-

Posts

420 -

Joined

-

Last visited

About Sea Hoss

- Birthday 10/10/1961

Contact Methods

-

MSN

john6976468@hotmail.com

Profile Information

-

Gender

Male

-

Location

Taunton, Massachusetts

-

Interests

Model building, arts

Recent Profile Visitors

-

Bill Morrison reacted to a post in a topic:

Sea Witch by Moltinmark - FINISHED - Lindberg - 1/96

Bill Morrison reacted to a post in a topic:

Sea Witch by Moltinmark - FINISHED - Lindberg - 1/96

-

Bill Morrison reacted to a post in a topic:

Sea Witch by Moltinmark - FINISHED - Lindberg - 1/96

Bill Morrison reacted to a post in a topic:

Sea Witch by Moltinmark - FINISHED - Lindberg - 1/96

-

ccoyle reacted to a post in a topic:

US Brig Syren 1803 by Sea Hoss - FINISHED - Model Shipways -1:64

ccoyle reacted to a post in a topic:

US Brig Syren 1803 by Sea Hoss - FINISHED - Model Shipways -1:64

-

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

Obormotov reacted to a post in a topic:

MONTAÑES by Amalio

-

FillNill reacted to a post in a topic:

USN Picket Boat #1 1864 by Sea Hoss - FINISHED - Model Shipways

FillNill reacted to a post in a topic:

USN Picket Boat #1 1864 by Sea Hoss - FINISHED - Model Shipways

-

Sea Hoss reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

Sea Hoss reacted to a post in a topic:

US Brig Syren 1803 by Overworked724 – Model Shipways – Scale 1:64

-

Sea Hoss reacted to a post in a topic:

Emma C Berry by ahb26 - FINISHED - Model Shipways - 1/32

Sea Hoss reacted to a post in a topic:

Emma C Berry by ahb26 - FINISHED - Model Shipways - 1/32

-

Sea Hoss reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

Sea Hoss reacted to a post in a topic:

HMS Winchelsea - FINISHED - 1764 - by Chuck (1/4" scale)

-

Sea Hoss reacted to a post in a topic:

USS Constitution by ERS Rich - Model Shipways - 5/32

Sea Hoss reacted to a post in a topic:

USS Constitution by ERS Rich - Model Shipways - 5/32

-

Thank you all for your generous comments...I just have to stop adding stuff before I over do it!

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks for the comments, she's getting to be a popular model, lots of fun building her! Yes Will, the model RR sites are great for diorama components.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

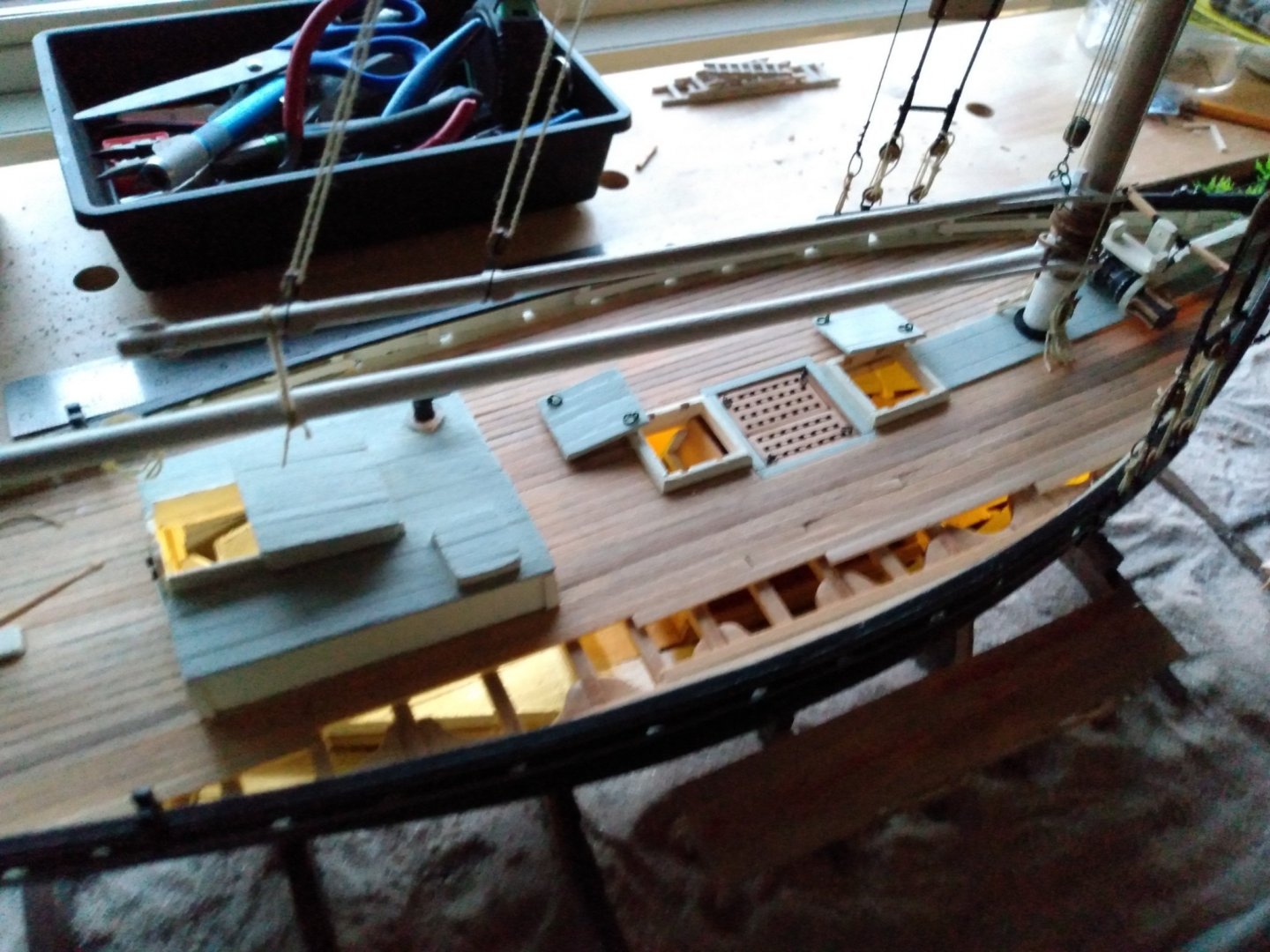

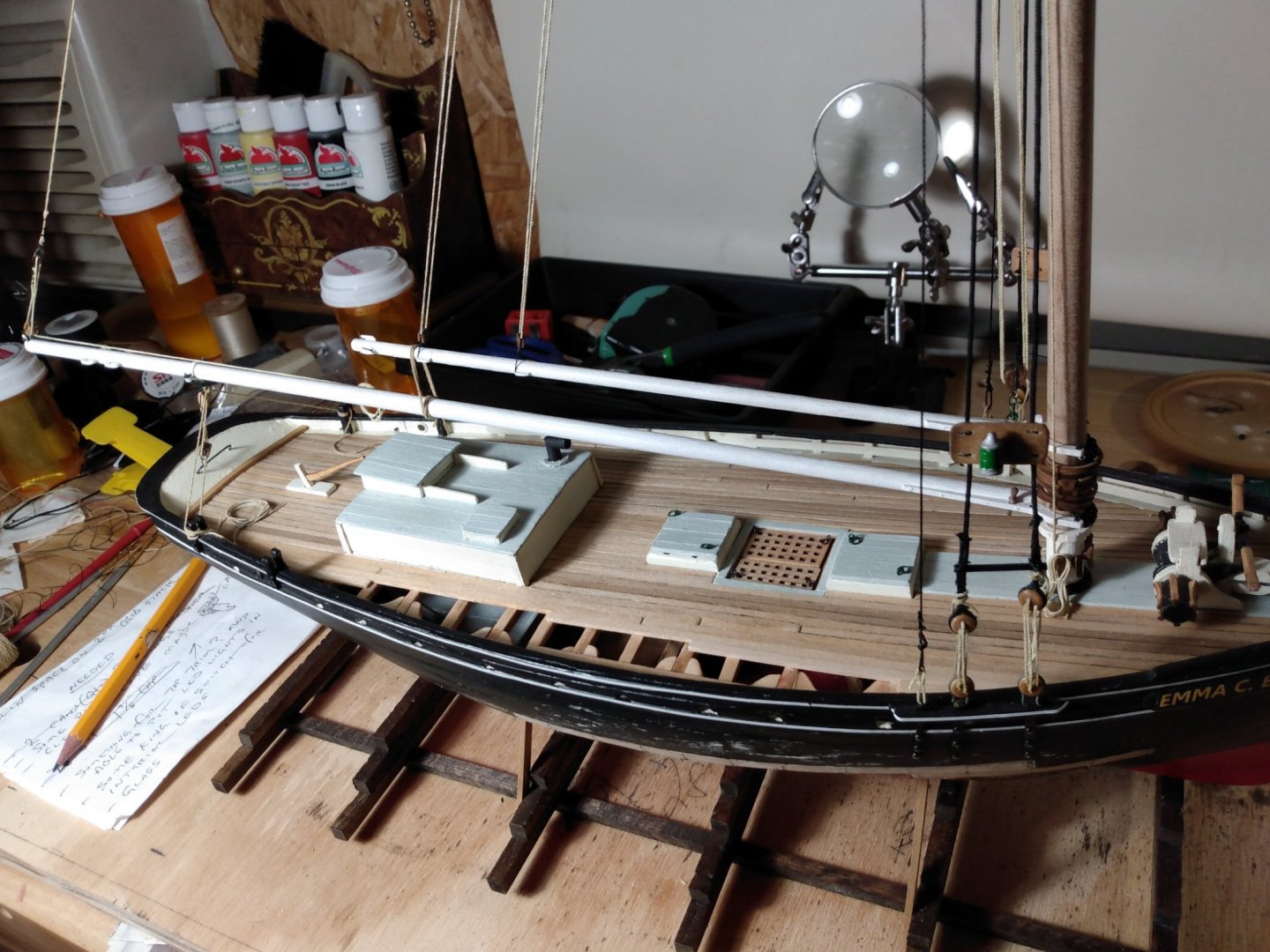

Fooled ya, got another update on my ECB... Got to work on the diorama and got the LED's on and working. Created some boatyard items to add interest. Still need to secure everything a little better and maybe add some rocks to the sand and a little construction debris. Eventually I'll get around to closing her up in glass and create a decorative top moulding. That's all for now.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

Sea Hoss reacted to a post in a topic:

USS Constitution by ERS Rich - Model Shipways - 5/32

Sea Hoss reacted to a post in a topic:

USS Constitution by ERS Rich - Model Shipways - 5/32

-

Sea Hoss reacted to a post in a topic:

Emma C Berry by Turangi - Model Shipways - 1:32

Sea Hoss reacted to a post in a topic:

Emma C Berry by Turangi - Model Shipways - 1:32

-

Sea Hoss reacted to a post in a topic:

HM Brig-Sloop Flirt 1782 by glbarlow - Vanguard Models

Sea Hoss reacted to a post in a topic:

HM Brig-Sloop Flirt 1782 by glbarlow - Vanguard Models

-

Sea Hoss reacted to a post in a topic:

Emma C Berry by Turangi - Model Shipways - 1:32

Sea Hoss reacted to a post in a topic:

Emma C Berry by Turangi - Model Shipways - 1:32

-

Sea Hoss reacted to a post in a topic:

Emma C Berry by ahb26 - FINISHED - Model Shipways - 1/32

Sea Hoss reacted to a post in a topic:

Emma C Berry by ahb26 - FINISHED - Model Shipways - 1/32

-

Thank you all for your kind words and acknowledgements. The Emma was certainly more complex of a build than I at first thought. I have and will continue to admire the other ECBs under construction!

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

Well, I believe that I have achieved a point in this build that I can declare the model "finished". I can now focus on the base/diorama/case. I am generally satisfied with it. As with all the previous models however, I tend to zoom in on the areas that make me wonder if I could have done better! Visitors to my workshop assure me that it is "perfect" and they are amazed that such a creation by the likes of me is just short of miraculous! (this doesn't always quell my doubts however). But all in all, the overall look of the Emma is pleasing. So since the last posting, I rigged all the blocks and belayed them. Added the shrouds, jib stay, topmast stay and back stays. Attached the sheer bars and running lights to the shrouds. Then I added some rope coils here and there. I'm sure I will add a few more "do-dads" to the deck for some interest before closing up the case. I apologize in advance for the poor quality of the photos. My phone camera is sub-par to say the least.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

I could see from the start of this model that the manual was vague and that the plans were sometimes wrong. I just opted to do what seemed "right" when confronted with a dilemma.

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Sea Hoss reacted to a post in a topic:

HM Cutter Cheerful 1806 by PRS - FINISHED - Syren Ship Model Company - 1/48

Sea Hoss reacted to a post in a topic:

HM Cutter Cheerful 1806 by PRS - FINISHED - Syren Ship Model Company - 1/48

-

Looking really good Andrew, the details are impressive.

- 161 replies

-

- Model Shipways

- Emma C Berry

-

(and 1 more)

Tagged with:

-

Hey there, got some more progress to share on ECB. After stepping the mast I began adding the boom and gaff. Connected the jaws to the mast with the parrels, then began rigging the blocks. Then I just let them hang there until I get further along with the standing rigging. When all that is completed, I can look everything over and finalise the the rigging and belaying all the running ends properly. Next, I focused on the shrouds. Quite straight forward. It was actually nice to work these at a larger scale than most of the ones I've previously done, (and no ratlines!). I will also neaten up the deadeye lanyards eventually. Next up is the jib stay, topmast stay and topmast back stays. Then the end will be in sight. Permanently mount her to the base and finish the diorama. Eventually, I plan on enclosing everything in glass.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

Thanks Rich. I have to give credit to a fellow modeller for the bristle idea. (I forget who it actually was). But I know lots of guys here use black mono filament also. I just noticed; you are a fellow Mass. guy, where abouts? Also your Connie is coming along beautifullly.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

Thank you Yves, much appriciated. I enjoy your work also.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

-

Stepped the mast and used wedges to get the proper rake and stability while I added the boom and topping lift and blocks. Also the main sheet set up and blocks were added. The boom was secured to the mast with a parrel bead rig. The parrel beads were not supplied with the kit so I purchased some 3/32 black glass beads at the local Michael's. They look just fine. I made the dicision to wait on rigging the shouds etc. until I got the boom/ gaff on as I could see it would be easier without them in my way. Before I put on the gaff a little distraction popped up. I had been meaning to add simulated treenails to the "newly" added hull planks. This I did by drilling holes in the appropriate spots, then, I harvested some black bristles from one of my hair brushes, dabbed in CA and pushed into the holes. Then after the glue cured, sliced off the excess with a sharp #11 blade. I think they look convincing. Now I can resume installing the gaff and the rest of the rigging. Also, I have been working on the base for the diorama. It will include a 3/16+ slot around the perimeter for the glass which will enclose it. Well, that's all for now... Thanks for looking and the comments and likes.

- 101 replies

-

- emma c berry

- model shipways

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.