-

Posts

202 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Penfold

-

Above should say ‘I wanted a dead smooth surface’. sorry

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

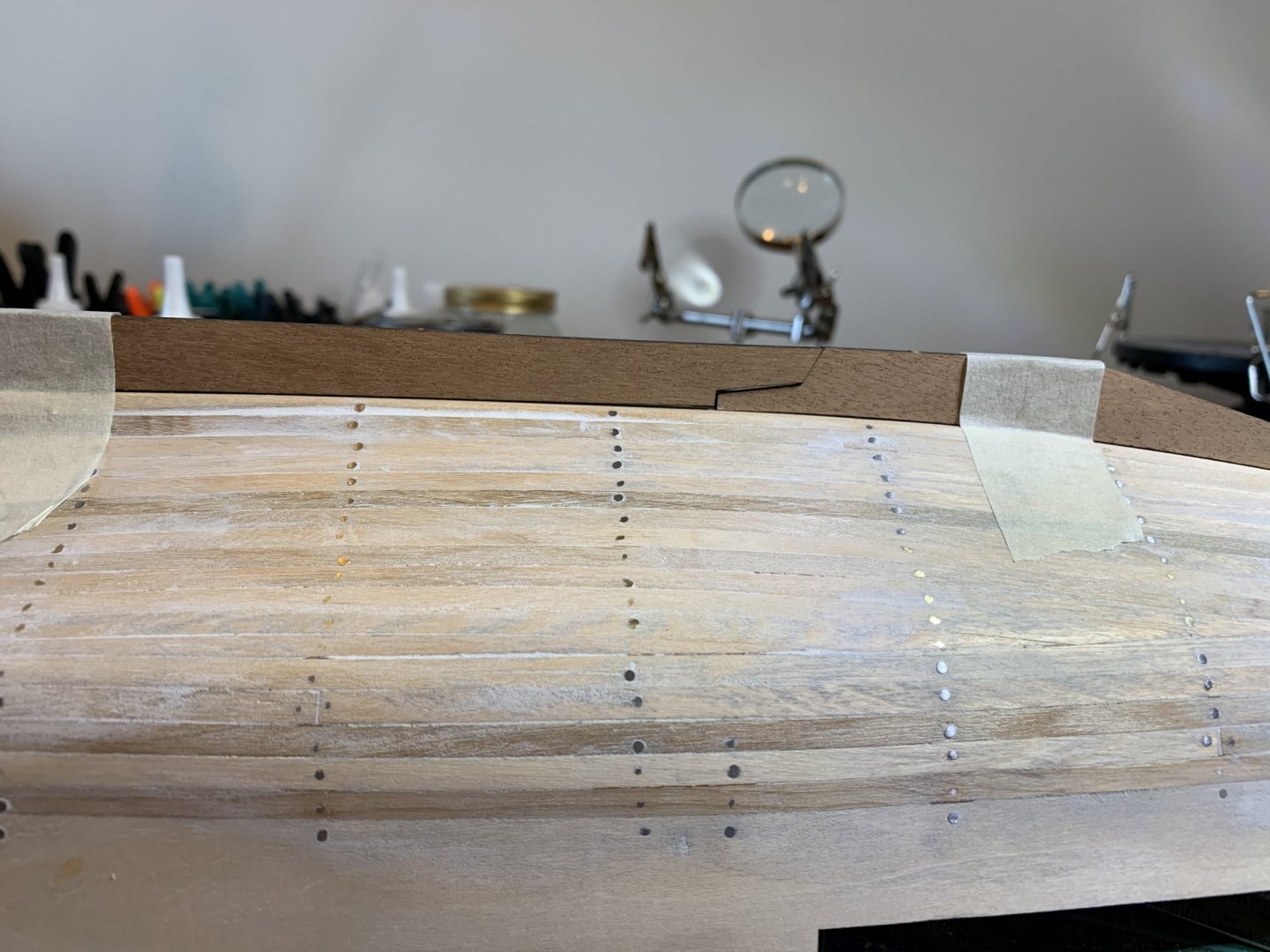

I struggled with the upper section of the hull as I was a dead smooth surface. The instructions (glibly) day to putty the whole upper section. However, I found the putty didn’t want to adhere to the hull. 🤔 so I had a think, and came up with idea of mixing some pva and water 50:50, brushed in on and let it go tacky, like you do with plaster. this gave a great base for the putty to stick to and I thought I’d got it cracked. There was an unforeseen problem though. When you rub it down and go through to the pva it doesn’t sand properly. Rather it goes all all stringy like pencil eraser rubbings. So I had to rub the whole lot down again and effectively painted on to the wood. Looks ok though. I’m happy with it. 👍

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

Ok... it’s taken a while and what seemed like a million coats of satin varnish on the planked section but I’ve managed to get the hull painted.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

Considering the two models are supposedly the same ship it’s surprising how different they are!

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

Thanks Hof. I’d seen the idea of the dowel for the keel on Mugje’s Pegasus build. Anything that involves drilling holes in the boat requires much plucking up of courage before it actually happens! One of my next jobs is drilling a 5mm hole in the stem for the bowsprite so I’ve got that to look forward to 😂😬 I had a look at your bluenose build... looked pretty damn good to me! This is my second build too, so if mine ends up half as good as yours I’ll be chuffed.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

If you’re in the UK you may be interested in the vice, which I found in Aldi’s for just £6.99! they also do a suction cup fit one, which I wish I’d got instead as it would have fit my desk better.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

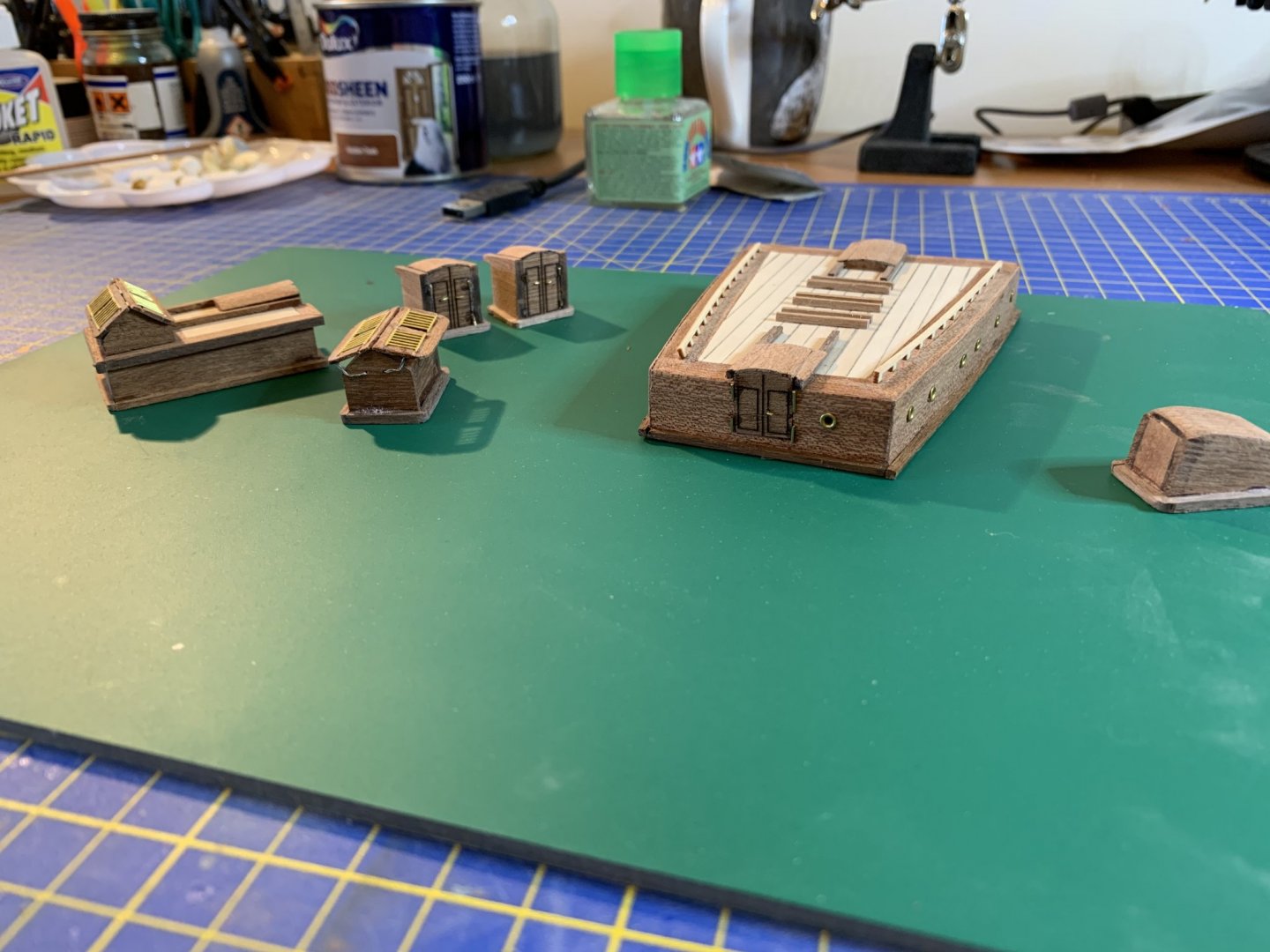

Any, here’s some piccies of how she looks at the moment, with the masts and deck furniture that I’ve made, dry fitted. Starting to look like a ship now.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

I also had the problem with my first keel fit that, when I put the boat in it’s stand, it had a distinct list!!! I had to redo, dry fit the masts to give me a clearer idea as to whether I’d got it at the correct angle or not.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

In the photo you can see that I’ve managed to get just a small gap, which I’m filling with wood glue/sawdust.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

Thanks Hof. I appreciate the support. When I was dry fitting the keel there was a gap between it and the false keel, and the two main keel pieces didn’t link particularly well. I was finding it difficult to know whether it all went together well or not as the pieces are just loose. I decided to join the two main keel pieces together (after sanding to achieve a better join). This enabled me to place it against the hull to see where wood needed to be removed. I could then be more confident with the two for’ard keel pieces. This appears to be one of the differences between wooden models and plastic models. With plastic, we get used to everything being a perfect fit and it’s an outcry when something fits poorly. With wooden, I guess it’s less of an exact science. Each of us will have a very slightly different shape hull and I think they build in tolerances which the modeller has to adjust for, and spend a bit of time sanding to achieve the required fit.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

The next puzzle needing to be solved is getting the keel fitted without any gaps. if anybody has tips or experience on this please advise.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

I think I can see how it’ll work now.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

Kind of looks to be in the ball park but also looks to be some issues to solve. most worried by the extent that the keel overlaps the stern, but guessing this can all be sanded to fit. Any advice welcome

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

Thanks, but I don’t think they’ll ship to the UK!

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

This would be good, except I don’t think they’ll post yo UK for free ☹️😂

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

Thank you Grandpa Phil. It does go through phases of me thinking I don’t have a clue what I’m doing, but I just have to take more time to think about what needs to be done.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

My bluenose won’t be carrying the little boats on deck. I think anybody whose tried to make them as per the AL instructions will understand why... blinking things 🤬🤯

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

-

I know there are some holes and gaps. Plan to double plank the bottom portion of the hull, but even so I’m to fill with putty and get it as smooth as can, even if that’s just for practice.

- 146 replies

-

- artesania latina

- bluenose ii

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.