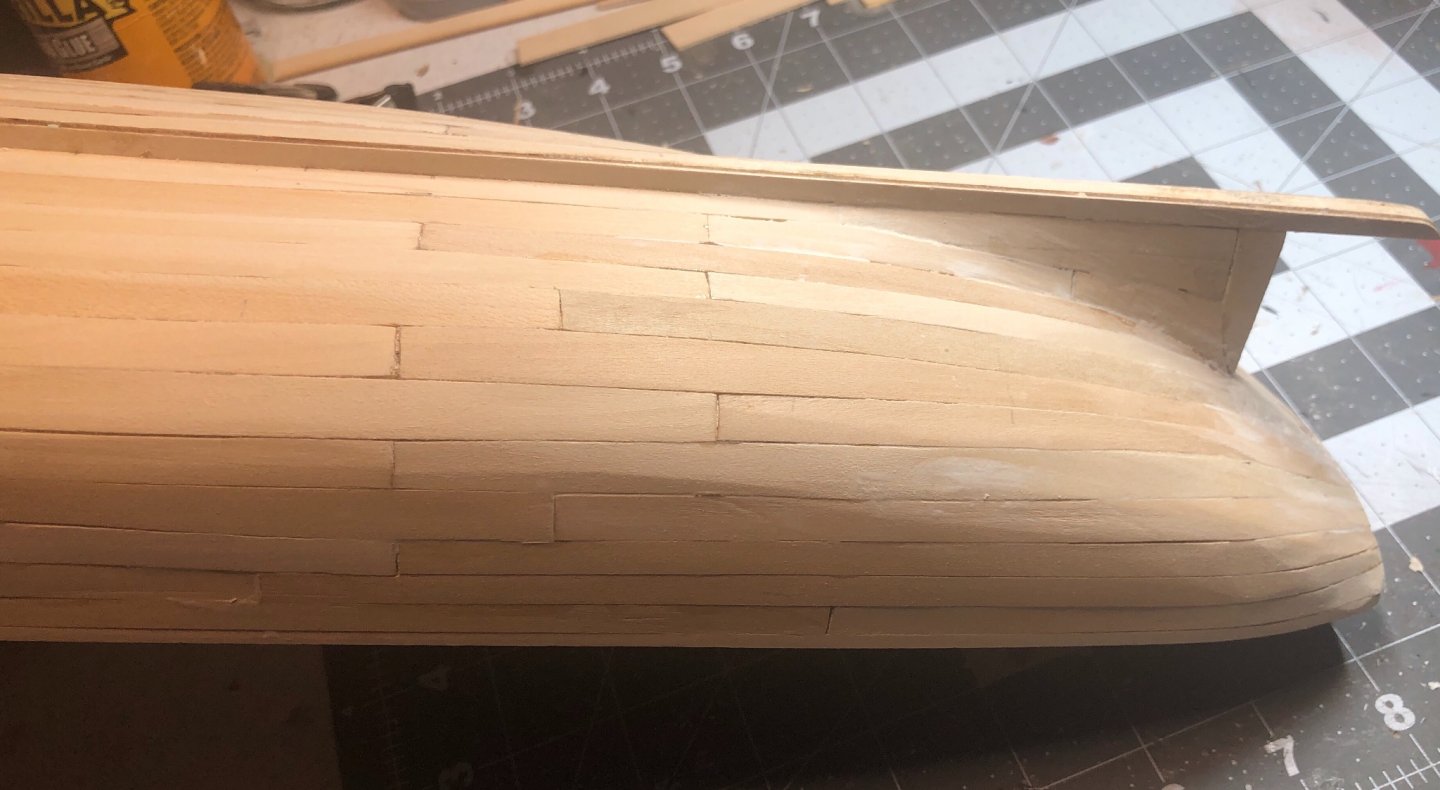

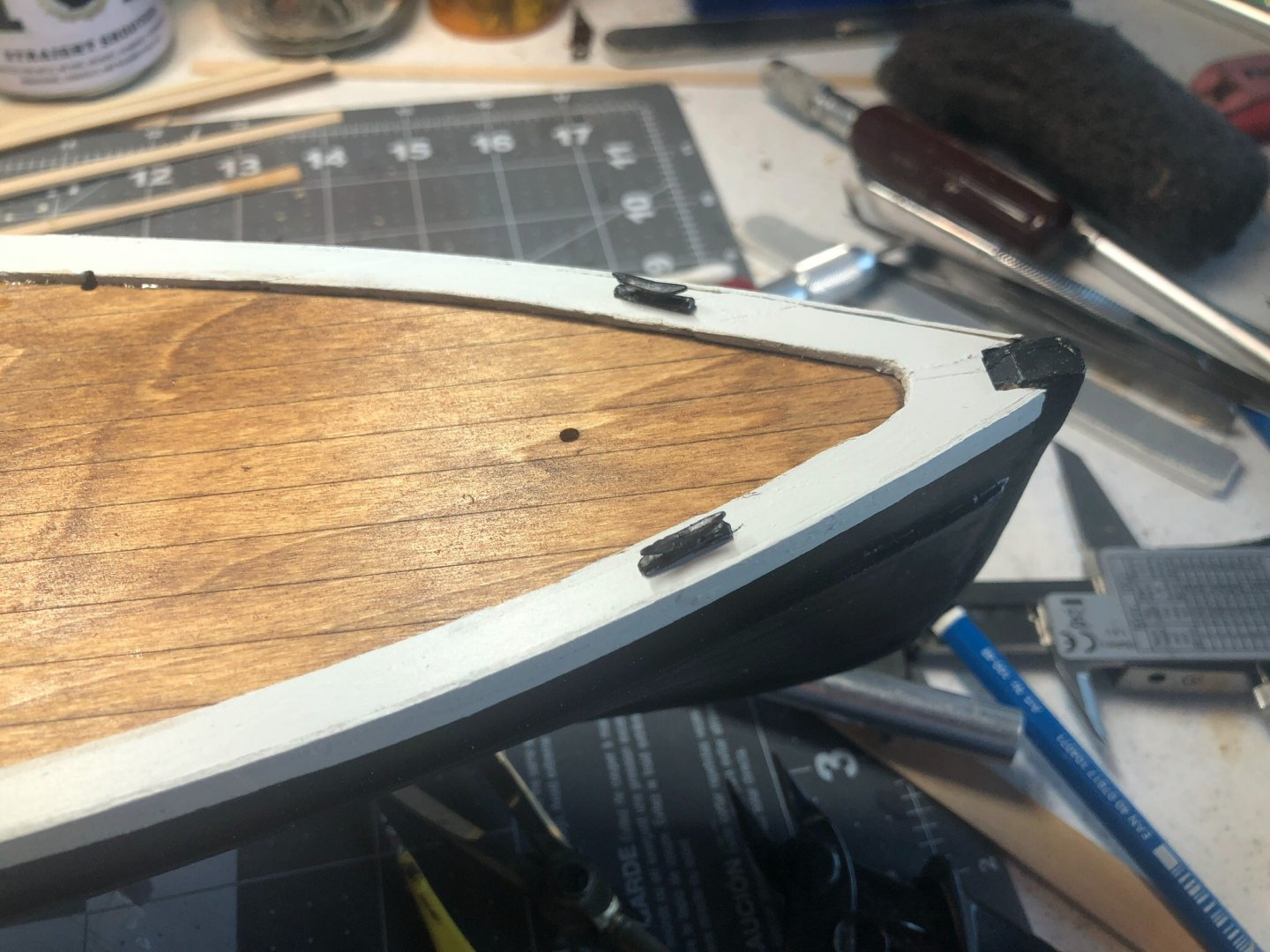

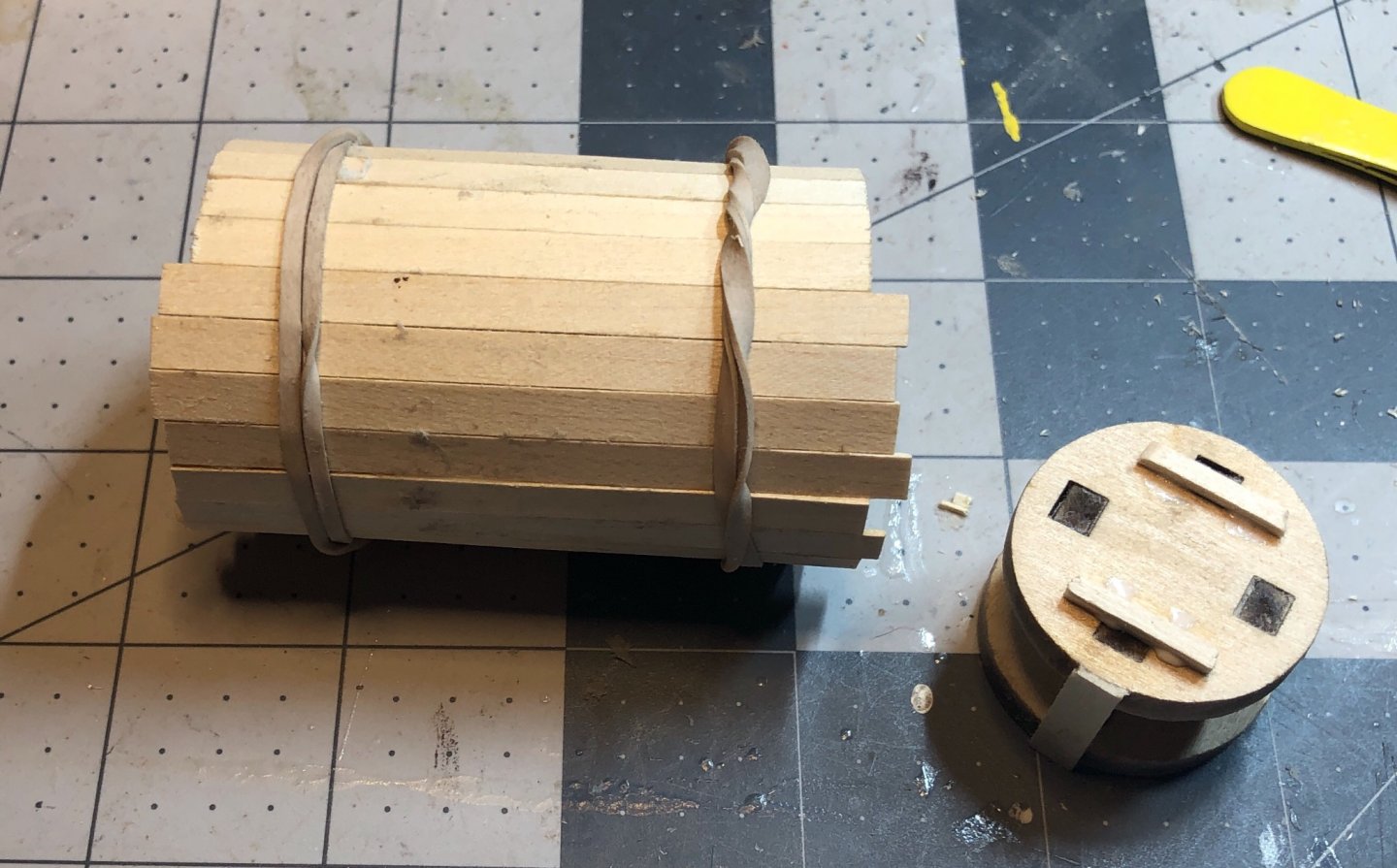

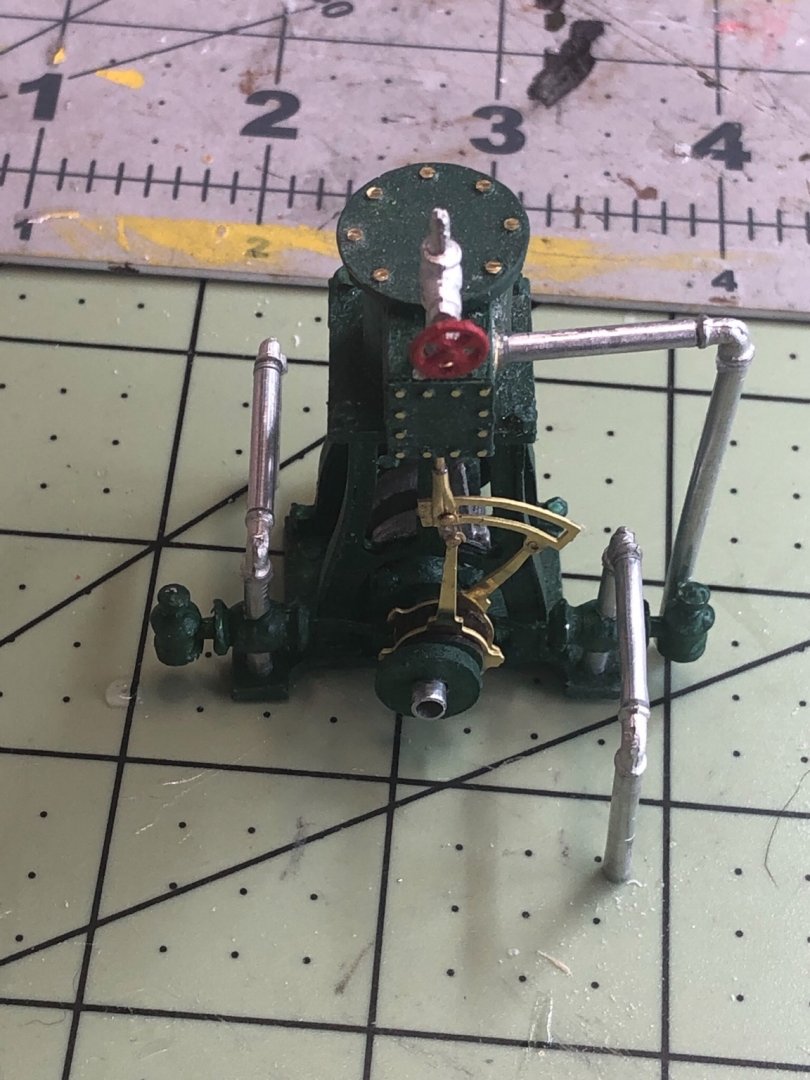

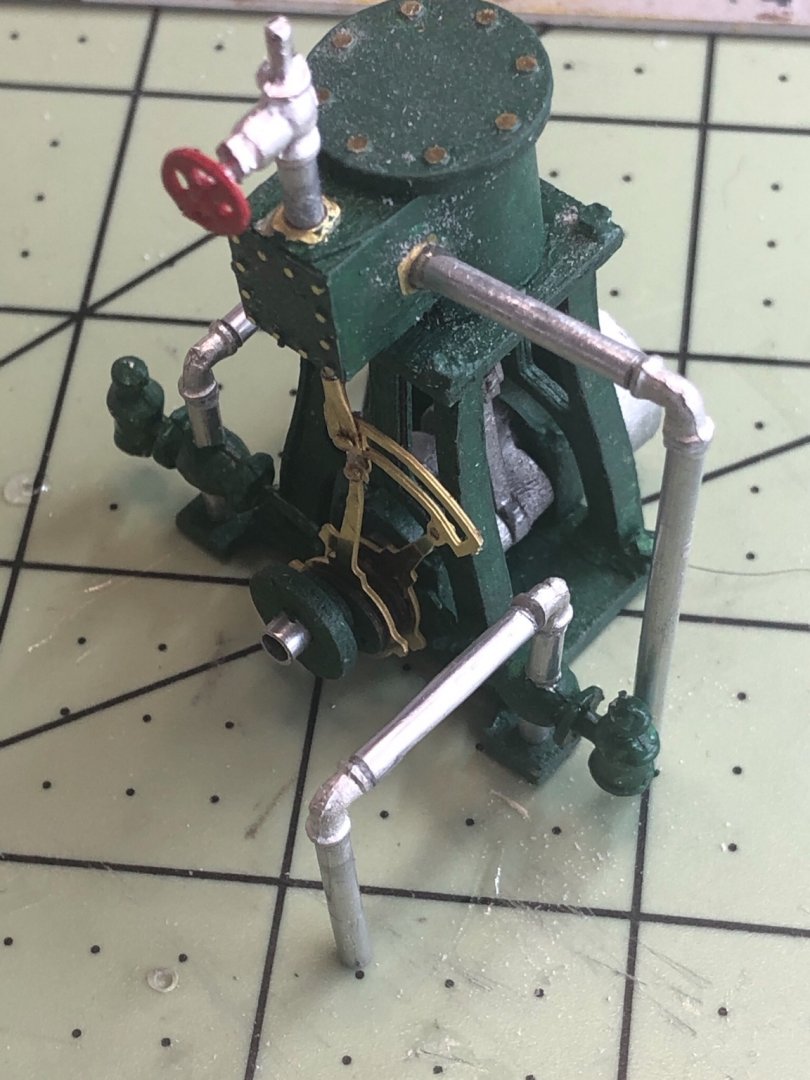

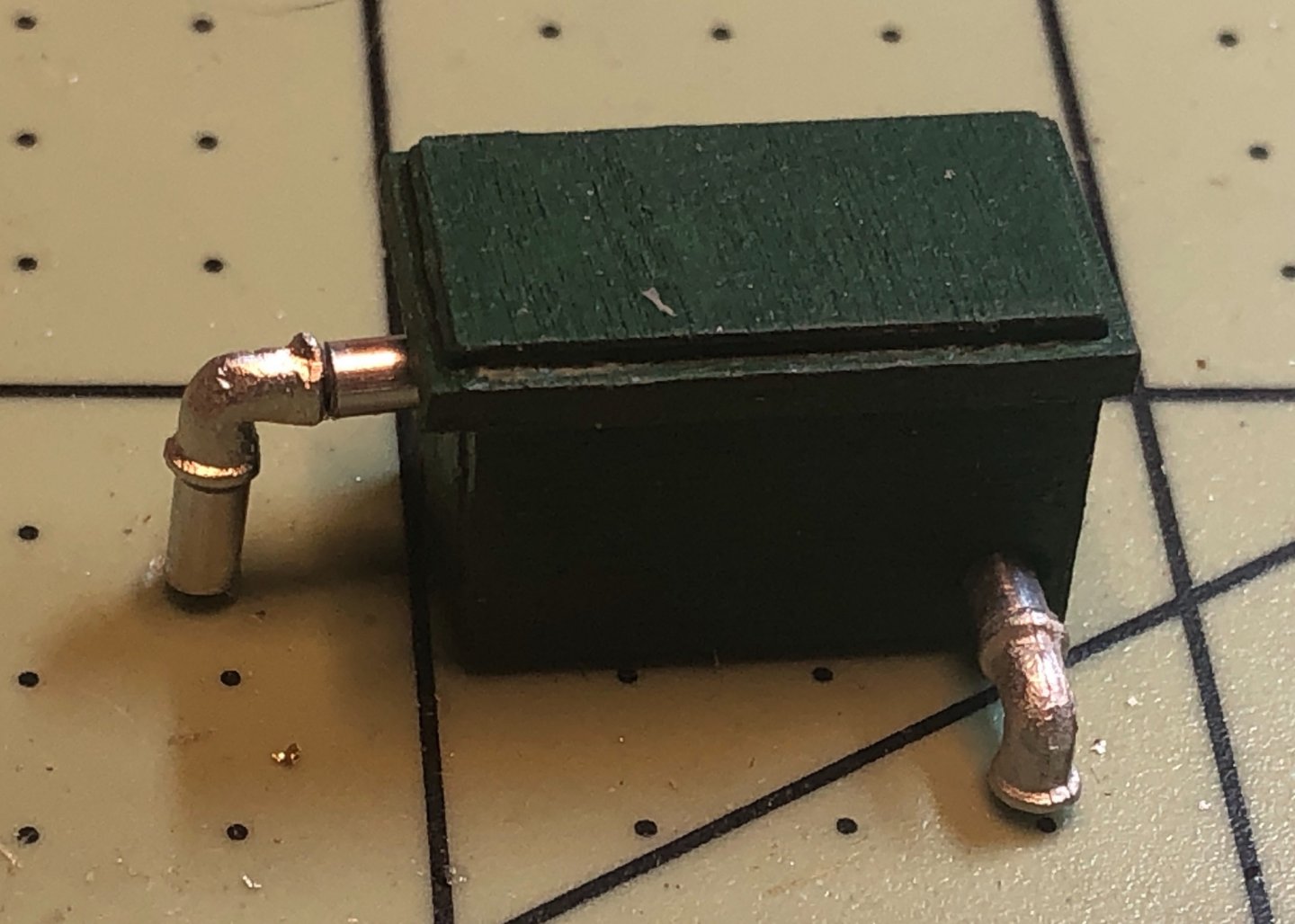

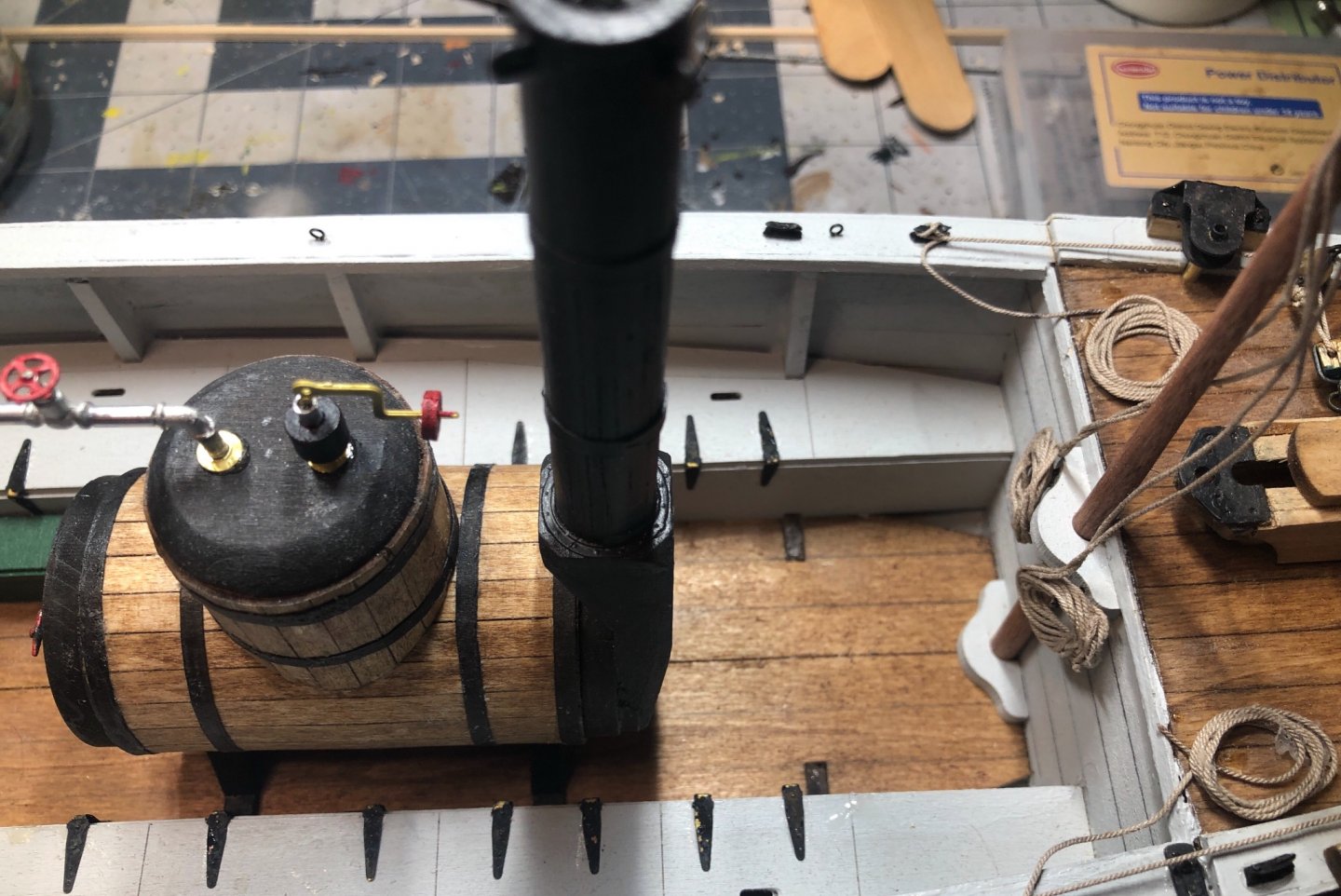

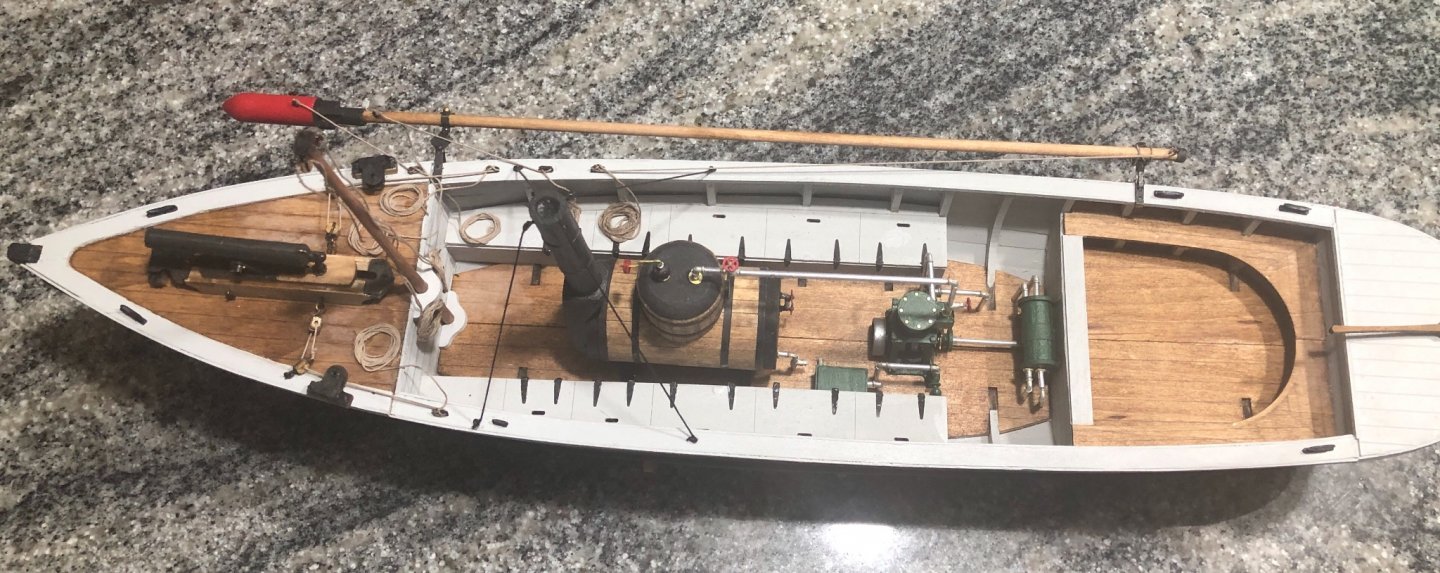

I finished this model and then I decided to post log pictures. There are lots of good build logs in this forum so I will post a sequence of progress pictures with few comments. I used a wide removable tape to spile the strokes. A pencil was used to mark the in-place strake and bulkhead marks for next strake. Tape was removed and marks joined using a French Curve. Tape was laid on wood and wood was cut and shaped as needed. Rudder and shaft Building interior parts Engine parts

- 6 replies

-

- Finished

- Picket Boat

-

(and 1 more)

Tagged with:

-

I like your new build progress. She's going to make a good looking boat.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

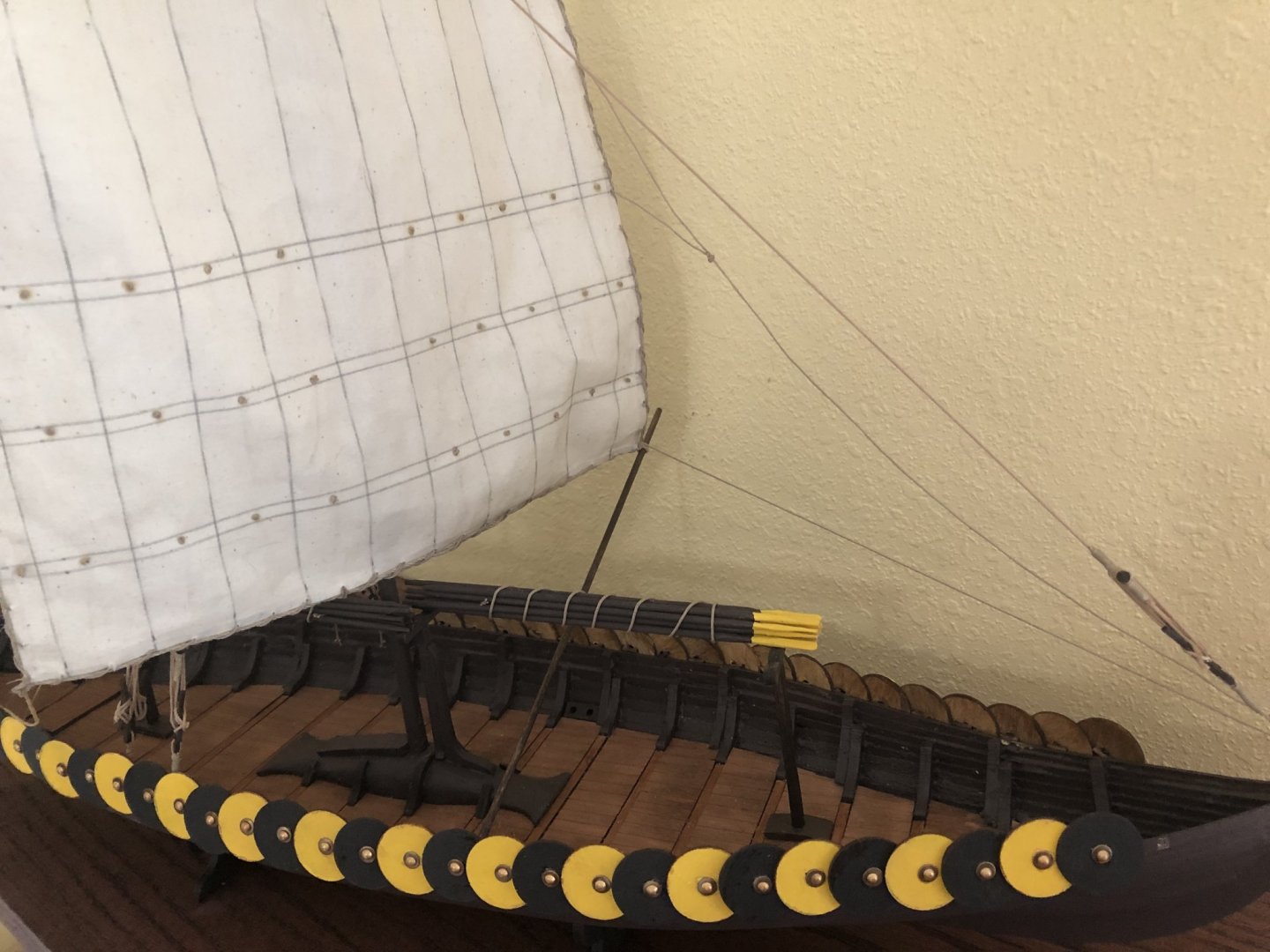

The sail mounting and sail rigging was completed. The oars were carved, painted and bundled. The Gokstad is finished. 😎

-

I assume the prototype had black and yellow shields else I would have gone with more colors. The boat builders did a fabulous job and they had fantastic skills for the tenth century. I finally finished the sail. Using the following steps : - Cut sail out - Mark sew lines and edge fold line with lead pencil - Cut corners for folding - Fold sail edges over twice using fabric glue and a hot iron - Mark and “punch” small holes in sail edge every 1/2” for needles. These holes will also be used to attach sail to mast. - Use needle and .35 rope around sail edge - Use same process for sail ties

-

I assume the prototype had black and yellow shields else I would have gone with more colors. The boat builders did a fabulous job and they had fantastic skills for the tenth century.

-

Finally have the shields done, painted and in place. The picture shows just one side done. I have decided to skip the oars for now and do the sail next.

-

I enjoyed seeing your work and what I see looks like a fine build so far. I really like the Dusek kit. I am slowing trying to finish mine but other things have taken me away for a while.

-

I have recently put the mast and main stays in place. Shrouds Now I am working on the yellow shields.

-

Justin, A very very nice build. Somehow I missed your log as it was proceeding.

- 66 replies

-

- Finished

- Model Shipways

-

(and 1 more)

Tagged with:

-

Went back to my New Bedford Whaleboat and decided to raise the sail. No log steps but I have some parting shots.

- 103 replies

-

- new bedford whaleboat

- model shipways

-

(and 1 more)

Tagged with:

-

I thought about using acetone to free them up, but allowing the strakes to follow their natural flow would result in shortening the strakes at the stem. The only solution then would be to cut new boards I believe you are correct in saying the shields will hide small errors. I have not had this issue before but I have learned I have to be more careful.

-

Yes there is a small kink on that side near the stern. I noticed it later after I was finished planking and did not know how to fix it except to remove several layers and reshape the frames as needed. That option was nixed as I have been using CA glue for the strakes. I should have been more careful and watched the fairing as I proceeded. Thanks for your comments, Paul

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.