-

Posts

722 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by capnharv2

-

-

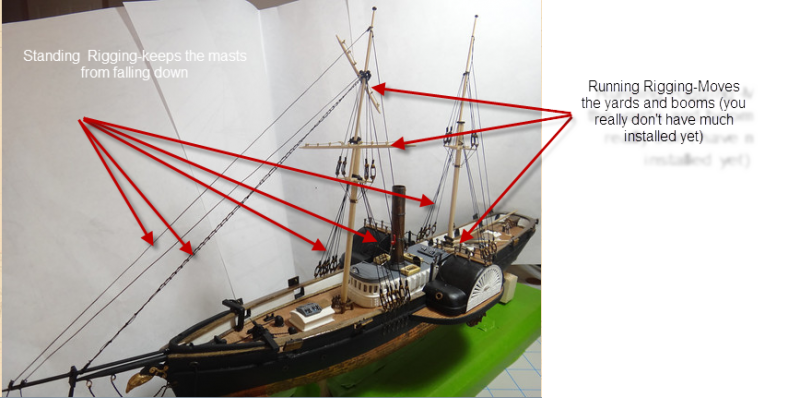

Thanks for the enlightenment Carl.

There's always things like that that blur the line. For example, I've sailed on boats that have fixed backstays (standing rigging) and running backstays (tightened and loosened on each tack). They act like running rigging, but I guess they're standing since they help hold the mast up.

-

-

I know some New Englanders have little affection for "Dude Schooners", but you can learn a lot by spending a week on one. We spent a week on the Lewis R French out of Rockland about 20 years ago, and it was really enlightening to learn the workings of an old schooner. And I still want to go back!

Thanks,

Harvey

- fnkershner and bhermann

-

2

2

-

Looks good Wayne. That's an almost impossible scale to work at (at least for me).

Question on your drawing. Are the green line going to the ends of the yard the lifts? If so, will you have lifts on all 3 yards?

Thanks,

Harvey

-

Gil,

You might want to take a daysail on Lady Washington when she's in the area. If there's a little wind you can help them "Let go and Haul".

I find that sailing (both on our boat and other boats) helps me better understand and appreciate the hows and whys of boat/ship design-which translates into a more accurate model.

Thanks,

Harvey

-

Dr. Per,

Might I suggest a 286 processor with MS-DOS 5.0? Who needs this Windows stuff anyway??

Harvey

-

Sarah,

What size lathe are you looking for? Unimat/Sherline/Proxxon (Micromark) or something a little bigger?

Regarding a drill press, I have the one for the Dremel (minus the Dremel). If you like, I can bring that along to the next meeting (I've been using my U3 milling head as a drill press lately, so I don't need it).

Thanks,

Harvey

-

Beautiful!

Thanks Garward!

Harvey

-

Thanks Crackers. My biggest problem with that setup? My electric drill doesn't work!

Harvey

-

And I started on my MS Constitution kit in 2007! I guess I can forget that scratchbuild fleet of Harold Hahn ships

Harvey

-

Garward,

I apologize for not getting back to you sooner. Thank you for the videos and photos!

I feel like I made a mess of the copper plating on my Constitution, and want to do a better job on the Agamemnon and Flying Cloud (should I decide to copper the FC). These will be a big help.

Thanks again,

Harvey

-

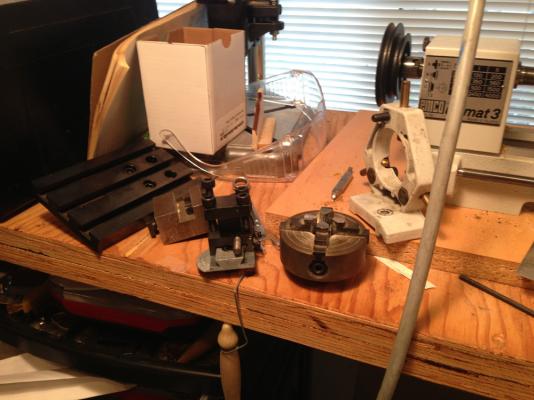

Sjors,

Here's my U3:

I weighs about 20 pounds. Mainly Aluminum alloy parts. I believe the only plastic are the drive pulleys and the handwheels (and they make replacement Al handwheel)

It's set up for milling some cannon carriages:

And here's most of the accessories for it:

I got it about 15 years ago for 50 dollars and an unused Dremel Tool. It came with the standard toolpost, 3 jaw and 4 jaw chucks, and a steady rest. Since then, I've had it refurbished, and added the milling post, milling vise, milling table and a compound angle toolpost.

That said, I have a lot to learn about using the tools and setting up the machining operations to get what I want. But I'm enjoying myself-and that's the point, isn't it?

Thanks,

Harvey

-

I haven't heard a lot about Proxxon lathes, but what I have heard has been positive. Aren't these also sold under the Micro-Mark label too?

-

Sjors,

I'll post some pictures later today. As Tony said, the Unimat 3 is one of the better lathes, but no longer available new. As far as the newest Unimats go, I agree, they aren't worth the trouble or money.

I debated getting a Sherline. I've heard lots of good things about them, and are larger with more capability. I decided to keep the Unimat and add the milling head because

a) I was familiar with it

The total cash outlay was less (I already had the lathe)

The total cash outlay was less (I already had the lathe)c) the overall footprint in my shop is smaller, and I will need to downsize in the near future

Thanks,

Harvey

-

Looks good Jeff.

Here's an idea. try soldering something like brass hoops to get a feel for how the soldering iron interacts with the flux, brass and solder. If you run out of brass, it's pretty easy to get. This will also help you understand the cleanliness required for soldering.

One of the problems I had with the deadeyes is the heat from the soldering iron would scorch the deadeyes. I don't know of any way around it, but I do know too much heat too long on the joint will yield char-broiled deadeyes. Not very tasty, and not very appealing.

Hope that helps.

Thanks,

Harvey

-

Well guys, I for one am happy with my Unimat 3. It does everything I want, and the only problems I've had are those of my own creation.

Thanks,

Harvey

-

Bob,

Maybe you can take one of the Ship's boats along to work on while you're there.

Harvey

-

American Small Sailing Craft. The MBLS shows up later in the book (around page 300).

Hope that helps.

Thanks,

Harvey

-

I had the same problem when I was kidding with Bob-mine posted twice.

Thanks Admins, for fixing the problem

Harvey

-

Bob,

You must really like this build since your comment repeated 4 times

Seriously, Toni, your work is an inspiration to those of us who aren't there yet (but want to).

Thanks,

Harvey

-

-

-

Thanks Geoff. That's what I'll do.

Harvey

-

Keith,

I've heard old linen handkerchiefs work well for making sails. Model Expo used to sell something called "Balloon Cloth" that was supposed to be thin enough, although I haven't seen it.

Your in the boonies? C'mon, Carbondale isn't that far away

Harvey

Methods for making Treenails

in Click Here for Topics dedicated to planking!!!!

Posted

Fantastic work Garward! Thanks for posting the pictures.

Harvey