-

Posts

651 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by DanielD

-

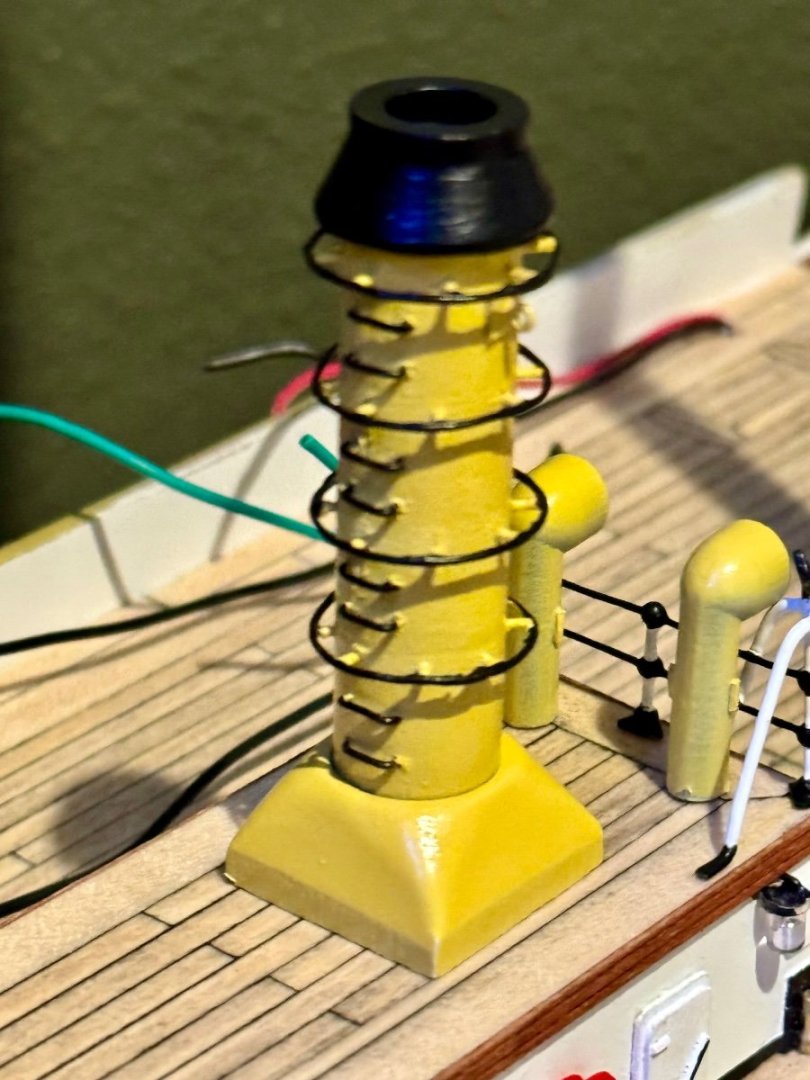

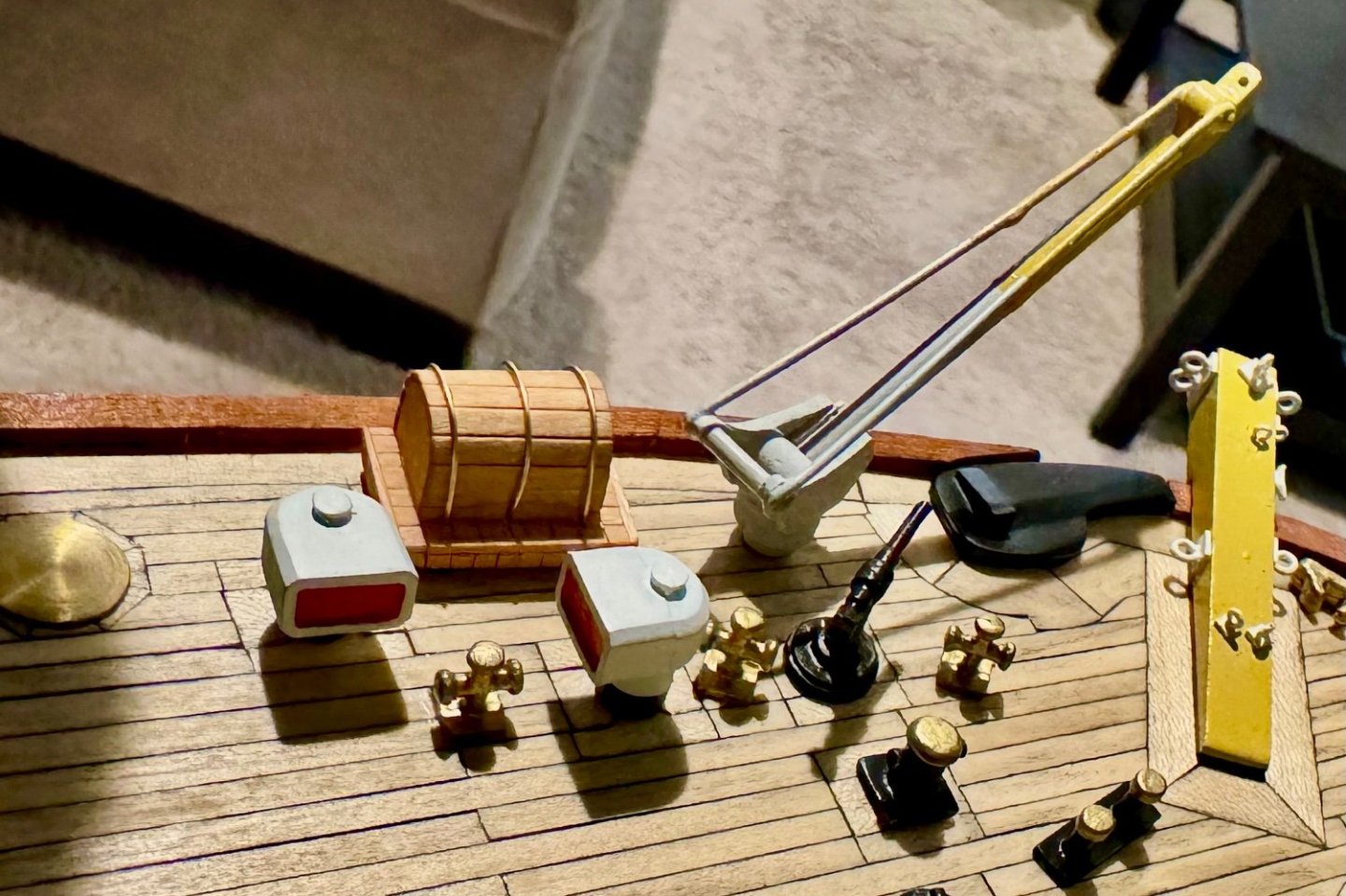

Good morning mates, well…its seems that the best laid plans need room for change. As I have been working on the mid ship crane/derrick, I discovered that there are two lights on it that are important for the lighting effect. Except that I didn’t plan for them in my initial design. After a little fishing and rewiring, I was able to get the derrick lights to work with the deck lights. Change is good, or so I’m told.

-

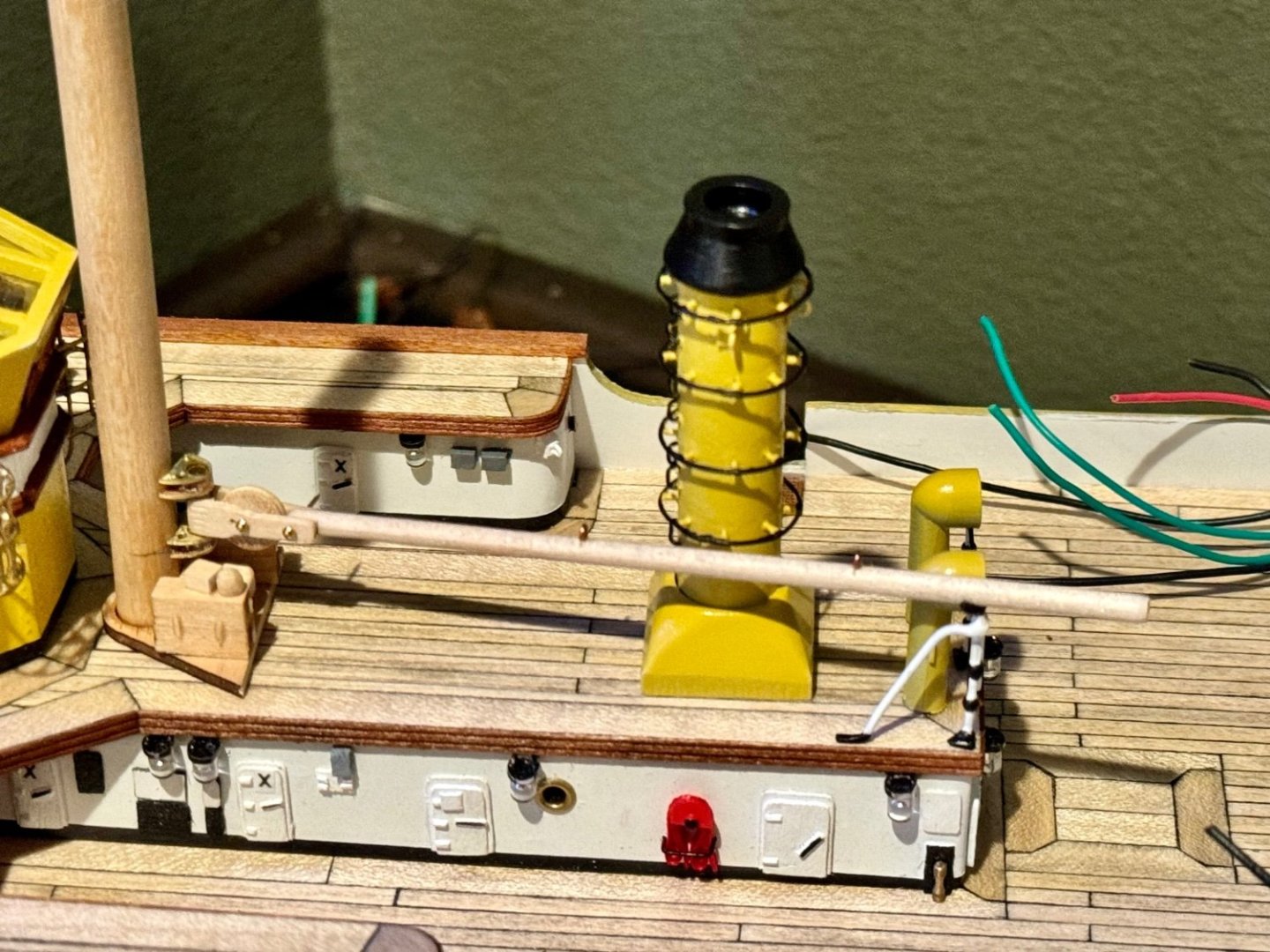

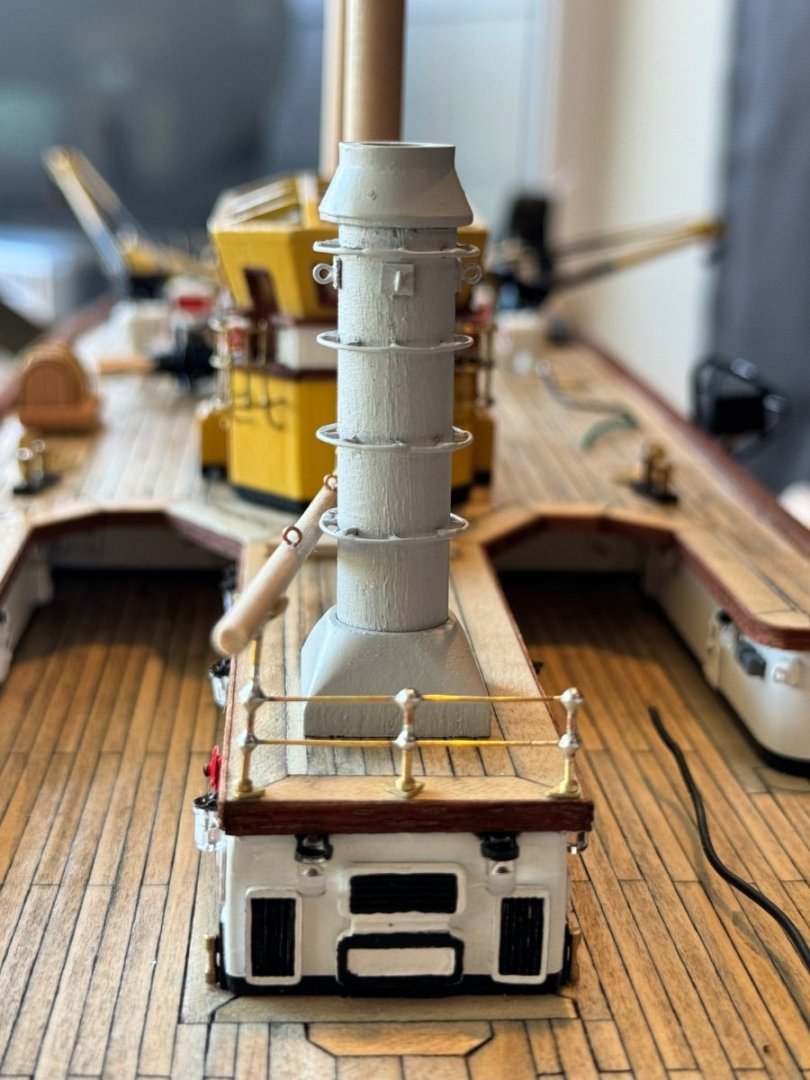

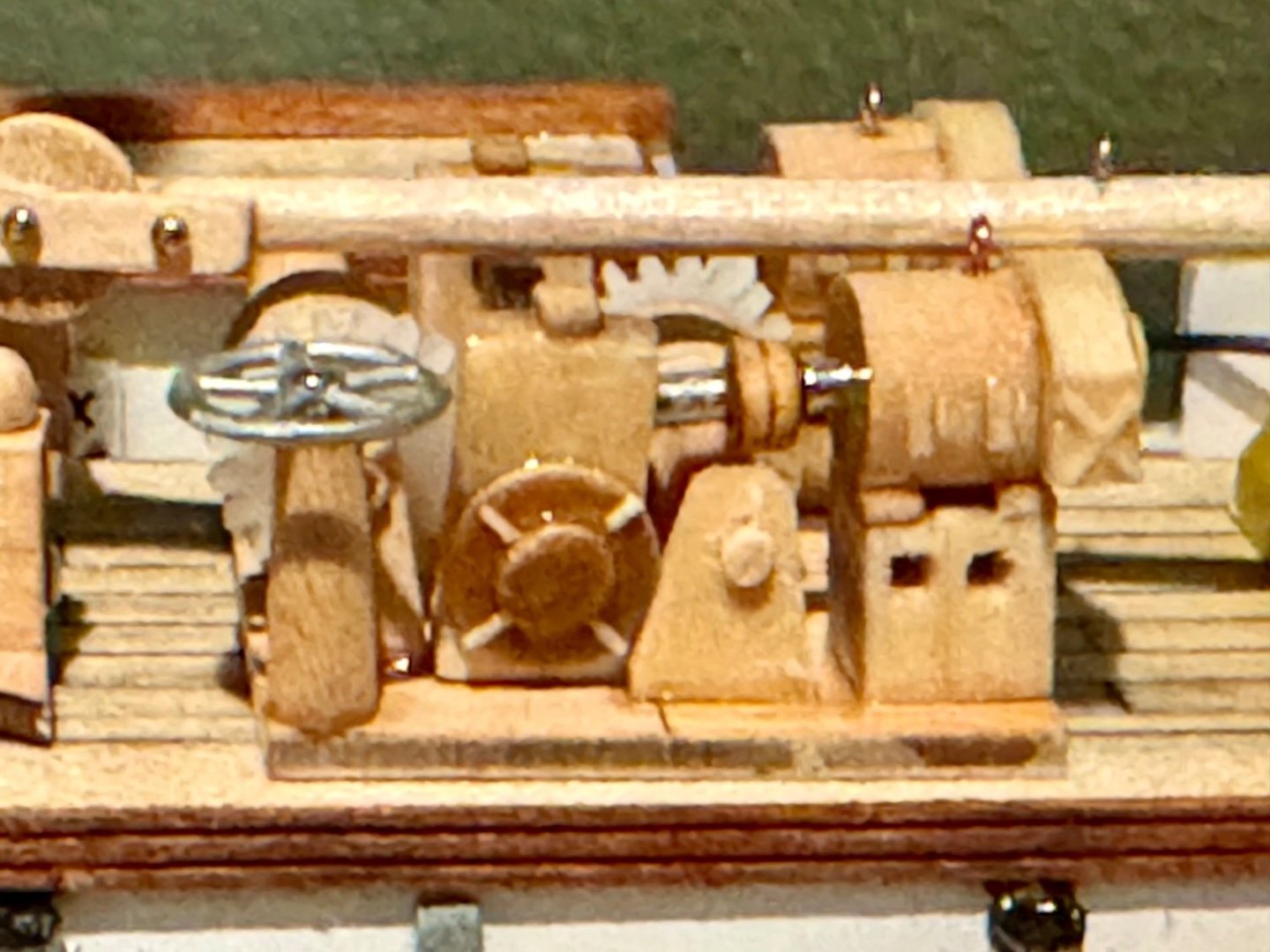

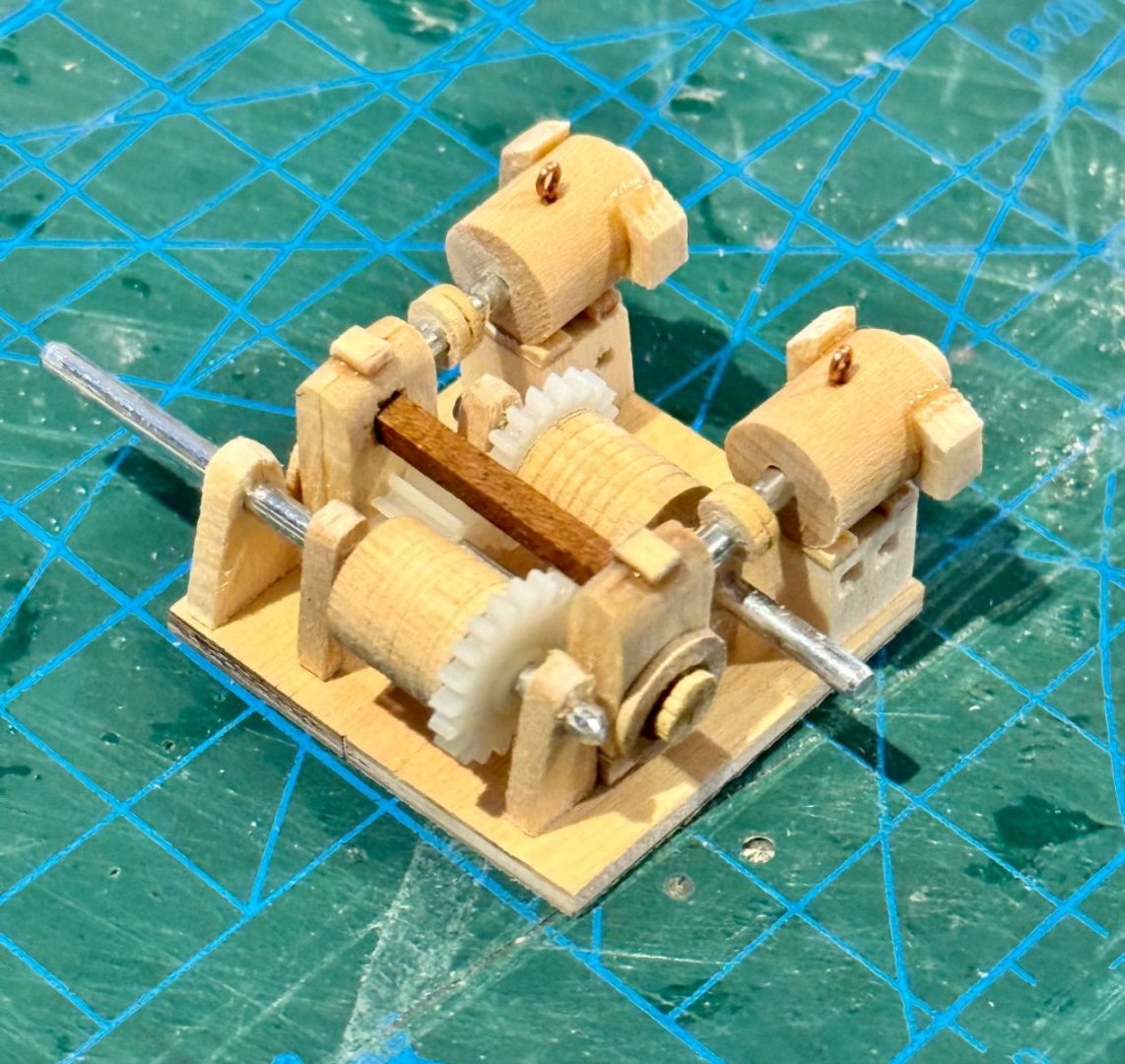

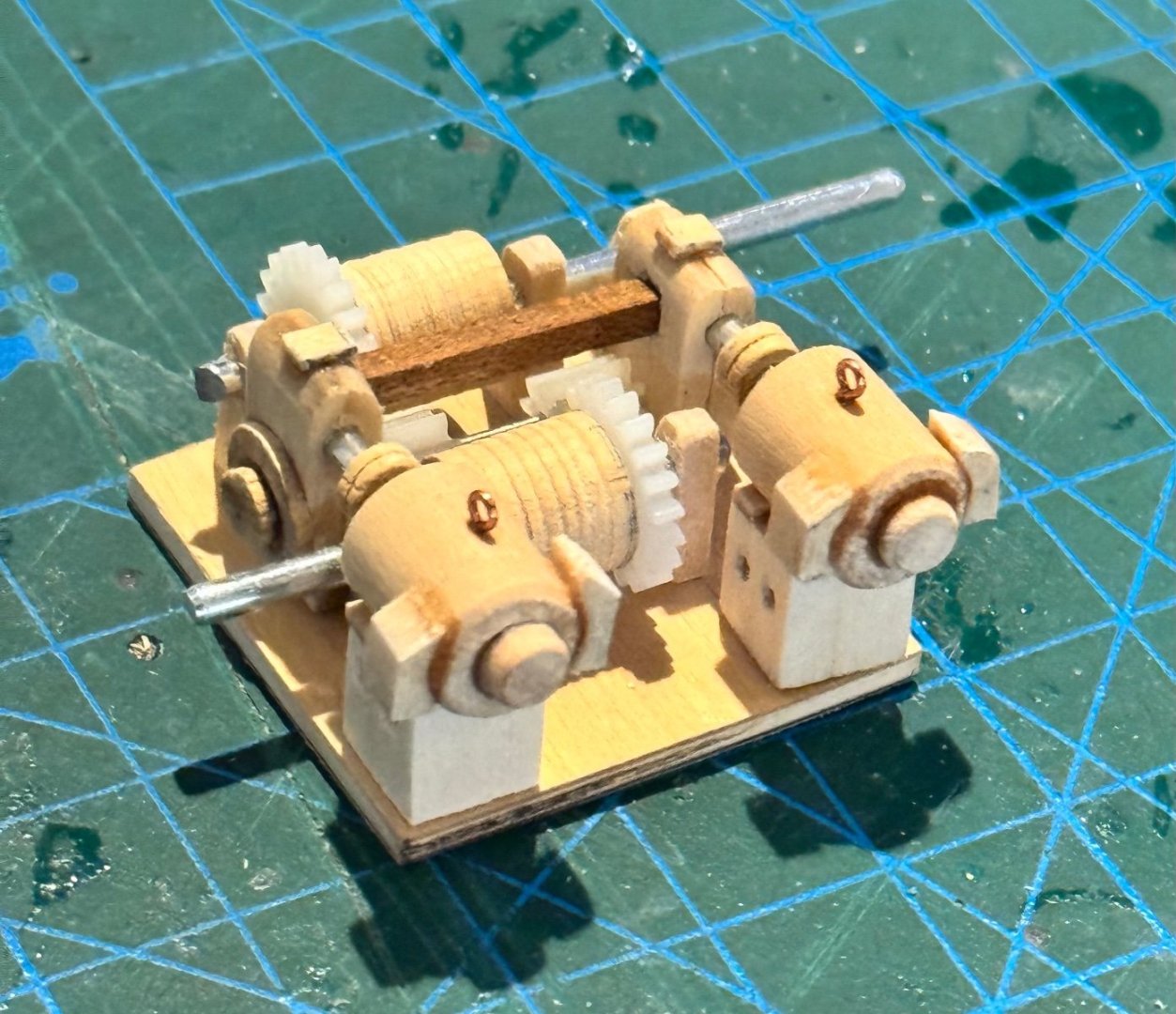

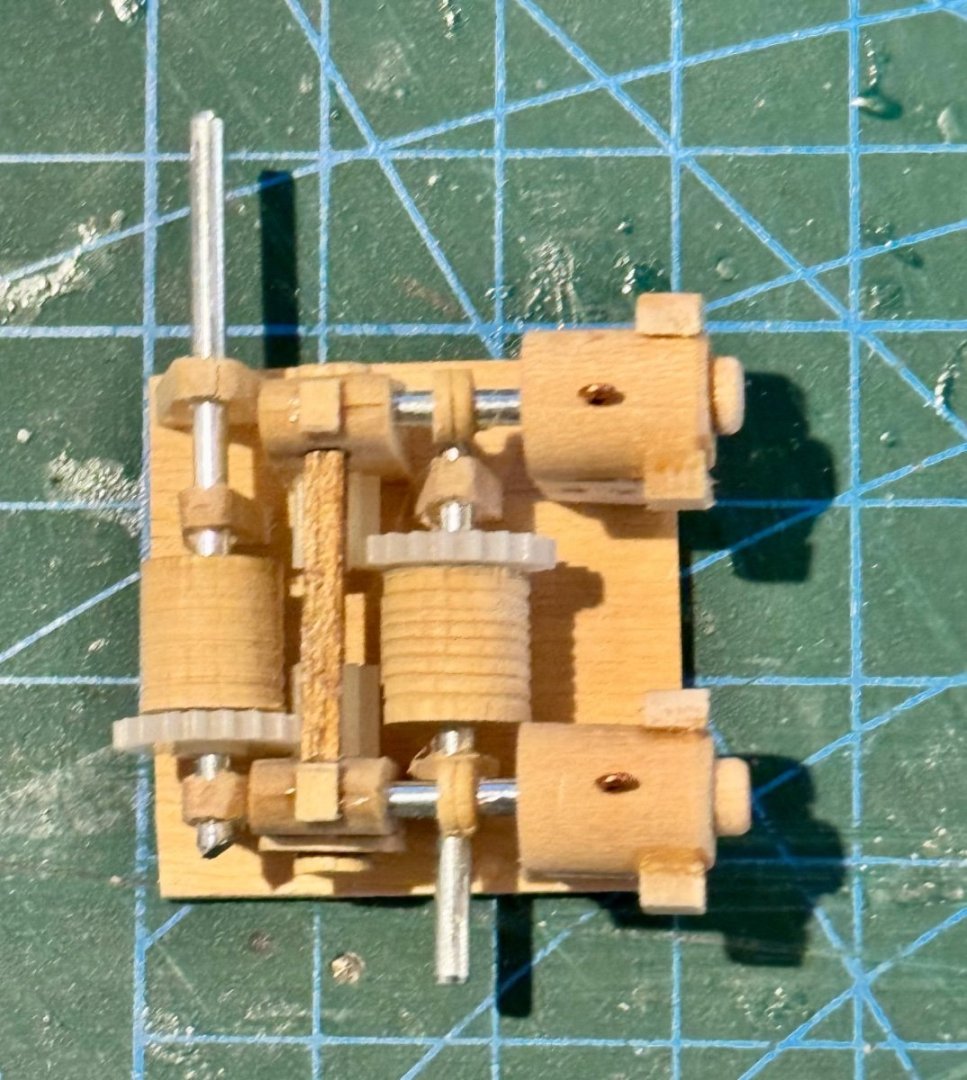

For all the US captains, Happy Thanksgiving and for all the other captains I hope you will have a great weekend! This last week I started working on the major crane on board the AV. I feel that OcCre failed us with their design of this portion of the ship in that their design feels/looks clunky. So…I have again deviated from the plans and am working from actual images of the Amerigo Vespucci. Below are the first images of my take on this section of the ship. The cranes boom is functional in both the x and y axis. If I was thinking about this area of the ship months ago in the planning stage, I think I could have made a working crane with motors, alas I didn’t think that far ahead. Also, I have finished the stack/funnel and first layer of primer and almost finished the railing with one more support to make before paint.

-

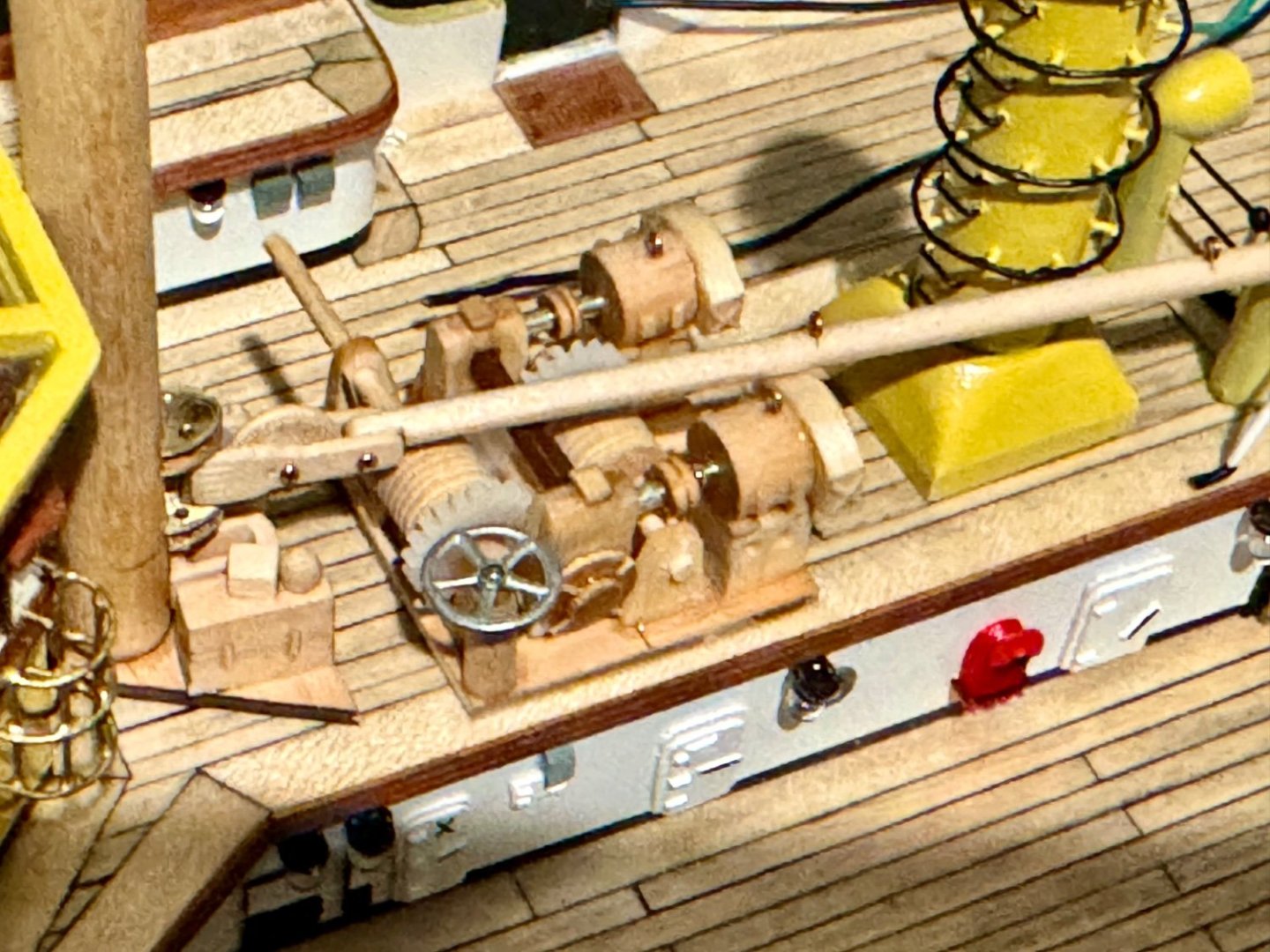

My next project was finding wheel handles for the vents. I needed round wheels 4mm in diameter with three spokes. I wasn’t able to find any for purchase with these specs so I decided to manufacture them myself. I first tried using wood dowels, but that didn’t work at all as the thickness of the wheel just makes wood way too fragile for this use. Next I used brass wire connecting the pieces together with CA glue. As you could imagine, this was very messy, gluing my fingers more than the wire. Finally I soldered the wire together. While this worked well, it took several attempts to get something I liked. Keith (clearway), why do we continually put ourselves through these kind of things? …just follow the plans, it’s so much easier!

-

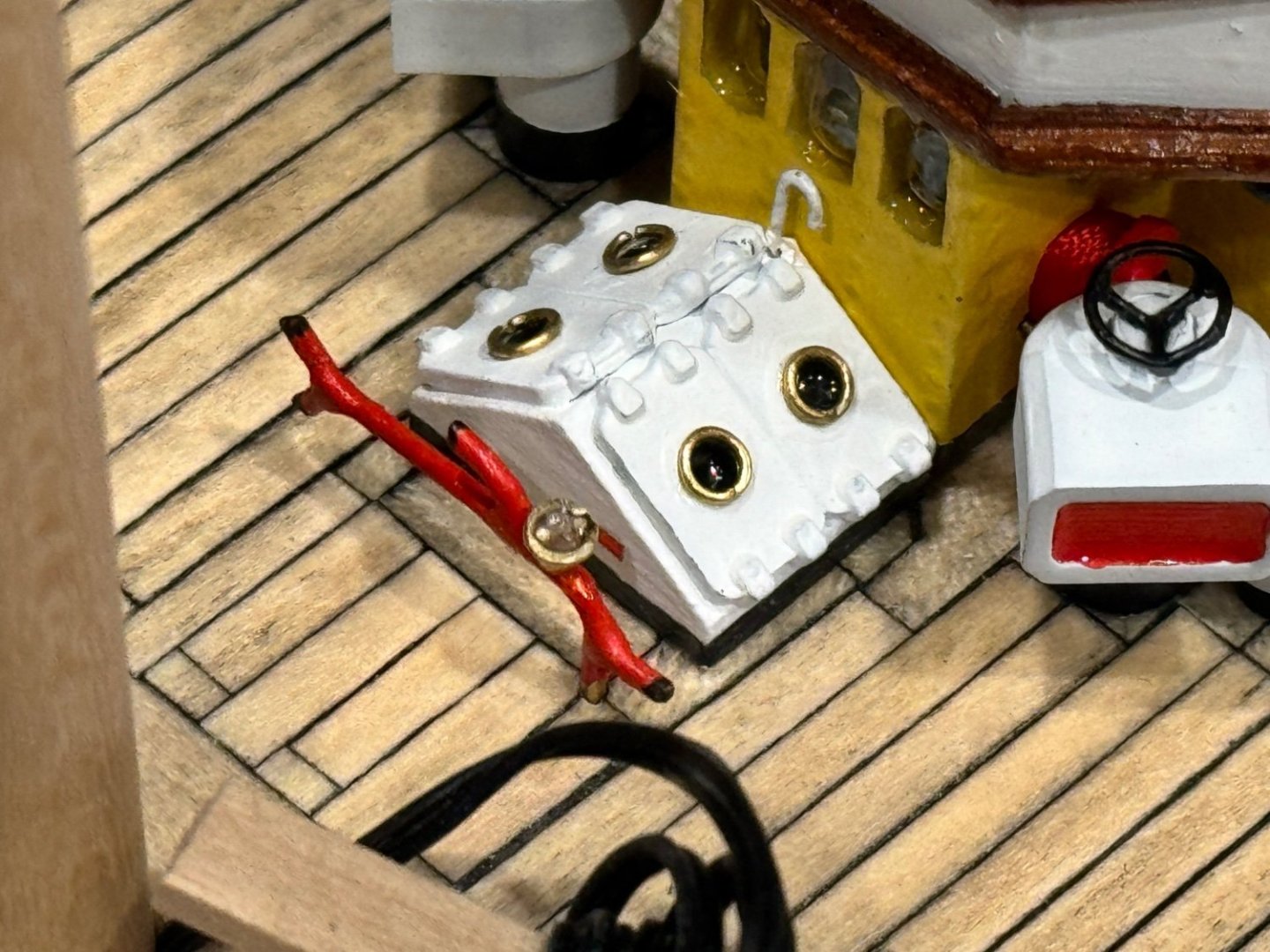

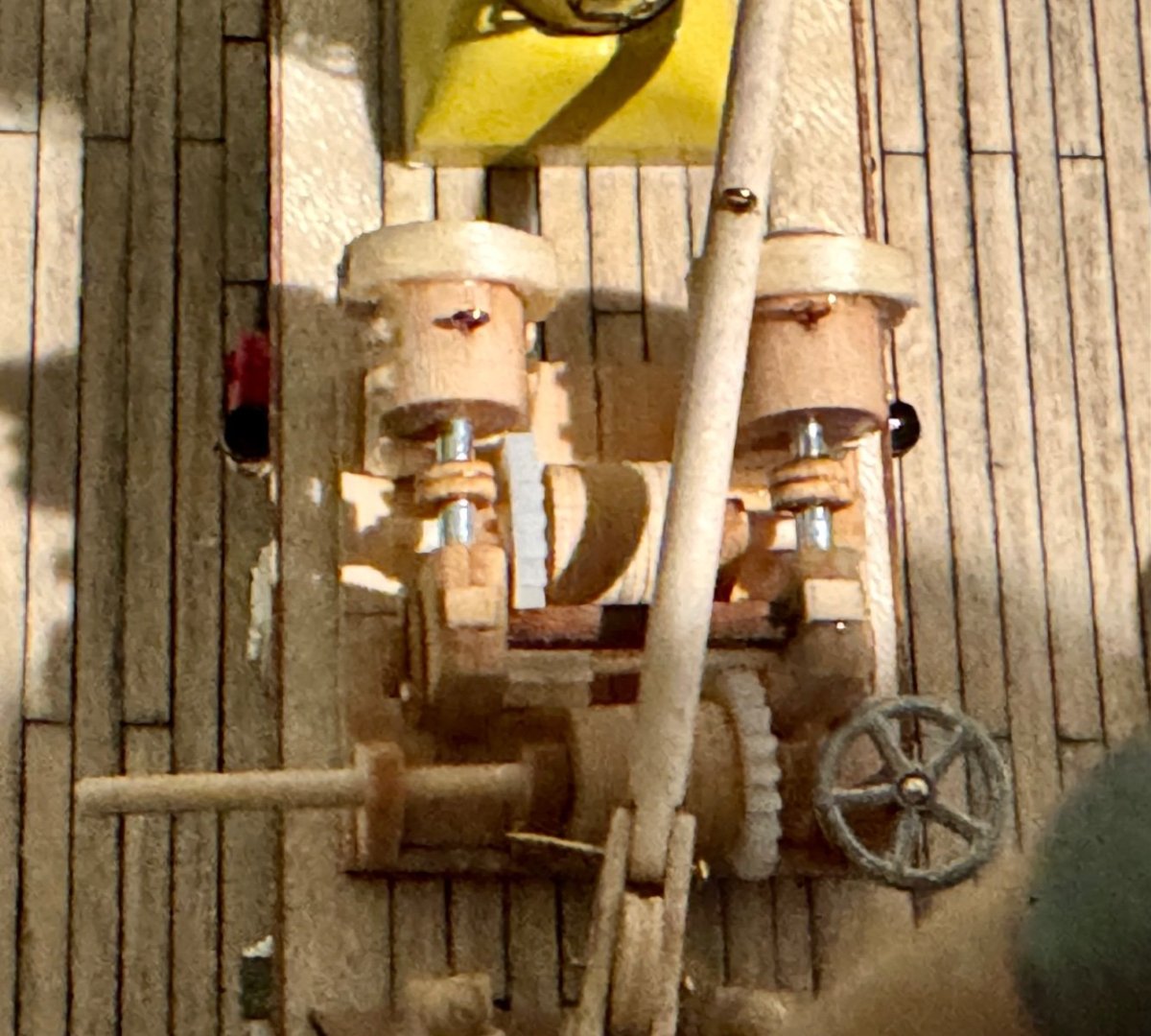

Good evening mates, finally finished the hatch by making the vent more scale appropriate, finishing the port holes and even added a small red sticker that is present in many of the AV images available. Also added a valve handle to the fire apparatus but not sure if I’ll leave it brass or paint it black.

-

Good evening mates, had a little time in the shipyard today after chores and was able to complete my second hatch. This time I used the OcCre provided parts as they appear the same as on the real AV. Also did a little fire fighting fittings. Had to make a couple of versions to get the scale correct as I was attempting to put too much detail in them which made the pieces way too big for a 1:100 scale model. Will see how this looks for a while, maybe make another one (or two)…

-

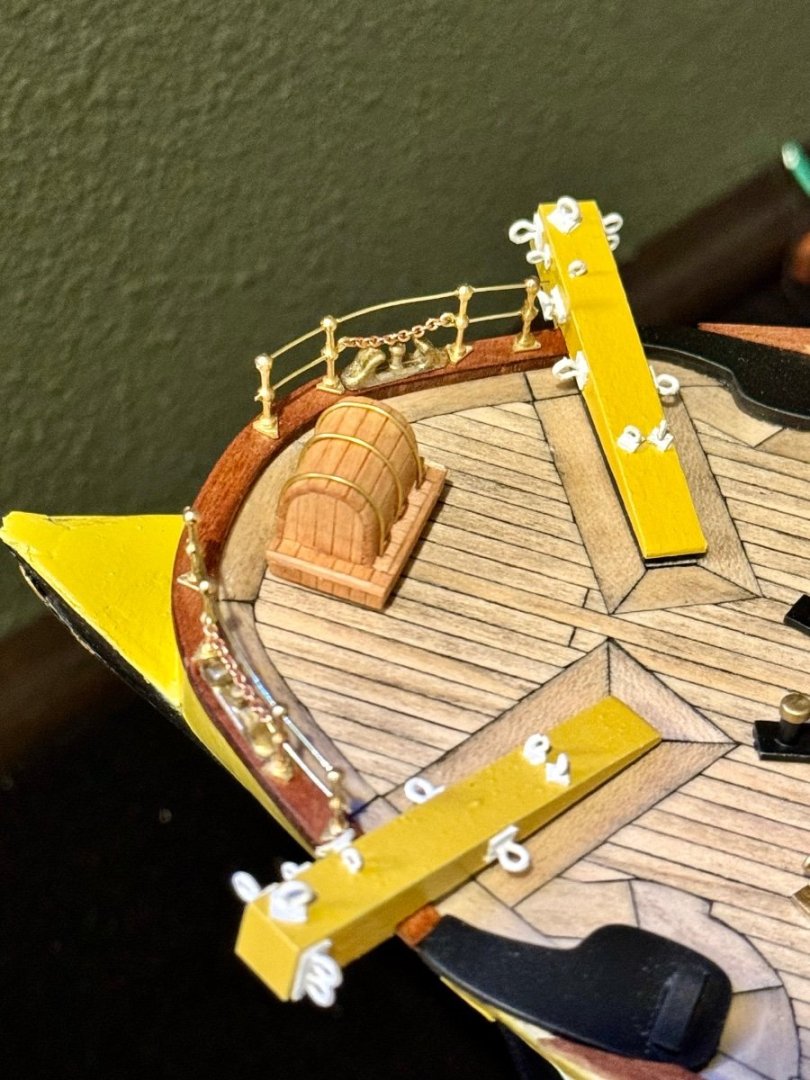

Good evening mates, the last couple of days I’ve been studying the Amerigo Vespucci fore deck railings. The kit supplied flat etched bollards are, well, very poor so changing it up a bit. It’s no easy task but I’m pleased with my progress. Not permanently installed yet as the railings get painted black and white, but getting there. Thanks for stopping by and for all your support.

-

Good evening mates, I spent the last couple of days getting some of the details on the chart room/sky bridge completed. Long list of “upgrades!” Life rings, horn speakers, fire fighting equipment, ladder cage, doors with handles…and I’m sure more things I forgot. Finally I have installed the building back on the hull for the last time.

-

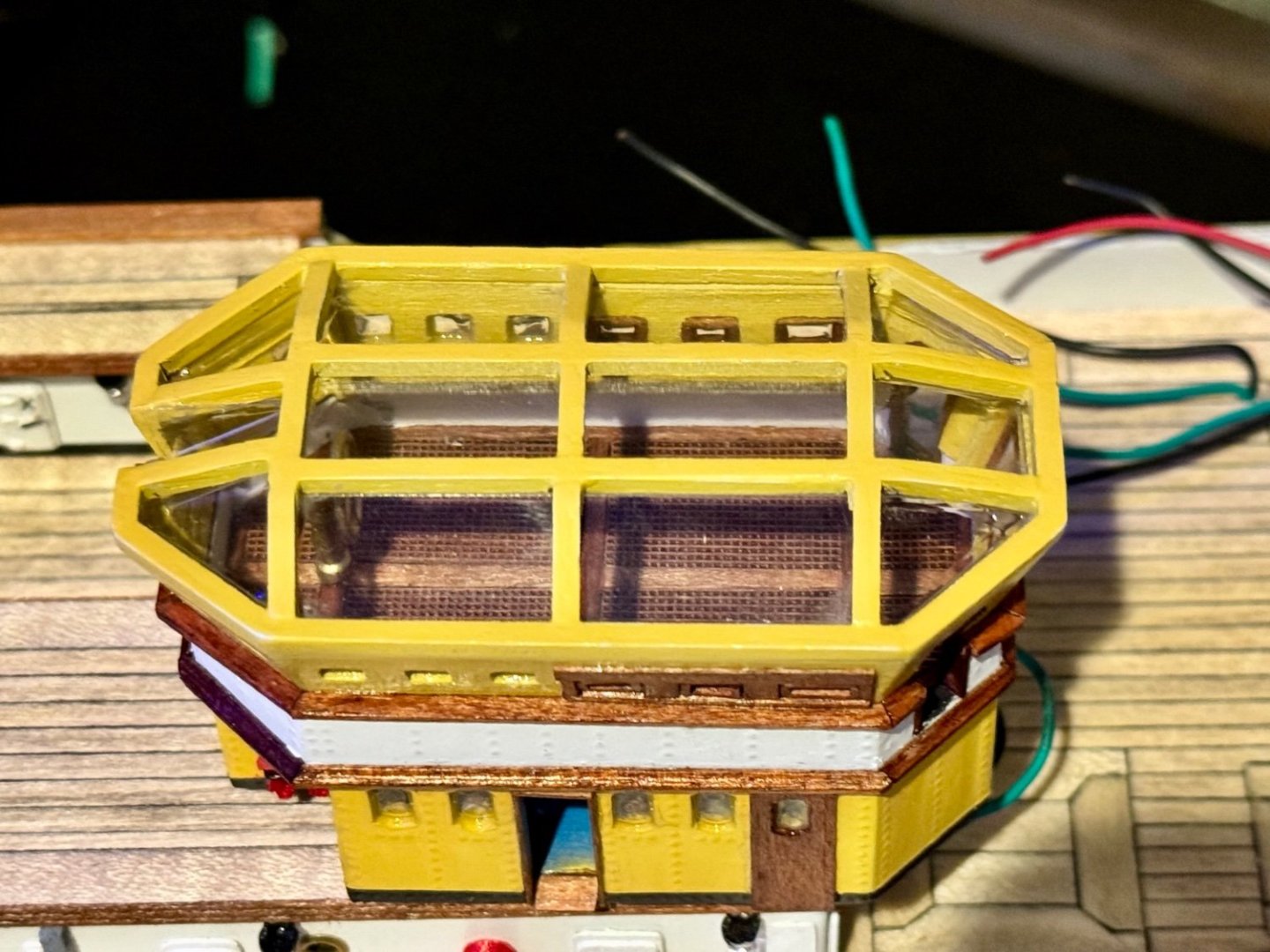

Good afternoon all, here is the progress on my new design canopy for the fly bridge. Next step, install the rivets, then prime again as the yellow paint does not like to stick to the rivets, then paint AV yellow, install glass, window trim, install on main structure and finally install molding between canopy and base. Wow, lots to do.

-

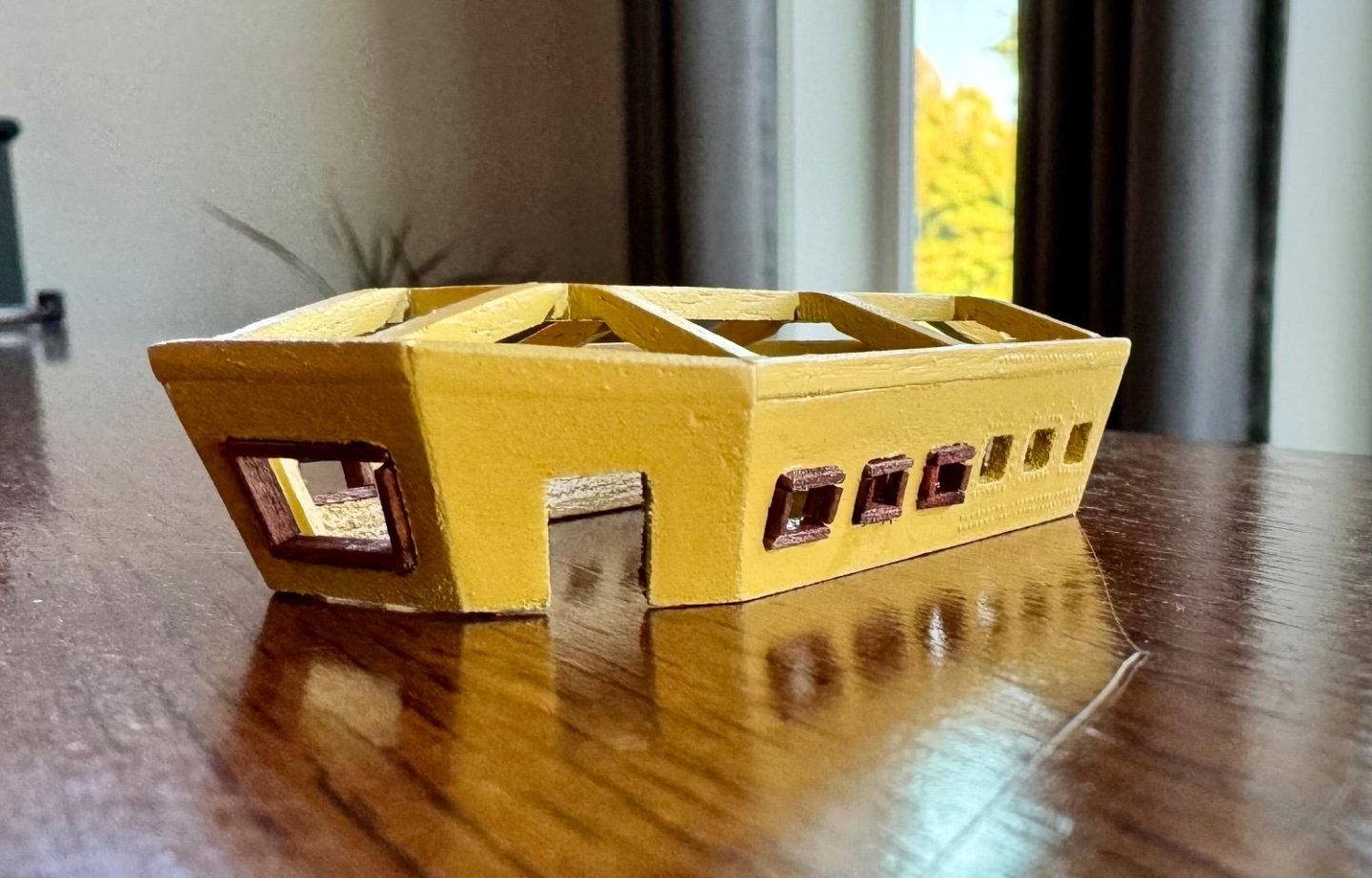

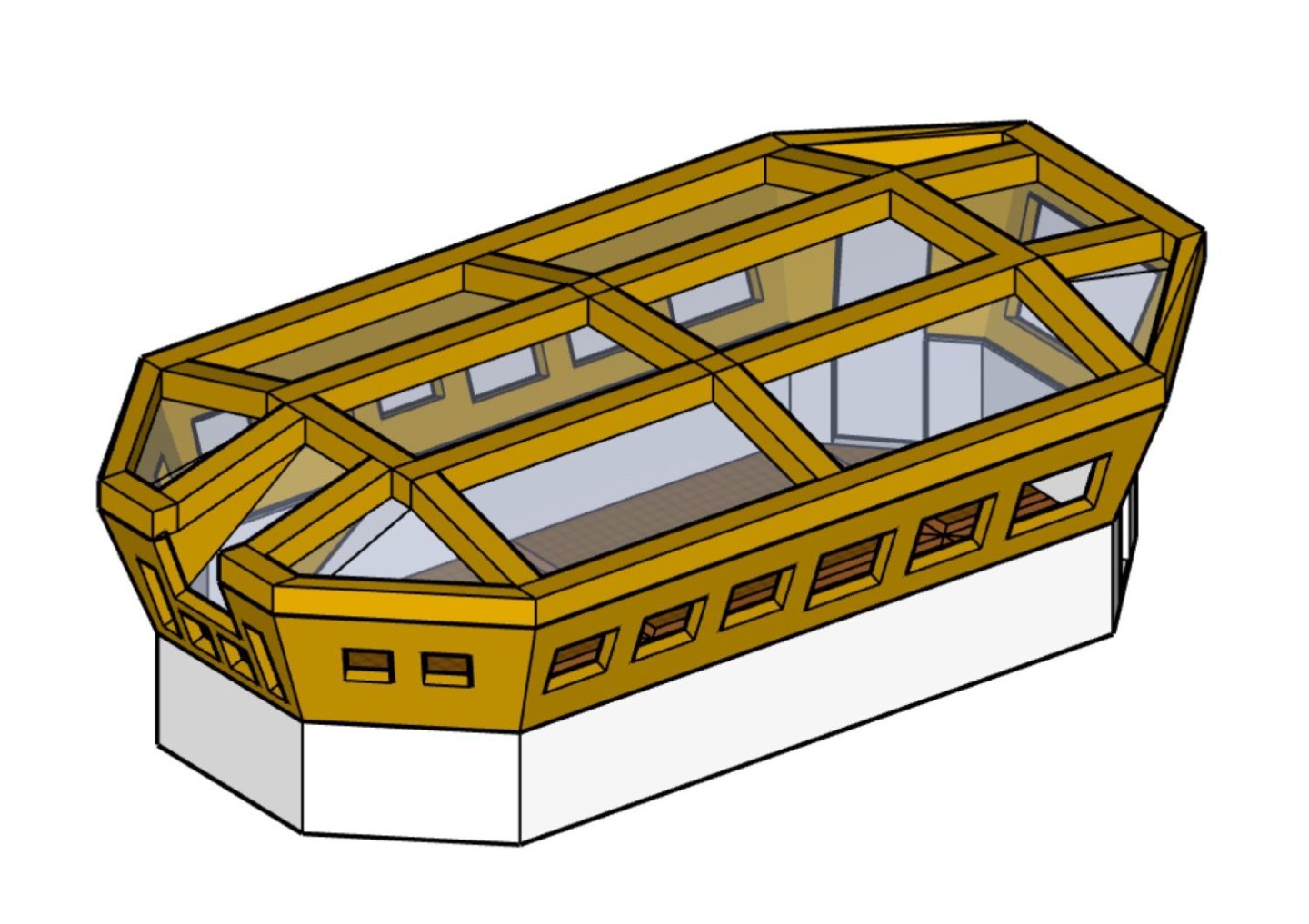

Well mates, it’s been a few days since my last update, so I thought I would give a little hint on what I’ve been up to. I’m not happy with the way OcCre designed the canopy for the fly bridge, basically gluing small pieces of wood stock to the clear plastic which makes sanding and blending very hard not to mention painting. So I’ve designed my own to be made of 1mm plywood, which will look like the sketch below. These pieces are small and I broke my first attempt, but a little redesign and I think this one will work.

-

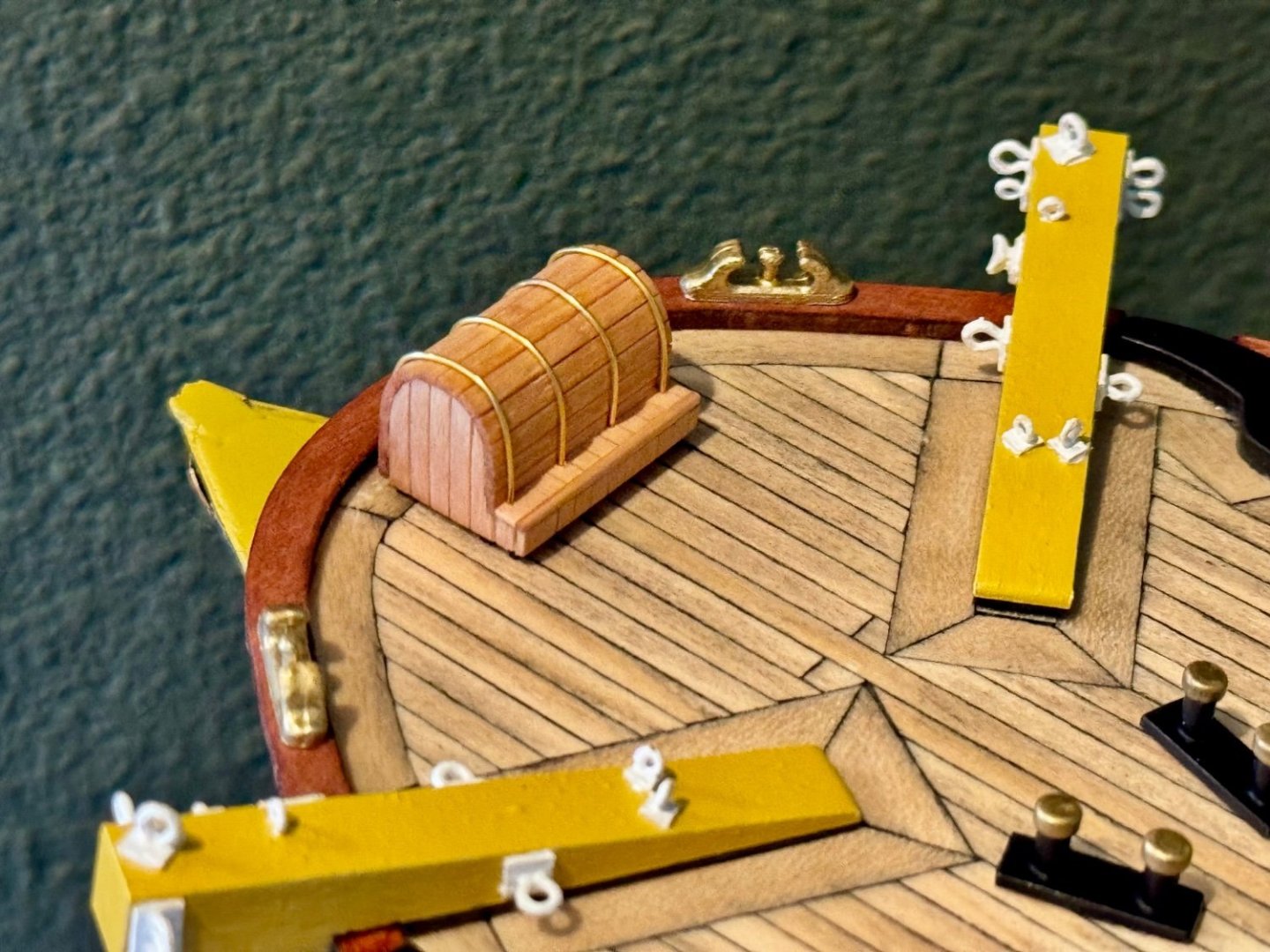

Good evening mates, I hope you all have had a great weekend. I’ve been a little under the weather so more time in the shipyard. This weekend I’ve been working on another storage bin with seats and a couple of cranes (see next post). For this one I had to modify the OcCre supplied parts and create one like the one on the real Amerigo Vespucci (see last image). I find that it takes hours to work on these miniature pieces, some of them about the size of an American dime.

-

Good evening mates, it’s been a couple weeks and very little AV progress. The admiral and I took our first ever cruise so have been out of touch. In this update, I have secured the equipment to the fore deck and am about to start working on the hatches and finish up the chart room / fly bridge building.

-

Good evening mates, I have spent a few days working on the forward capstan, lots of layers of paint and time between coats. Below is the before raw metal version provided by OcCre, followed by my completed version, and the last image the real one installed on the foredeck of the Amerigo Vespucci. The real version appears more straight, but I’m not sure I want to make one from scratch. Keep in mind that this entire piece of equipment is smaller than an American dime.

-

Good afternoon, more deck equipment for today. I took on the task of making the brass deck “scuttles” (waterproof hatches, sometimes used to load coal). These were made from flat brass stock, cut into an approximate circle, then soldered a brass rod to the bottom center so that I could turn in my mini lathe.

-

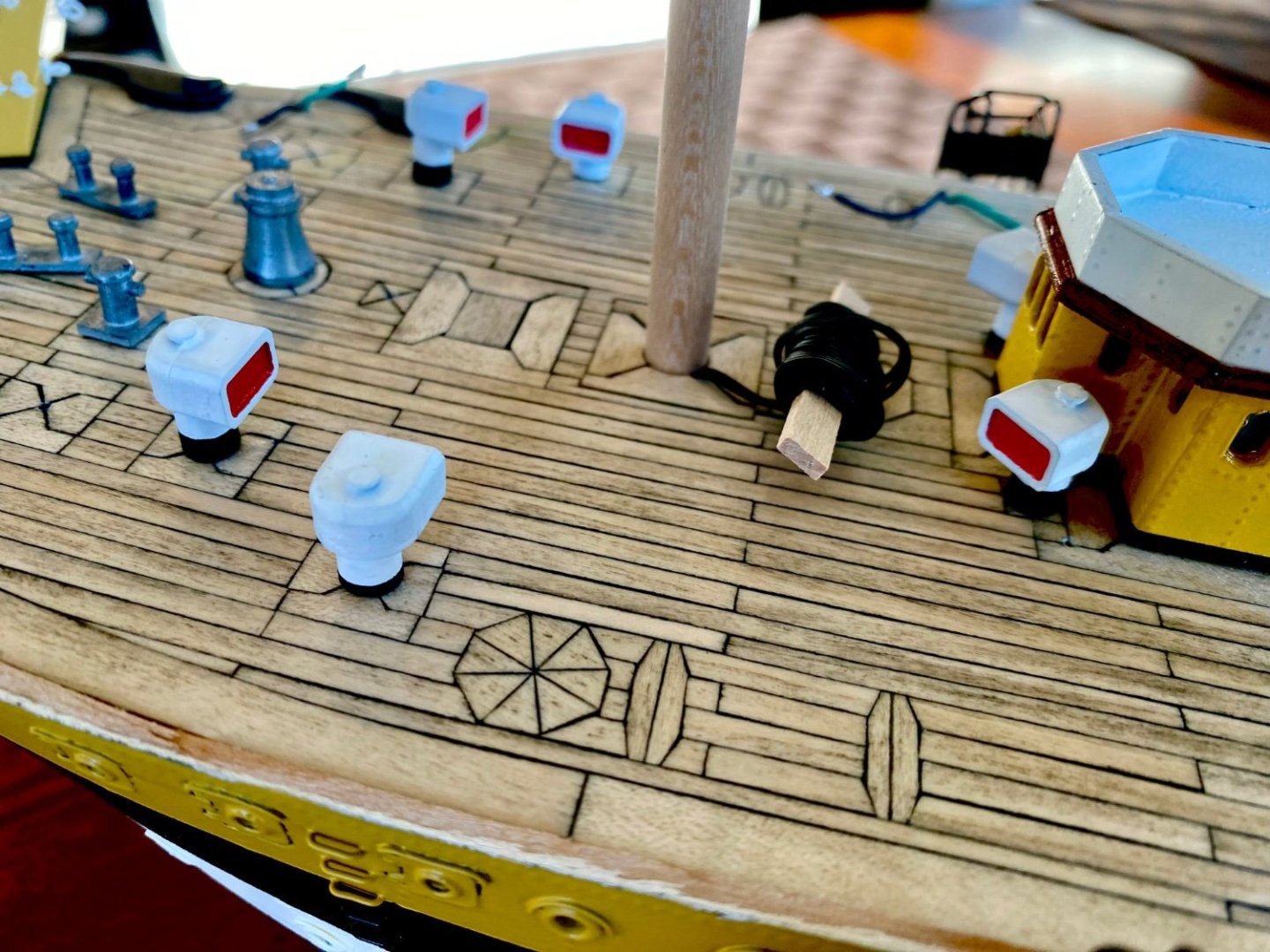

Good morning mates, more work going on for the deck equipment. I’ve been painting up the deck vents (not sure what they are called) but they add some nice color to the ship. Interesting note, I showed the completed vents to the admiral and her first comment was “why does the one vent not have a black base like all the others?” Ummmm, well, I really don’t know. However, when you look at pictures of the actual AM deck, this one vent has a white base while all the others have a black base. Not sure why, but that’s the way it is. Thanks to the Amerigo Vespucci virtual tour for the real deck image.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.png.496398561b129526bb2e1c02155f6f7d.png)

.png.e02033ffd686ae893c03e59a4705ac4f.png)