modeller_masa

NRG Member-

Posts

950 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by modeller_masa

-

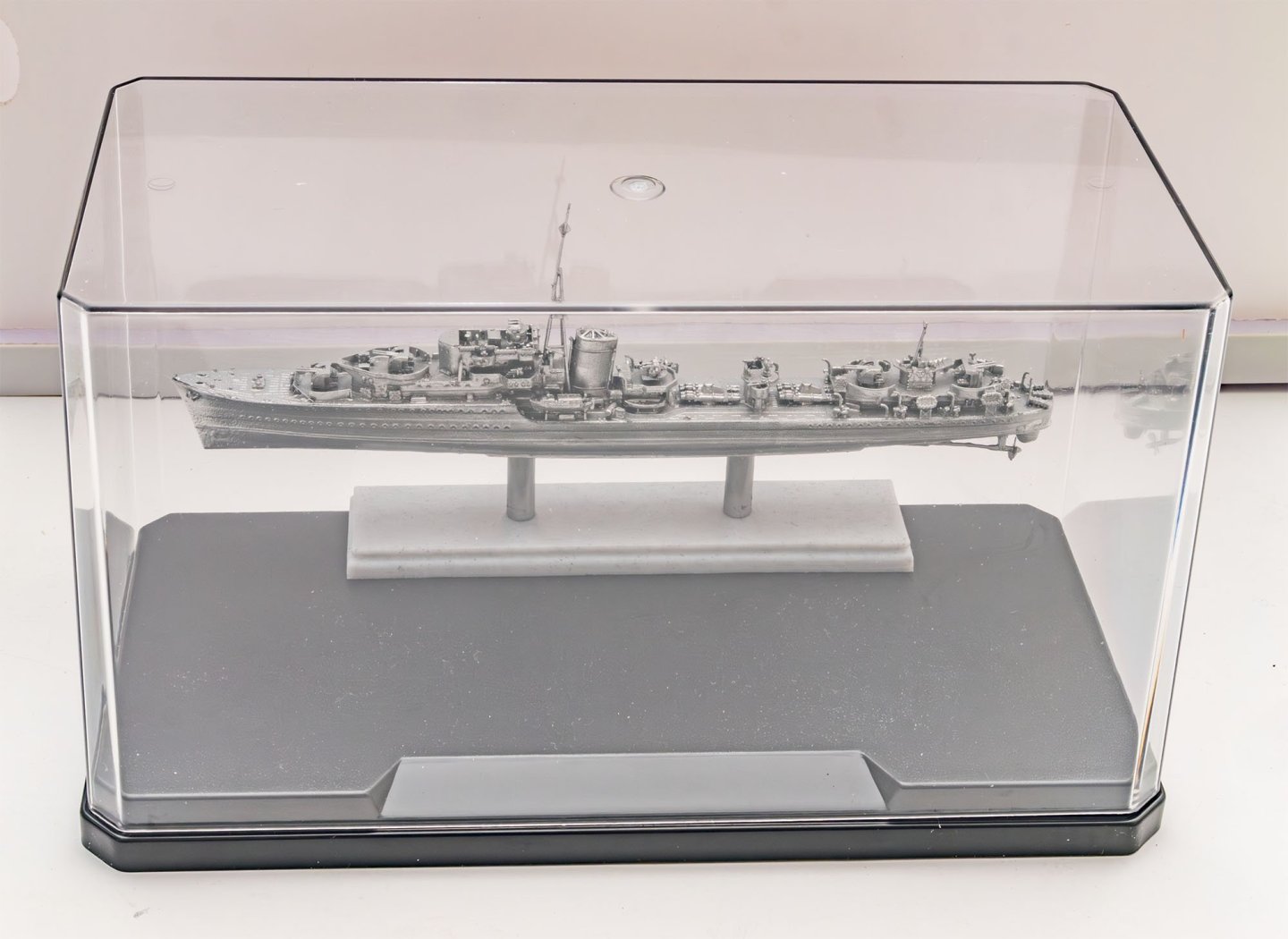

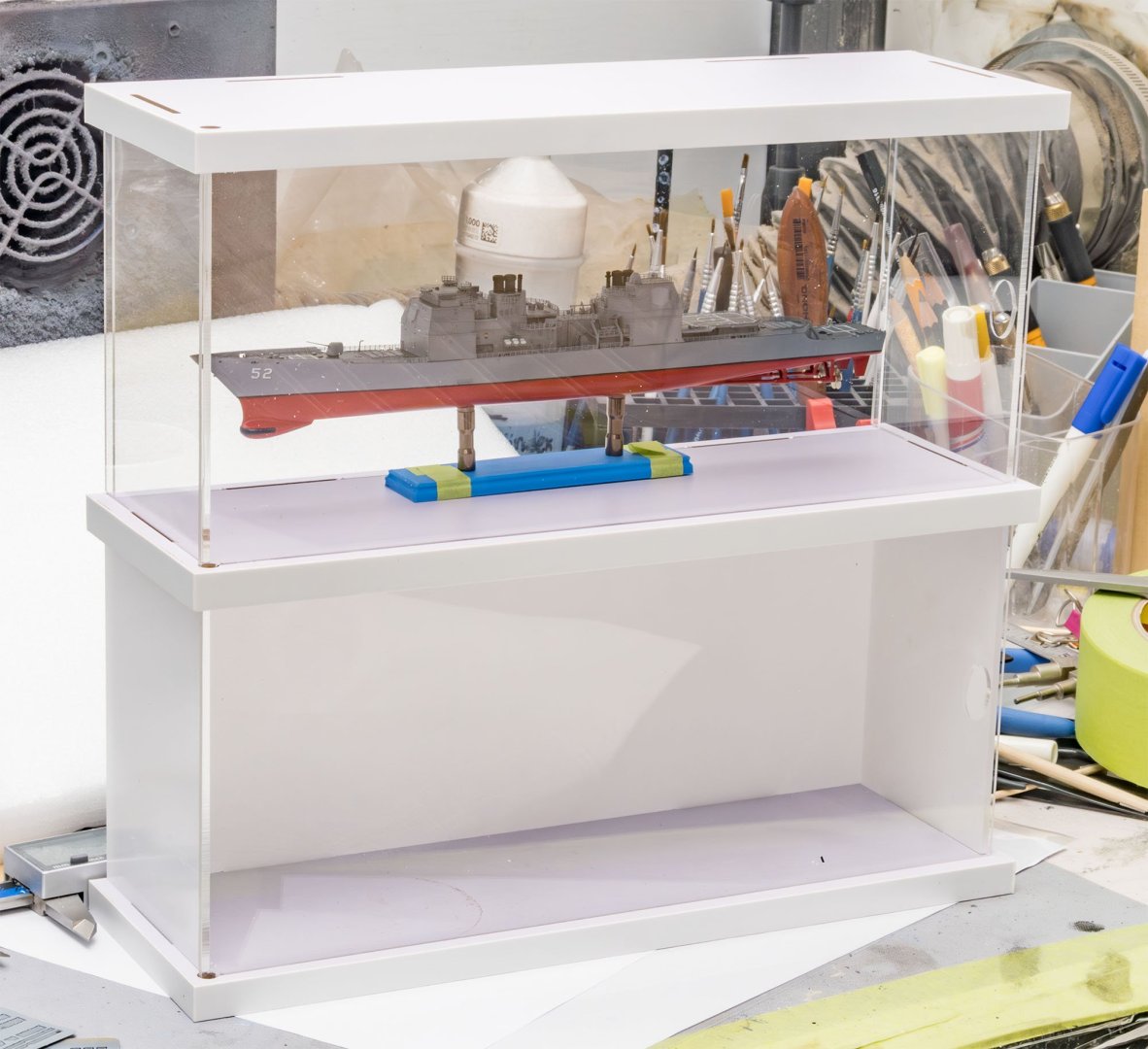

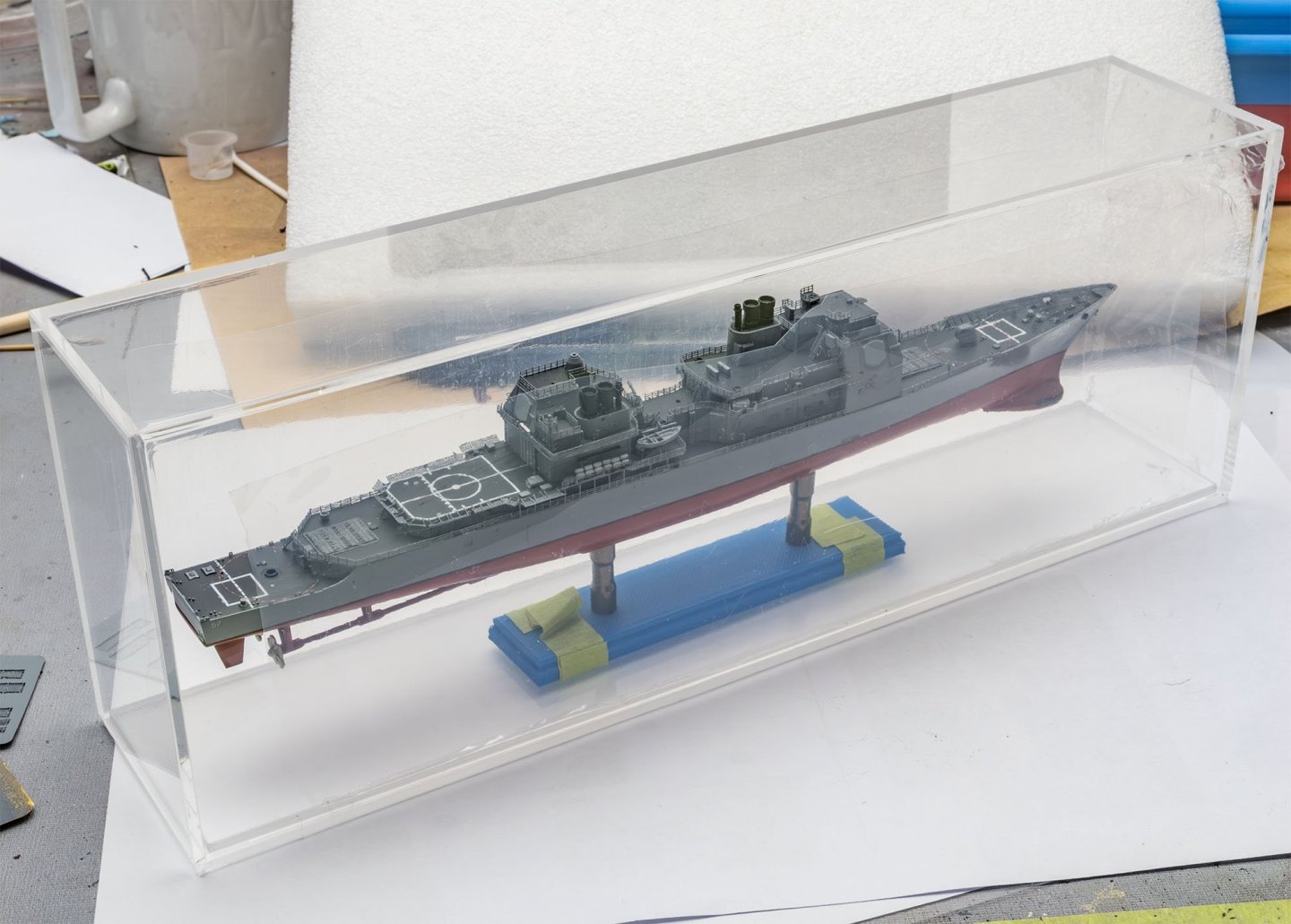

I've tested several acrylic (Plexiglass) cases. My final choice was an order-made case with 3mm thickness. I'll add 3D printed corner supports. Unfortunately, I measured the height wrong, so I ordered a new case. The price is $20.

- 9 replies

-

- Bunker Hill

- Flyhawk

-

(and 2 more)

Tagged with:

-

In my opinion, 1/700, 1/350, and 1/200 big scale models are different classes, like the boxing weight classes. I'm making many mistakes on 1/700 scale models, but they are not visible thanks to their small size. 1/200 scales have only a small tolerance to fold PE parts. I think 1/700 scale ship models are good for fast and easy introduction kits.

- 9 replies

-

- Bunker Hill

- Flyhawk

-

(and 2 more)

Tagged with:

-

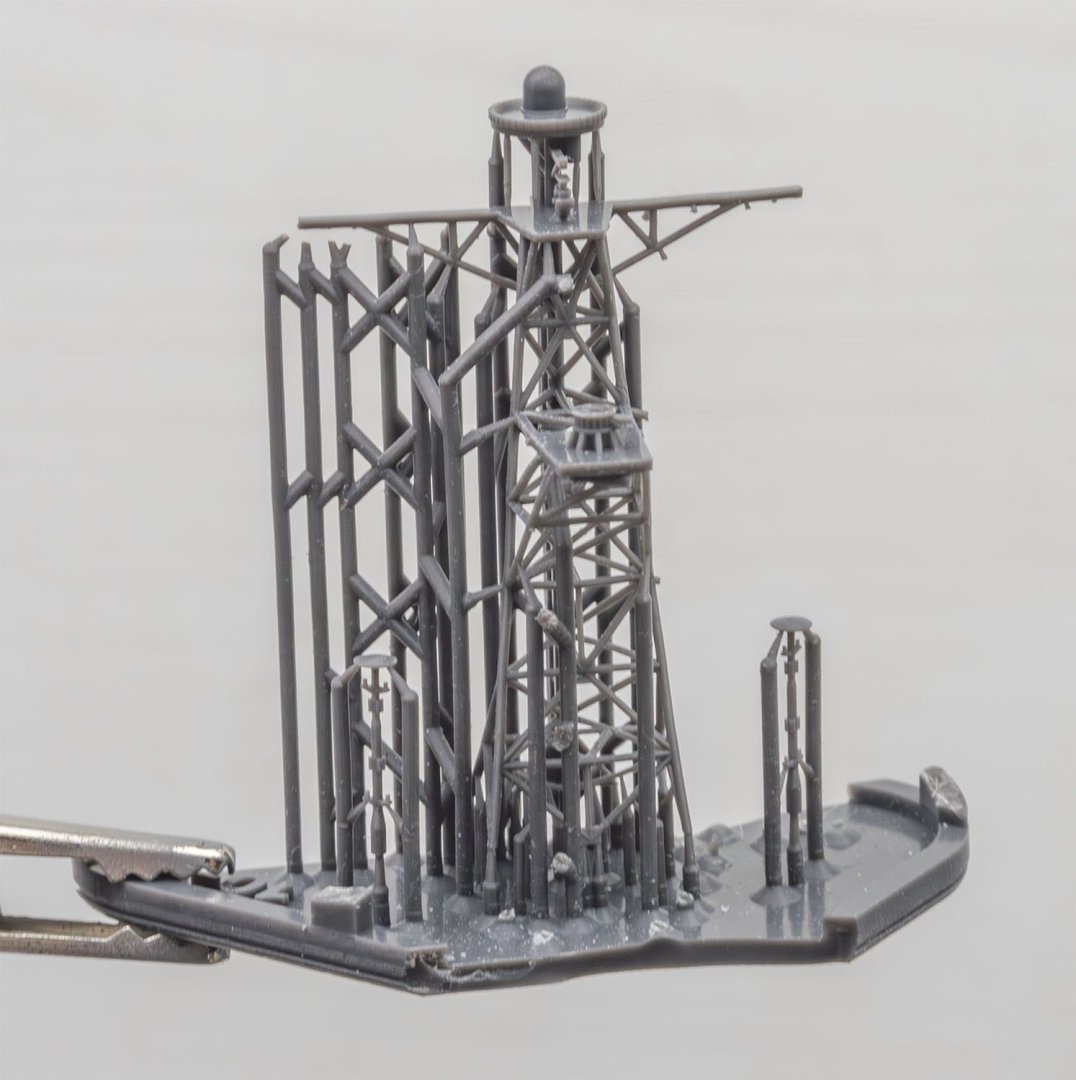

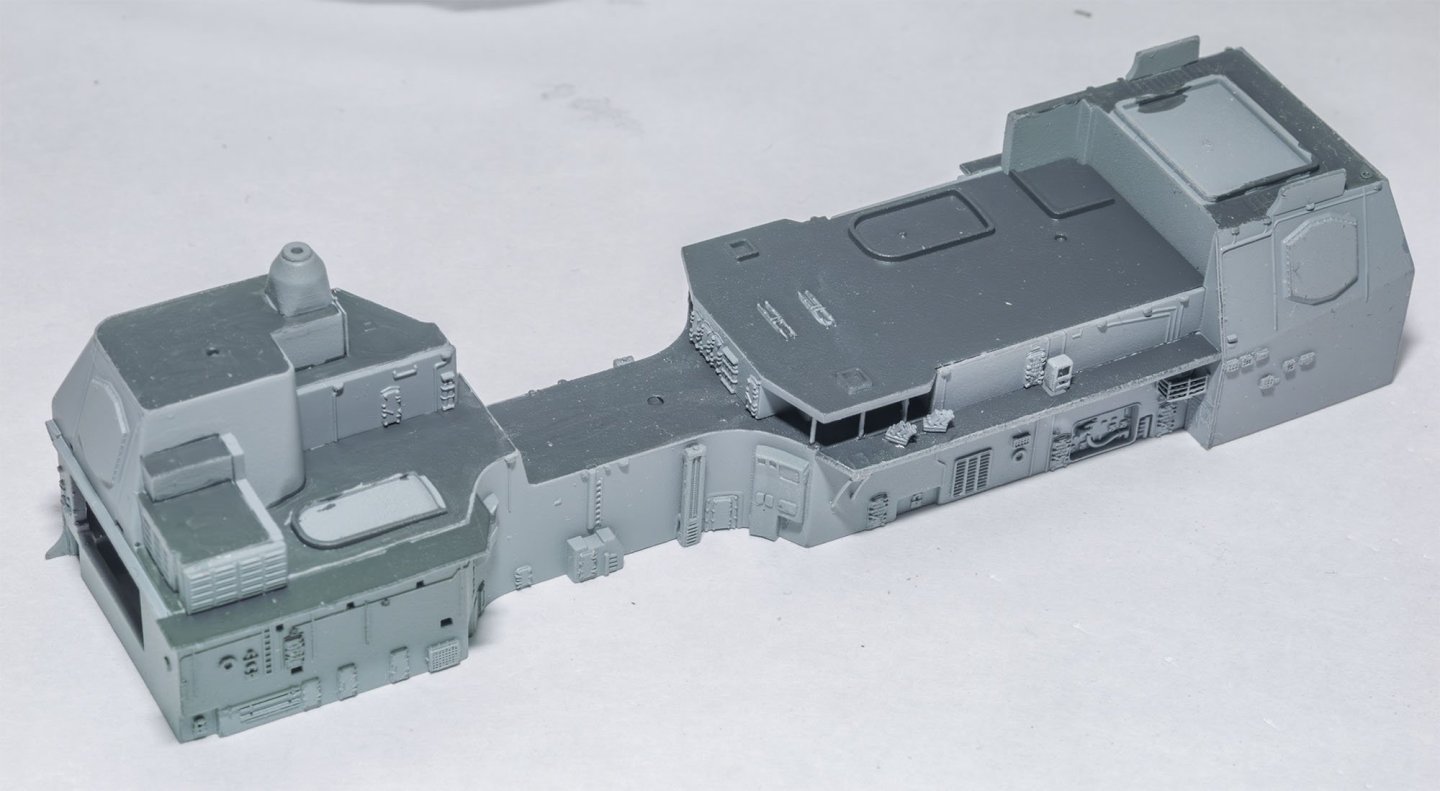

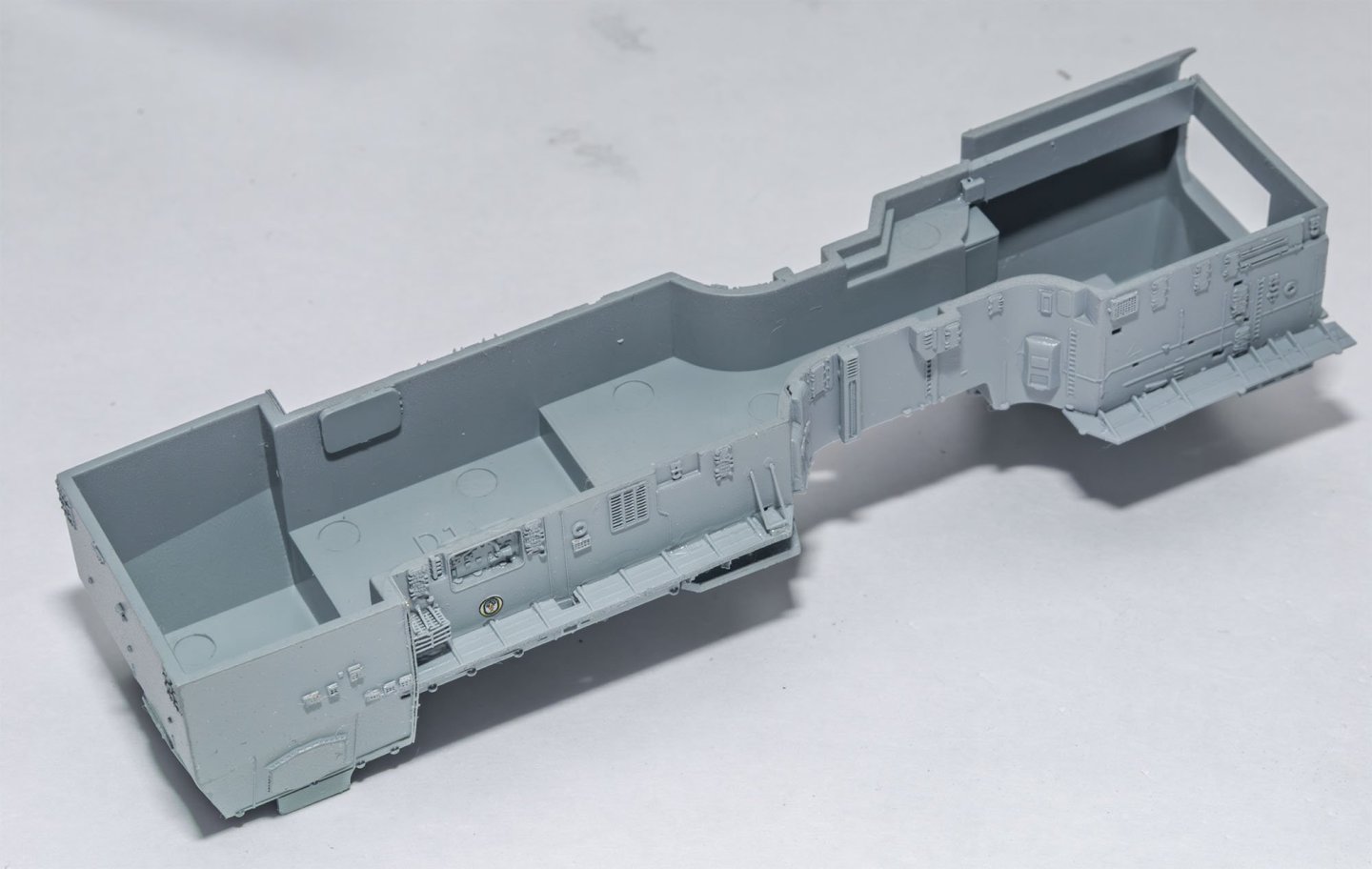

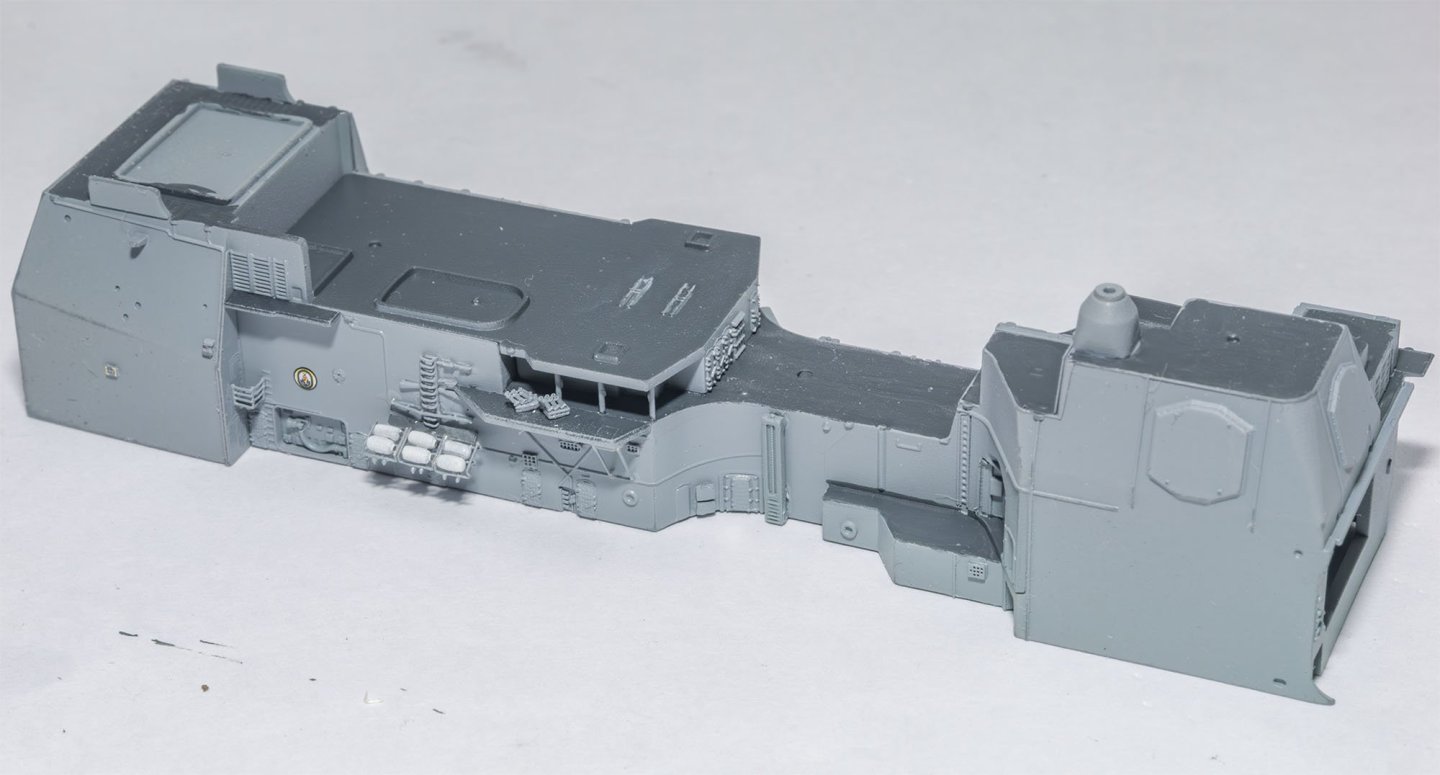

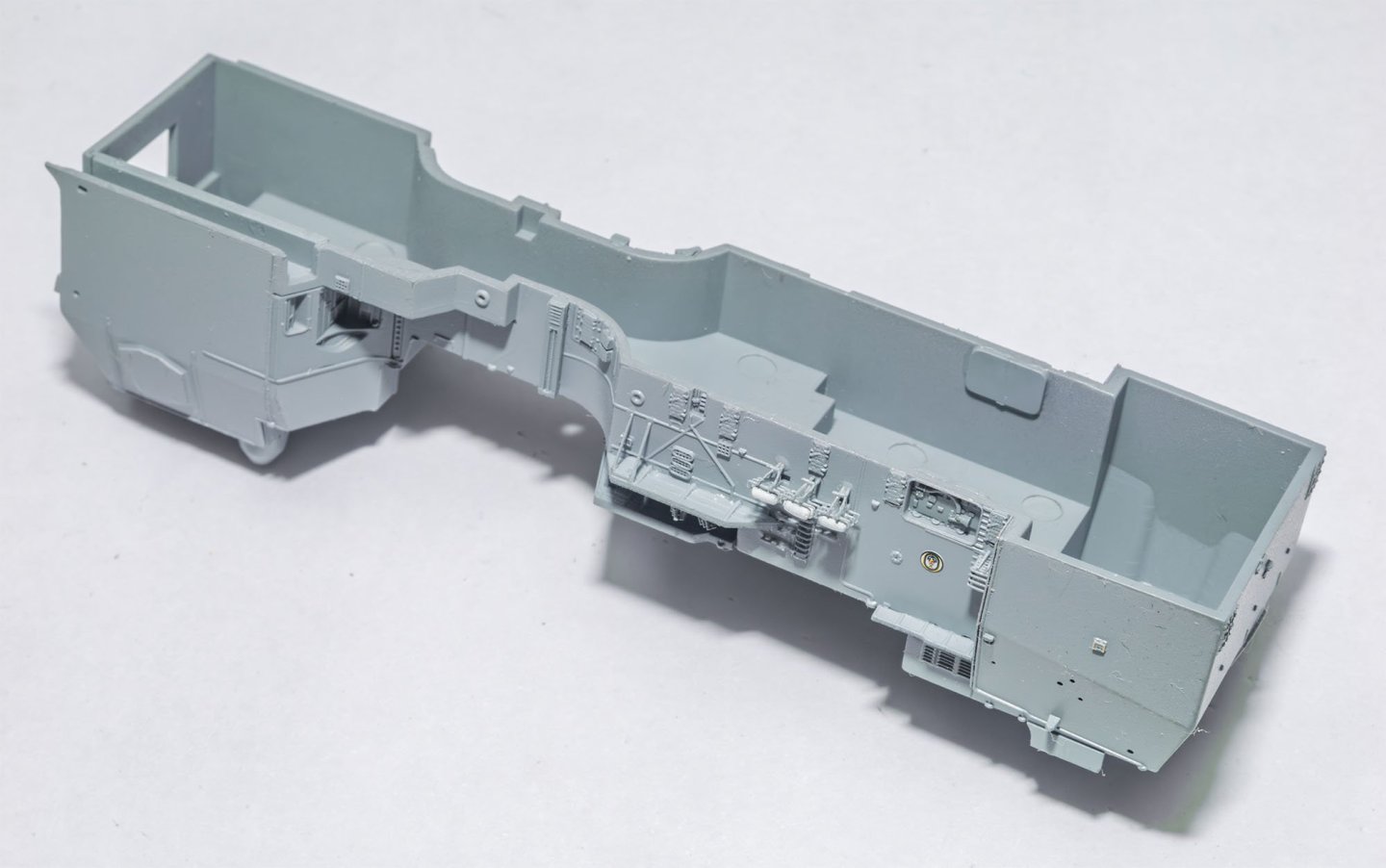

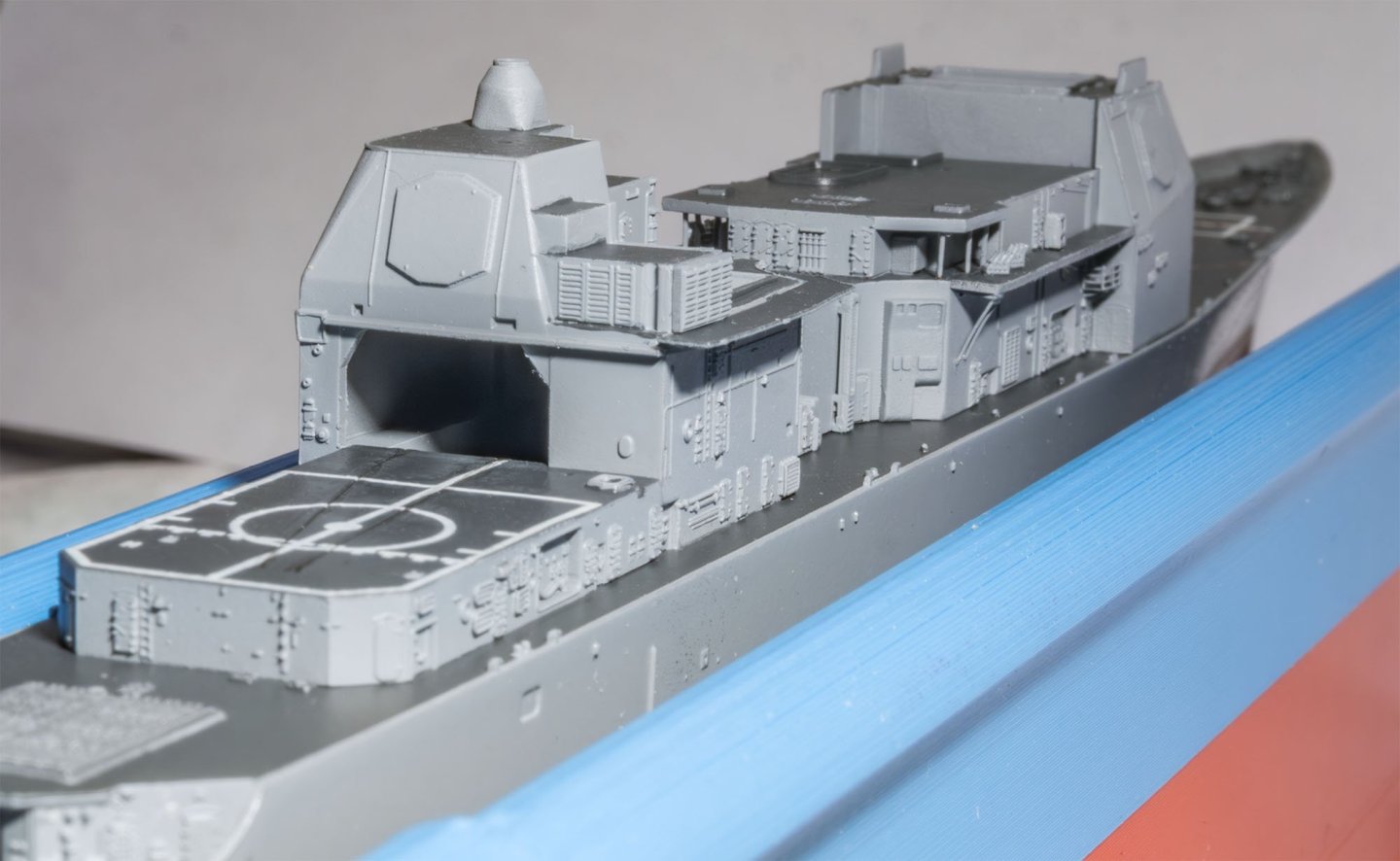

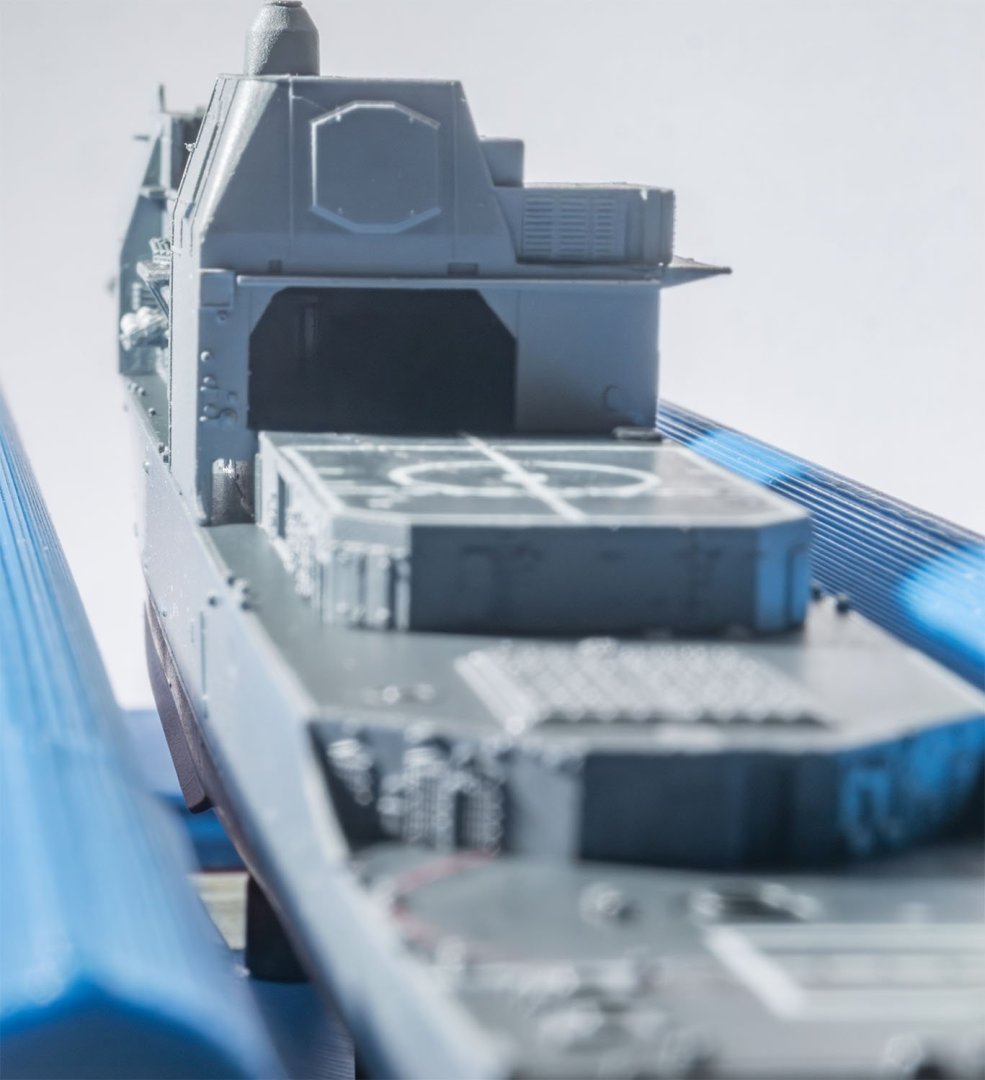

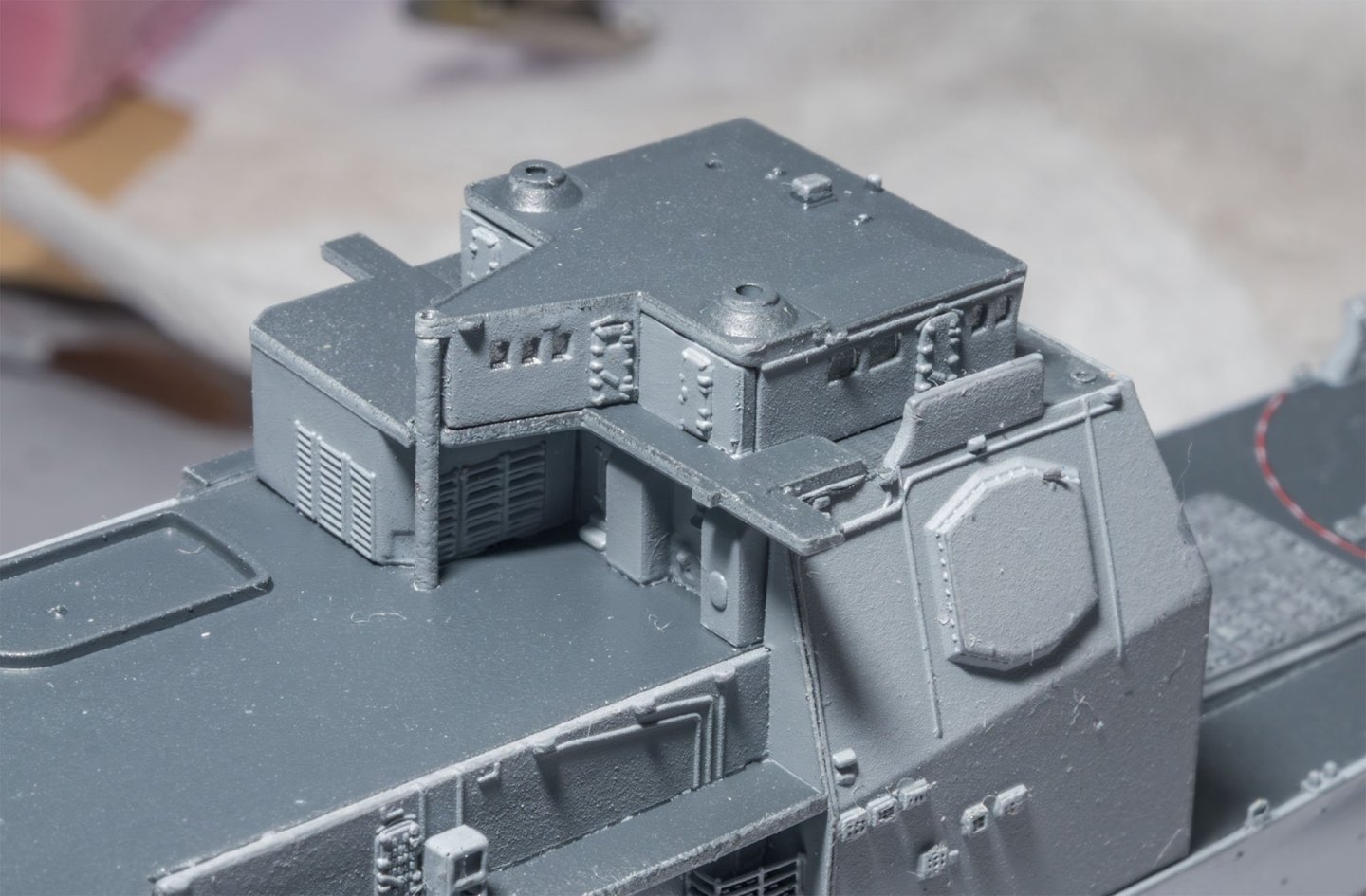

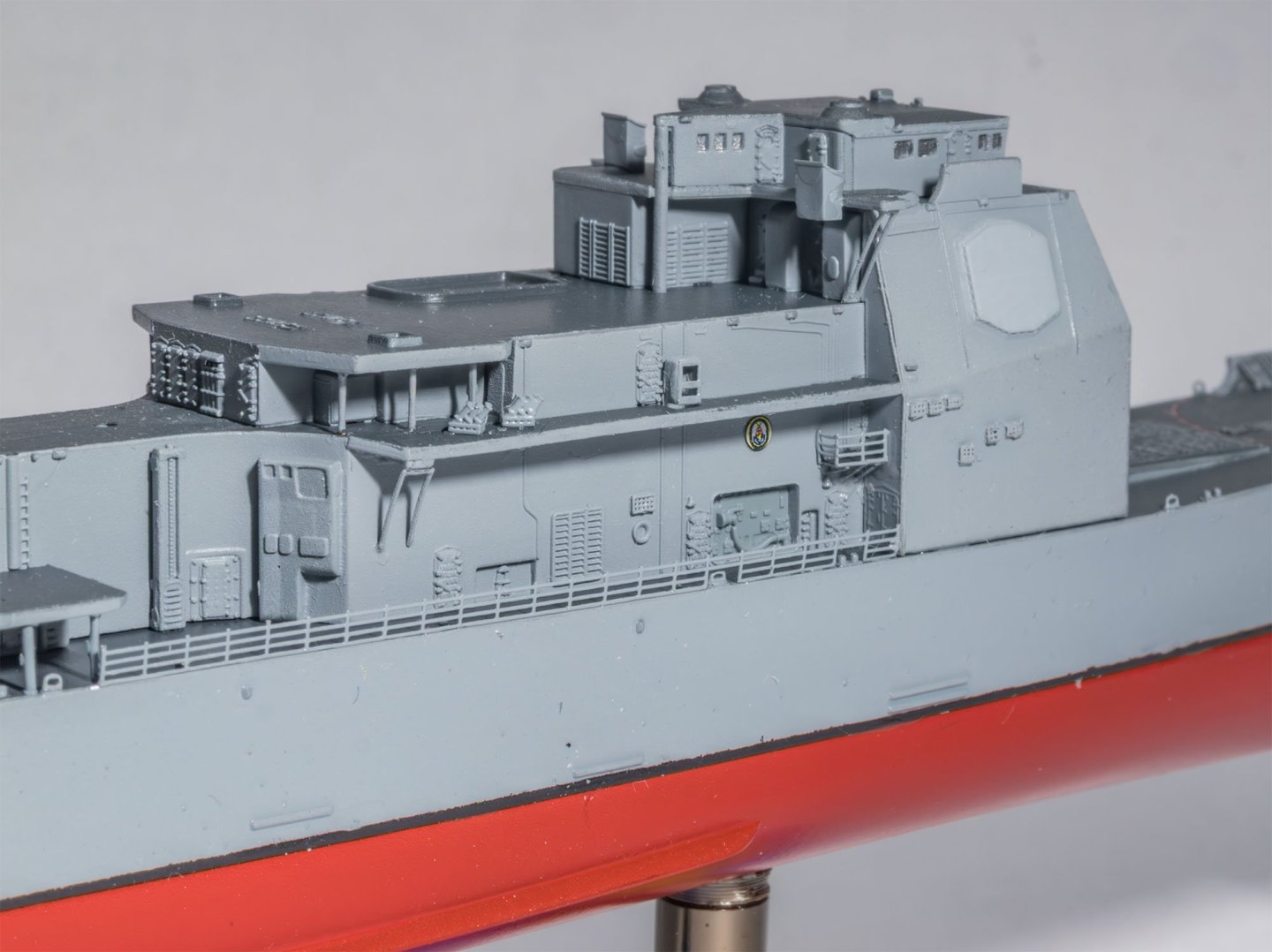

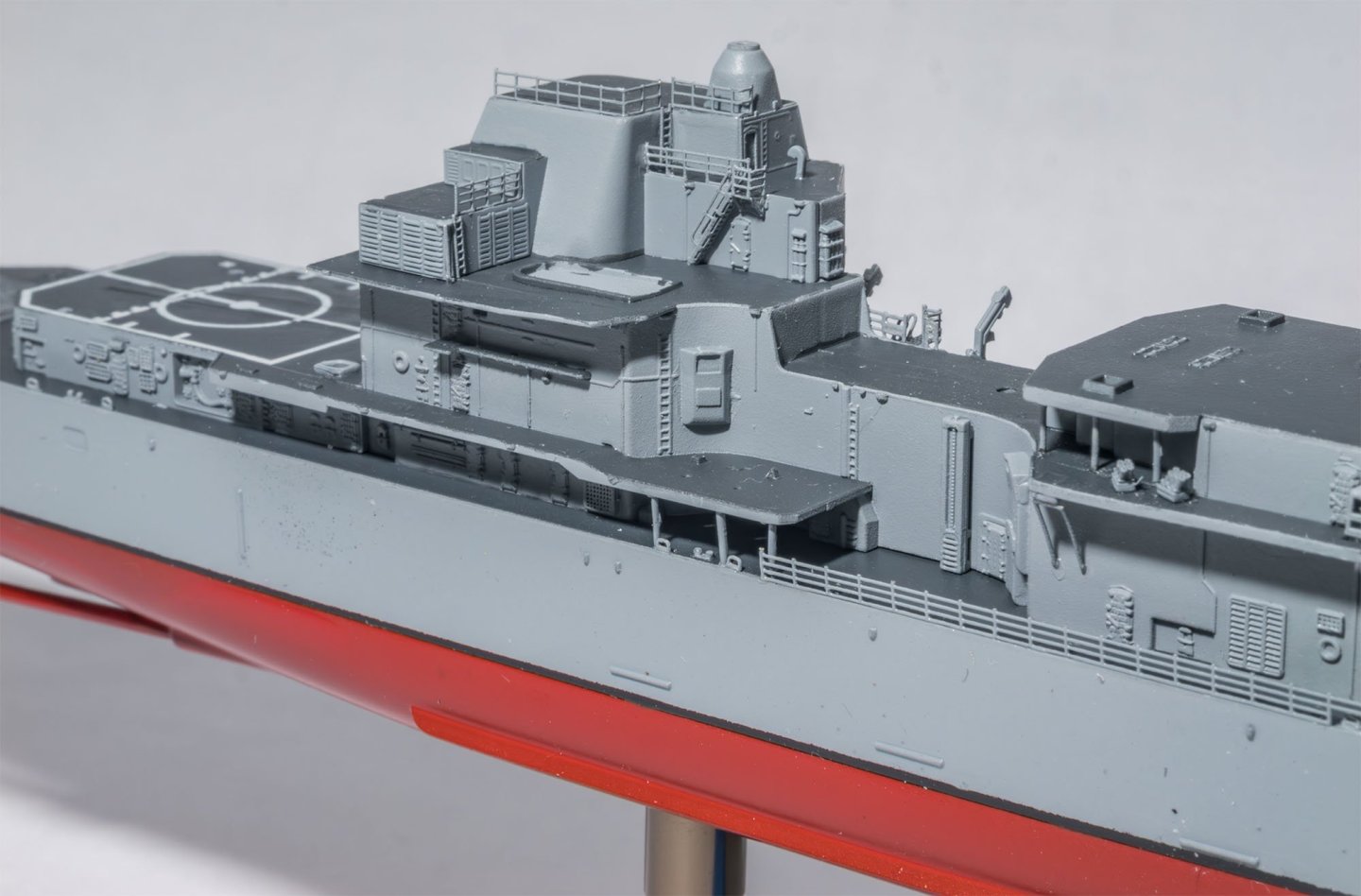

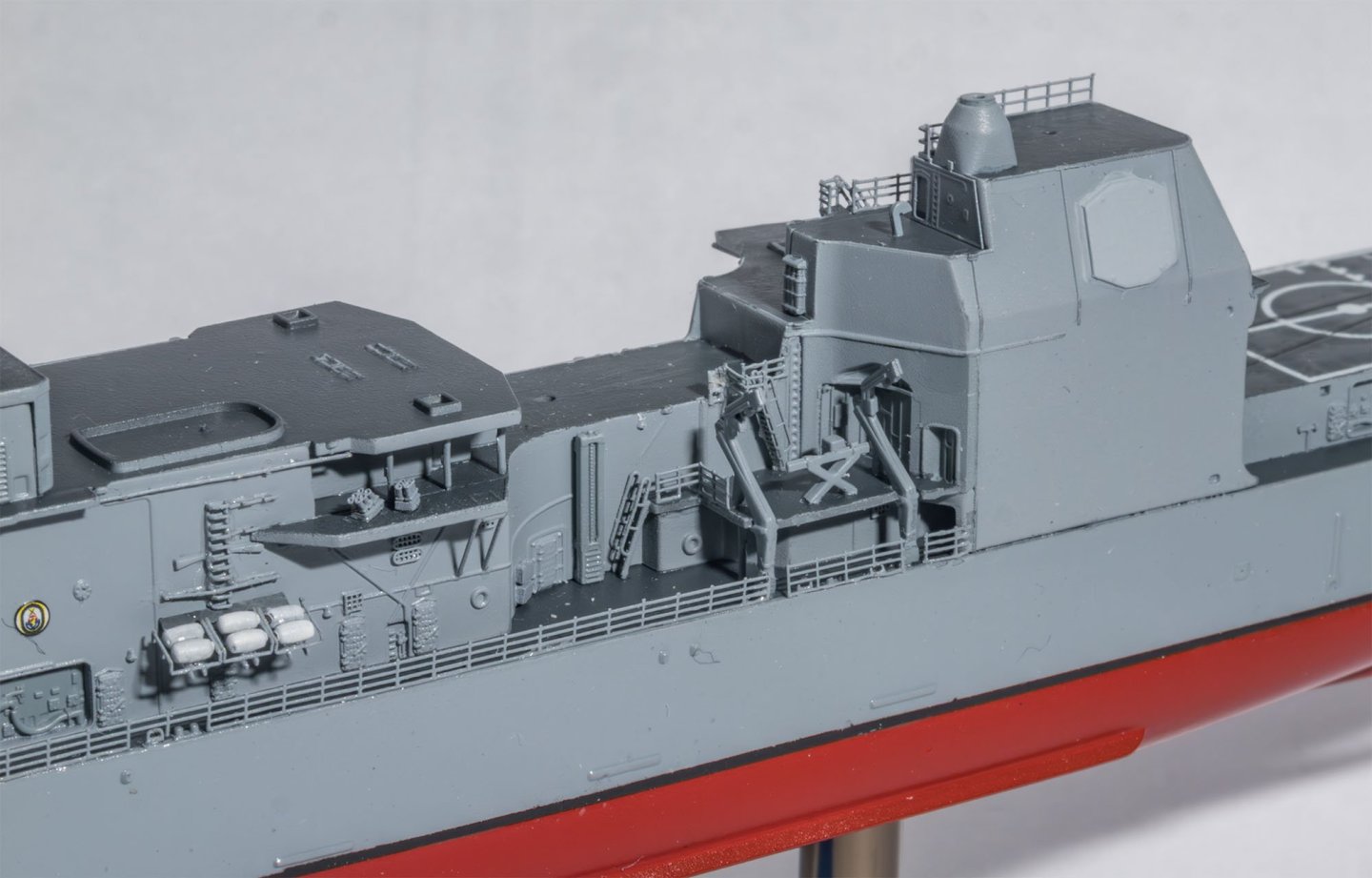

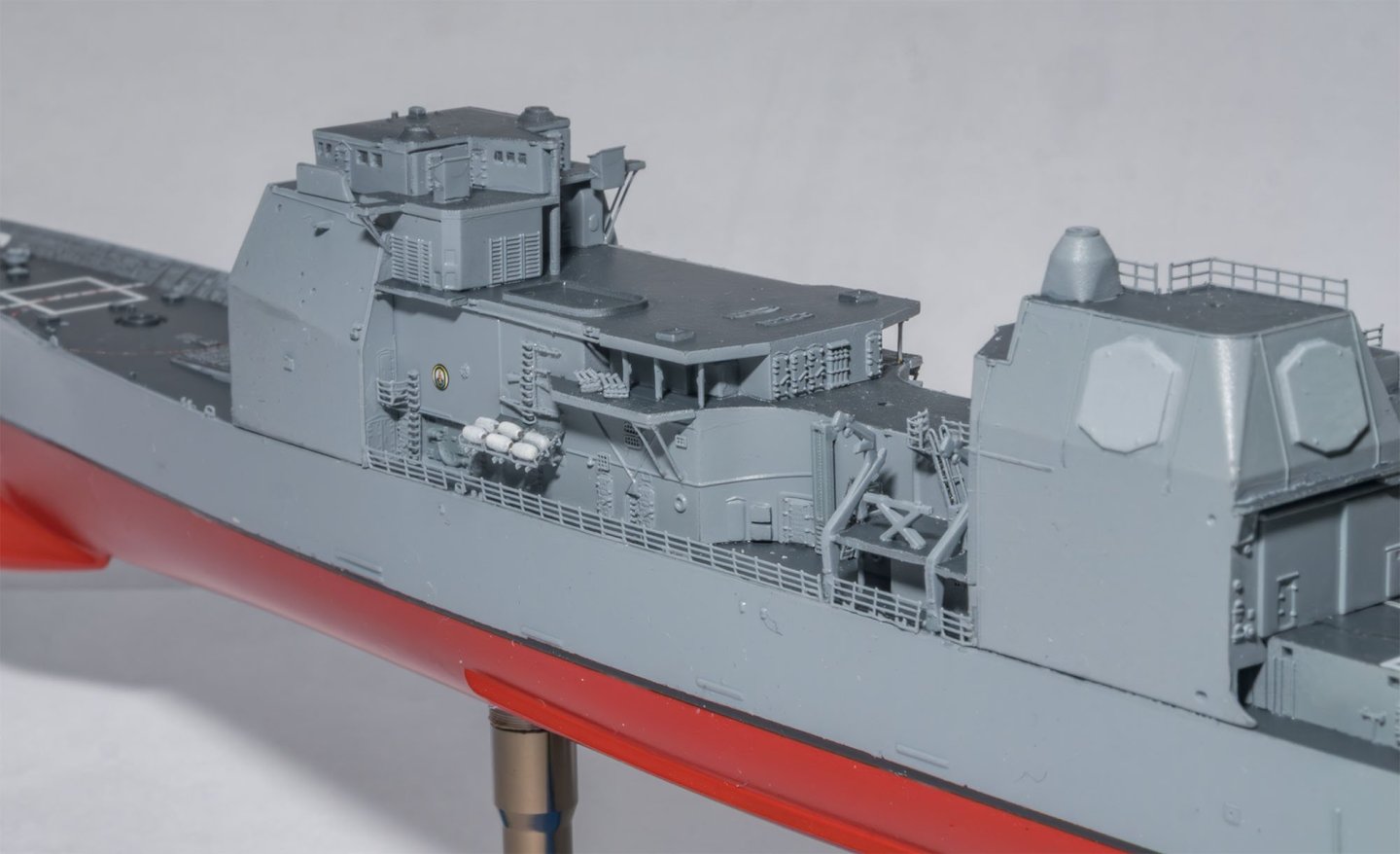

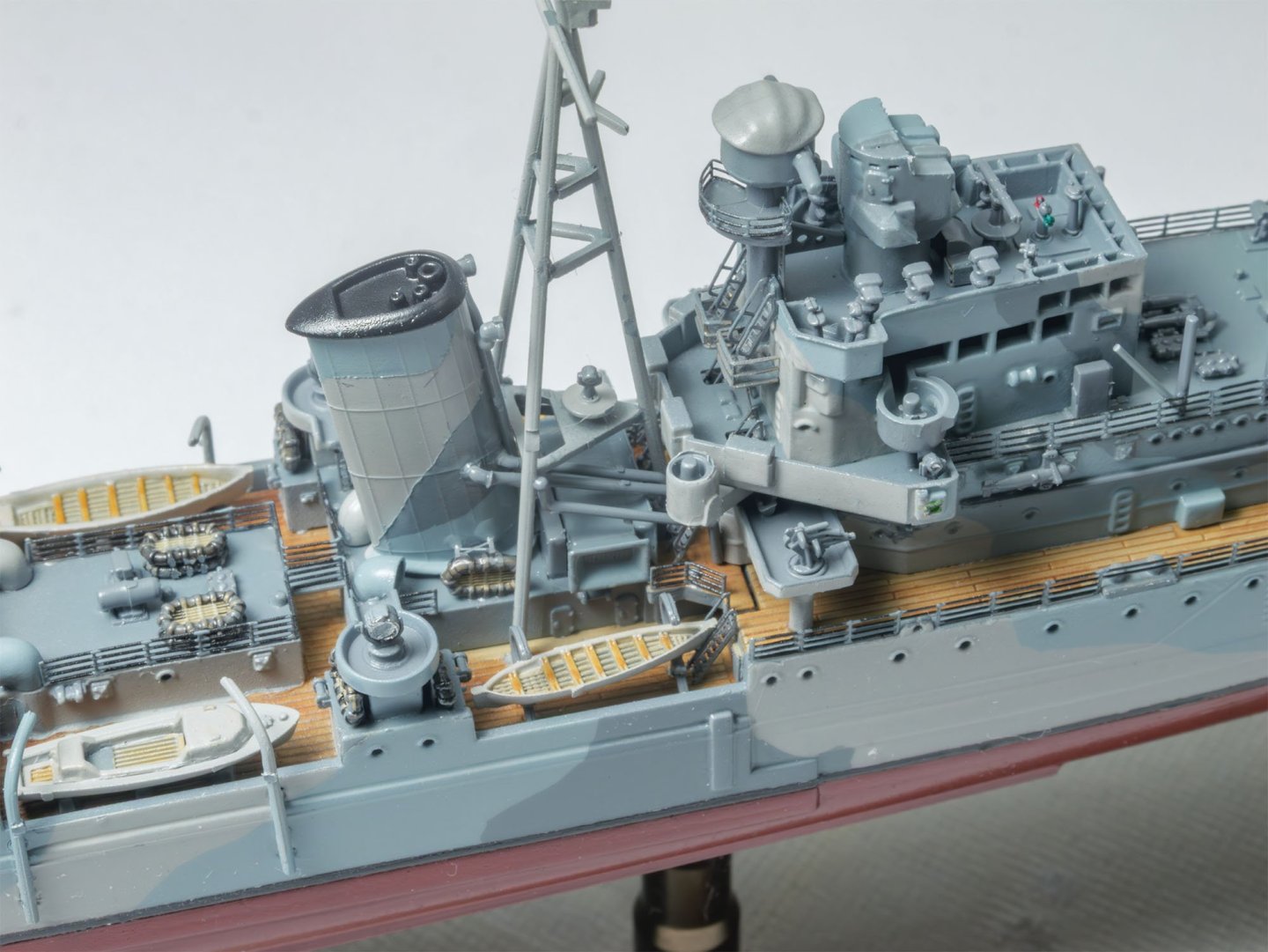

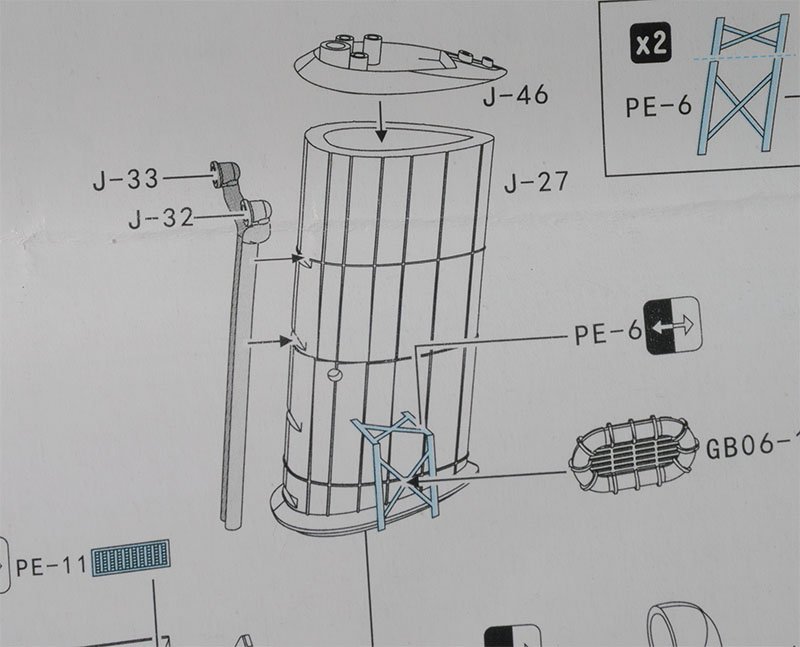

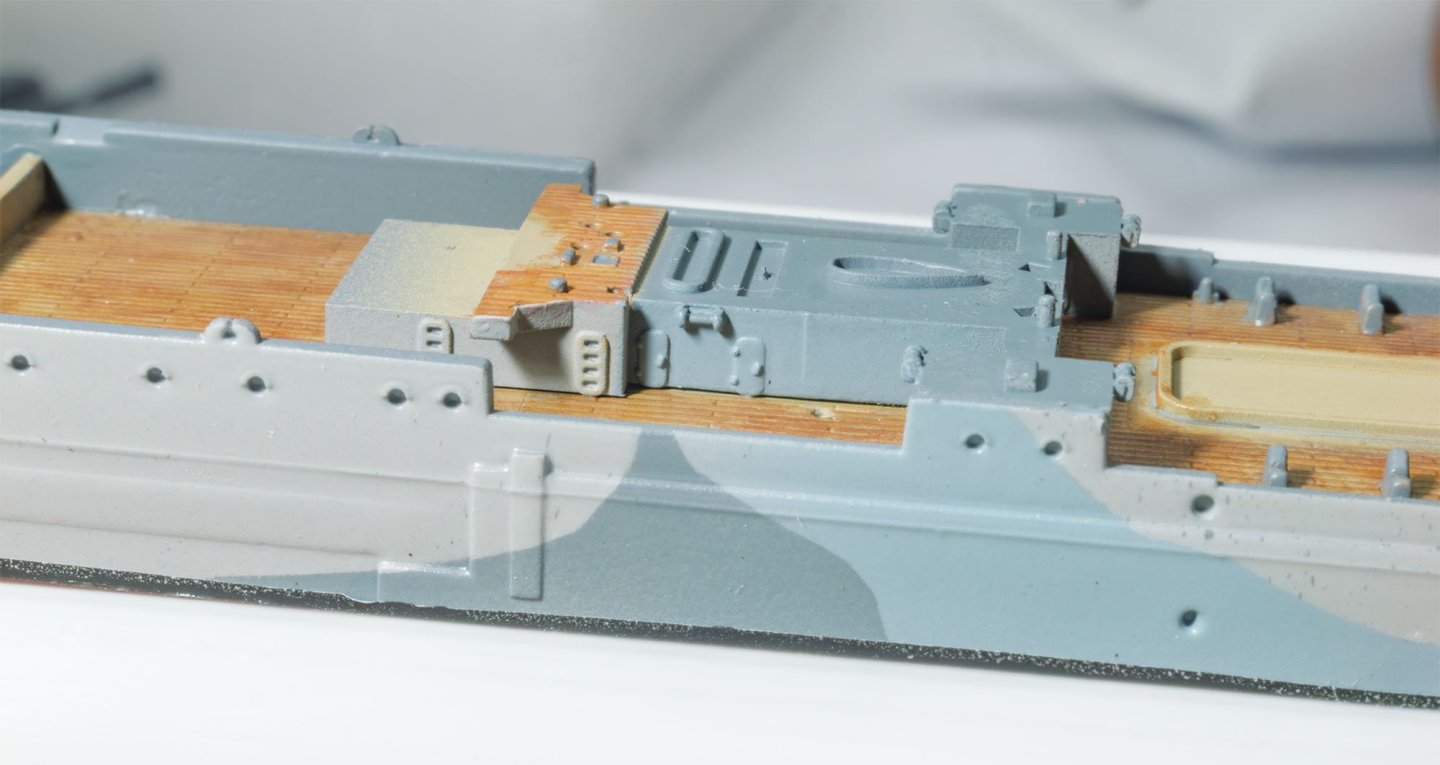

Walkthrough #1 This is a really difficult kit. Most parts are interconnected with other vertical floors, including PE railings and stairs. I need to check every pages of the manual again and again to avoid a critical mistake.

- 9 replies

-

- Bunker Hill

- Flyhawk

-

(and 2 more)

Tagged with:

-

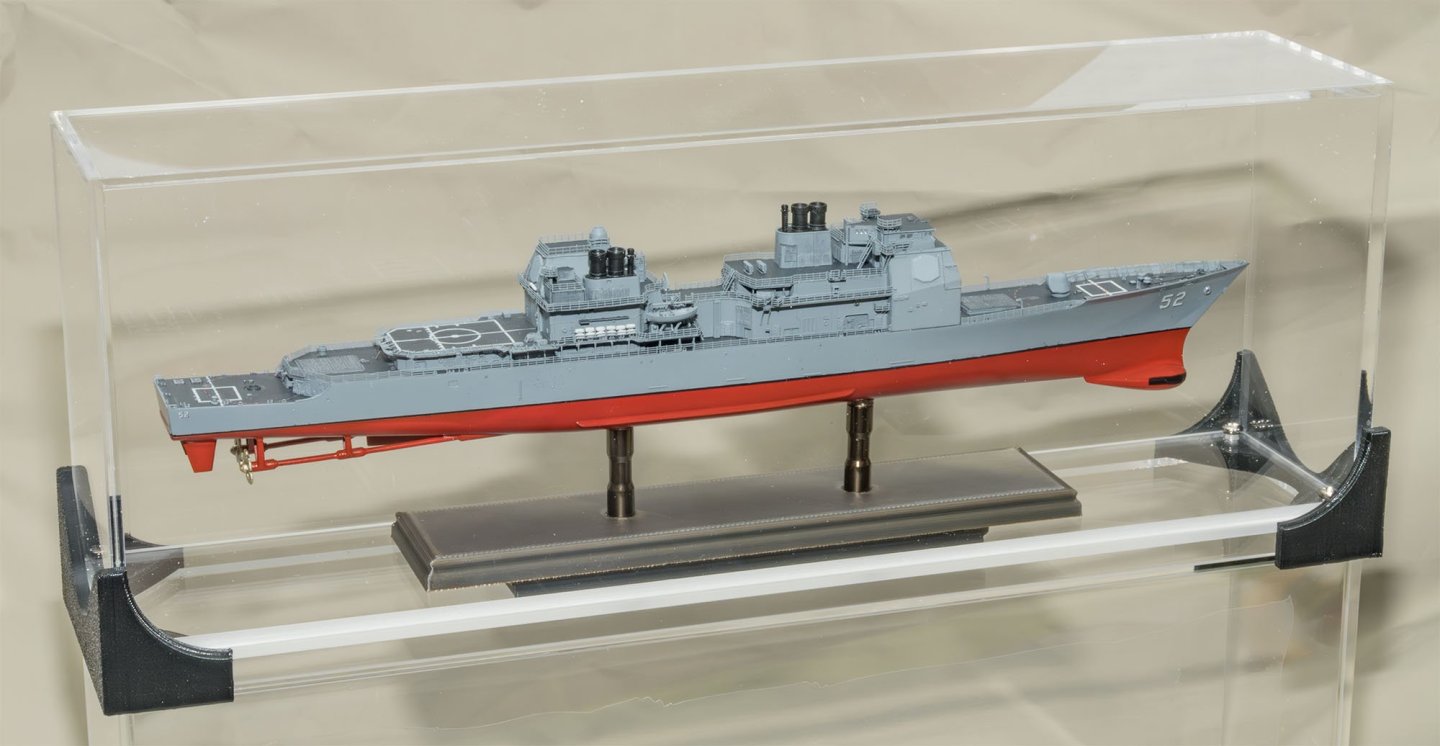

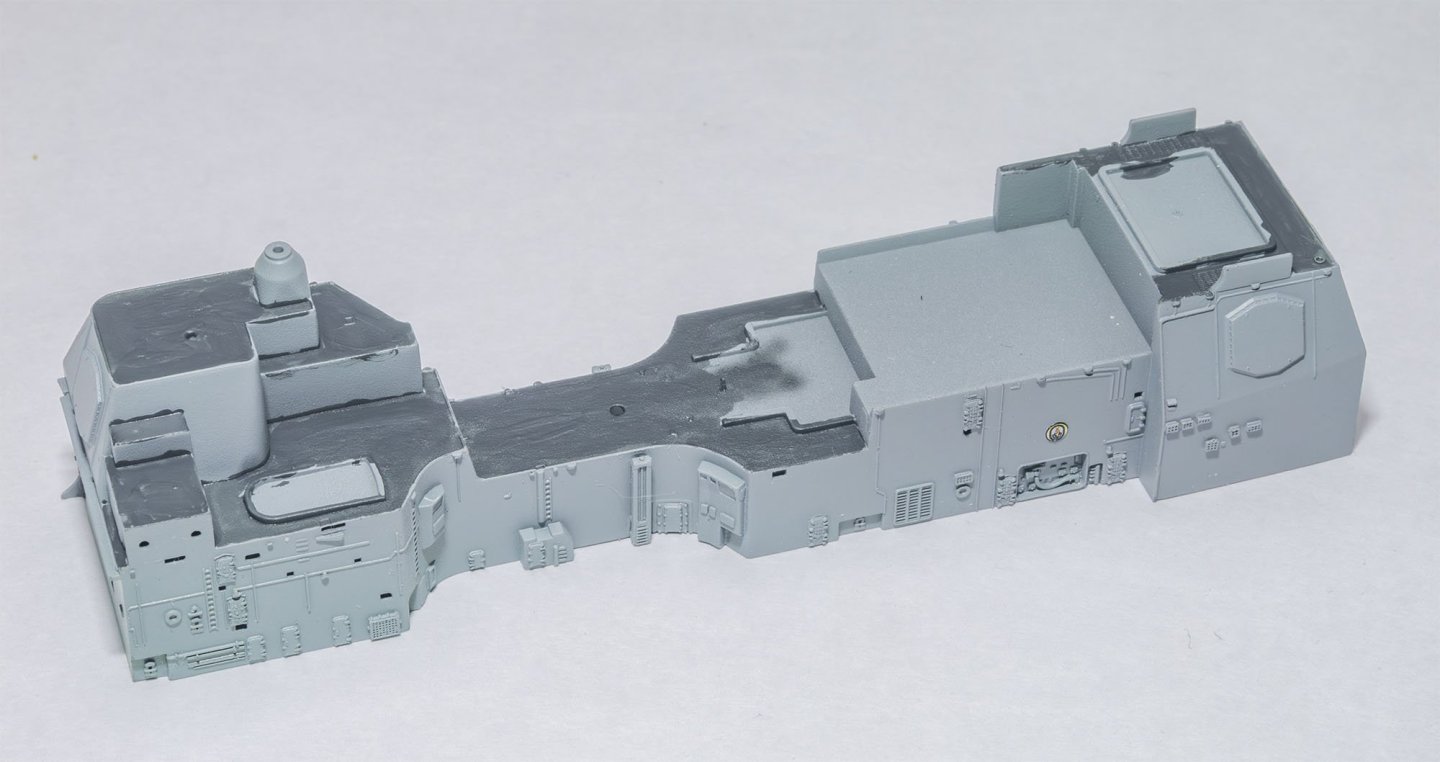

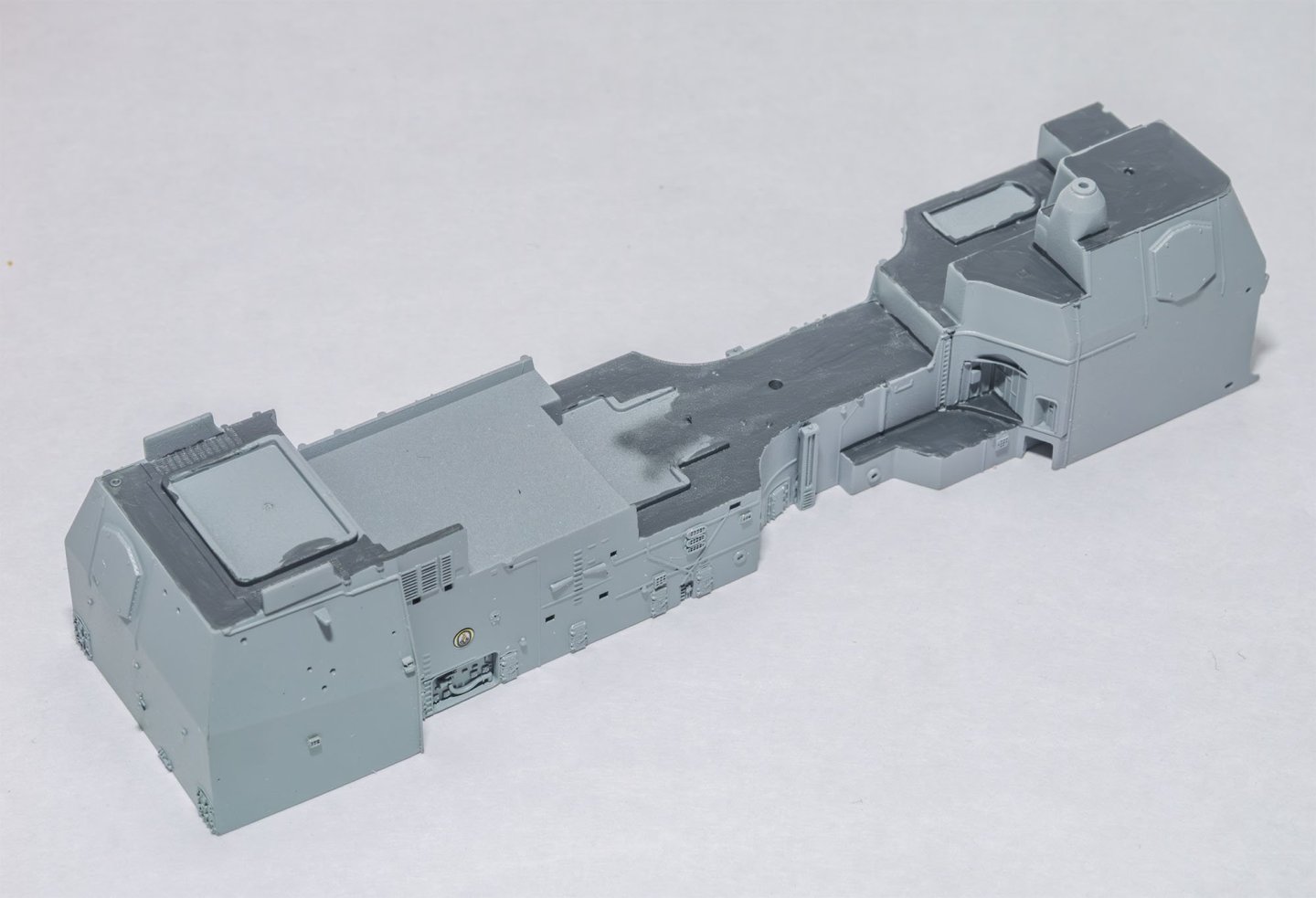

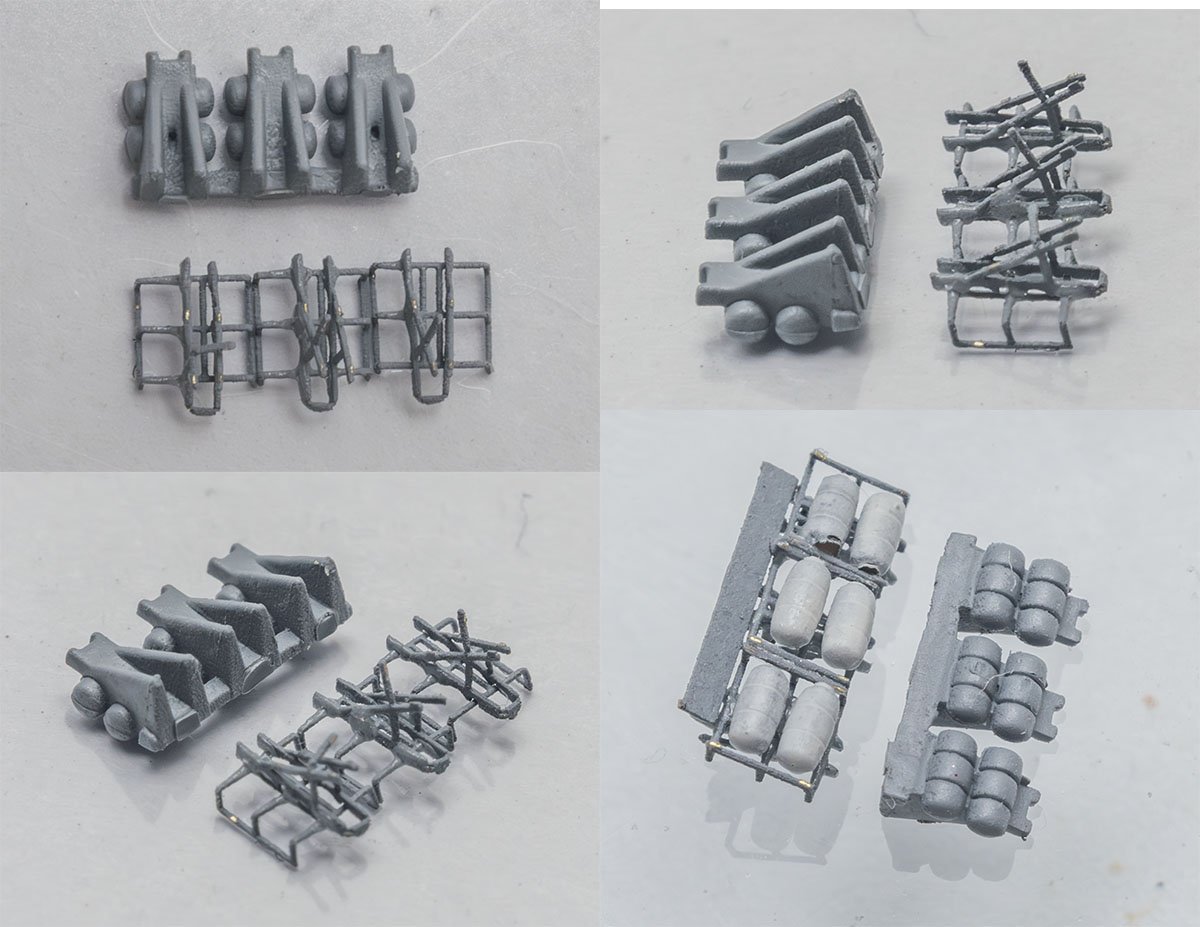

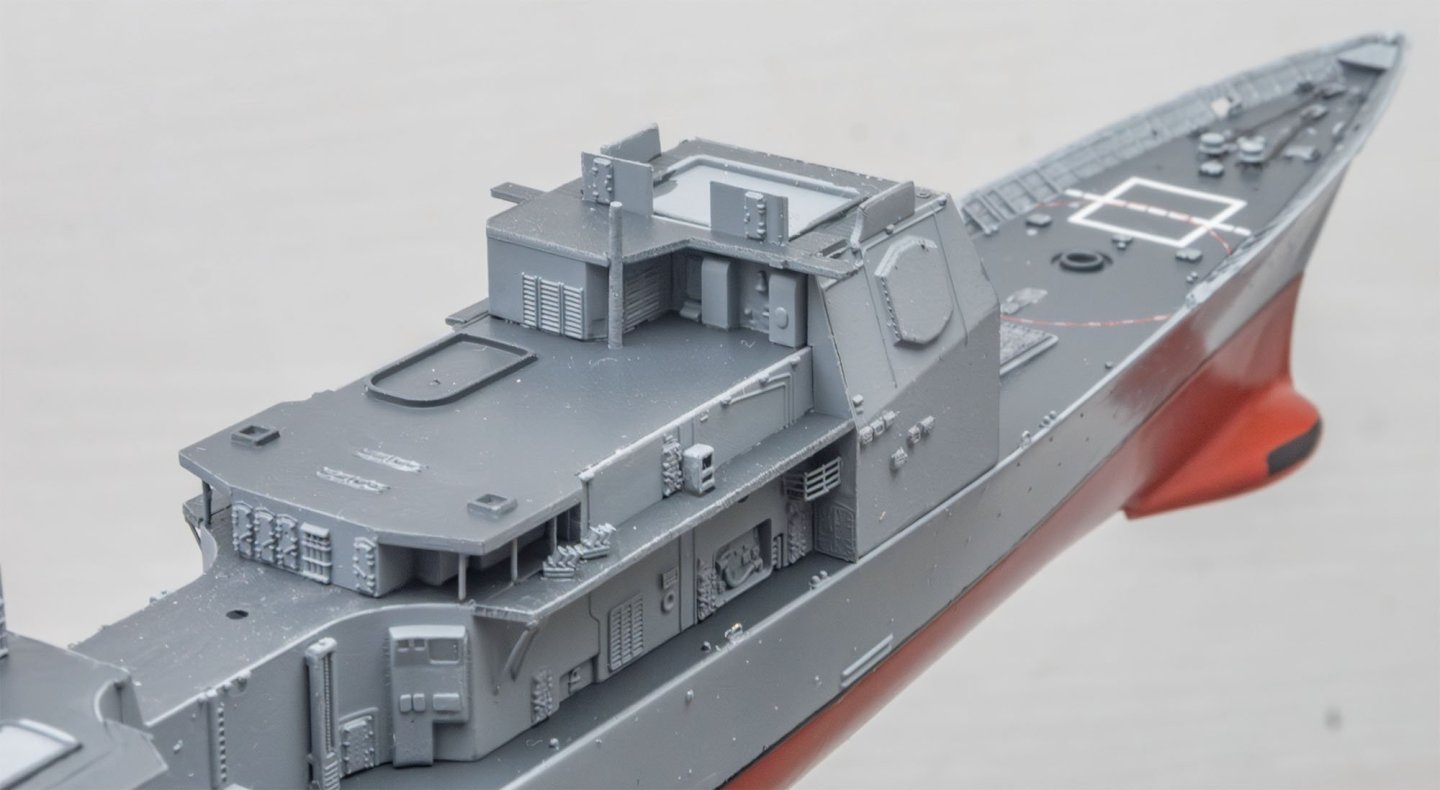

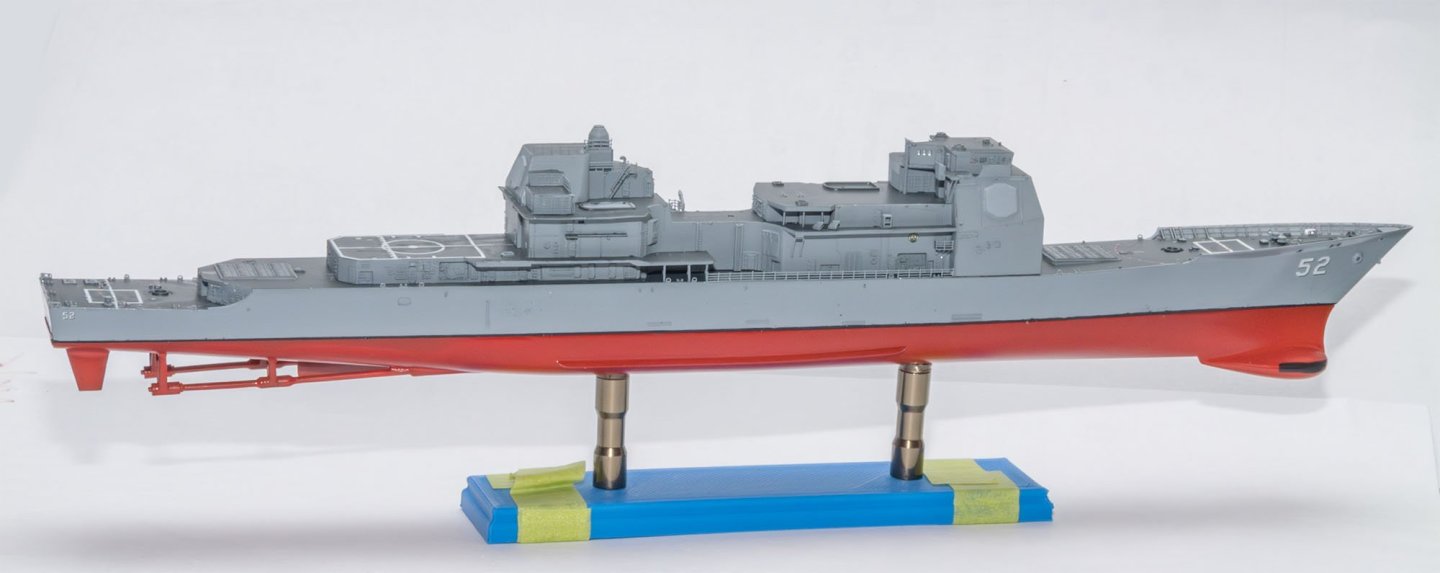

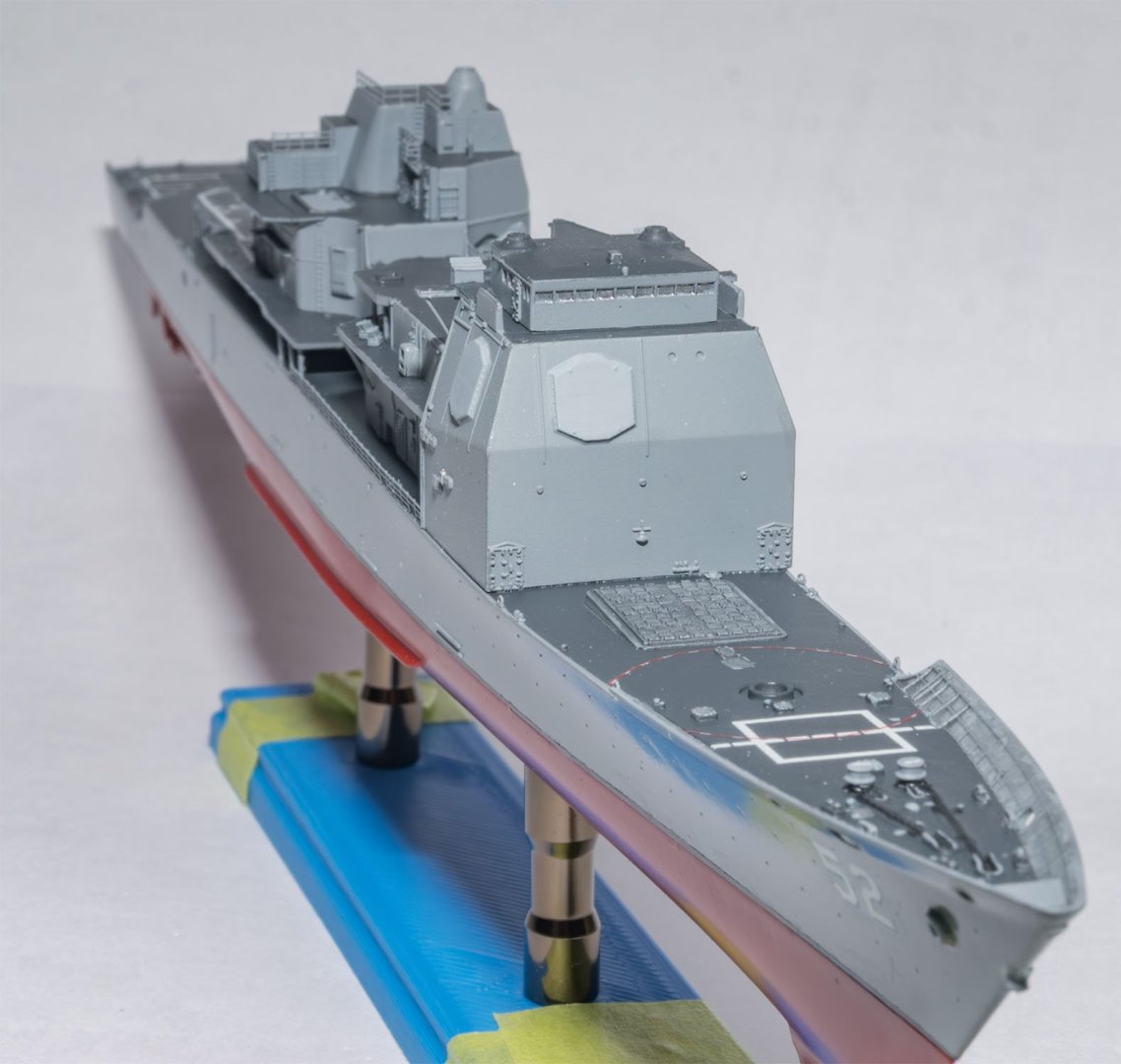

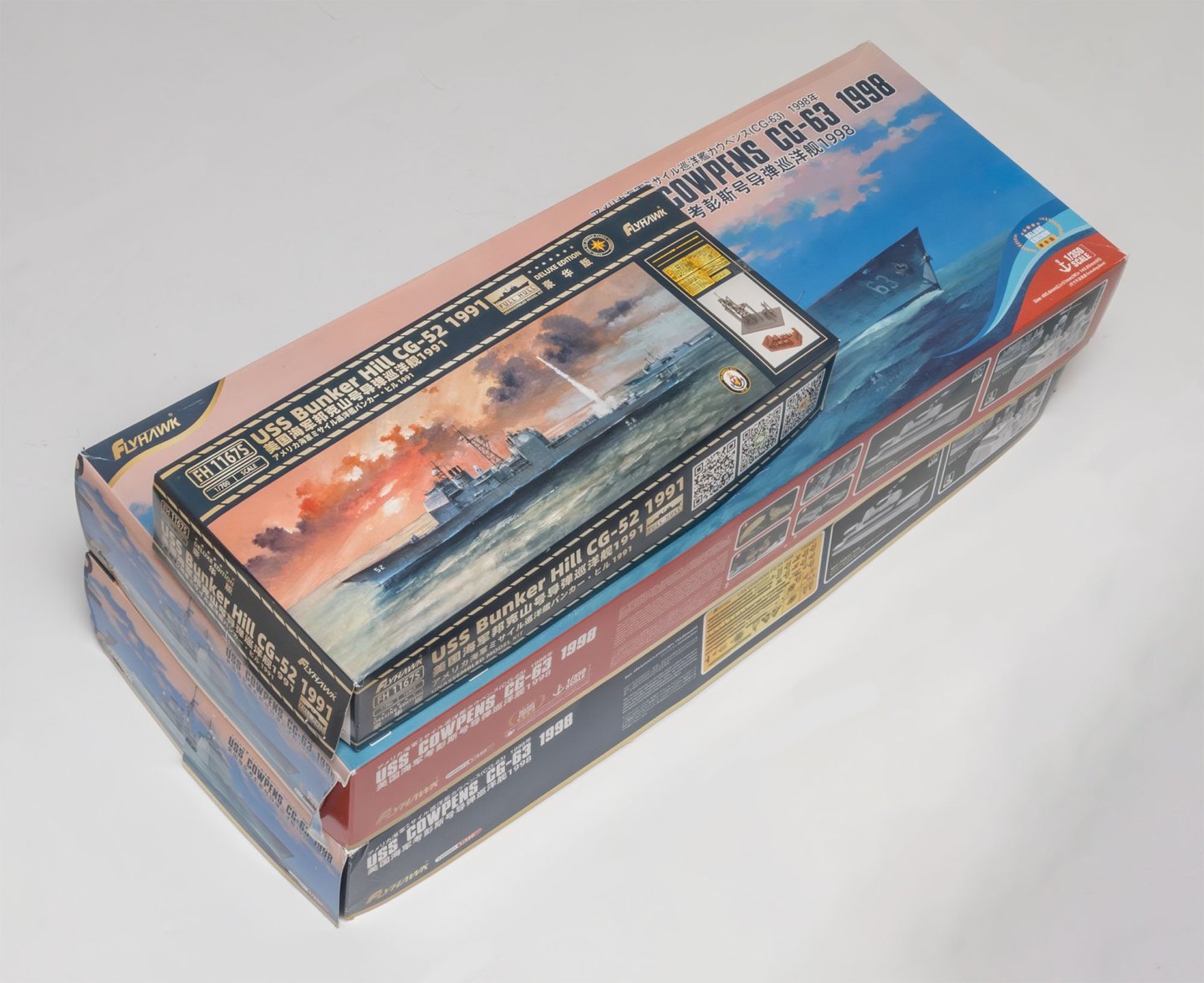

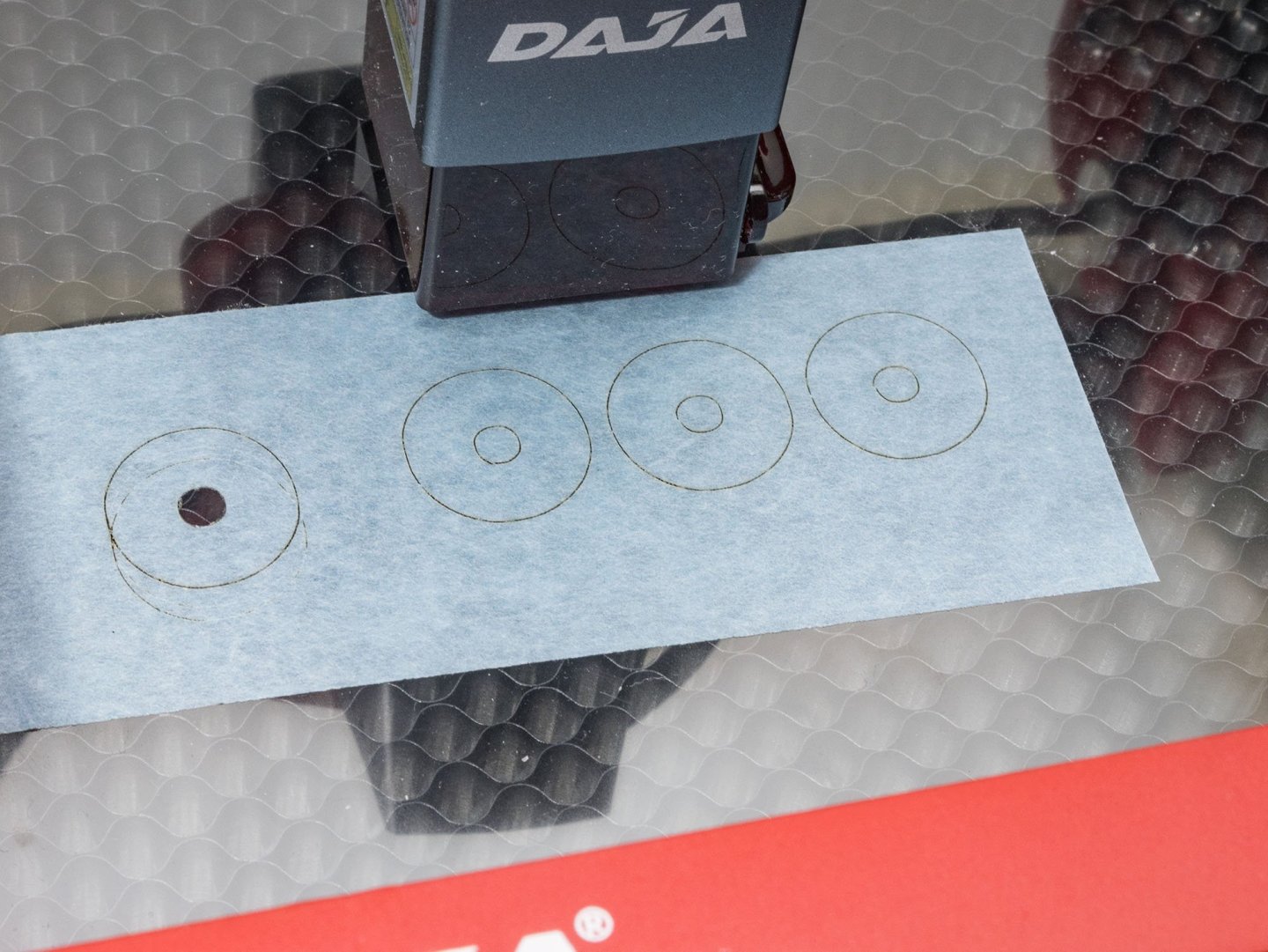

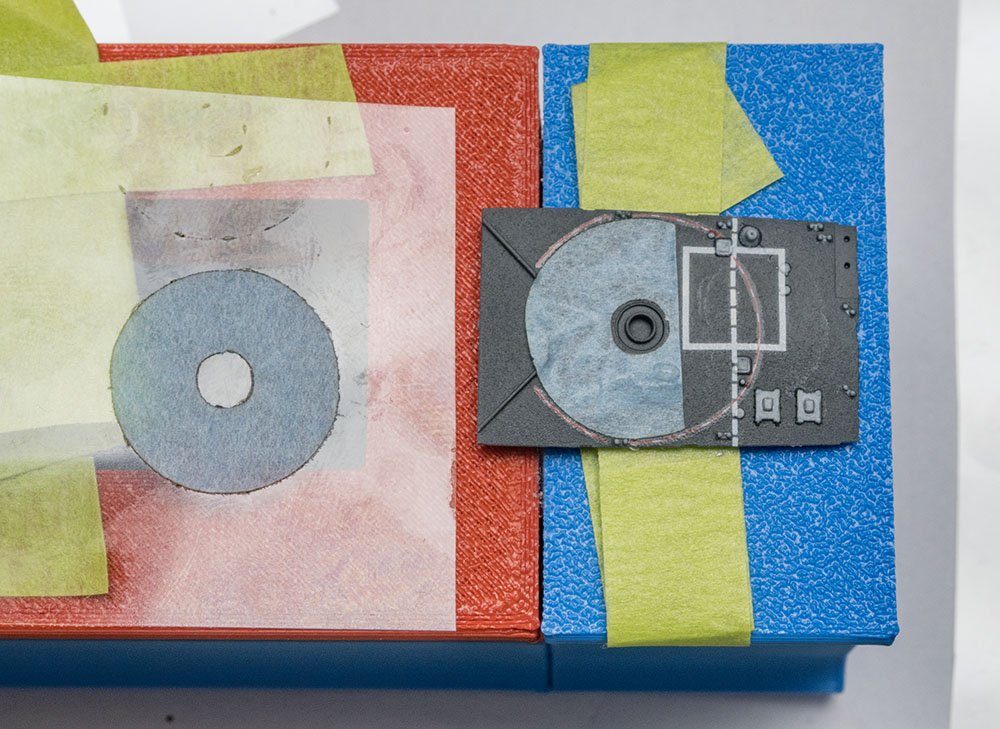

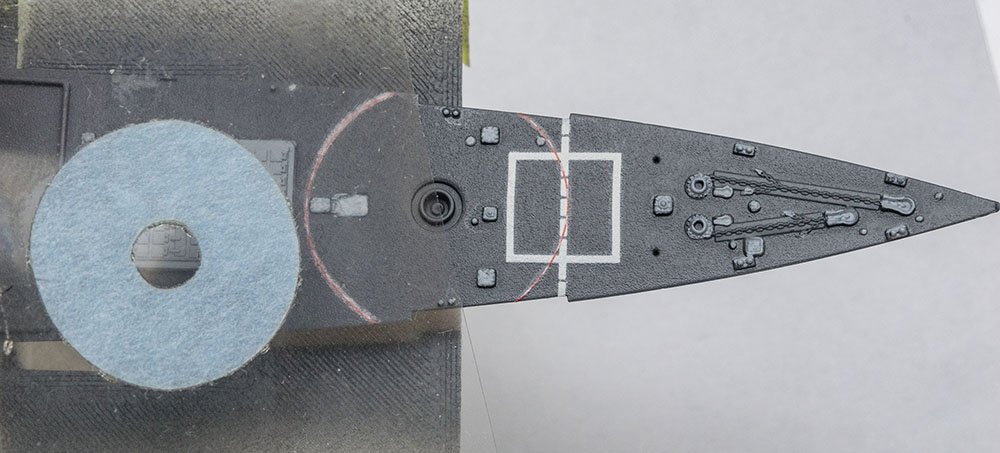

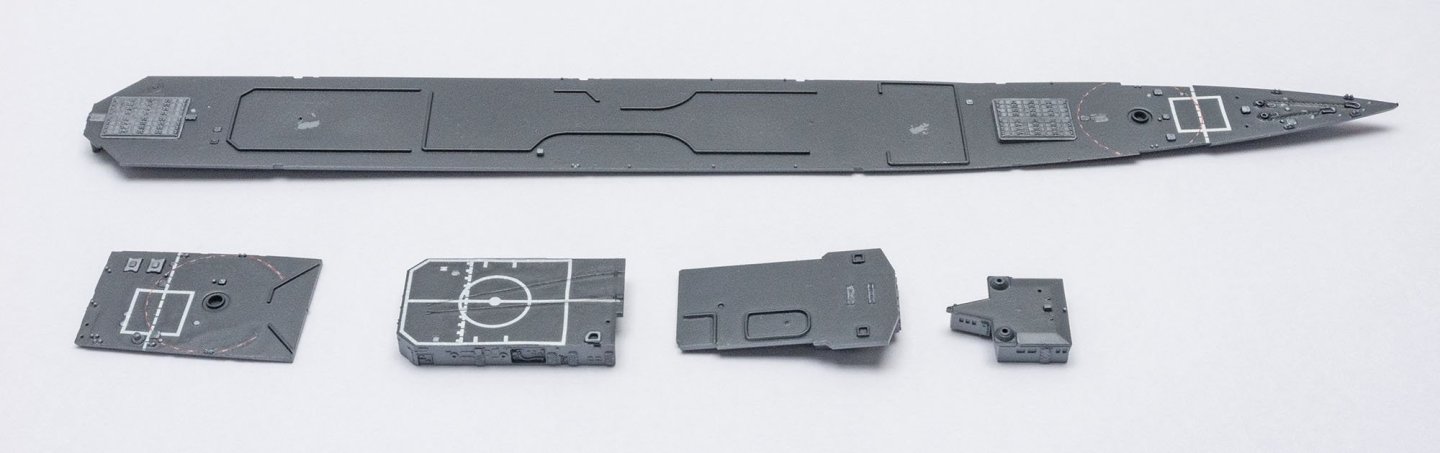

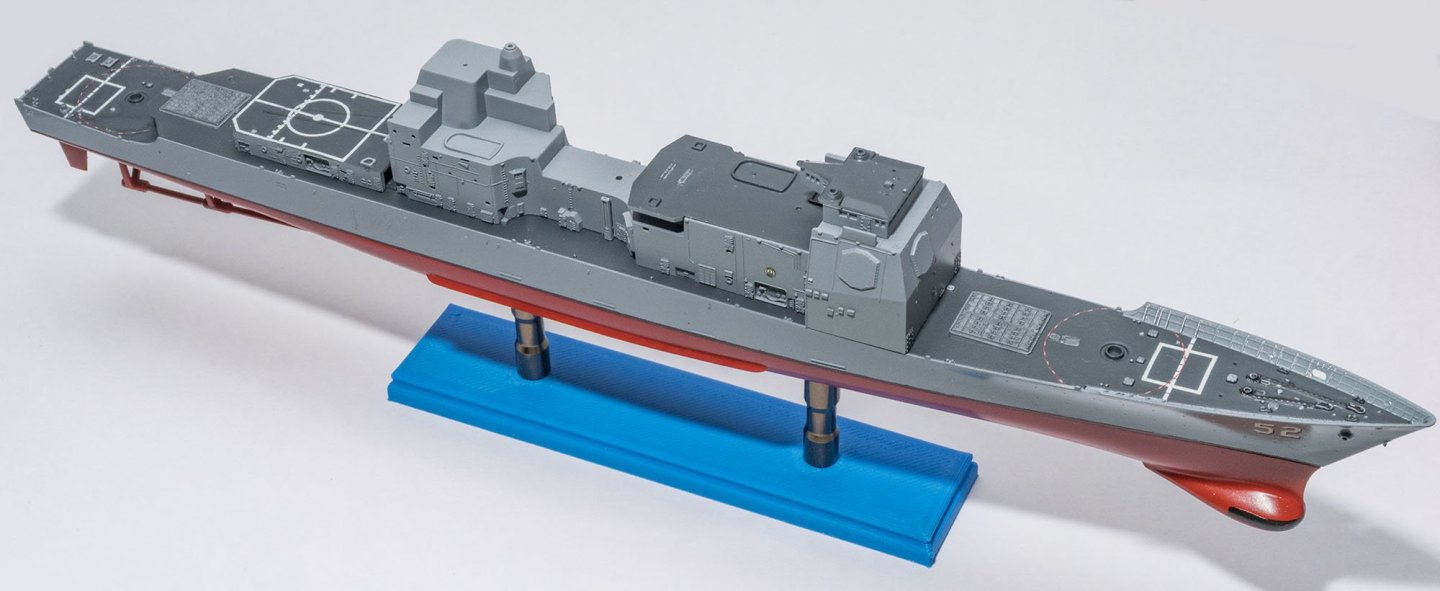

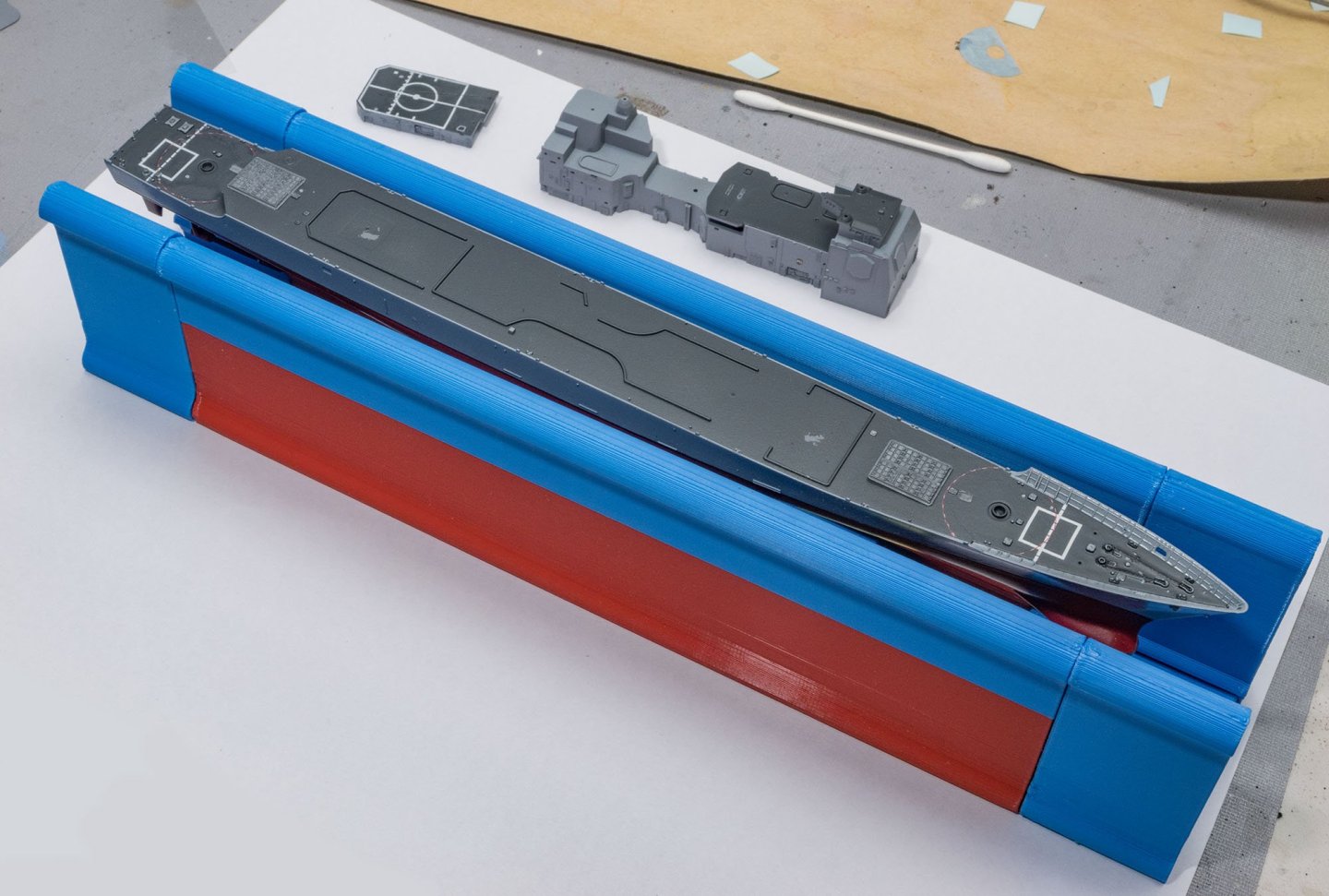

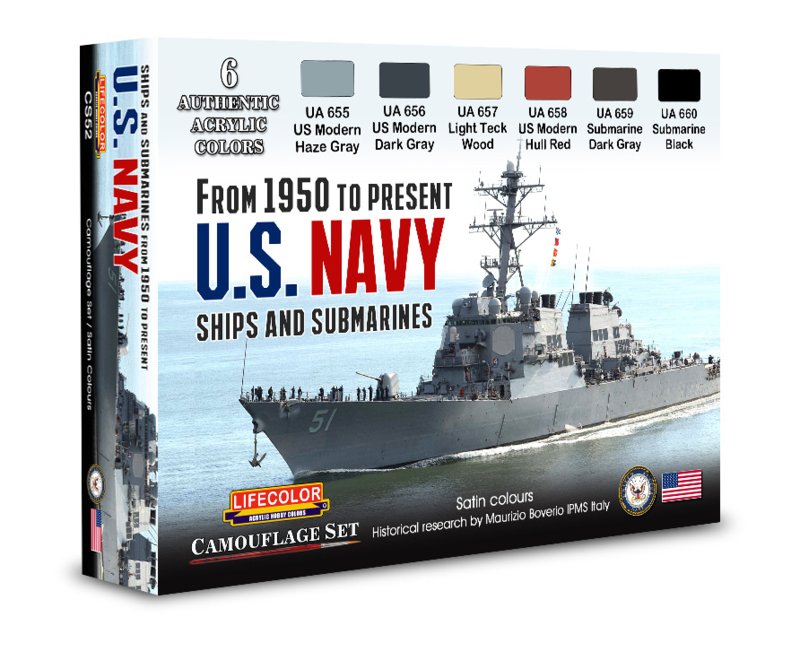

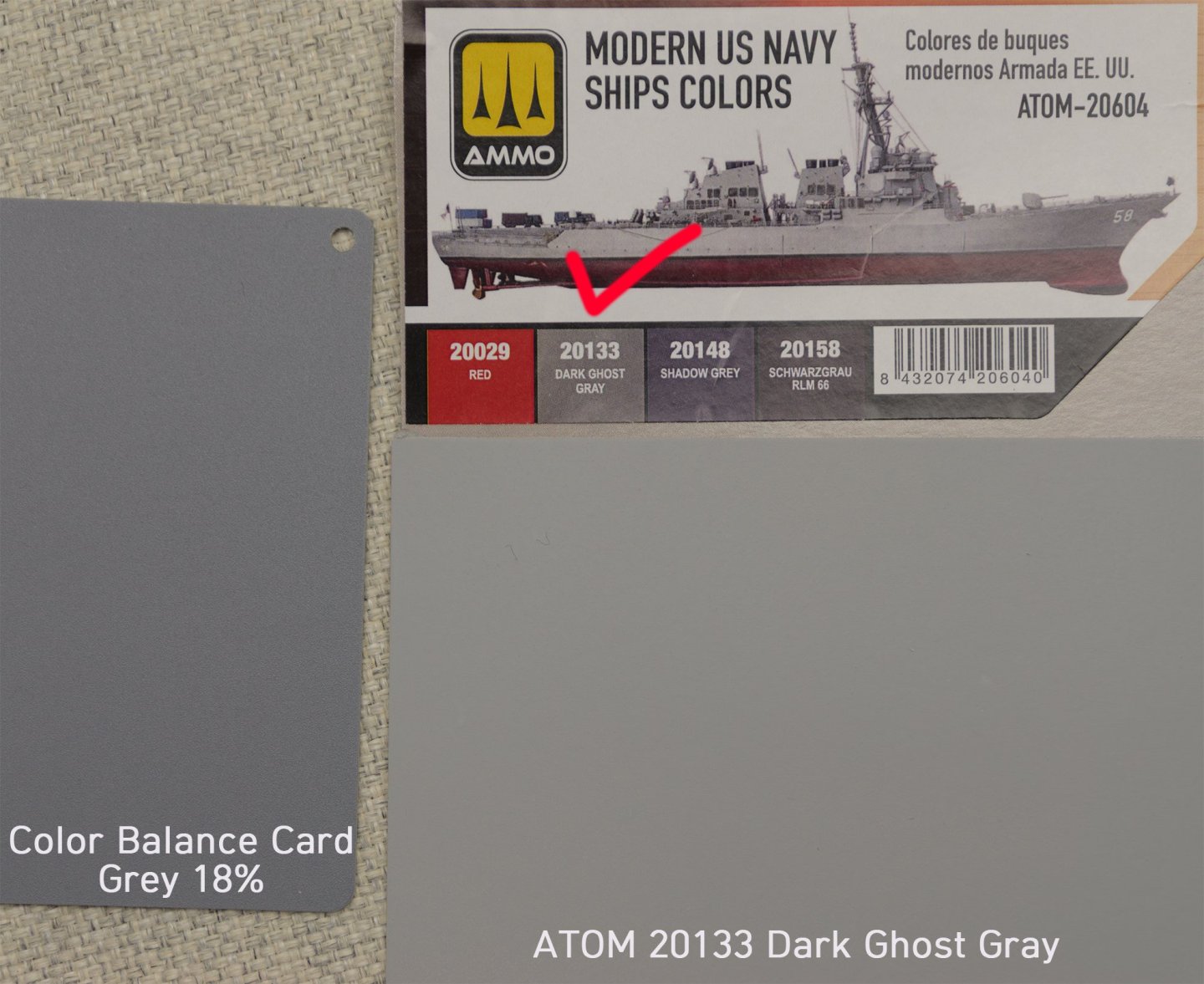

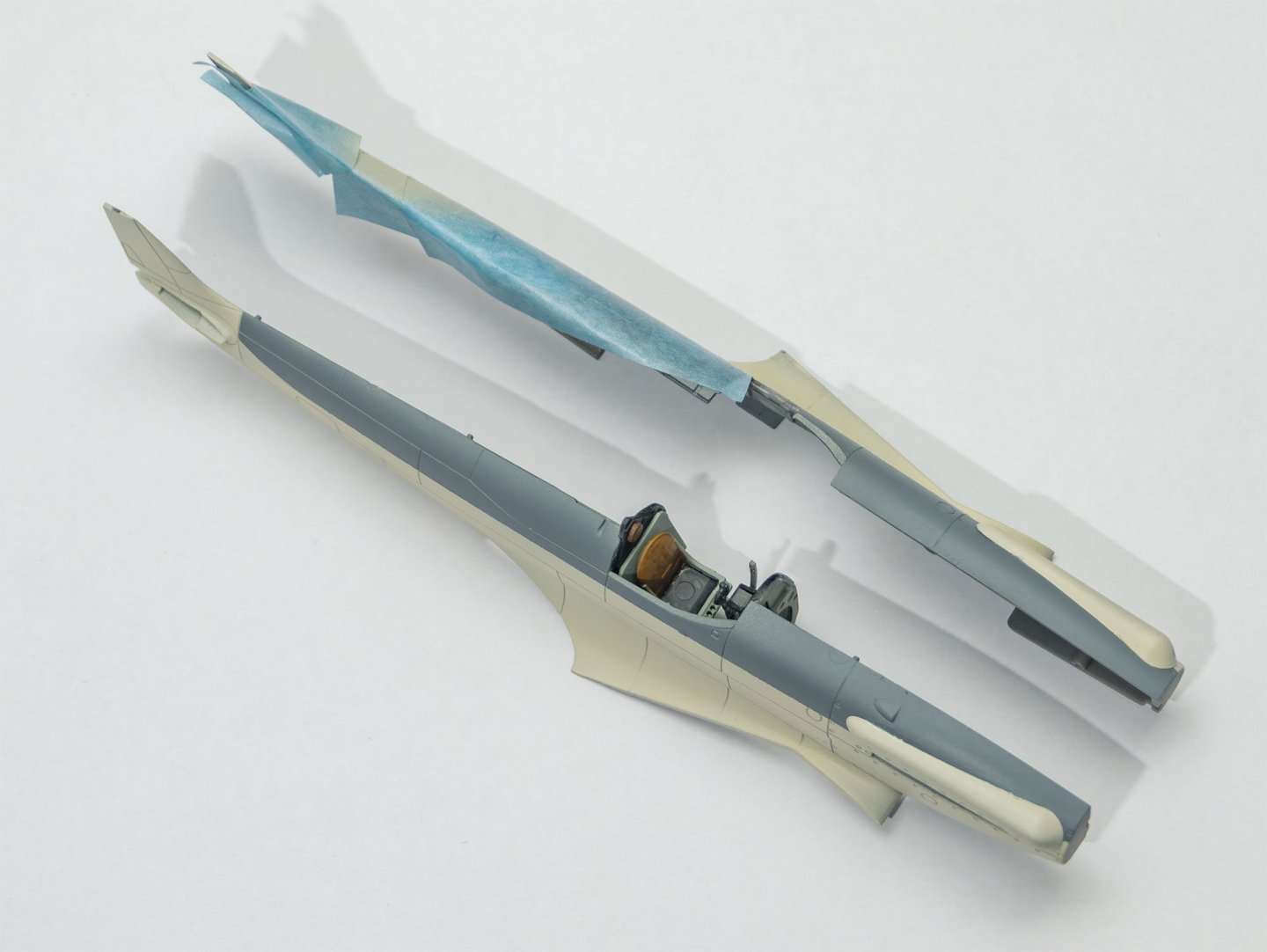

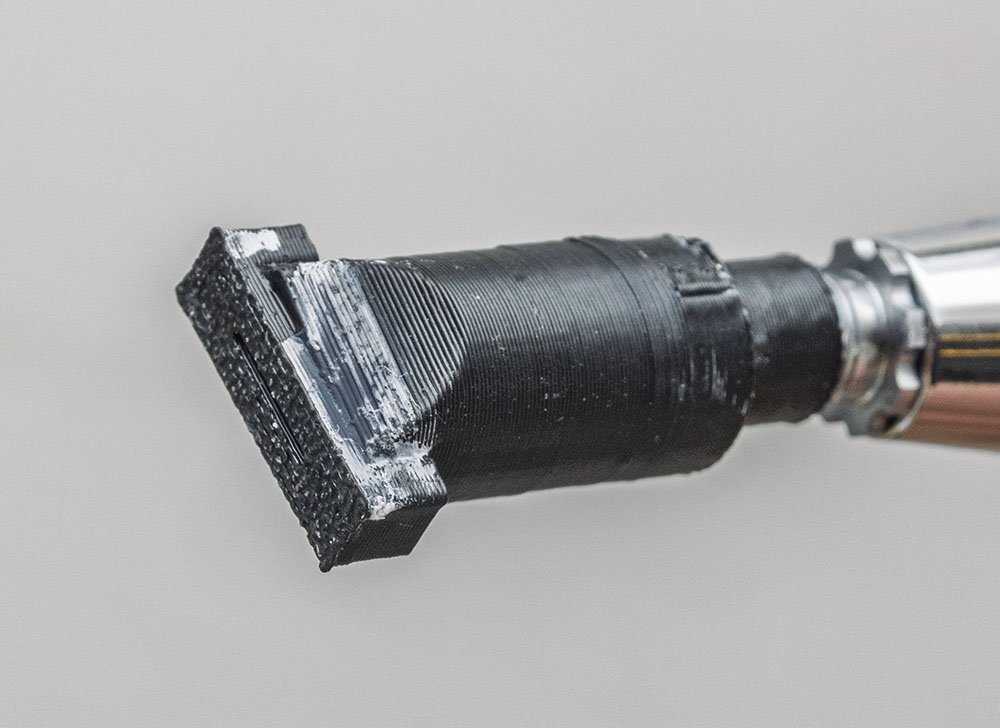

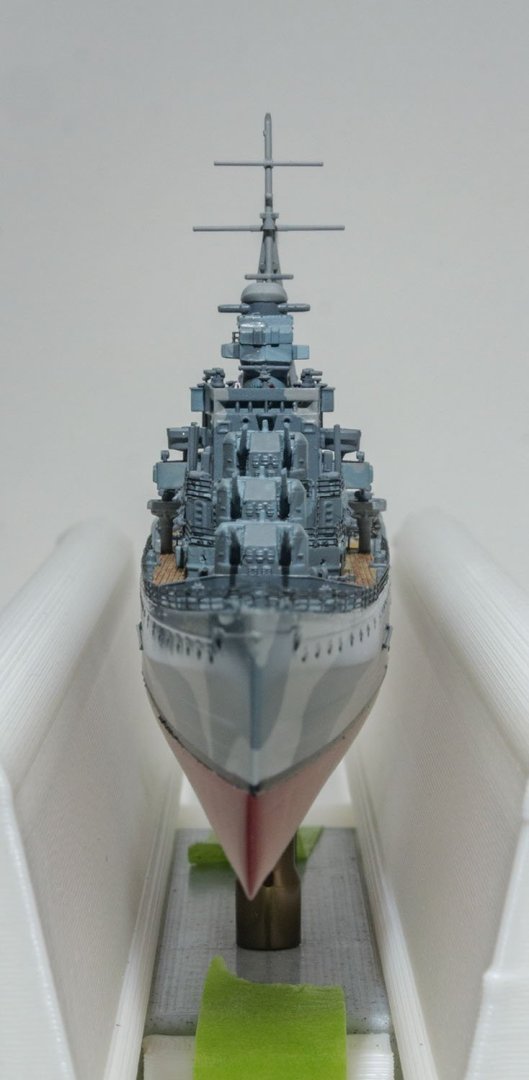

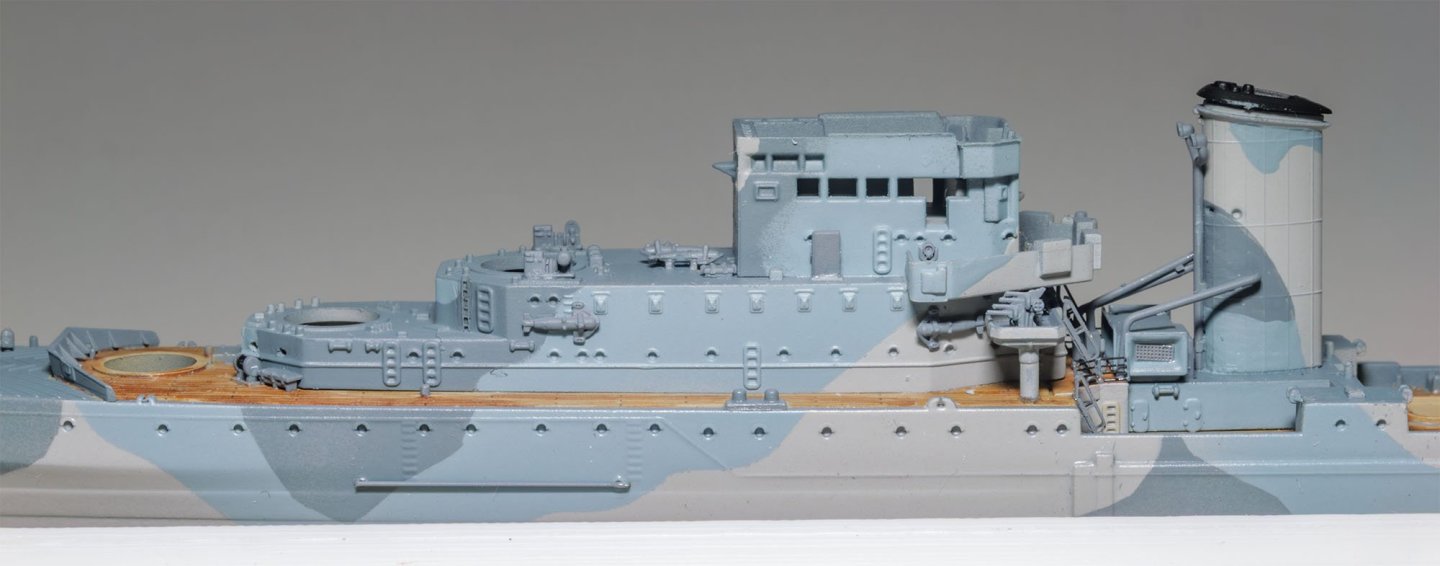

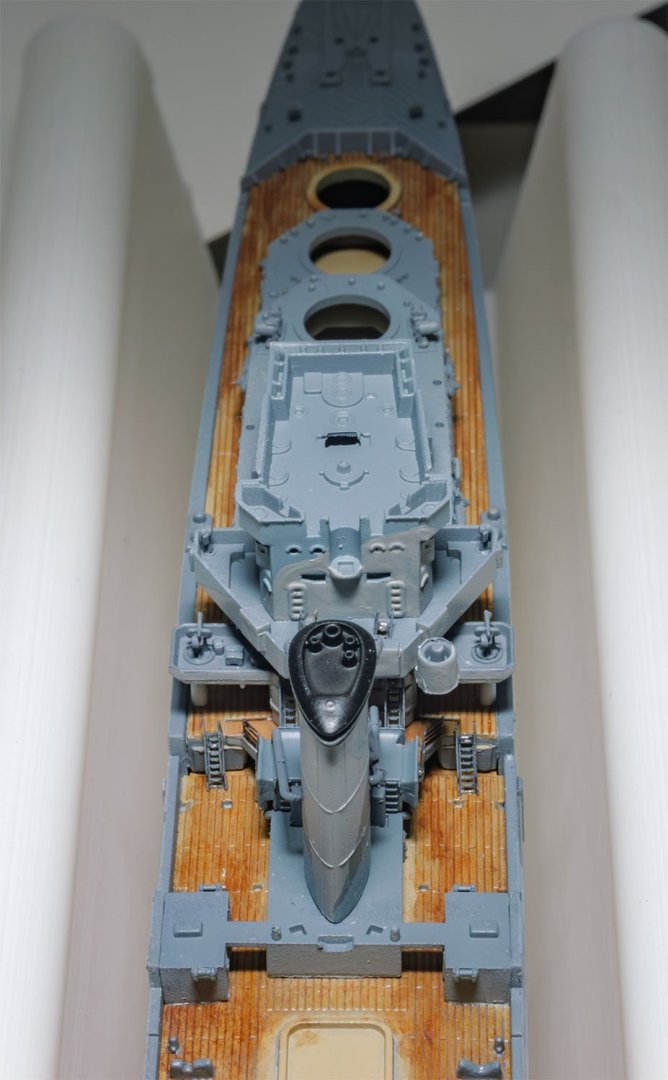

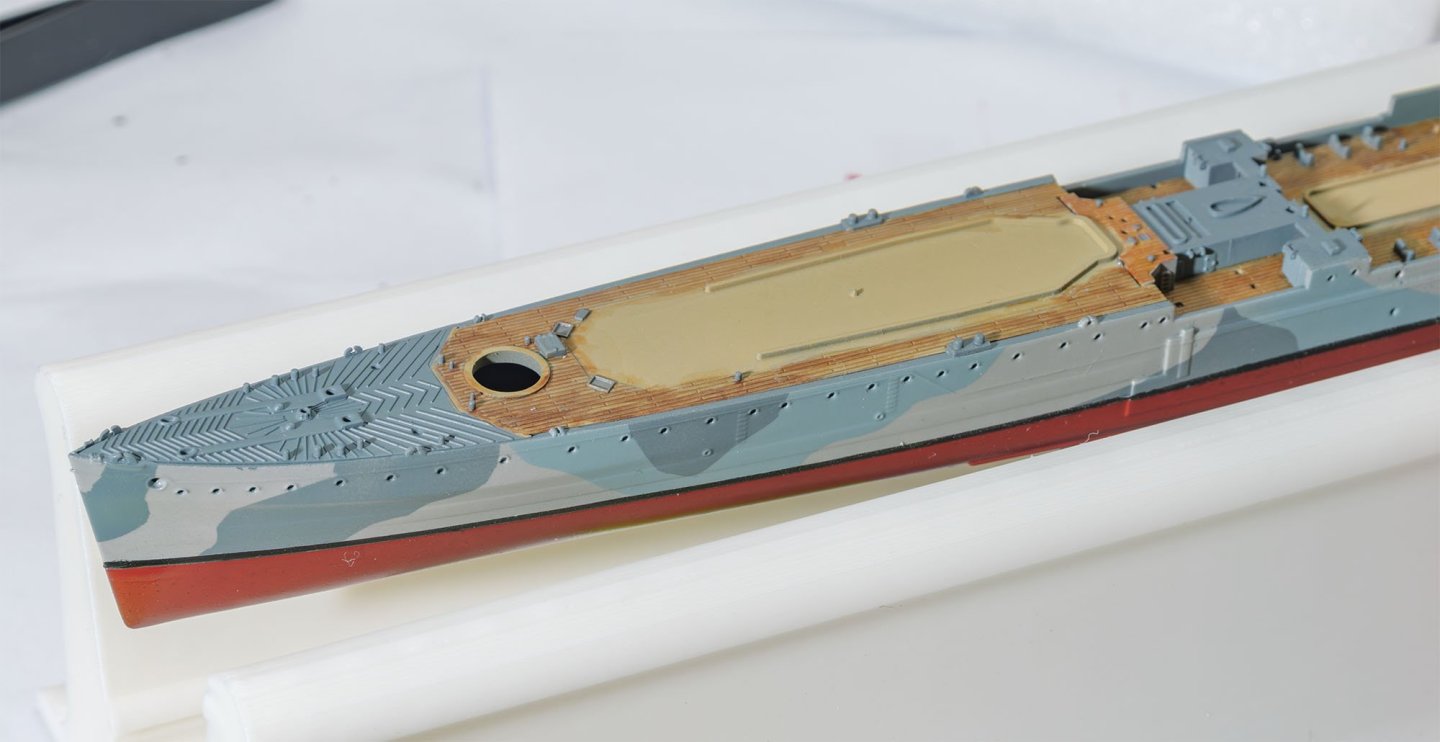

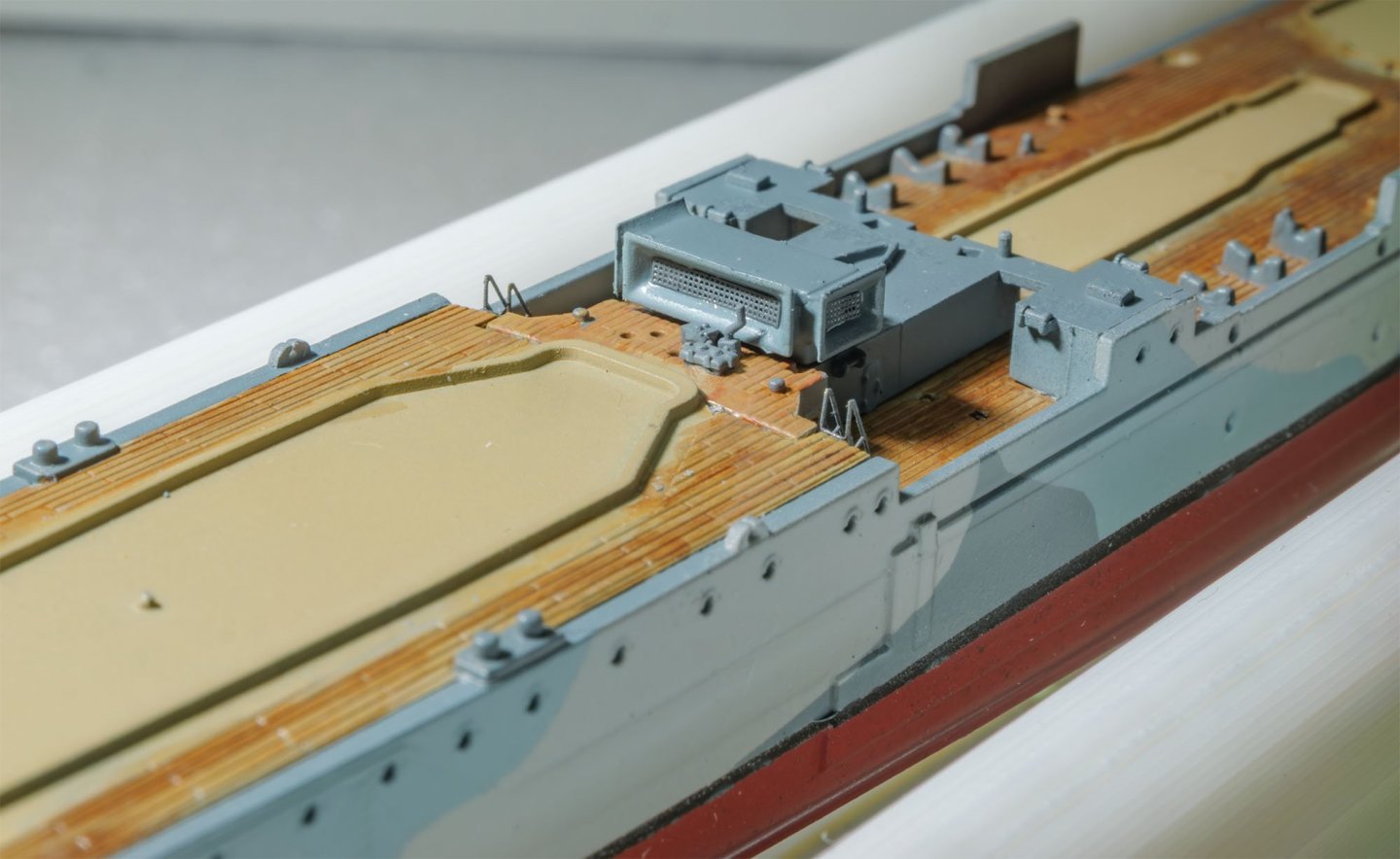

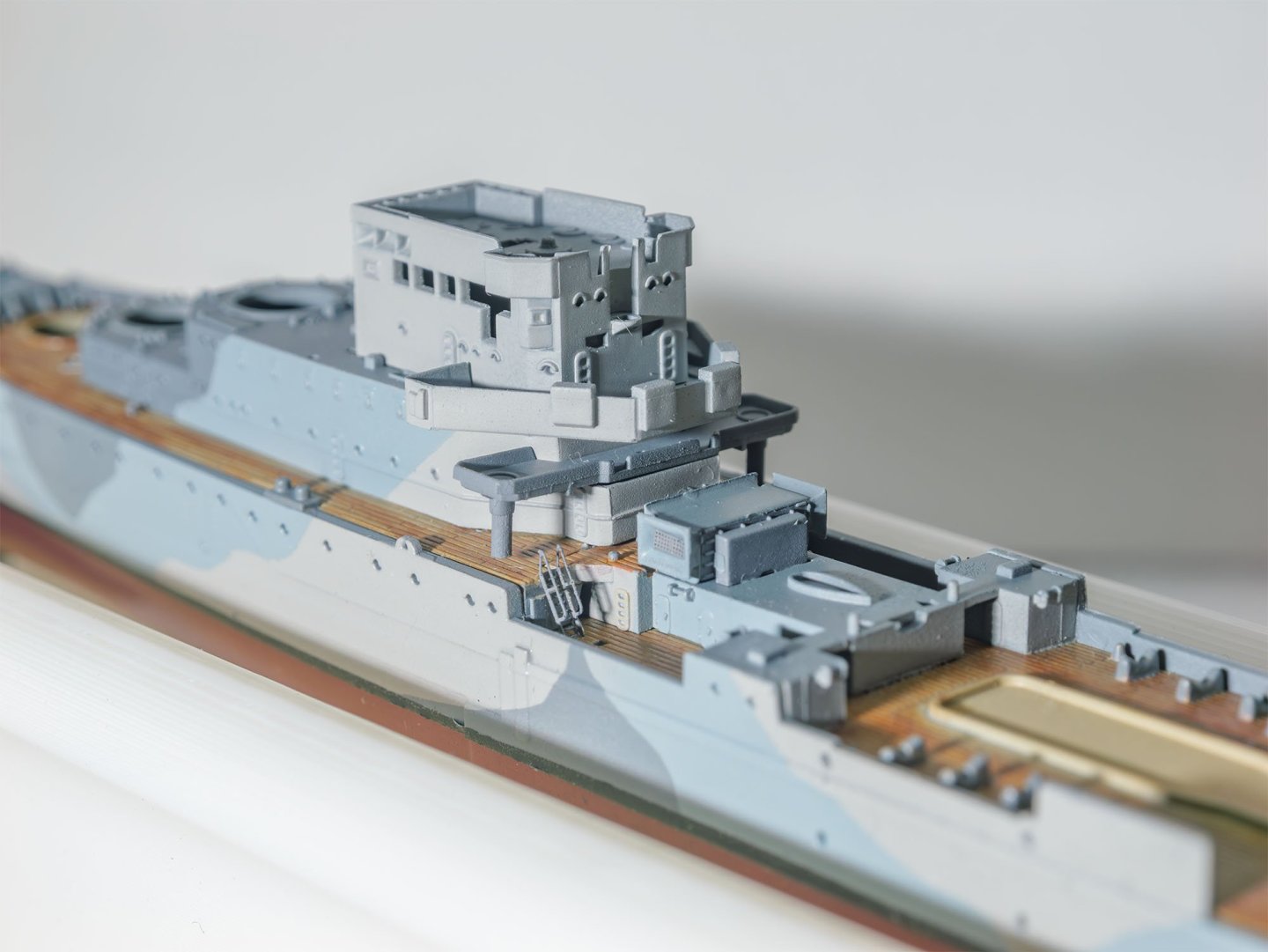

The next project is 1/700 Ticonderoga class cruiser USS Bunker Hill CG-52 1991 Gulf-war version from Flyhawk. Before I started the modern US Navy ship kit, I inspected a new acrylic paint set. AMMO ATOM is a brand-new 2024 water-based acrylic paint to compete with stronger environmental regulations. It appears to be the most recent and advanced high-quality paint set. However, the color selection of the ship color set is not suitable for ship models. (From 1950 to present US NAVY ships and submarines, Lifecolor CS-52) This is the closest color set to Snyder and shorts' paint chips I've ever seen. In this project, I used Lifecolor UA-655 and UA-656 colors. This kit has several tricky waterslide decals. I used a laser cutter to cut half-inch sized circles. Not bad... The burned edge of masking tape was very rough. Should I use my Silhouette CNC paper cutter? Deck and decals are done. Temporary assembly. I also made a custom handling grip. I can't build any Flyhawk kits without the handling grip.😎

- 9 replies

-

- Bunker Hill

- Flyhawk

-

(and 2 more)

Tagged with:

-

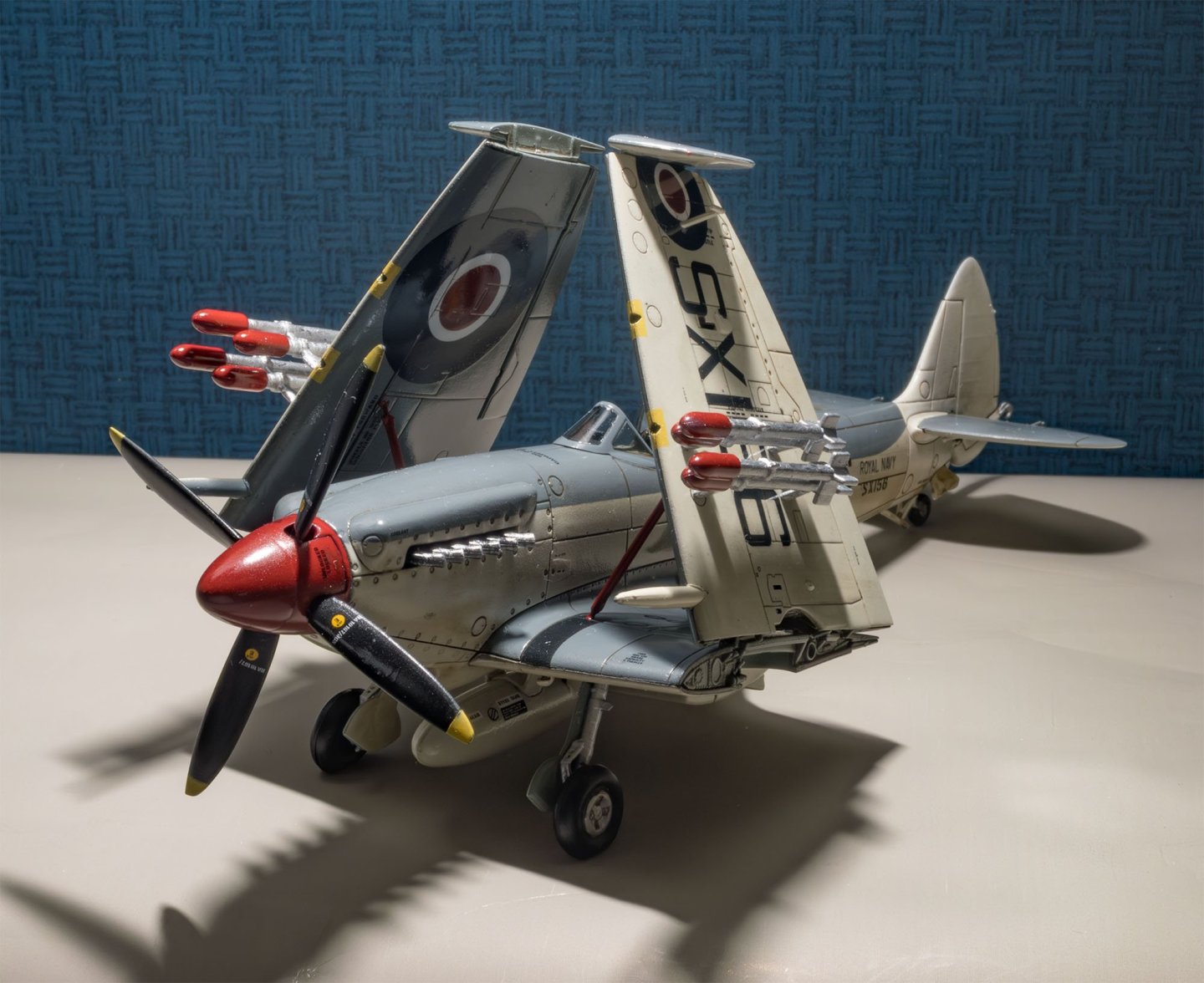

I'm collecting the folded-wing series. The Airfix Seafire kit is one of the best Seafire kits with a complete folded-wing option. In other words, it is quite a complex kit. Not for a weekend project. I had a big issue with Airfix decals. I used my favorite GSI-Creos Mark Softer, but it literally melted the Airfix decals. I lost the starboard side decals. 😪 I had nice results from the Tamiya Markfit series. The assembly was nicely done. I had only a few polishing works. Also, I'll use a gloss finish. The matte finish didn't look realistic compared with pictures from museum airplanes.

-

- 4 replies

-

- Invincible

- Flyhawk

-

(and 2 more)

Tagged with:

-

- 4 replies

-

- Invincible

- Flyhawk

-

(and 2 more)

Tagged with:

-

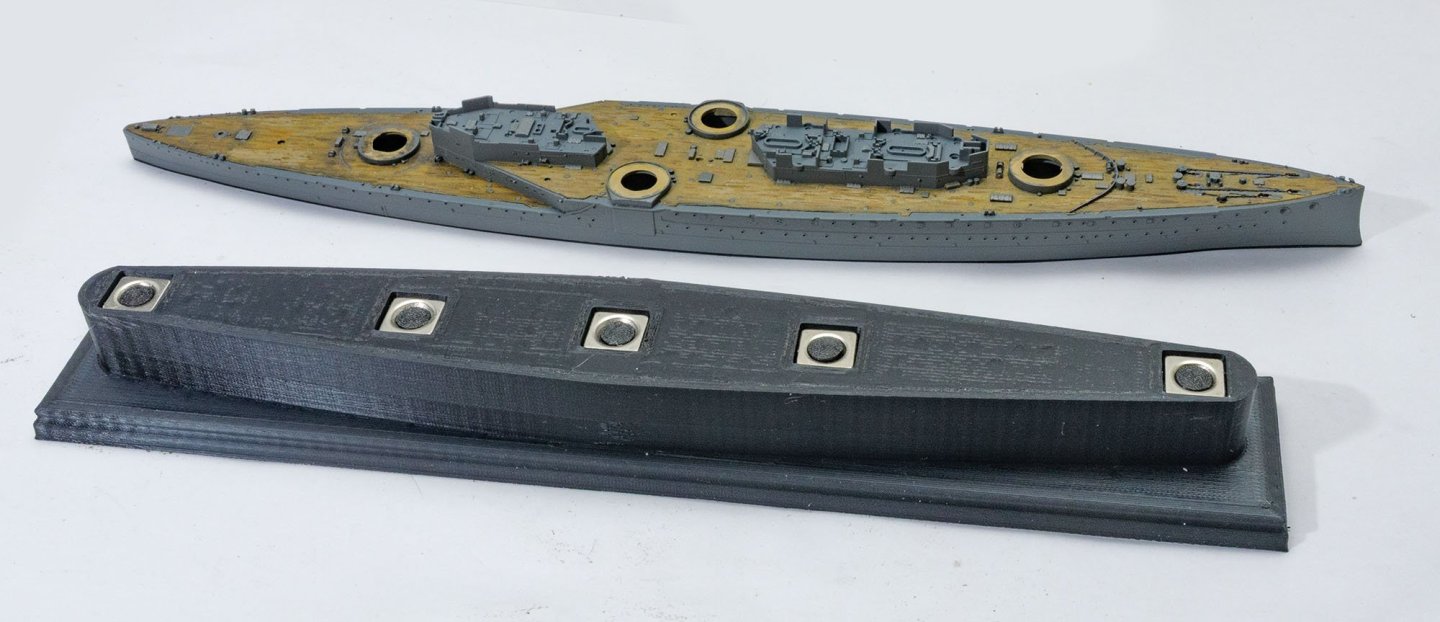

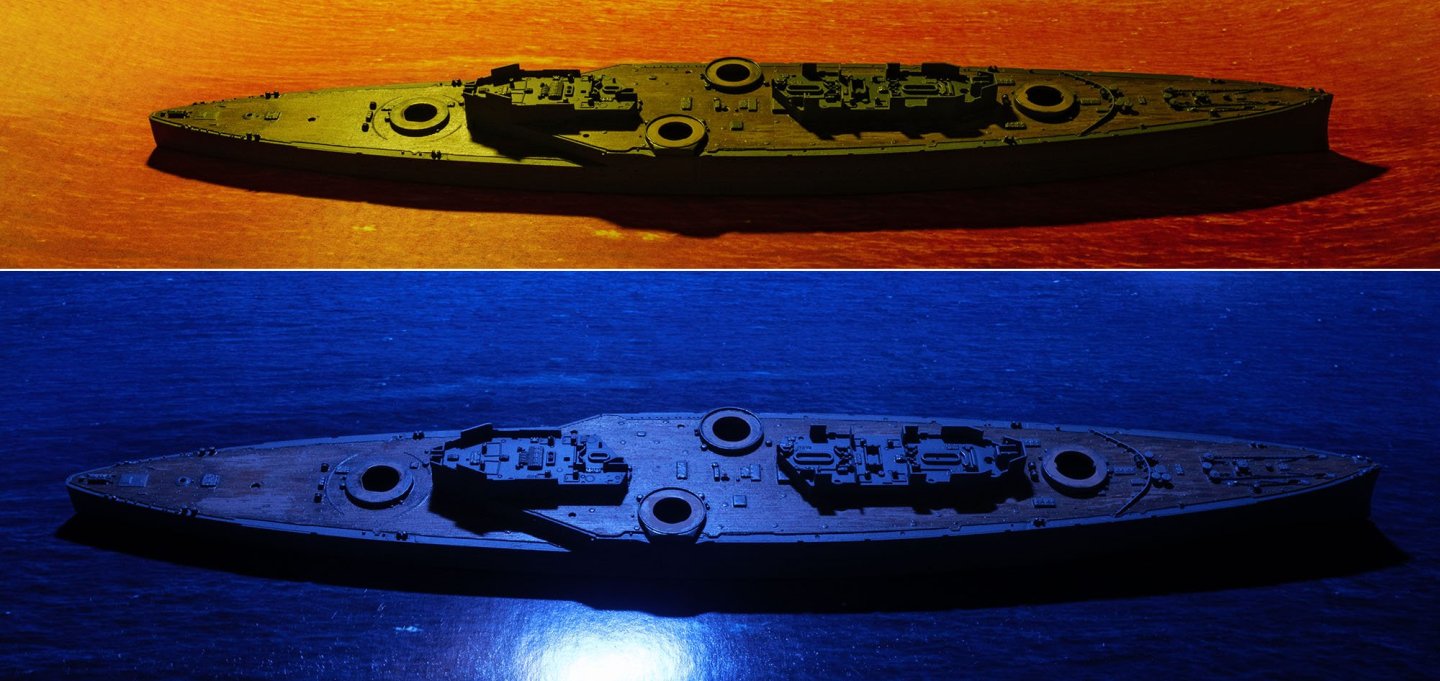

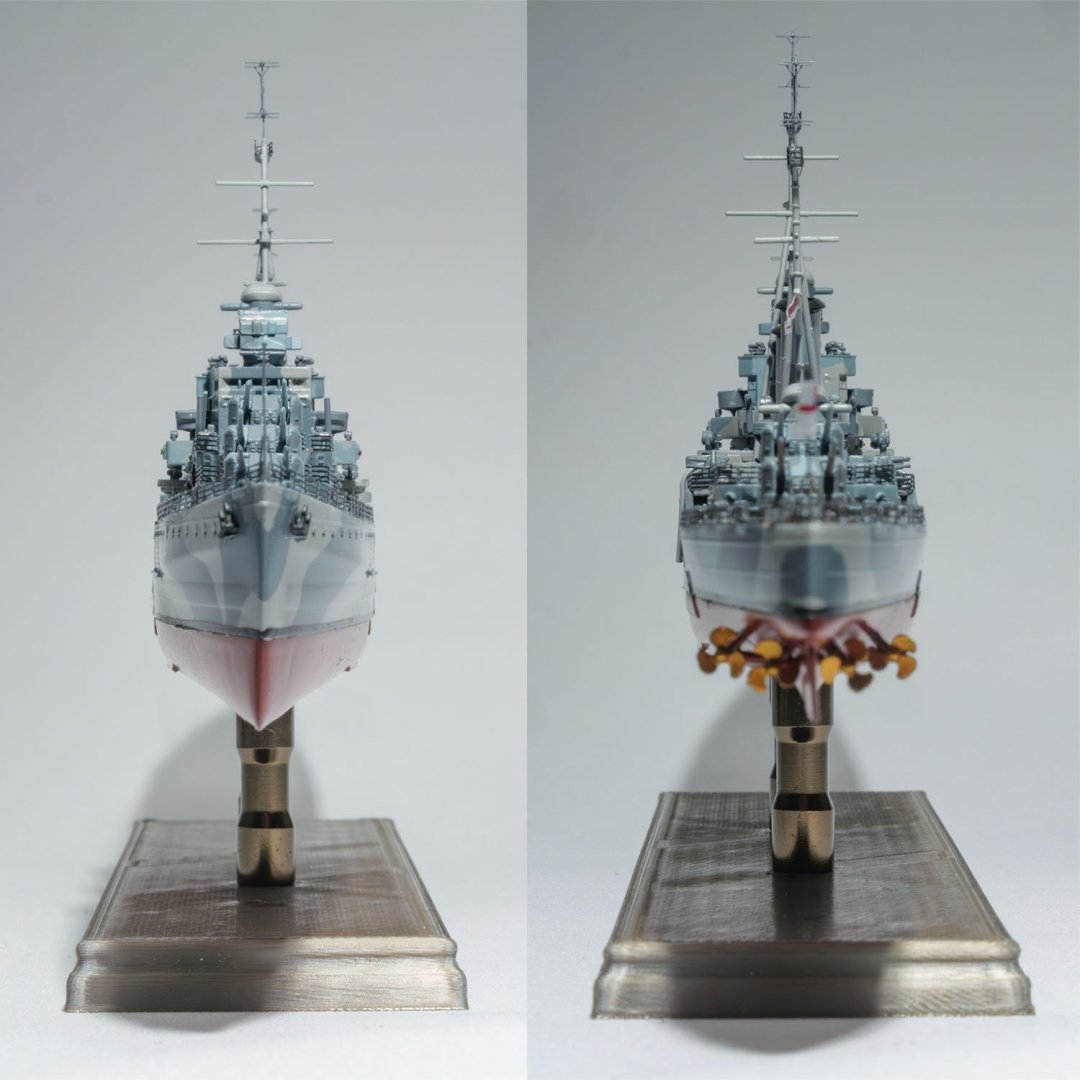

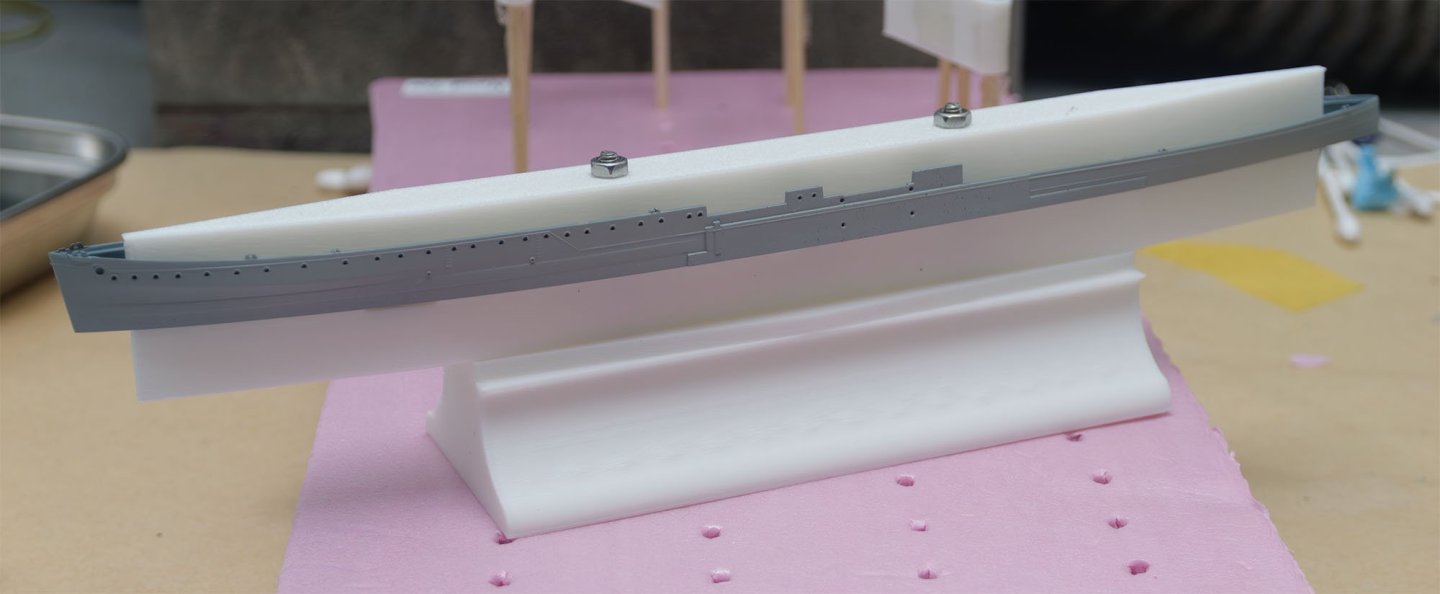

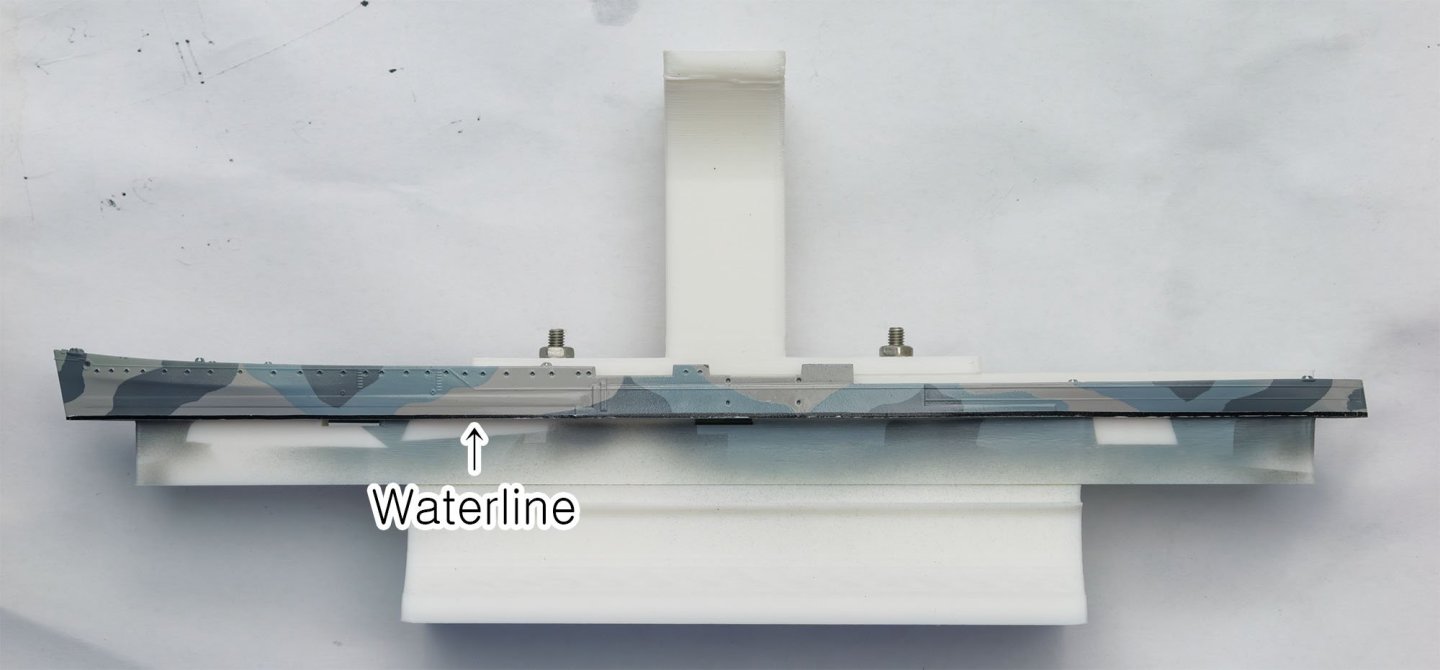

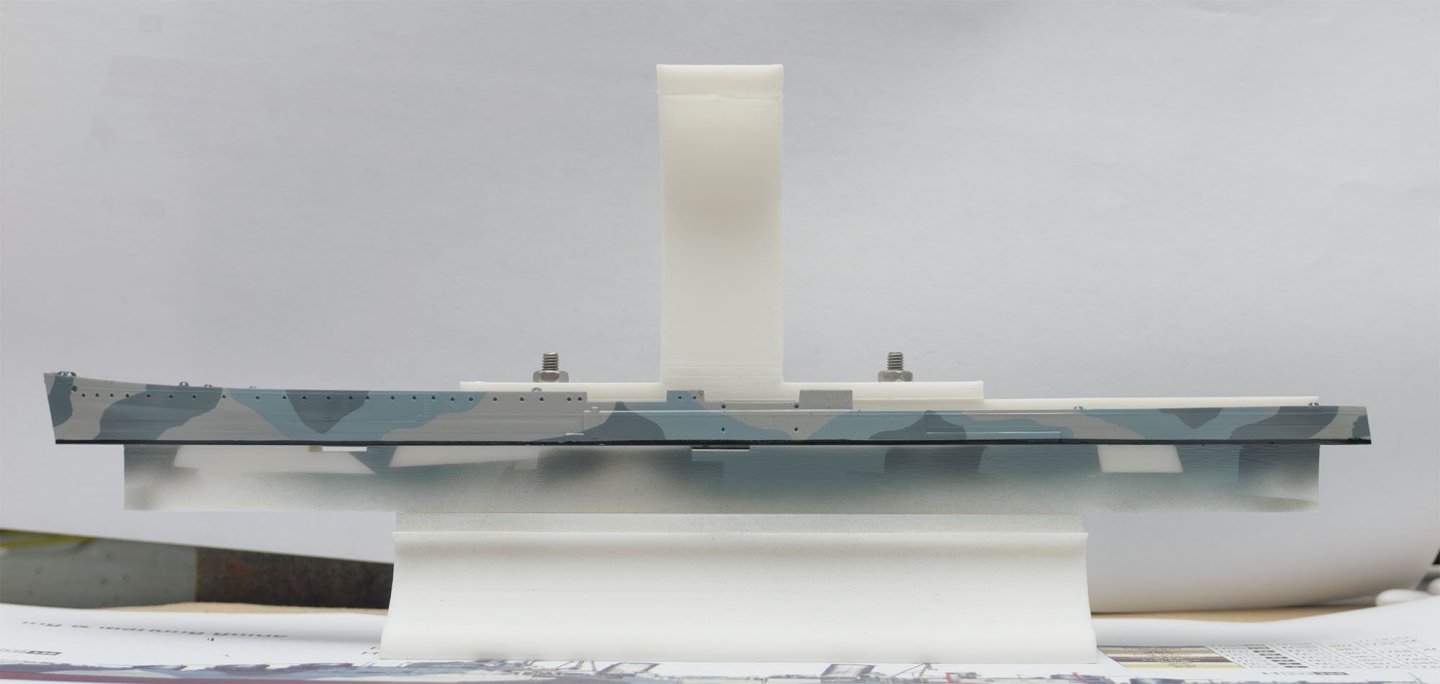

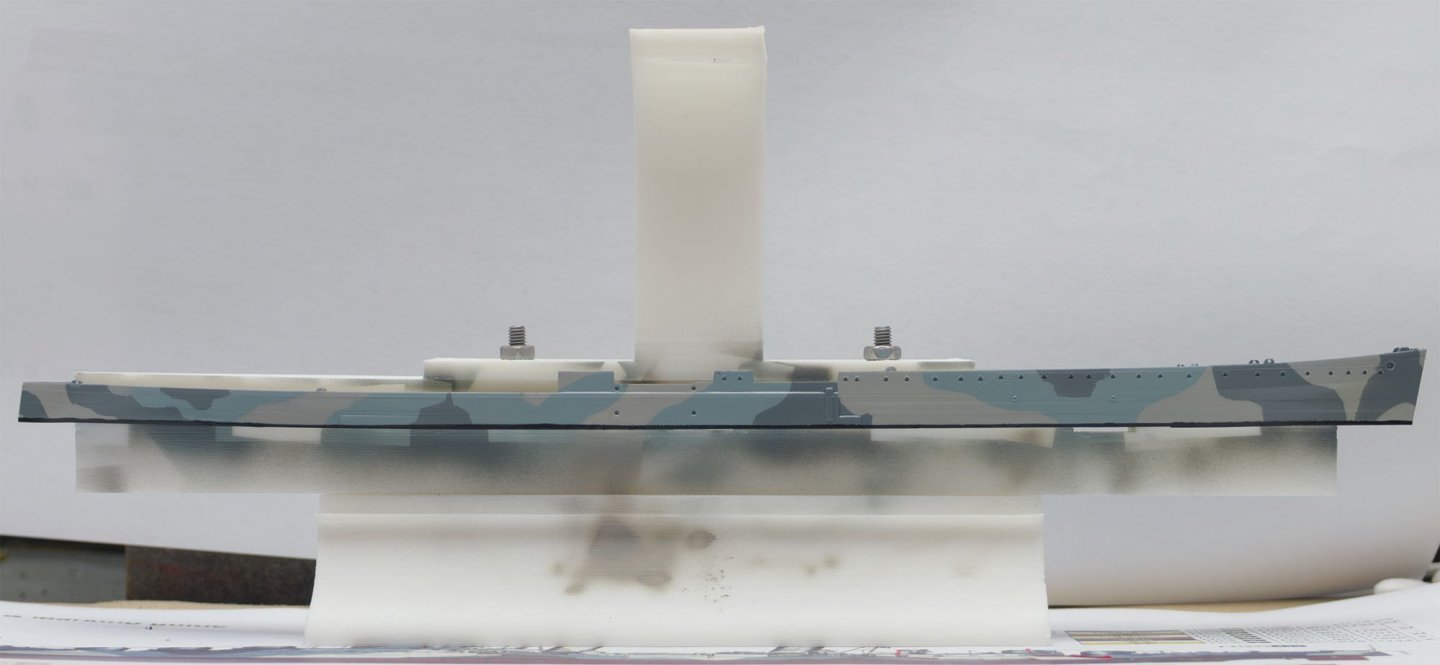

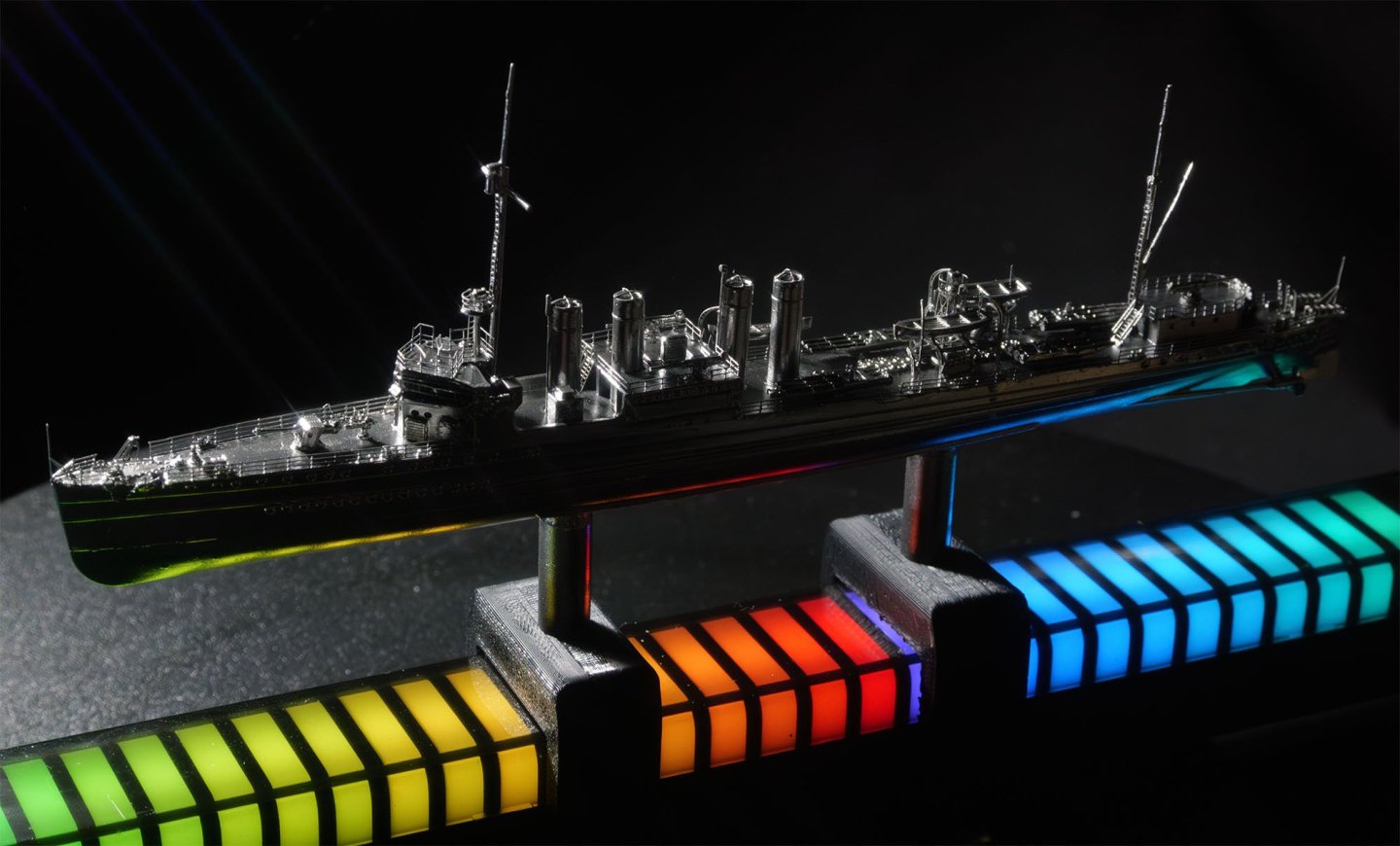

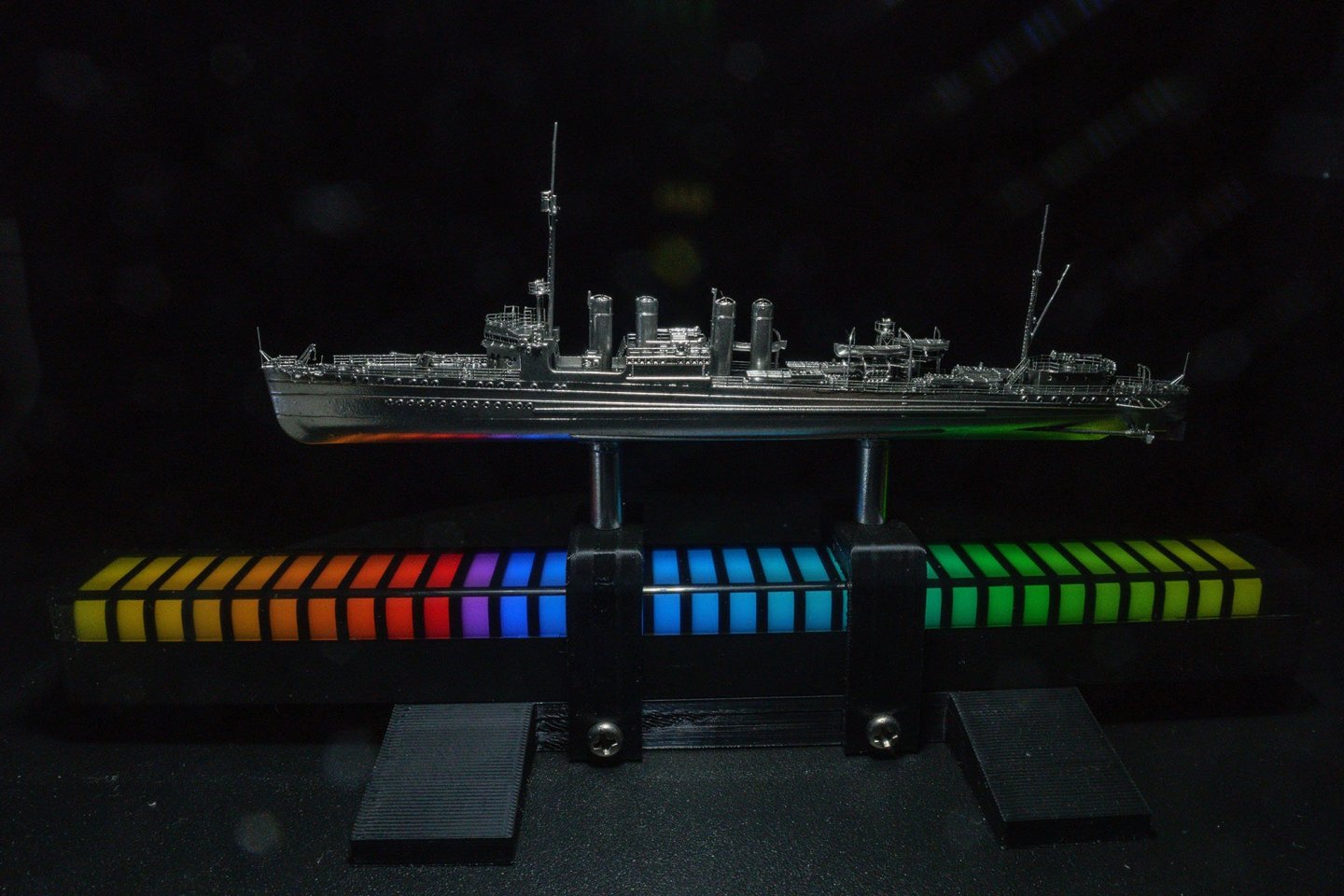

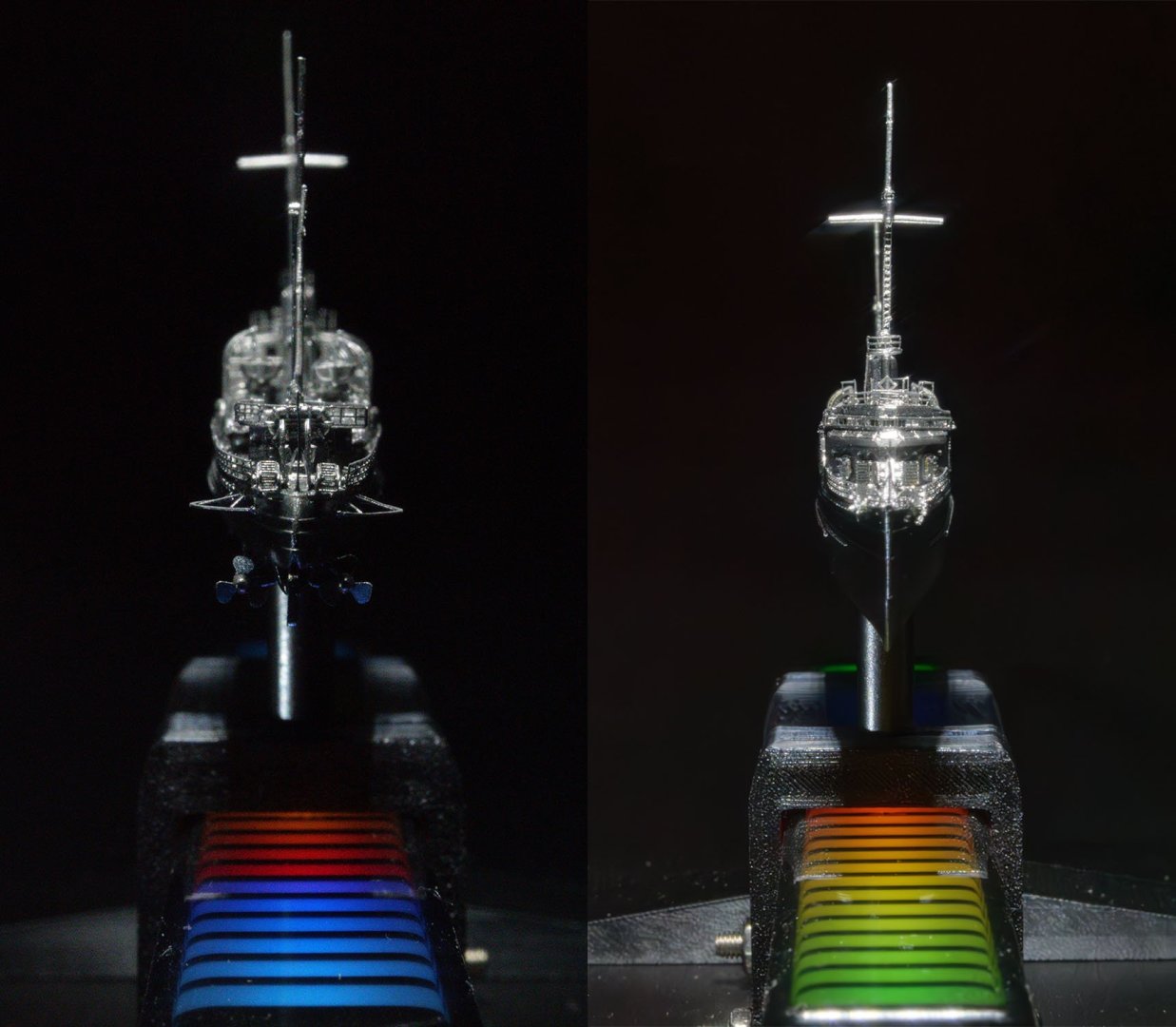

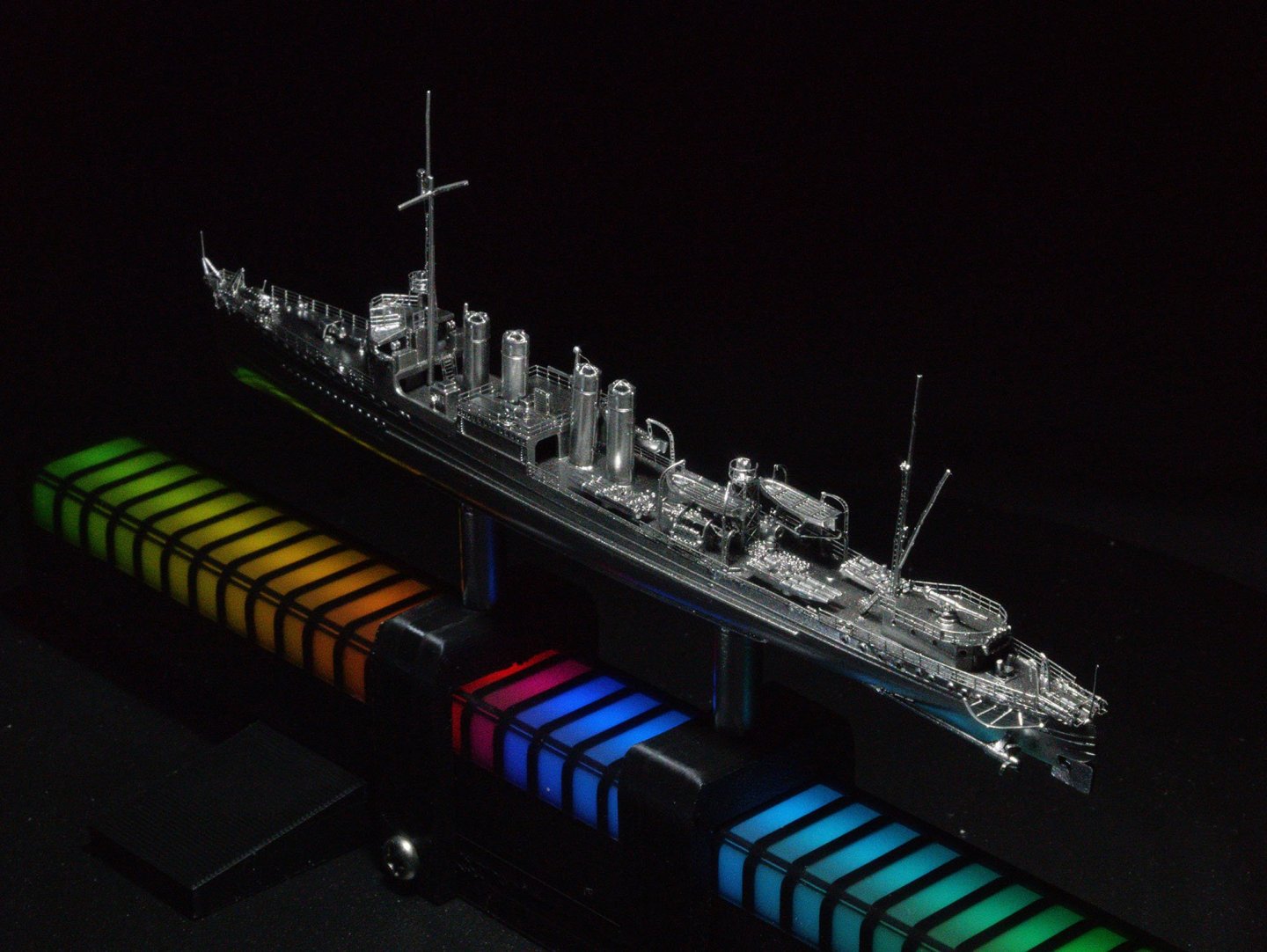

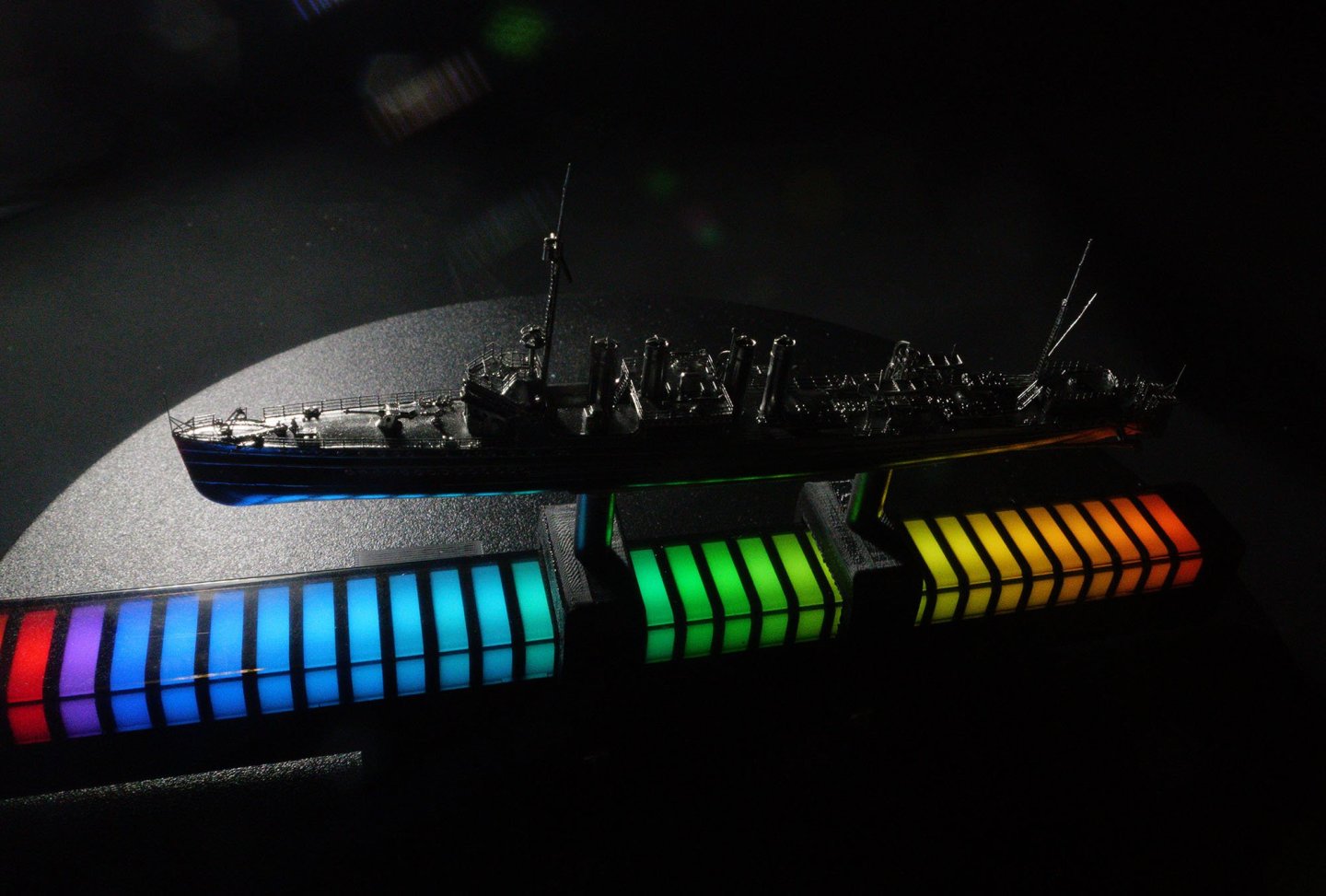

Walkthrough #2 I don't like waterline kits because I have to make a diorama, too. This magnet stand is my simple solution to the obsession. 😎 I'll show you more variants when it's over.

- 4 replies

-

- Invincible

- Flyhawk

-

(and 2 more)

Tagged with:

-

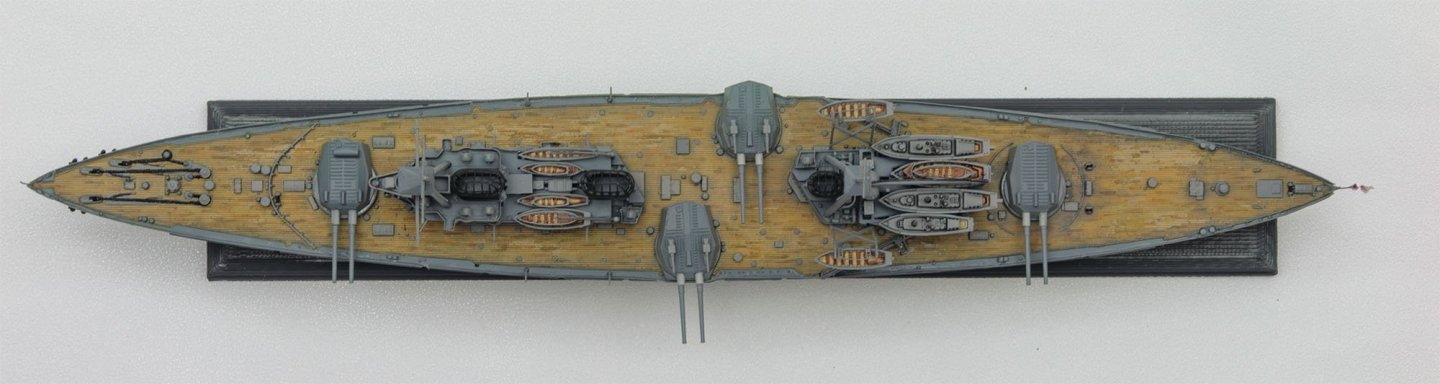

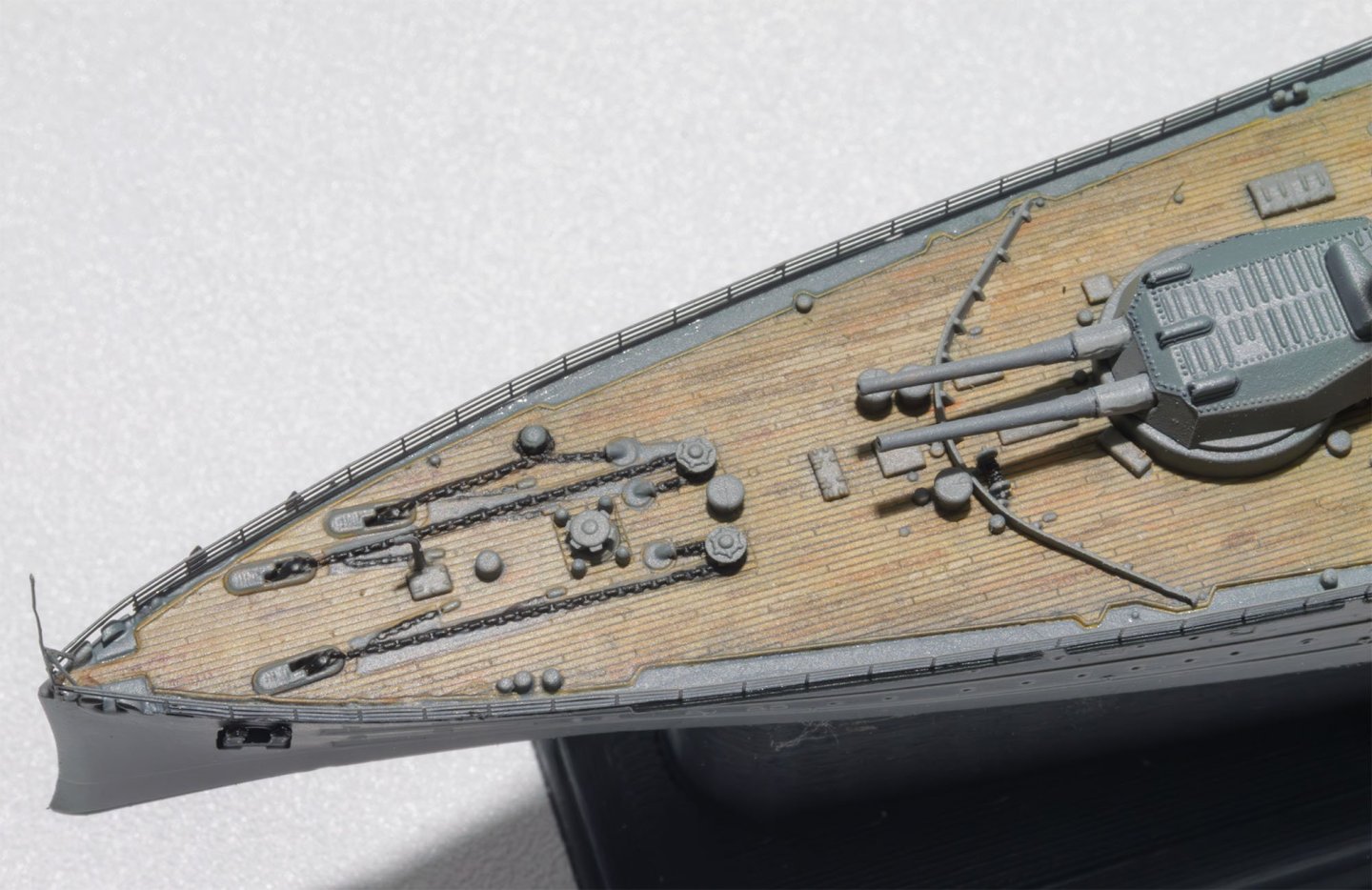

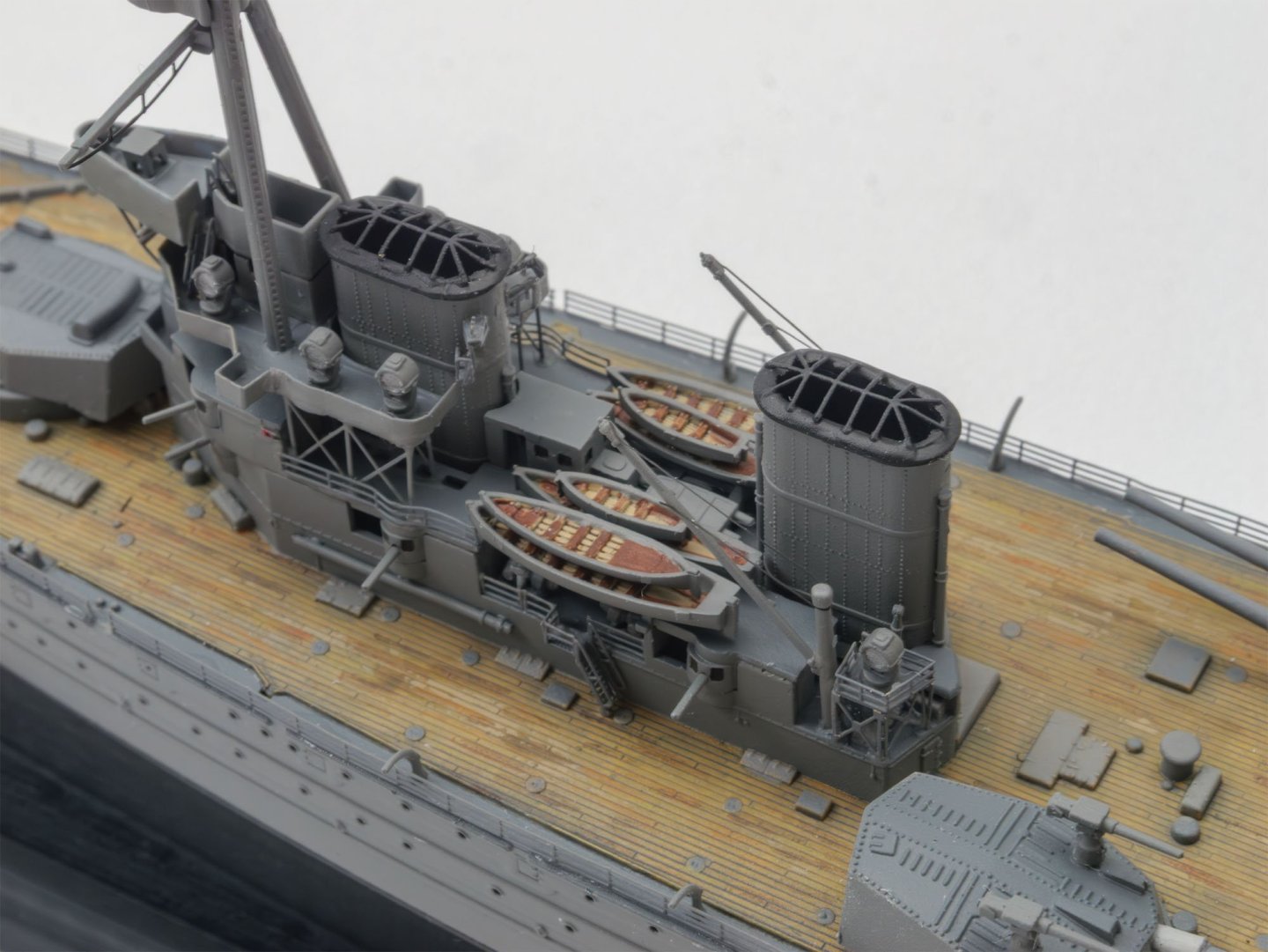

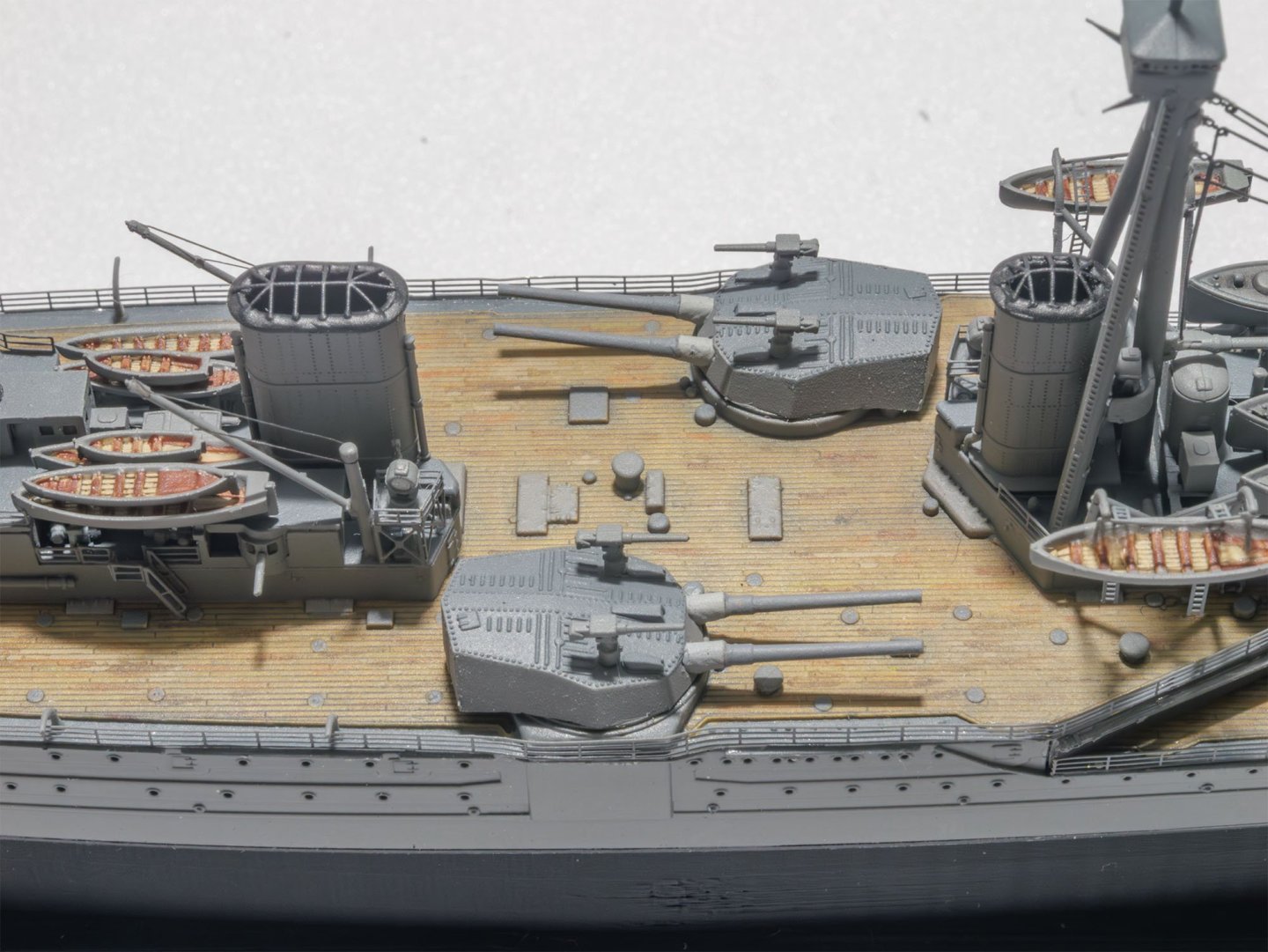

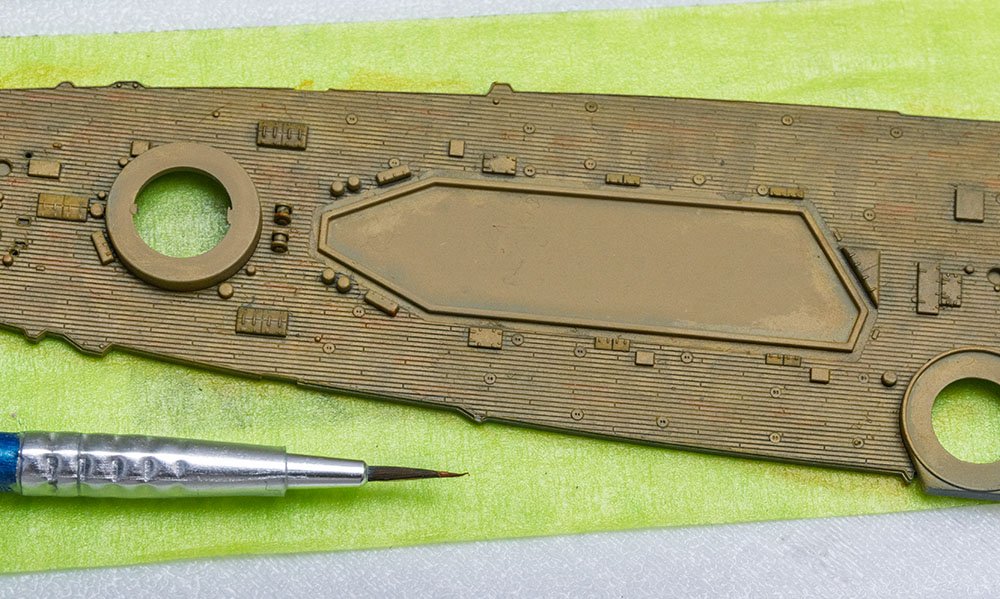

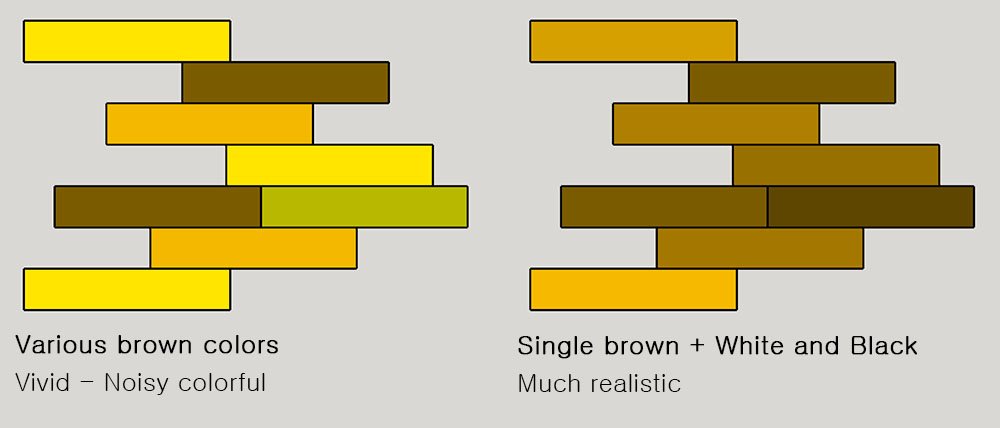

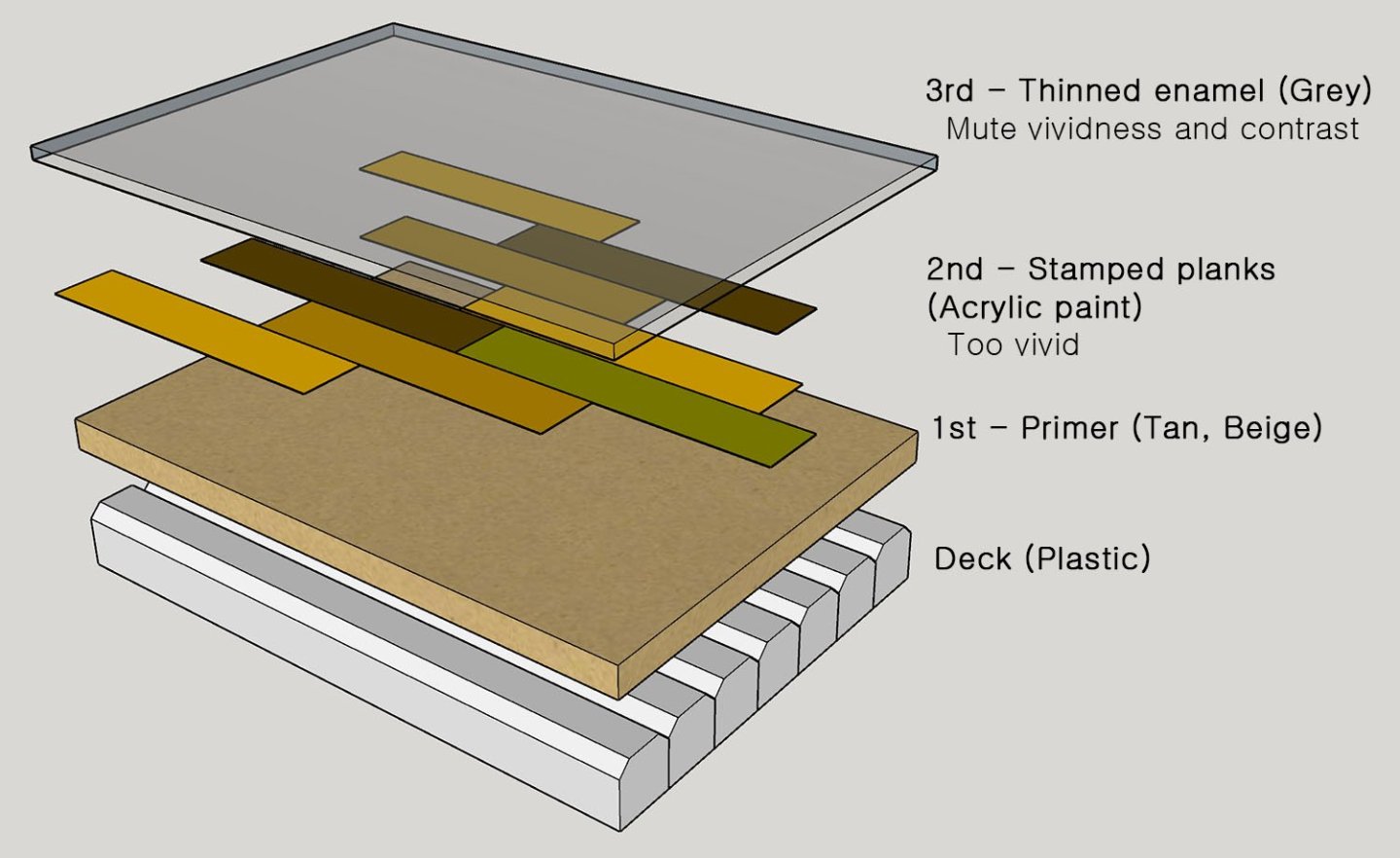

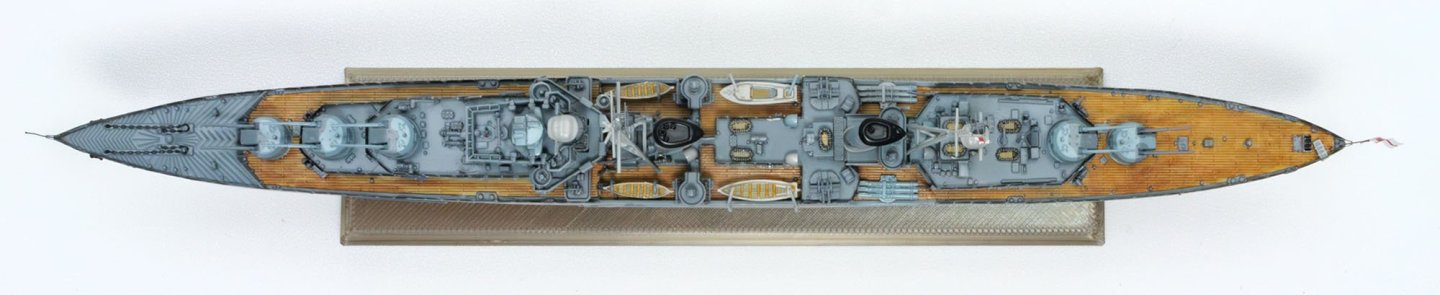

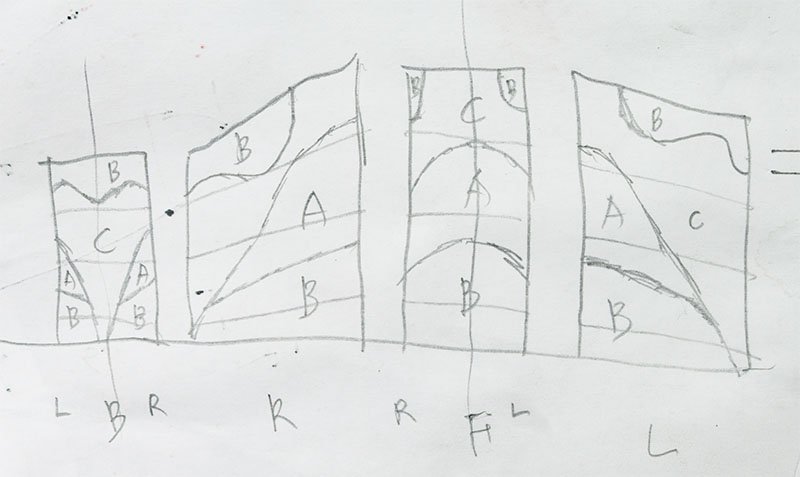

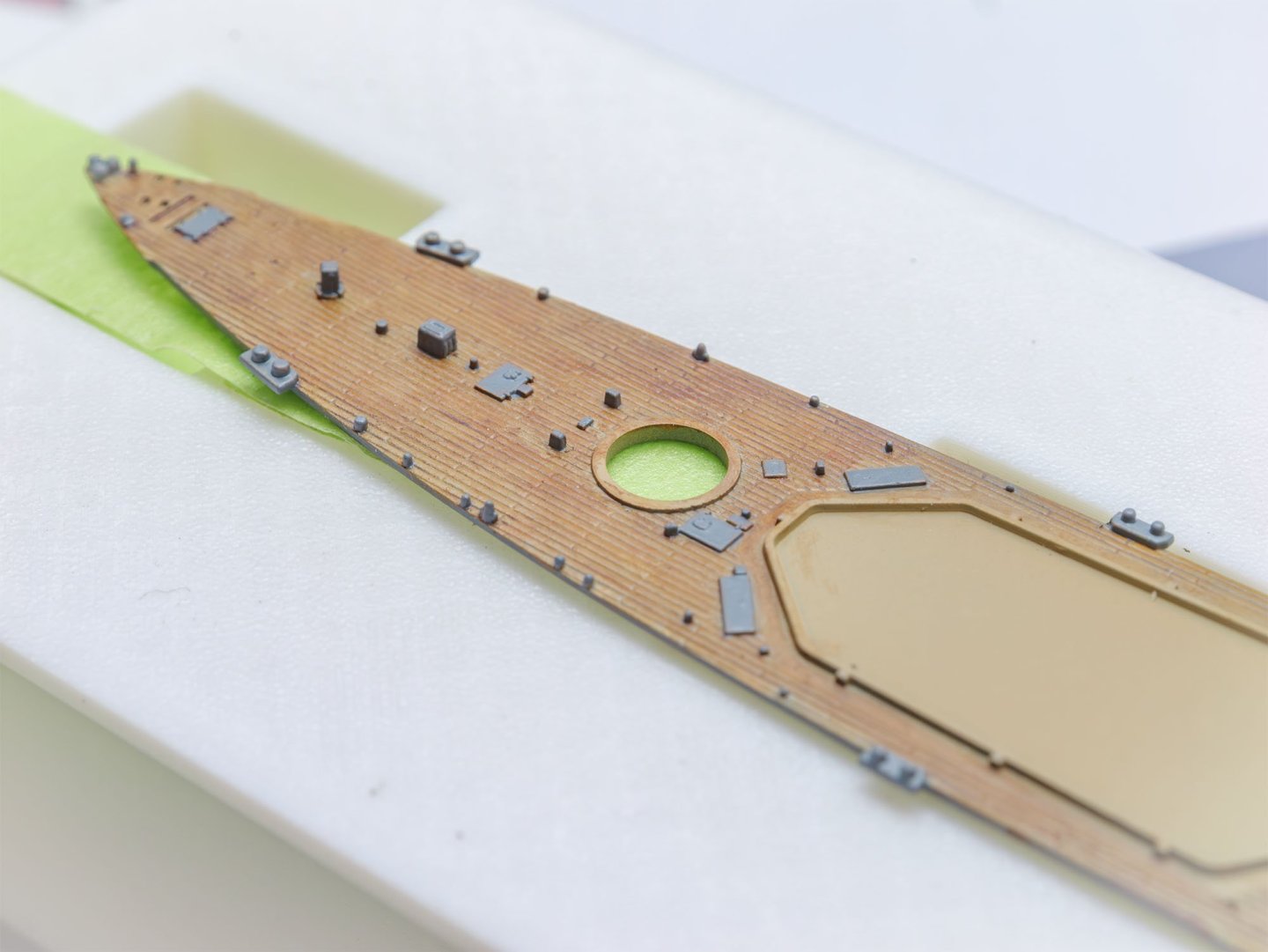

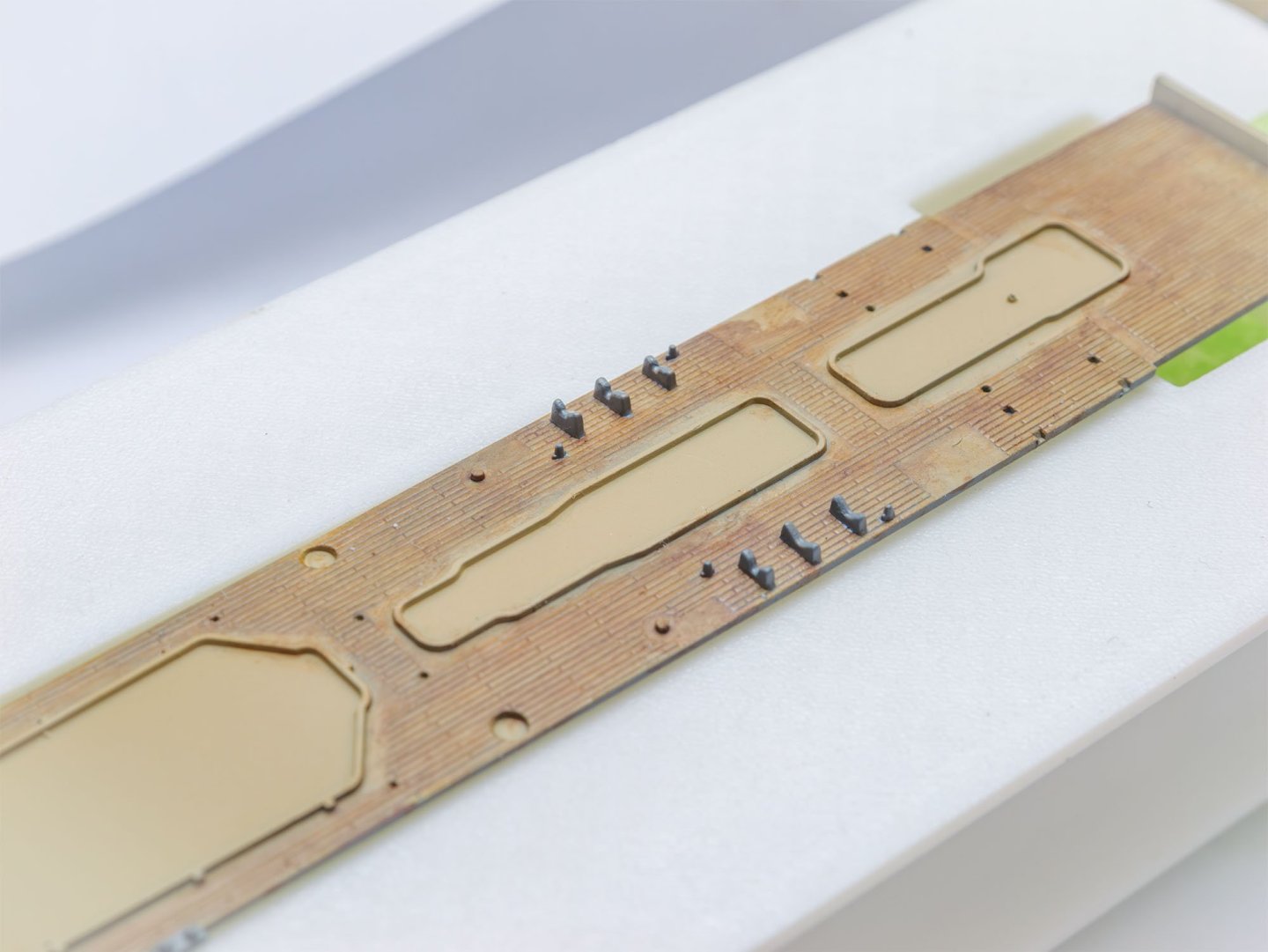

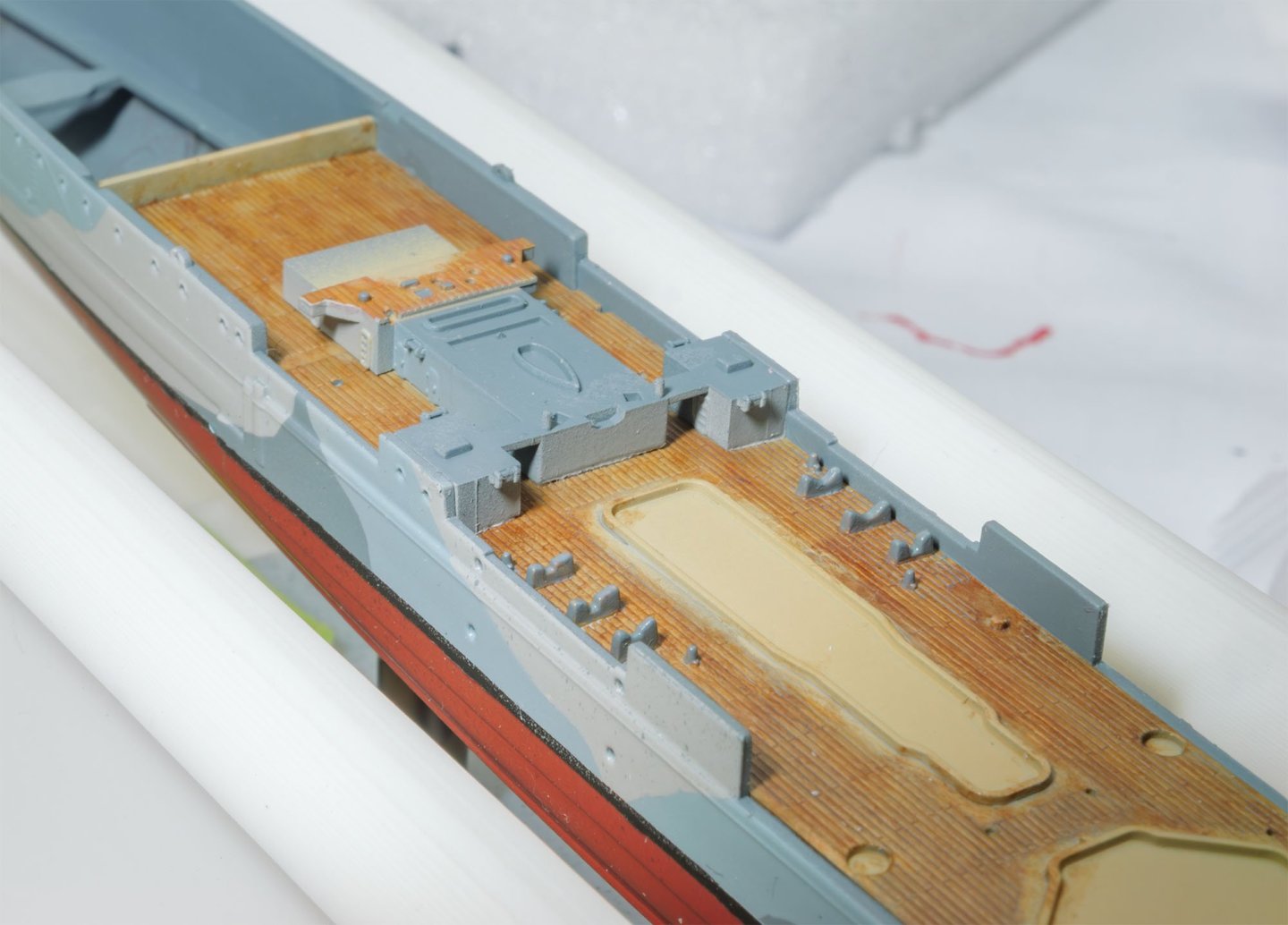

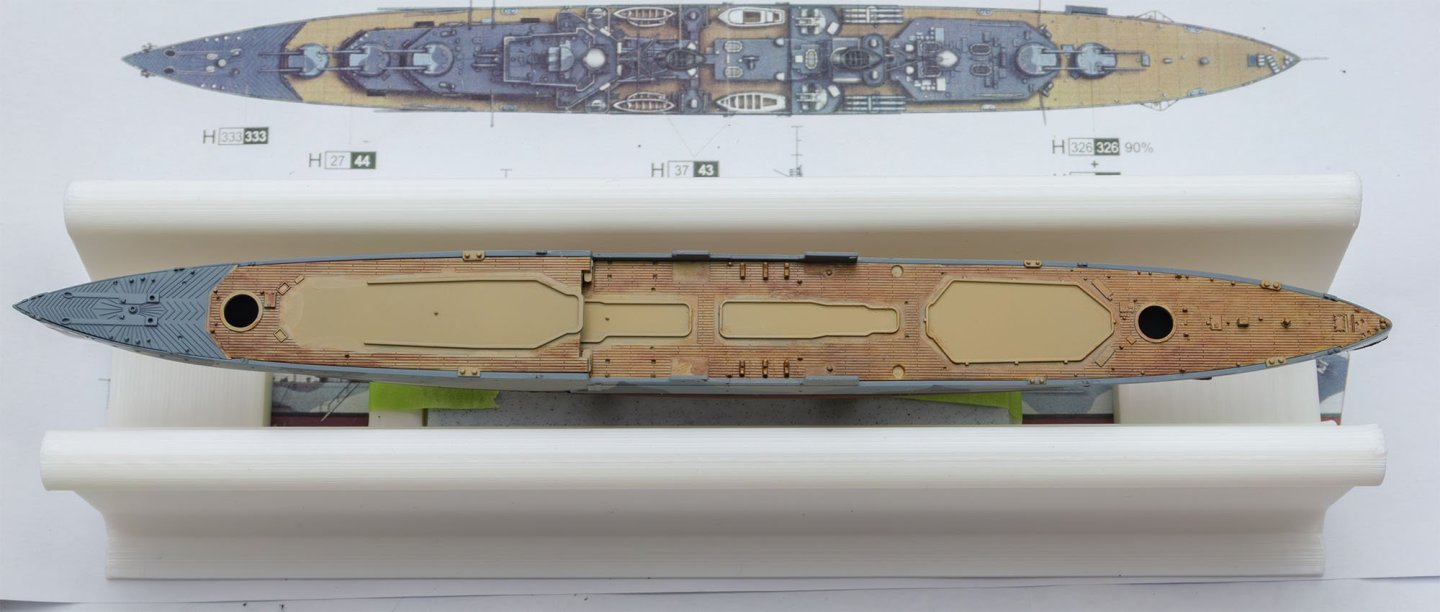

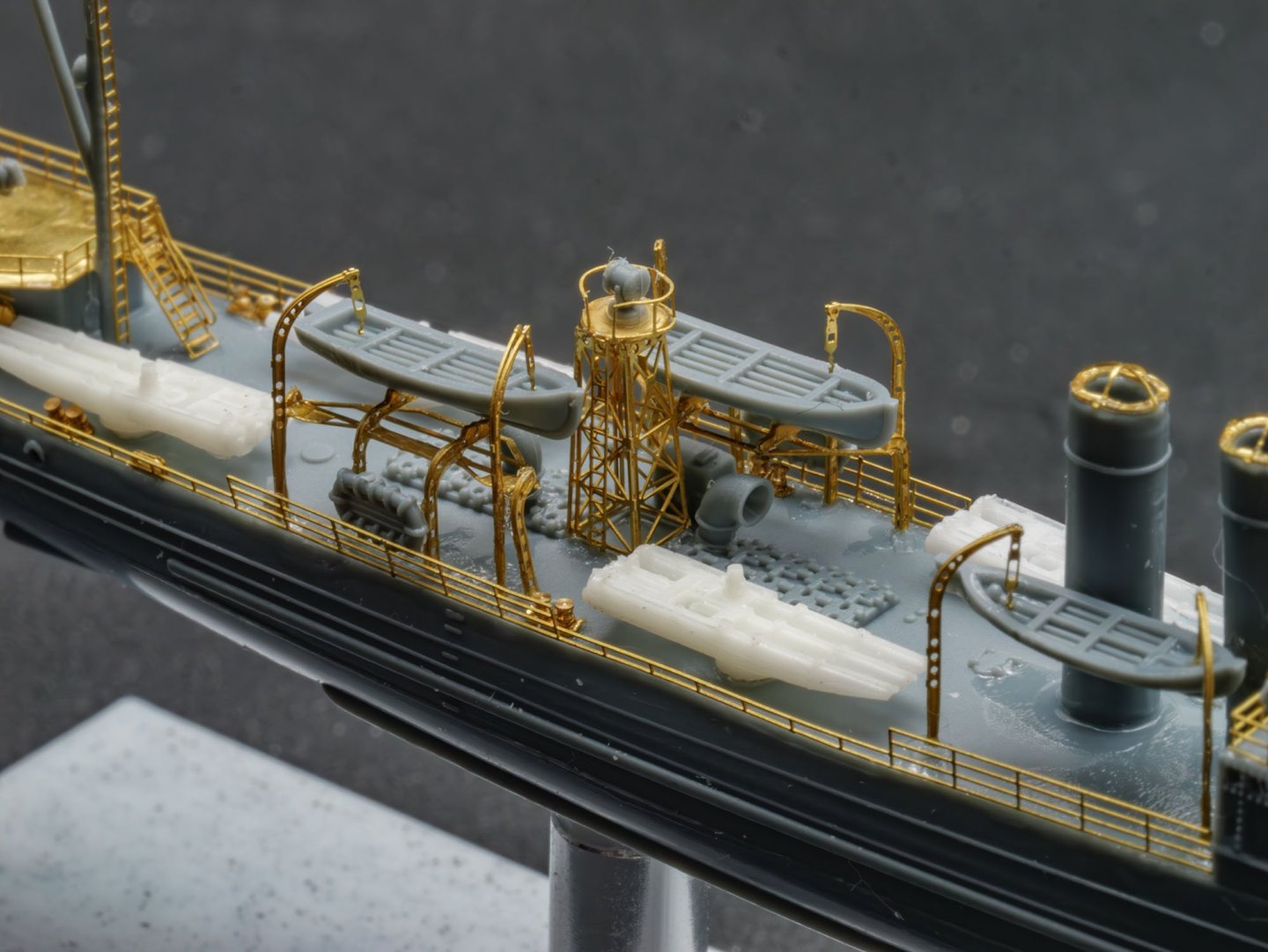

I tried to paint each planks in different colors. Brushing was so boring work... I made special nozzle caps for airbrush, but the result was not significant. The final attempt was stamping. It was super easy, so anyone can do it. However, the color selection was too vivid. It looks like a German BF109 camouflage pattern. For the next project. I applied thinned grey enamel paint to reduce the high saturation and brightness. This is a summary of my deck painting. I may not need the thinned enamel next time.

- 4 replies

-

- Invincible

- Flyhawk

-

(and 2 more)

Tagged with:

-

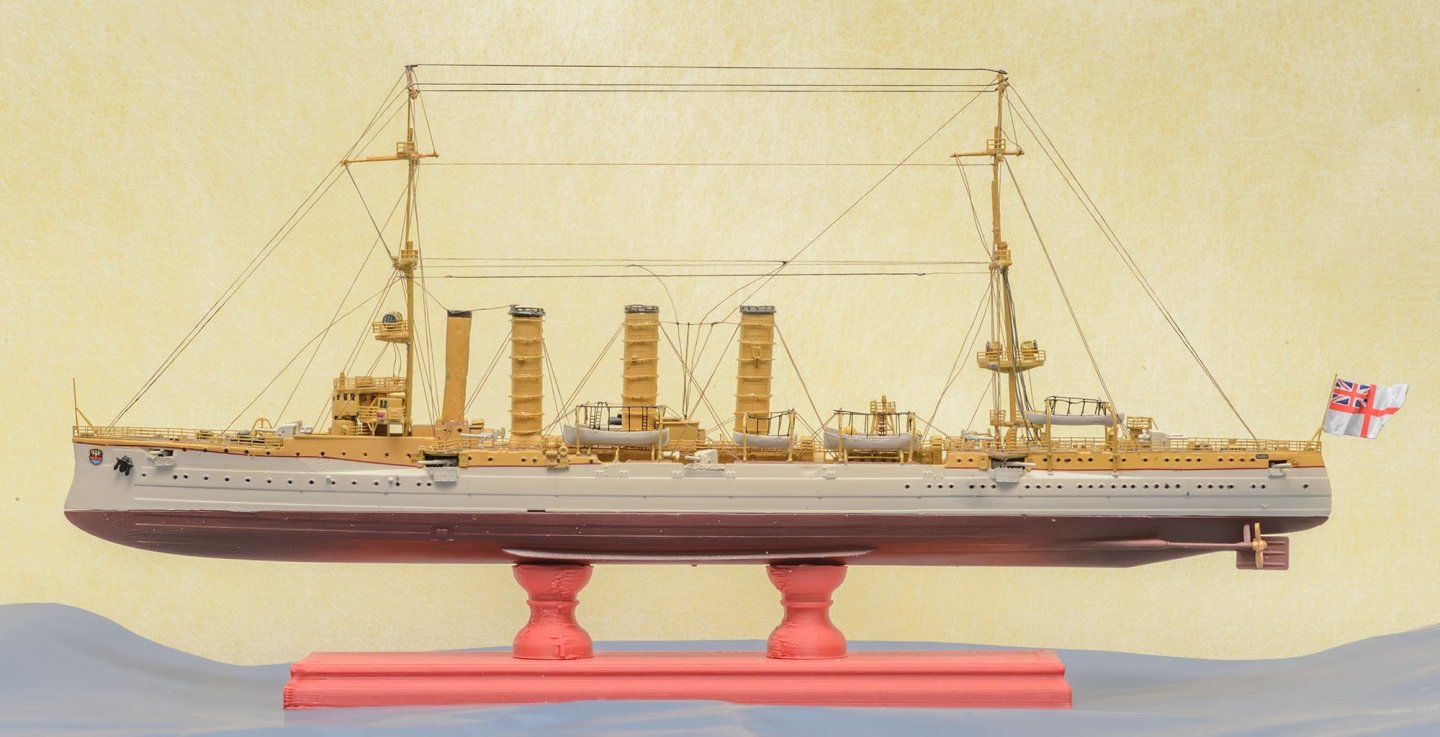

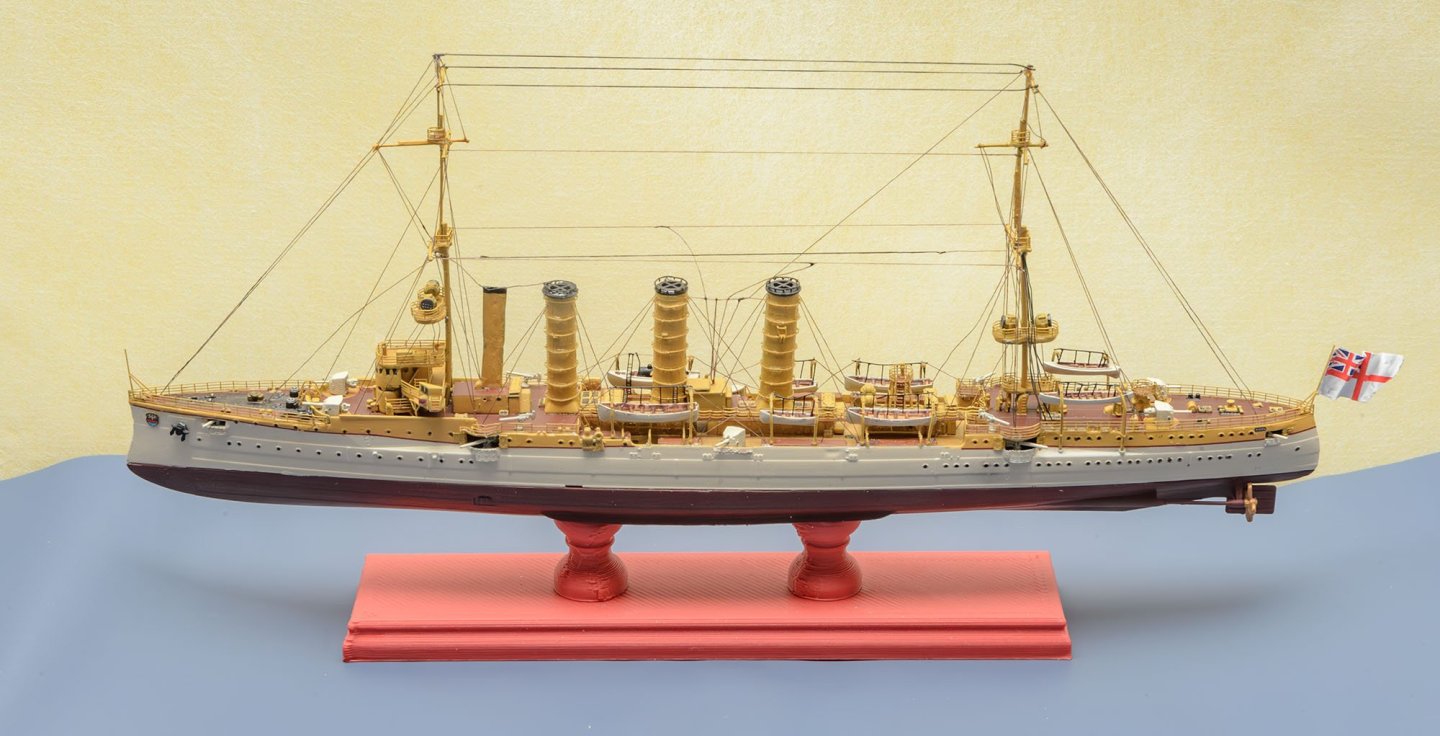

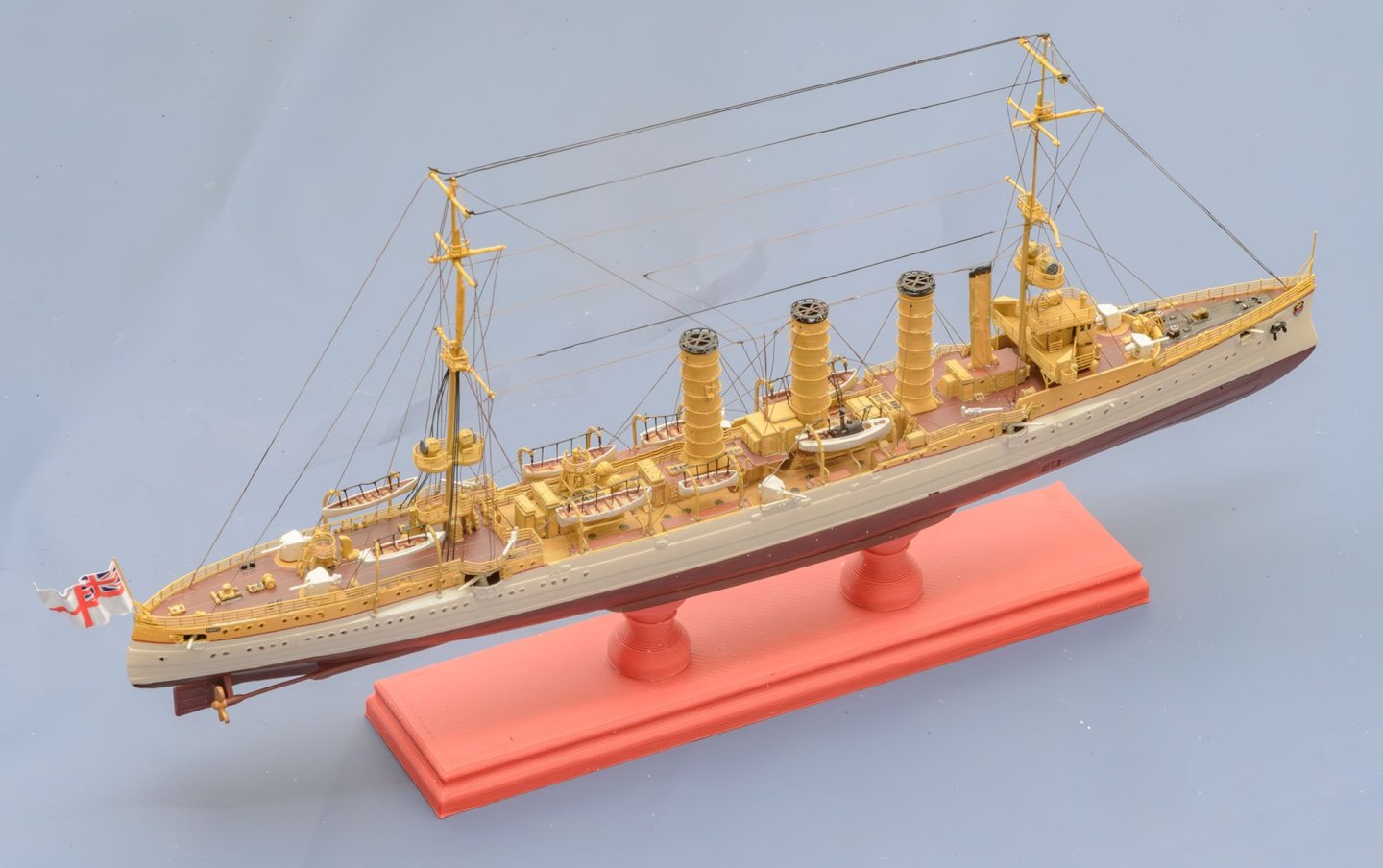

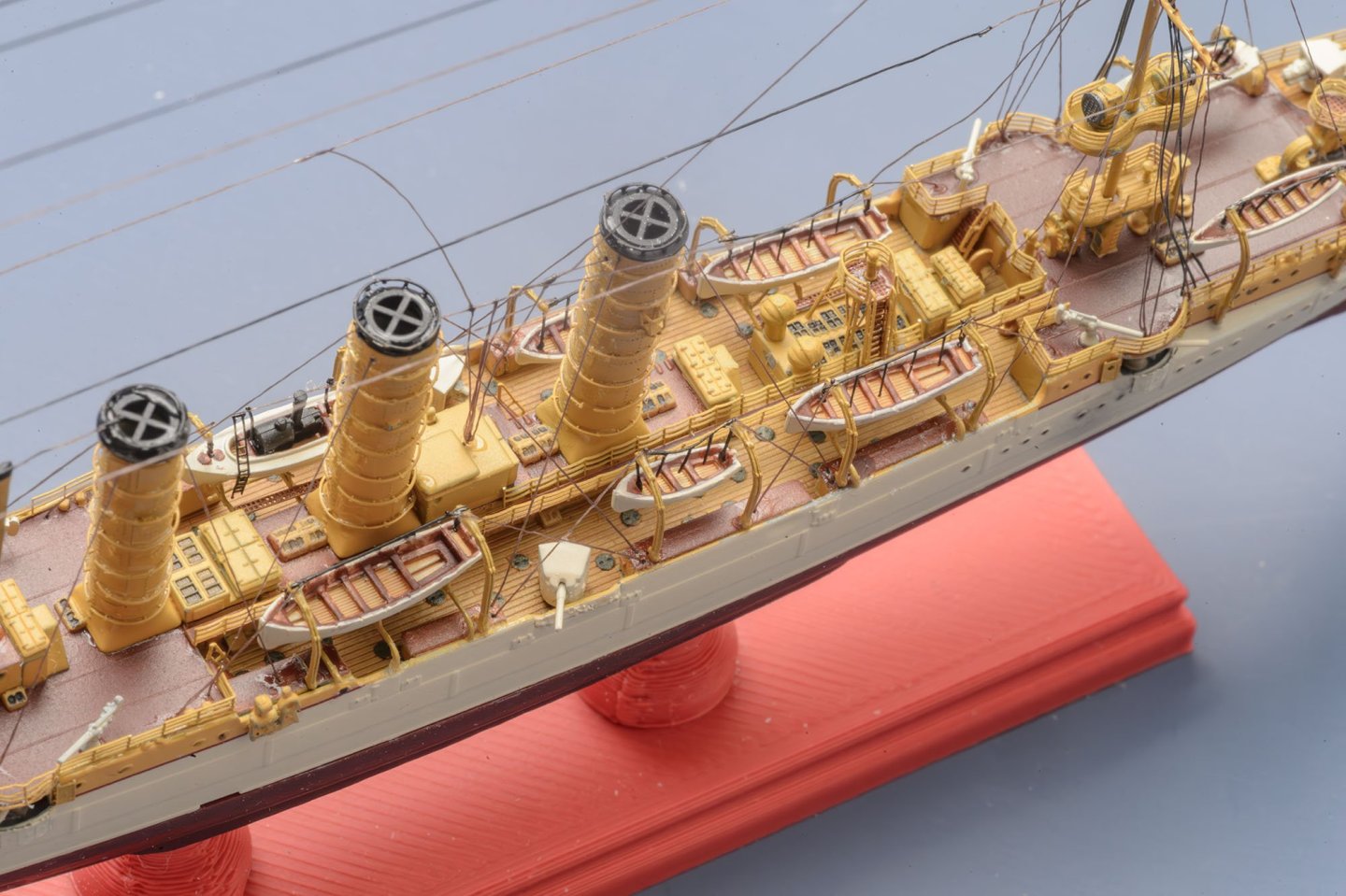

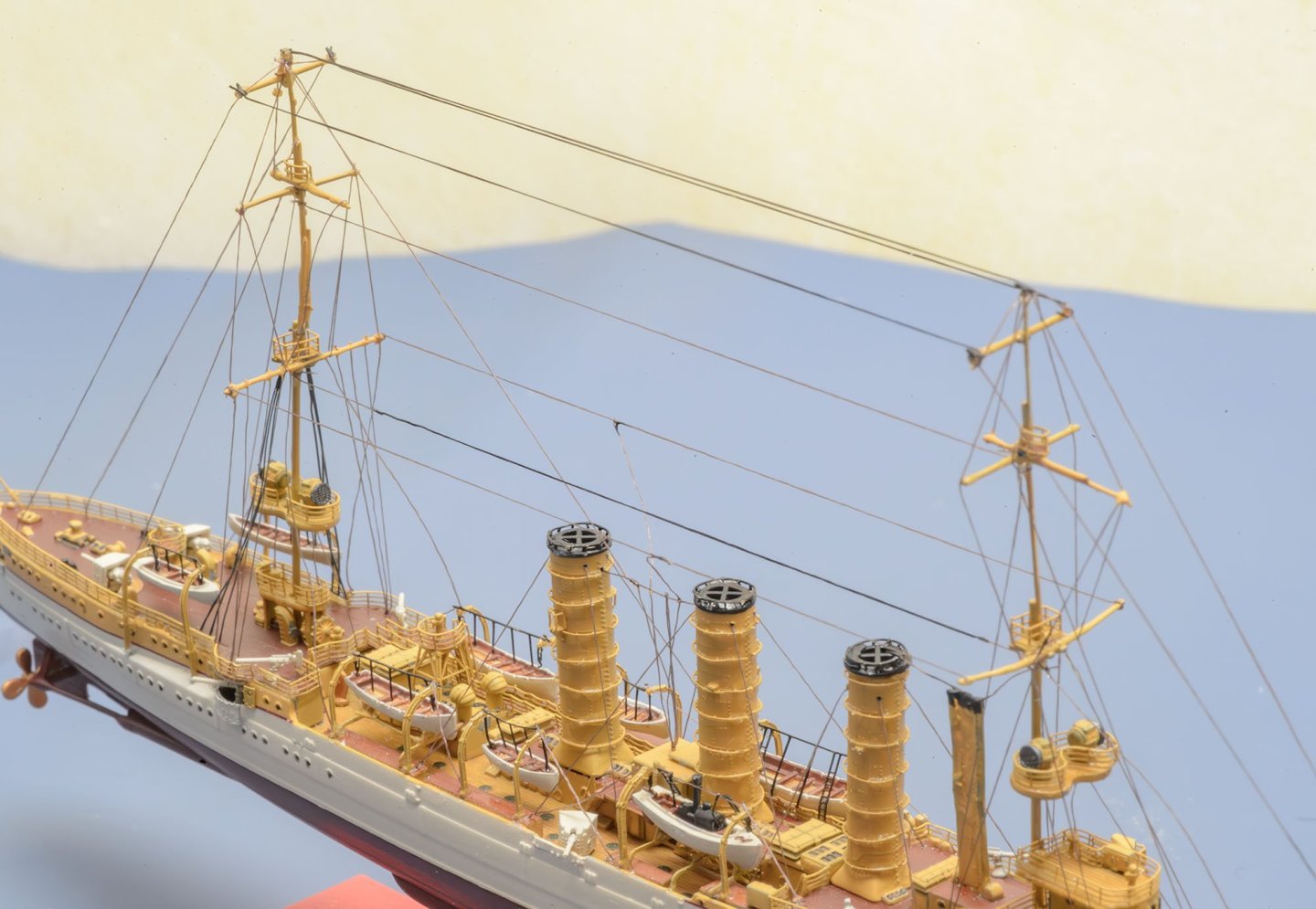

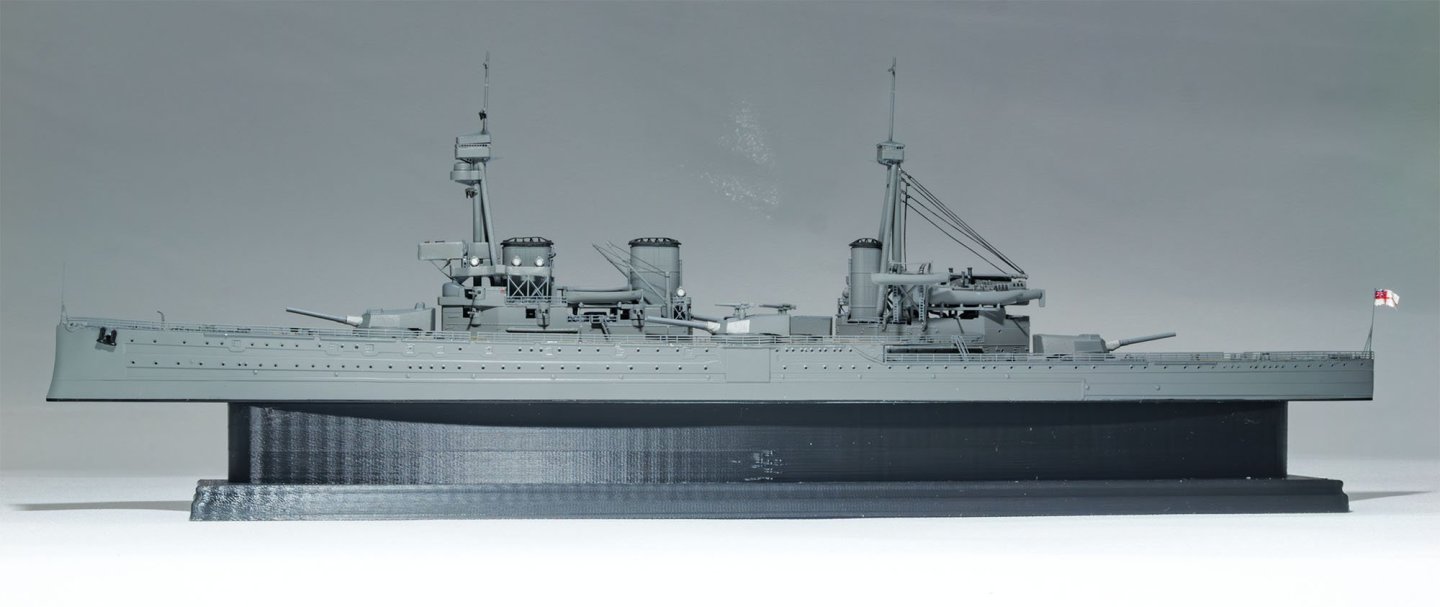

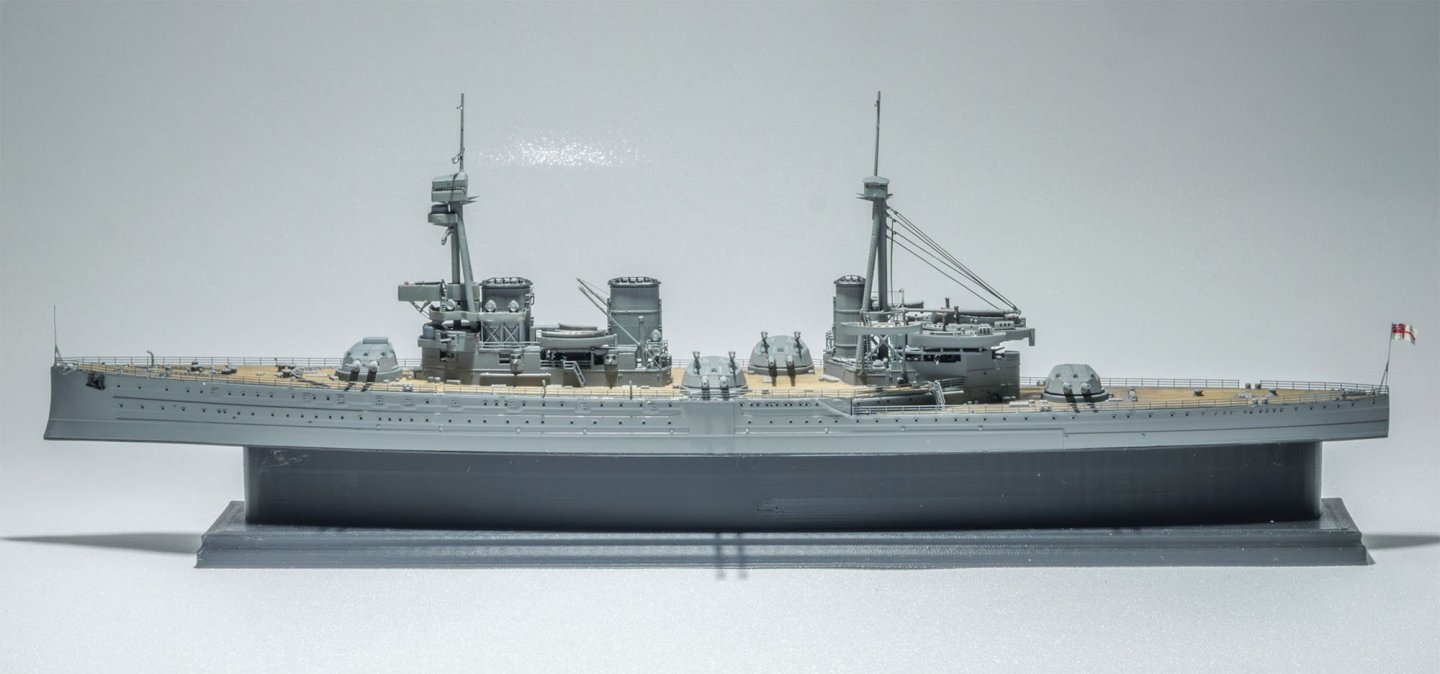

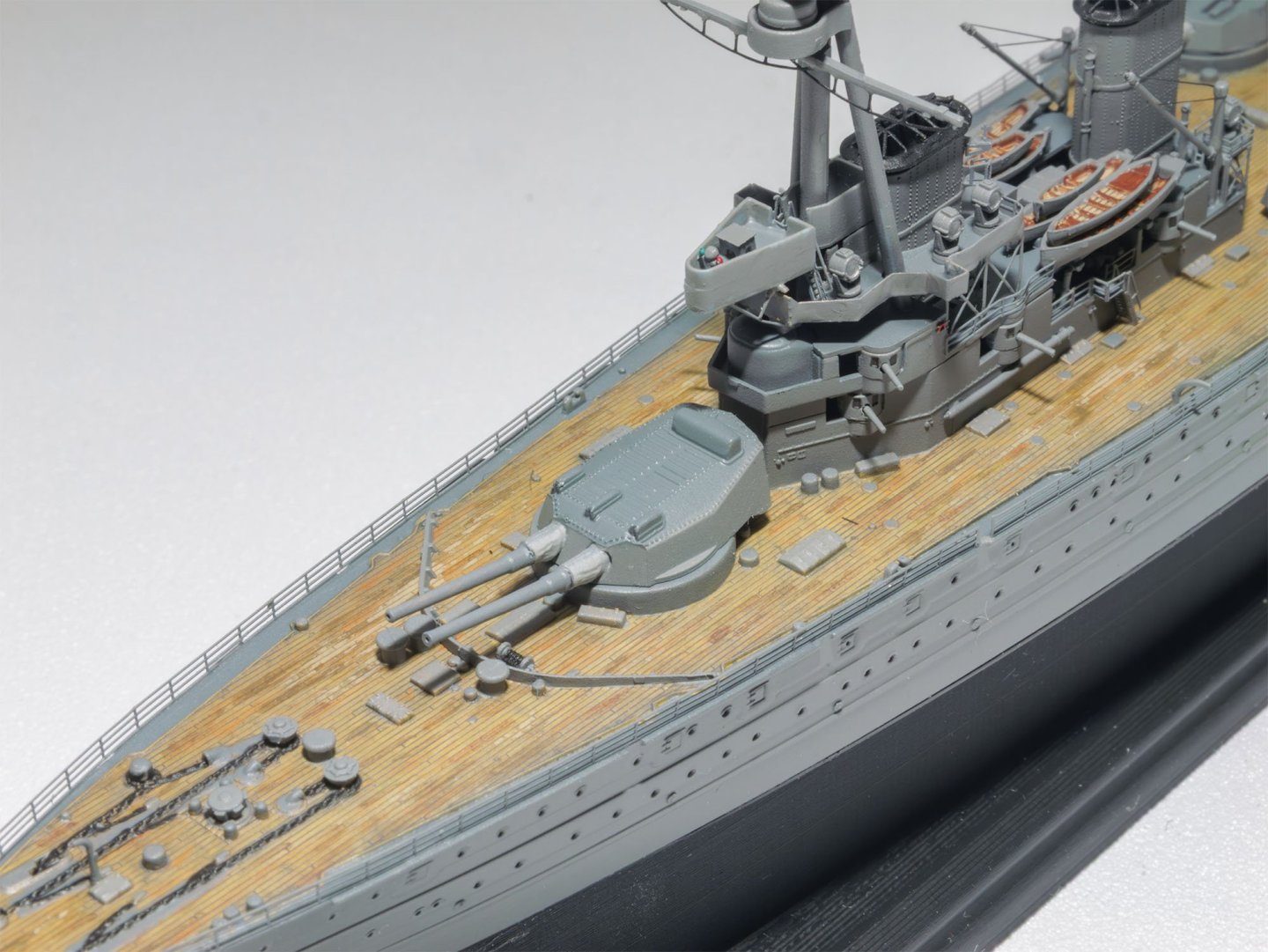

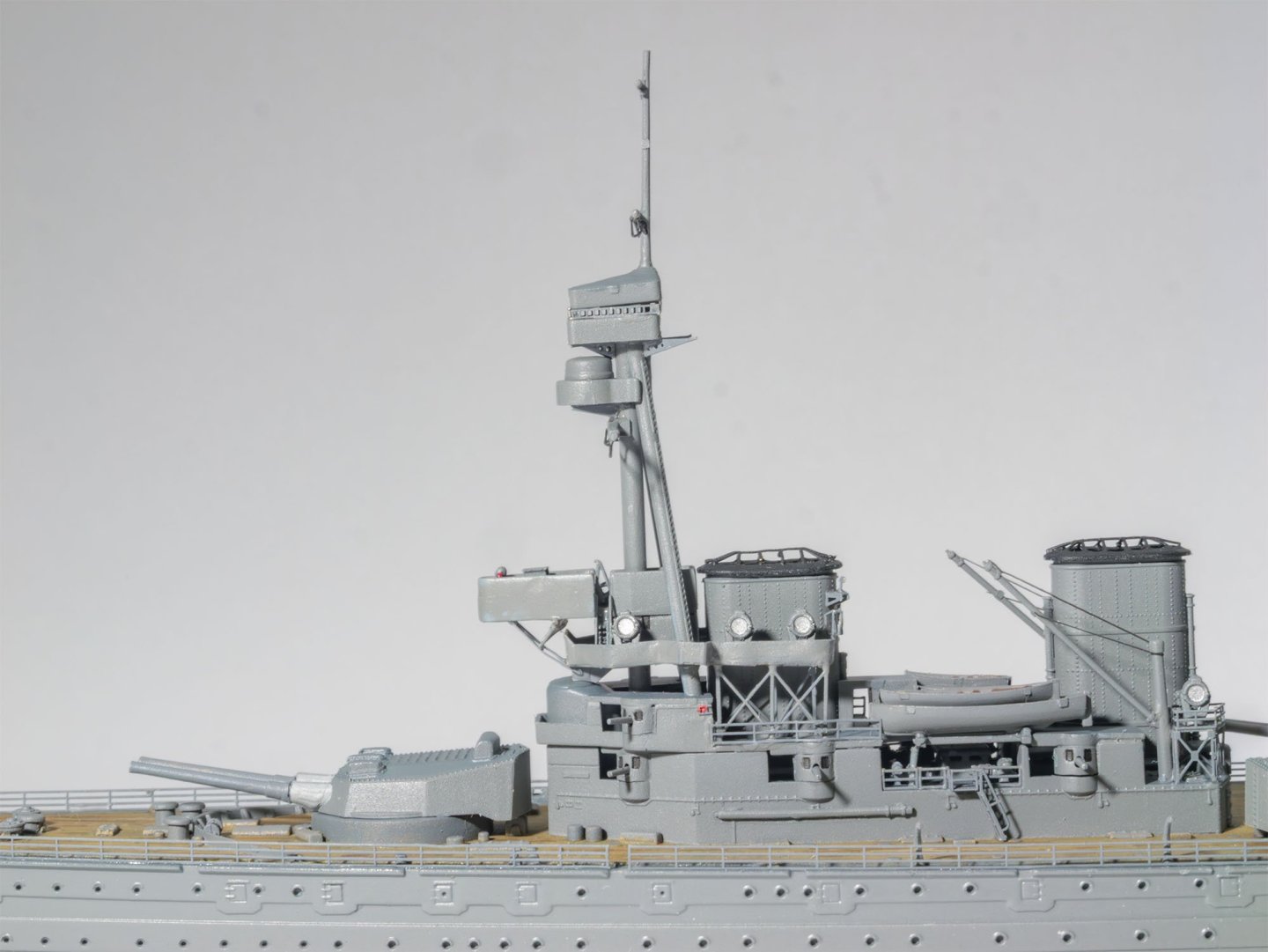

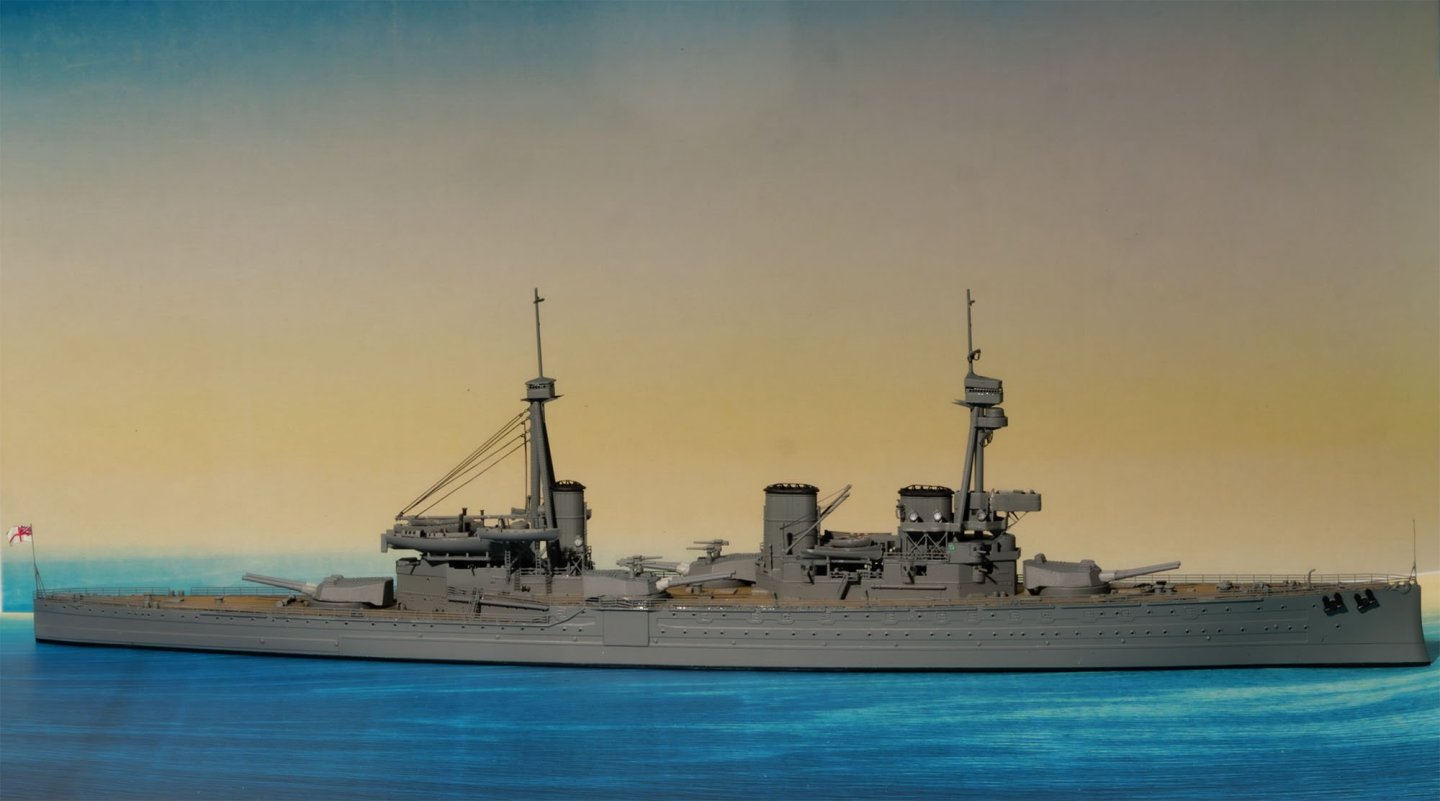

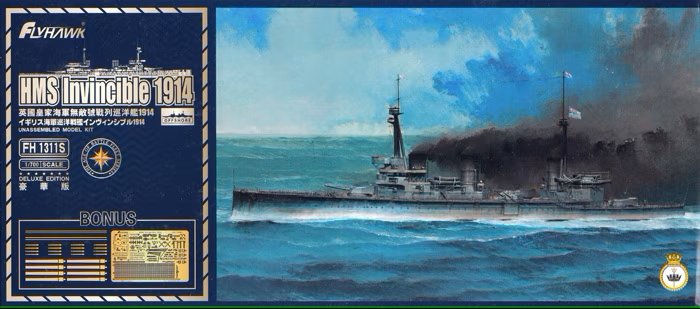

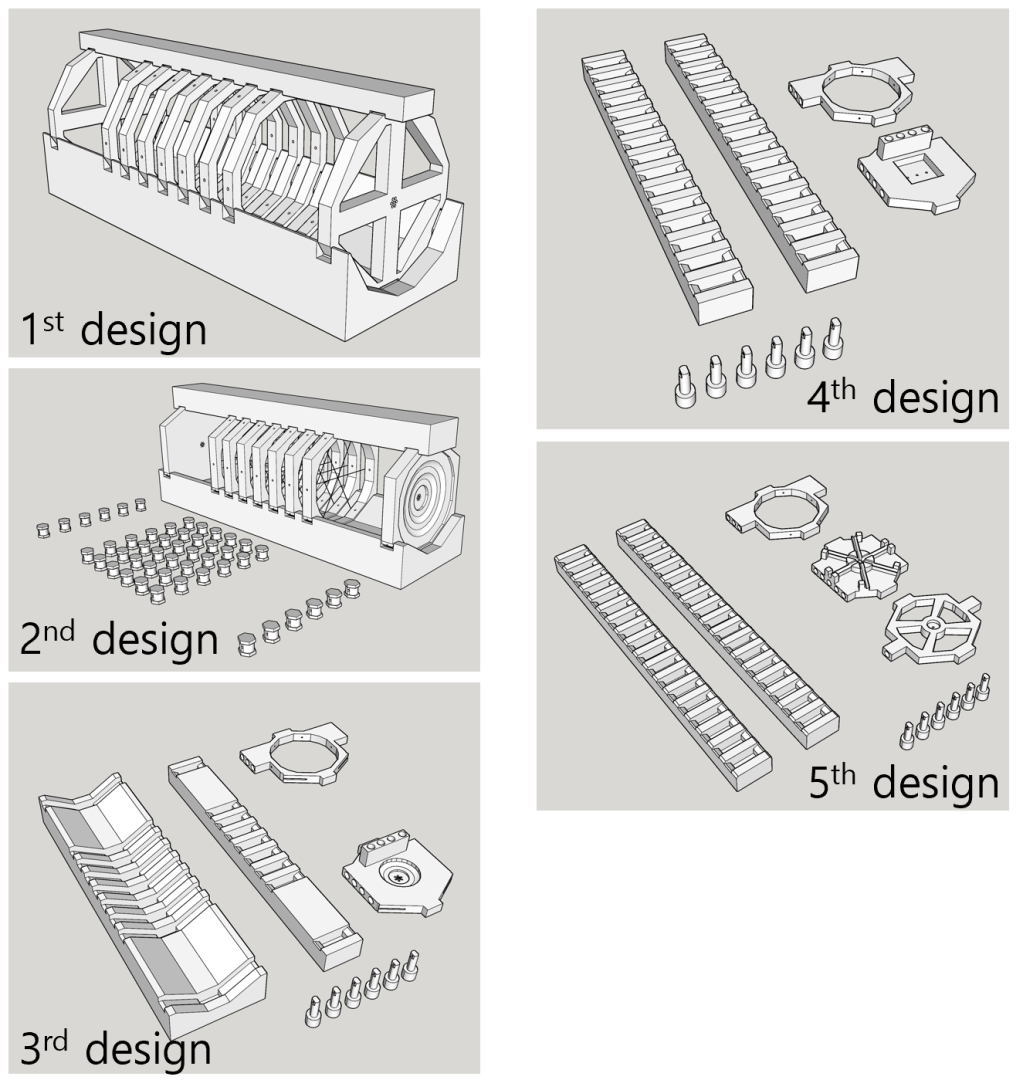

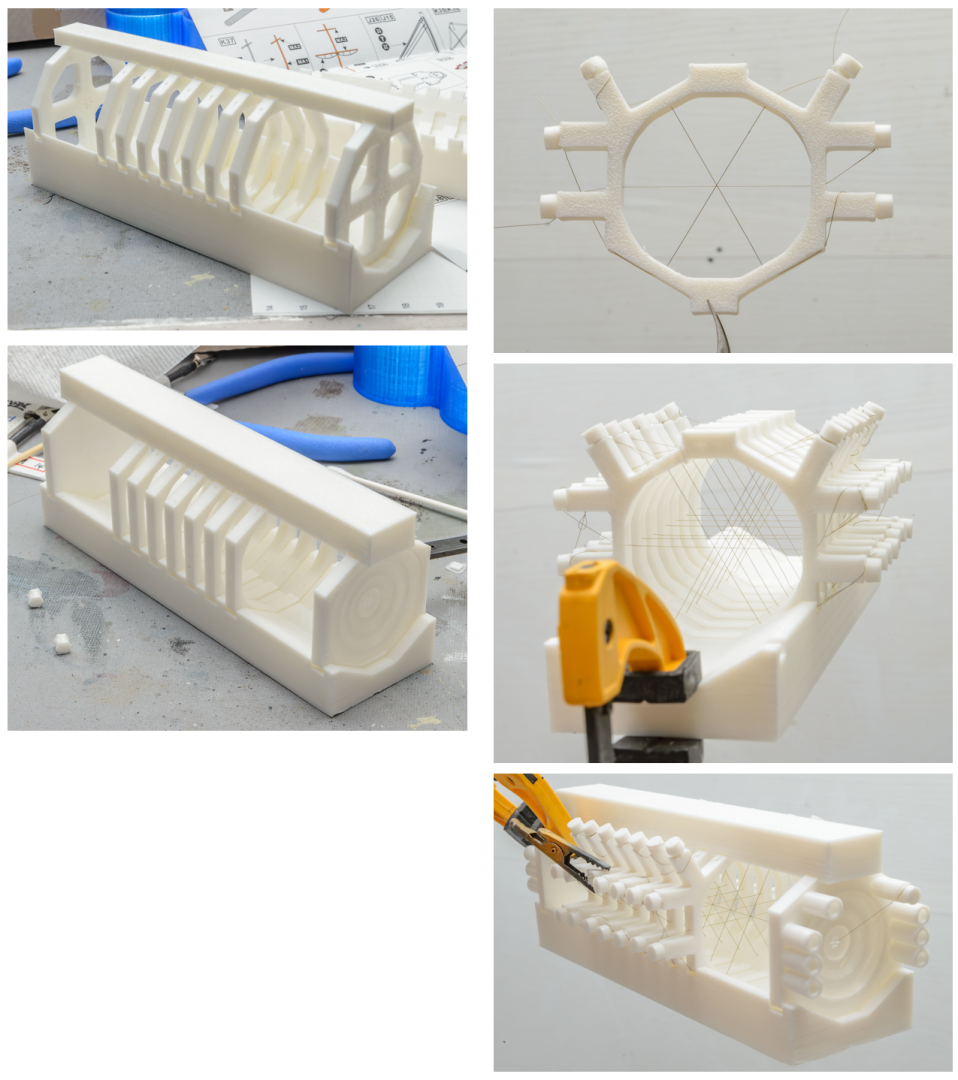

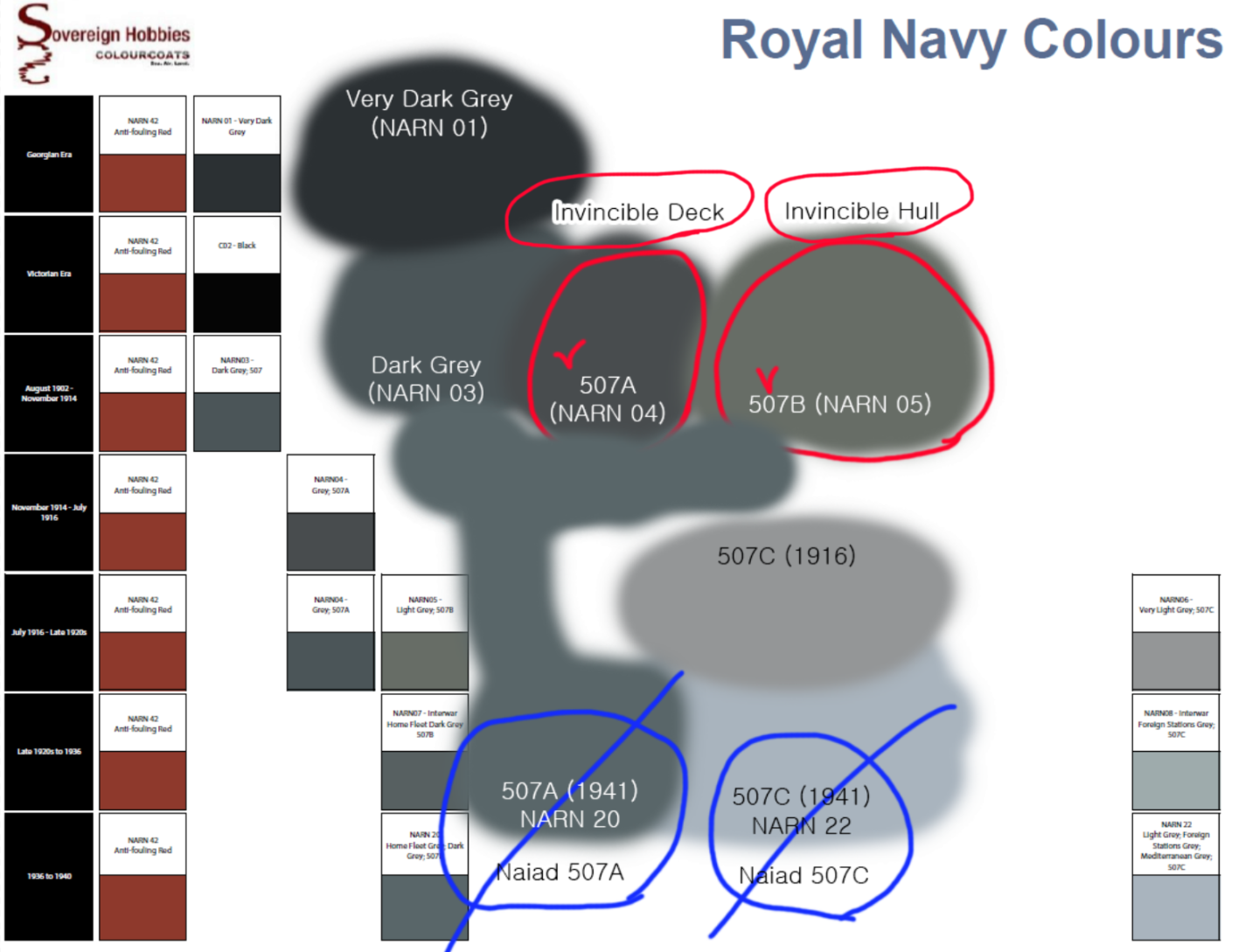

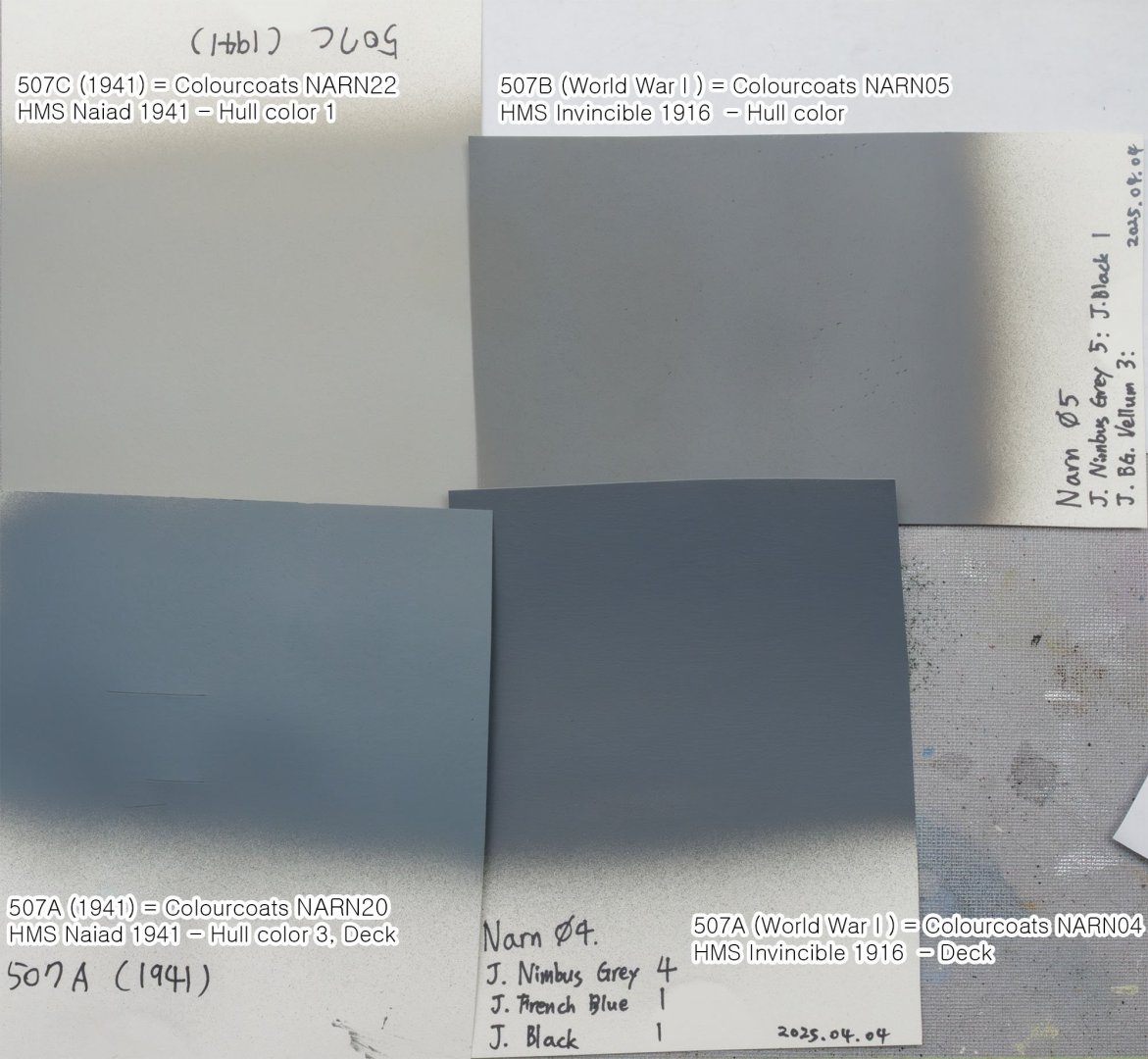

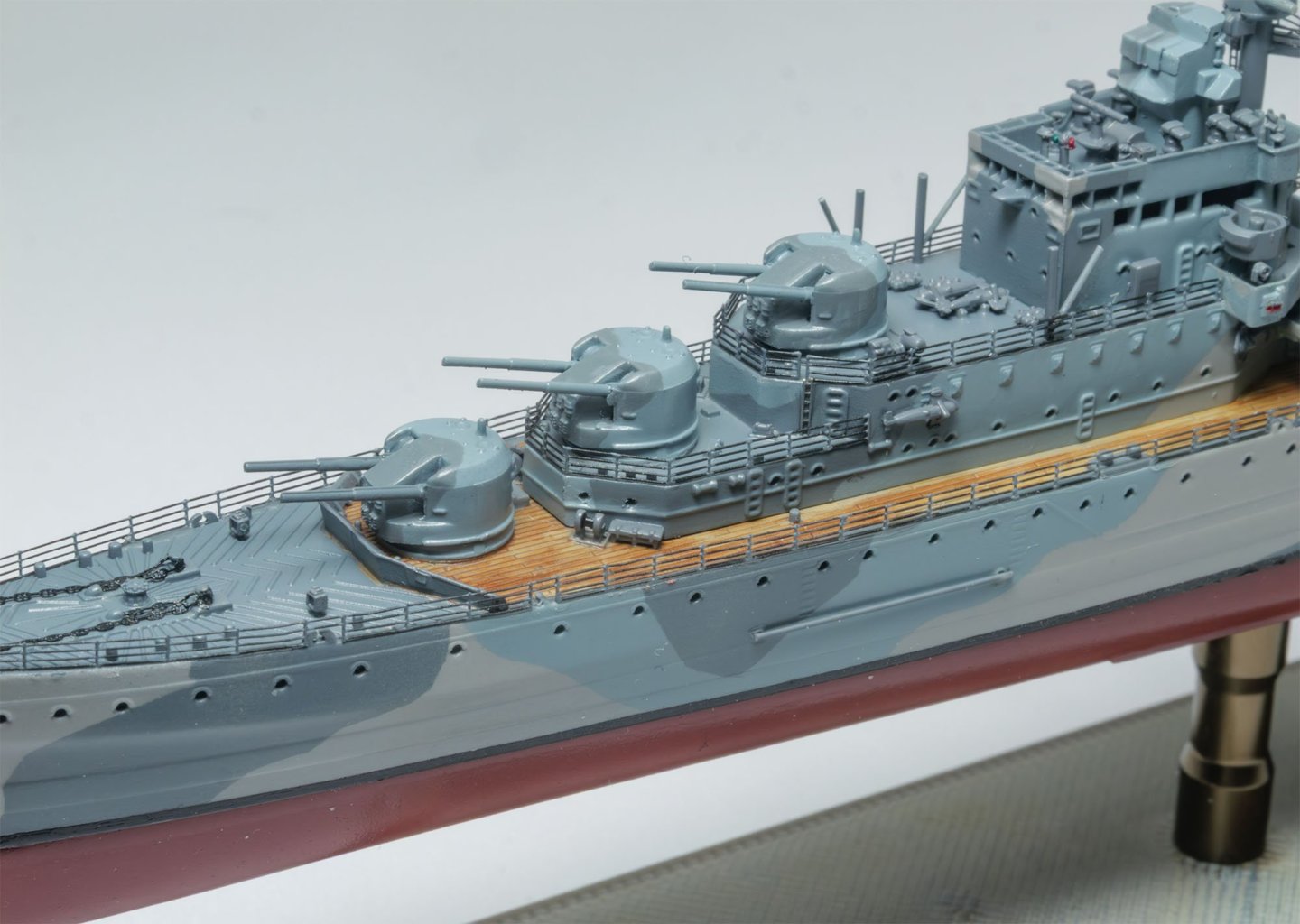

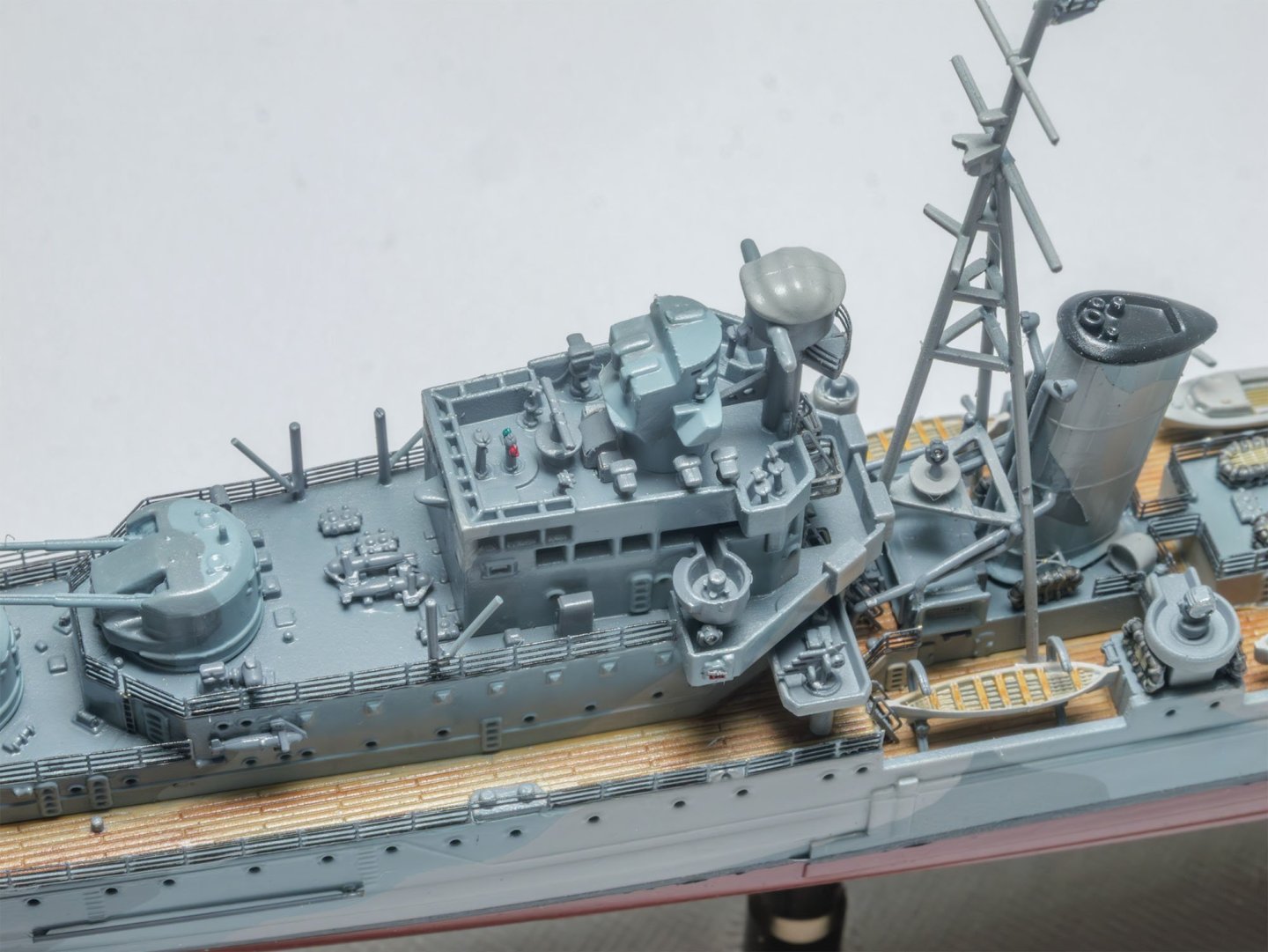

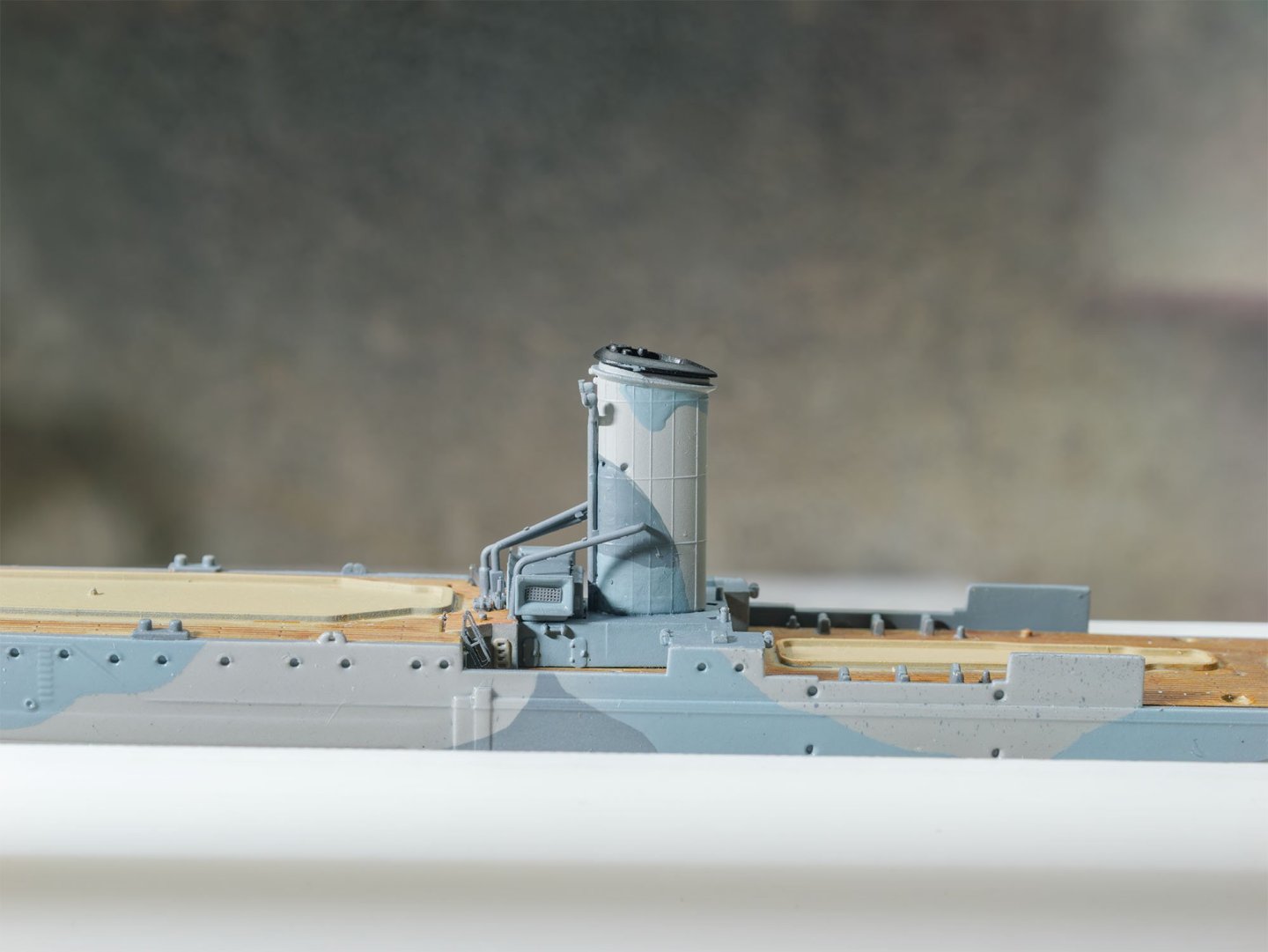

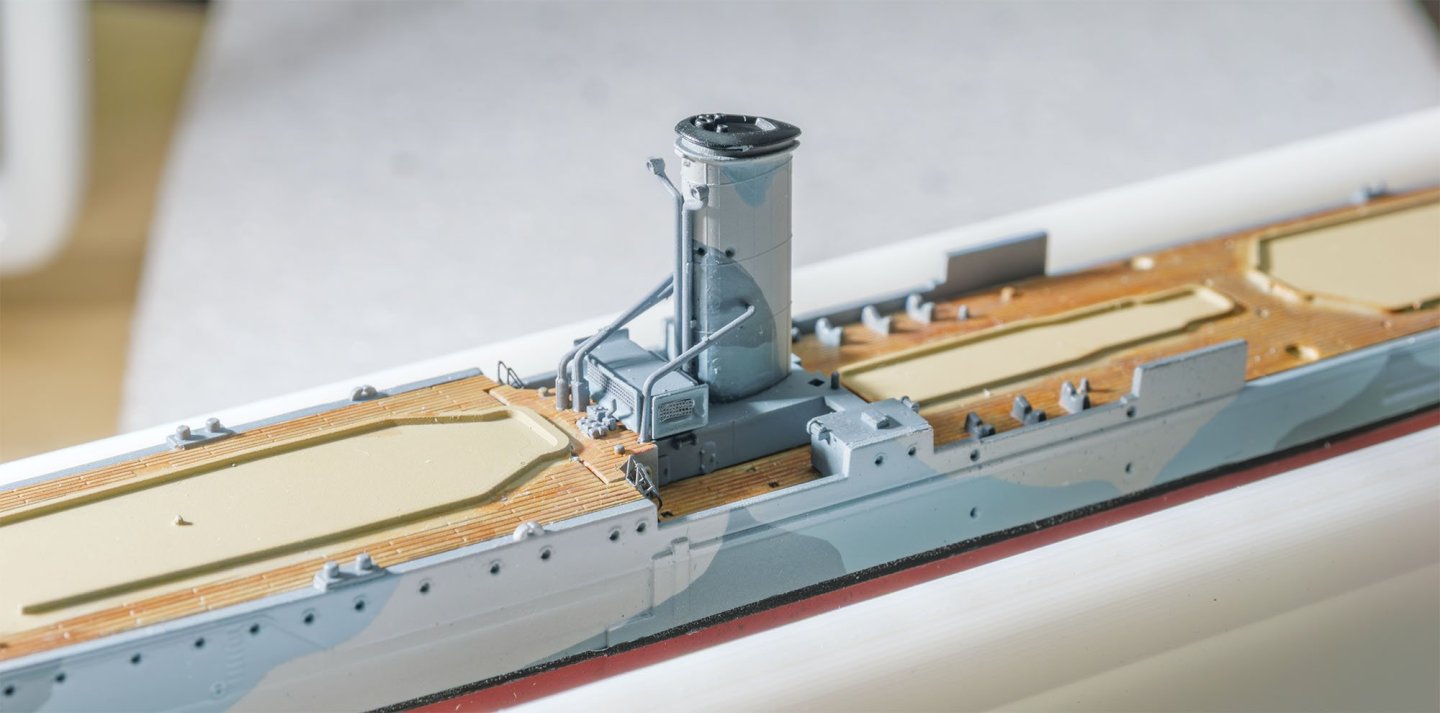

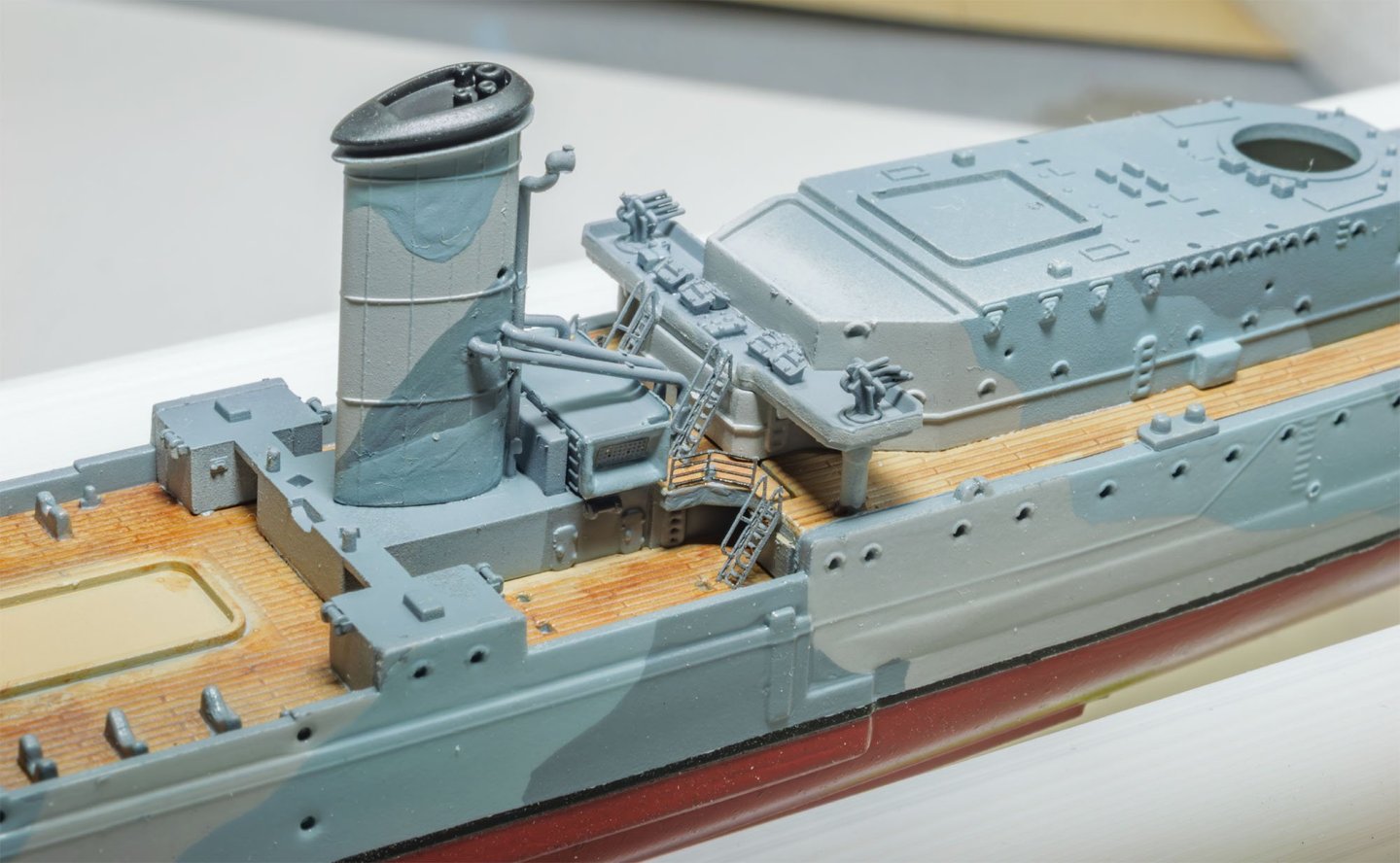

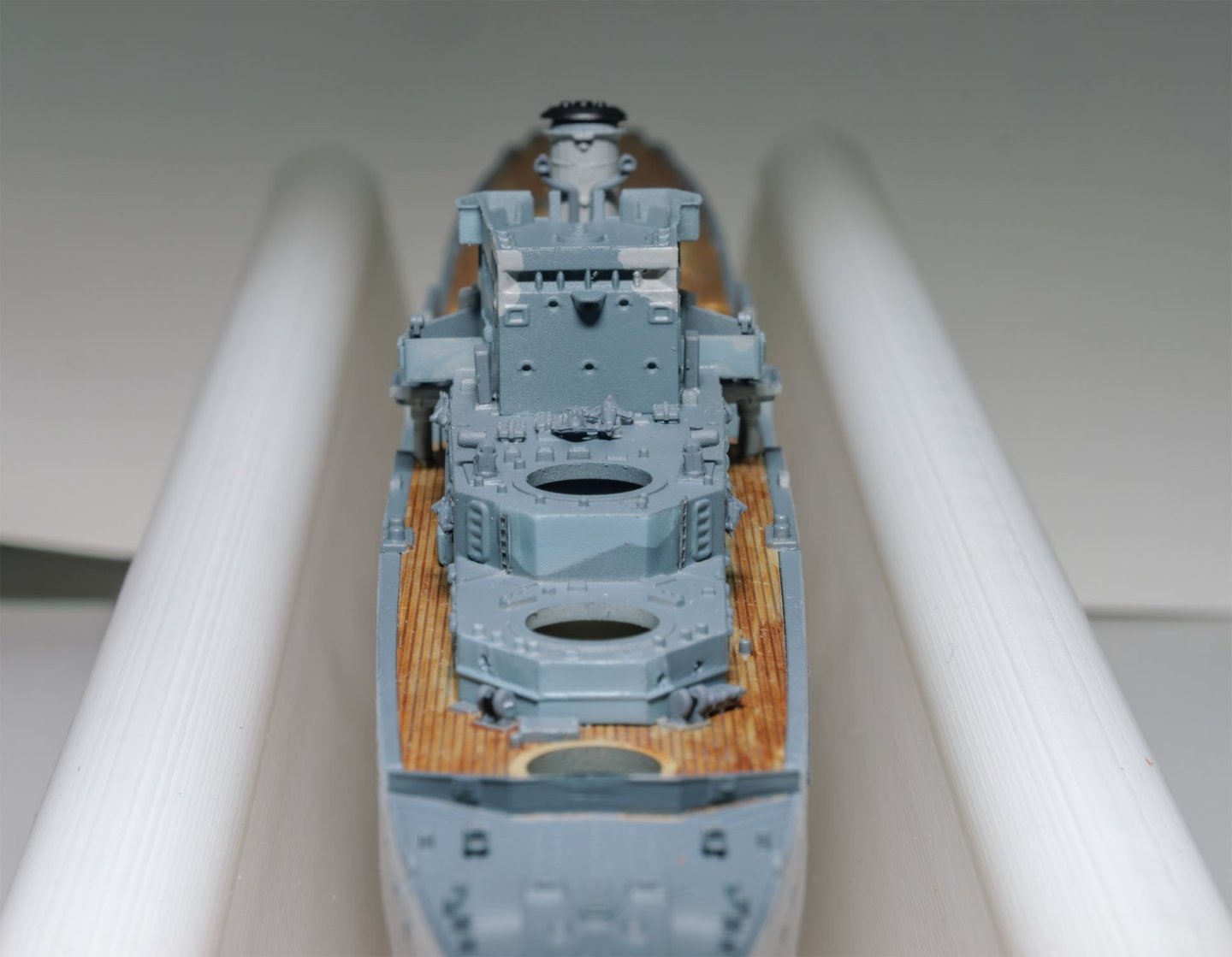

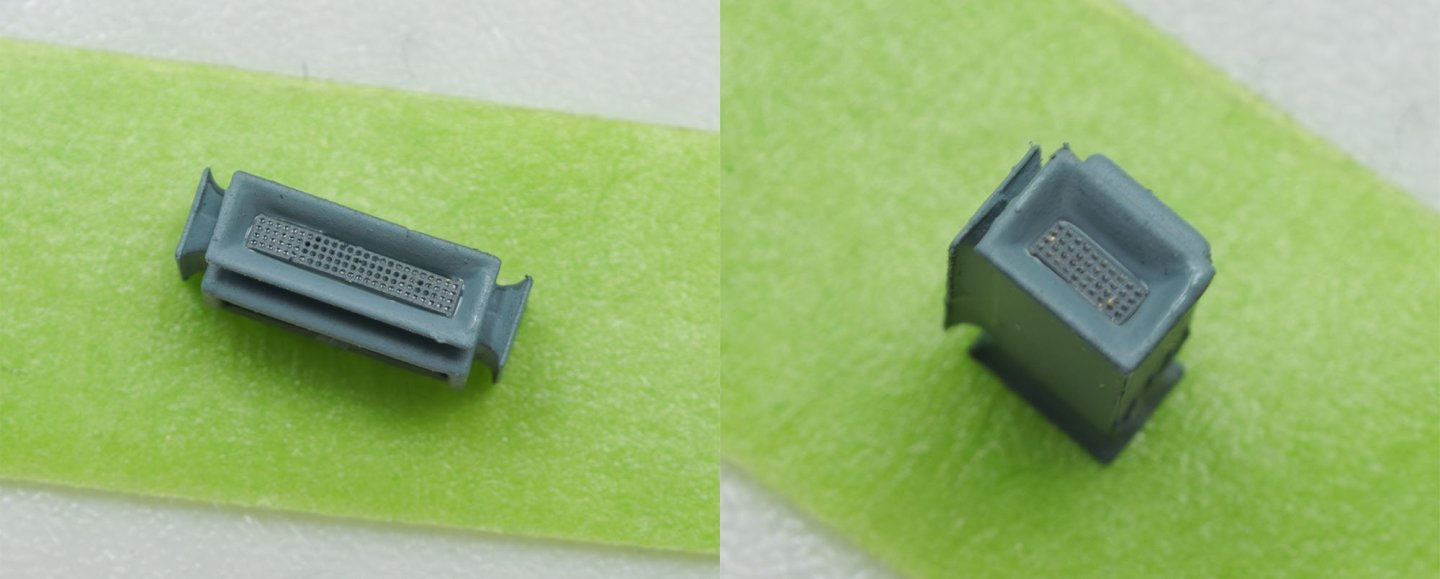

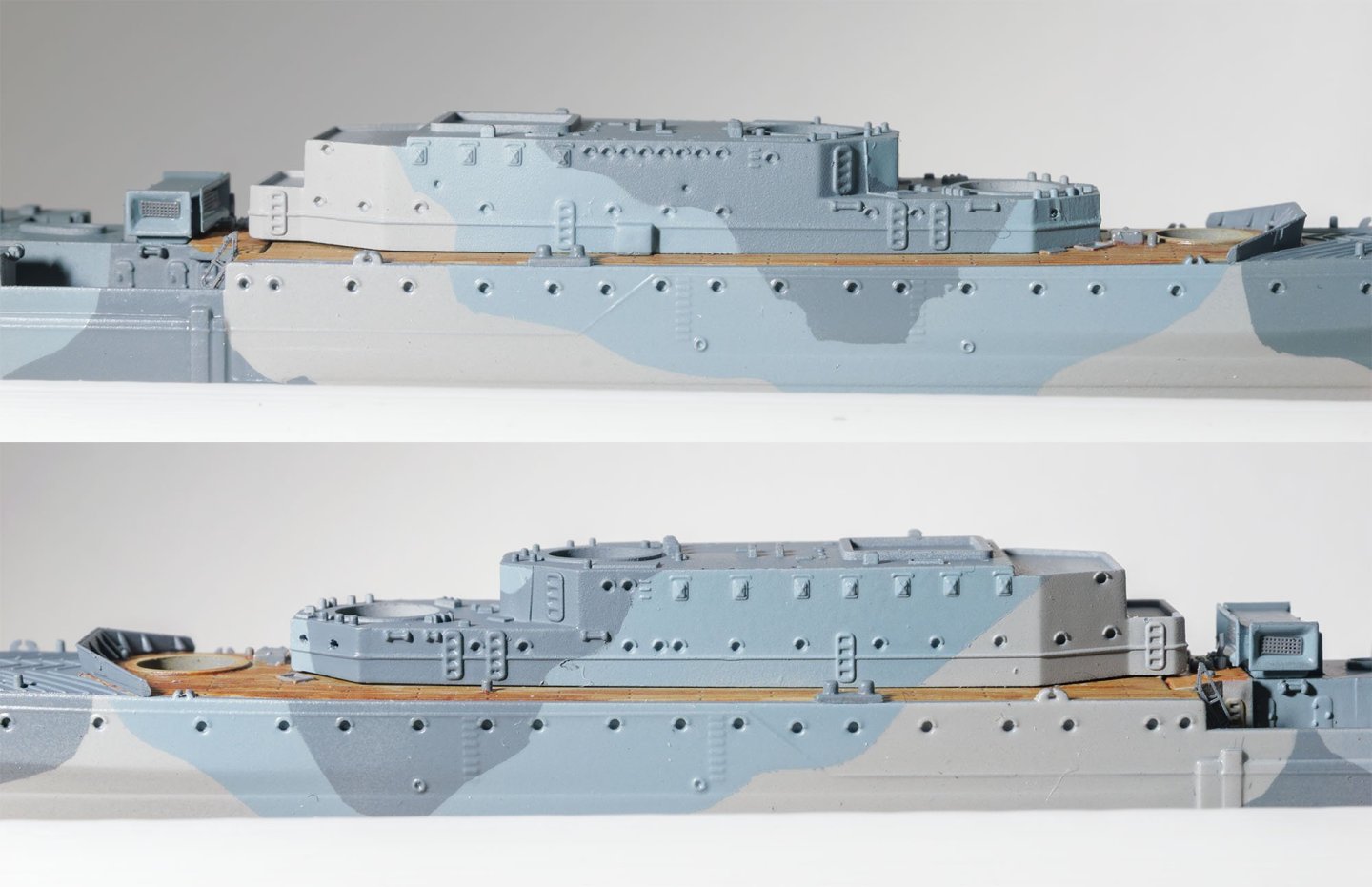

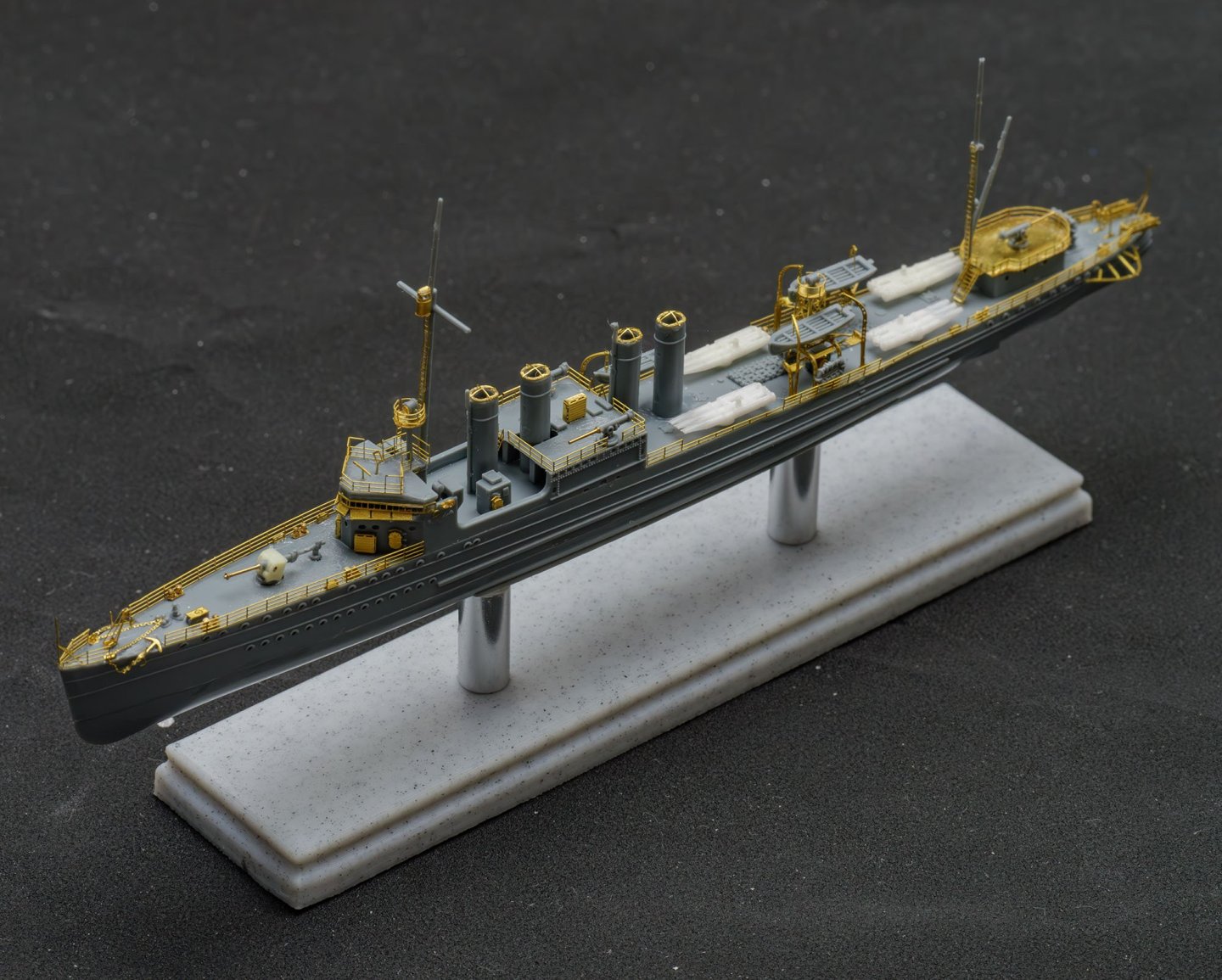

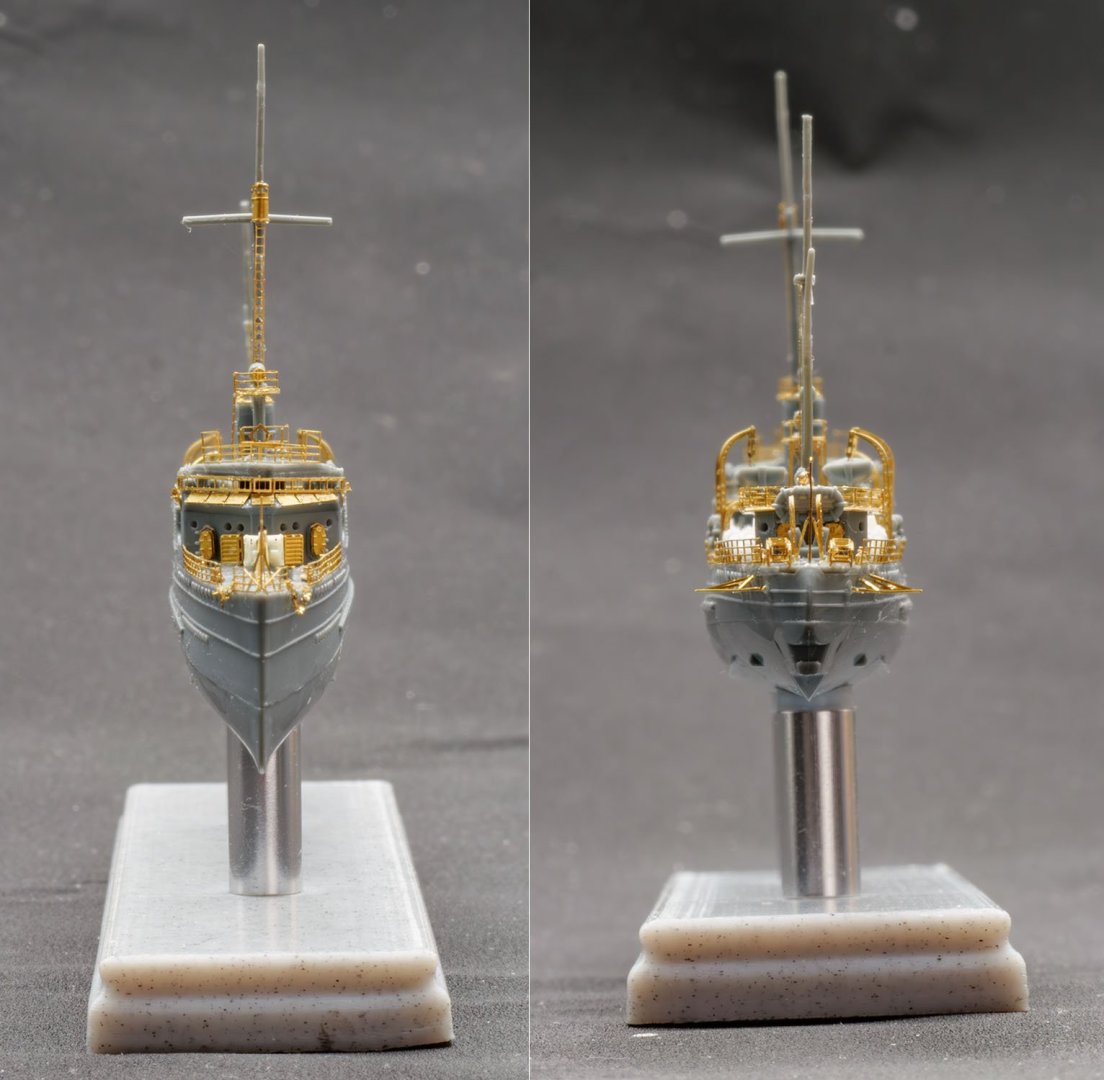

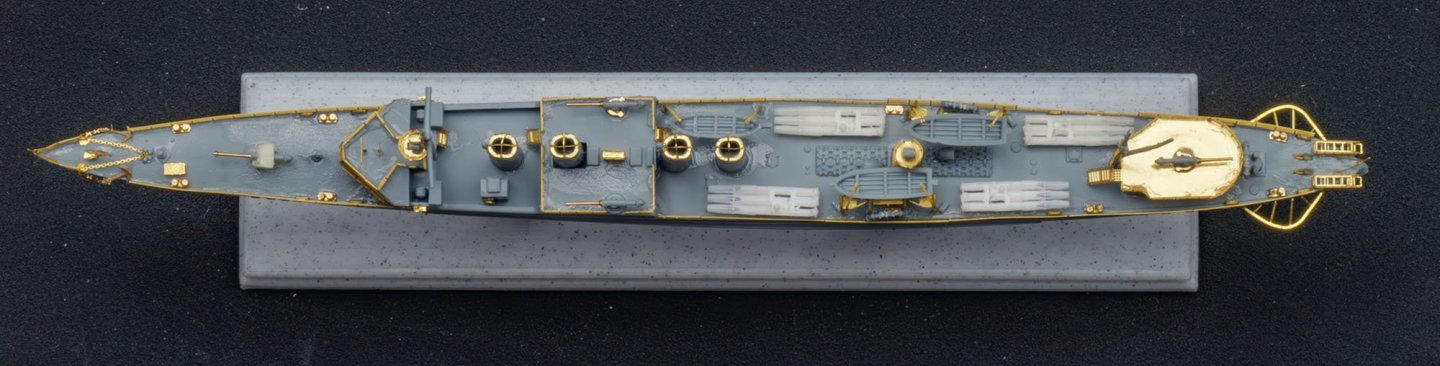

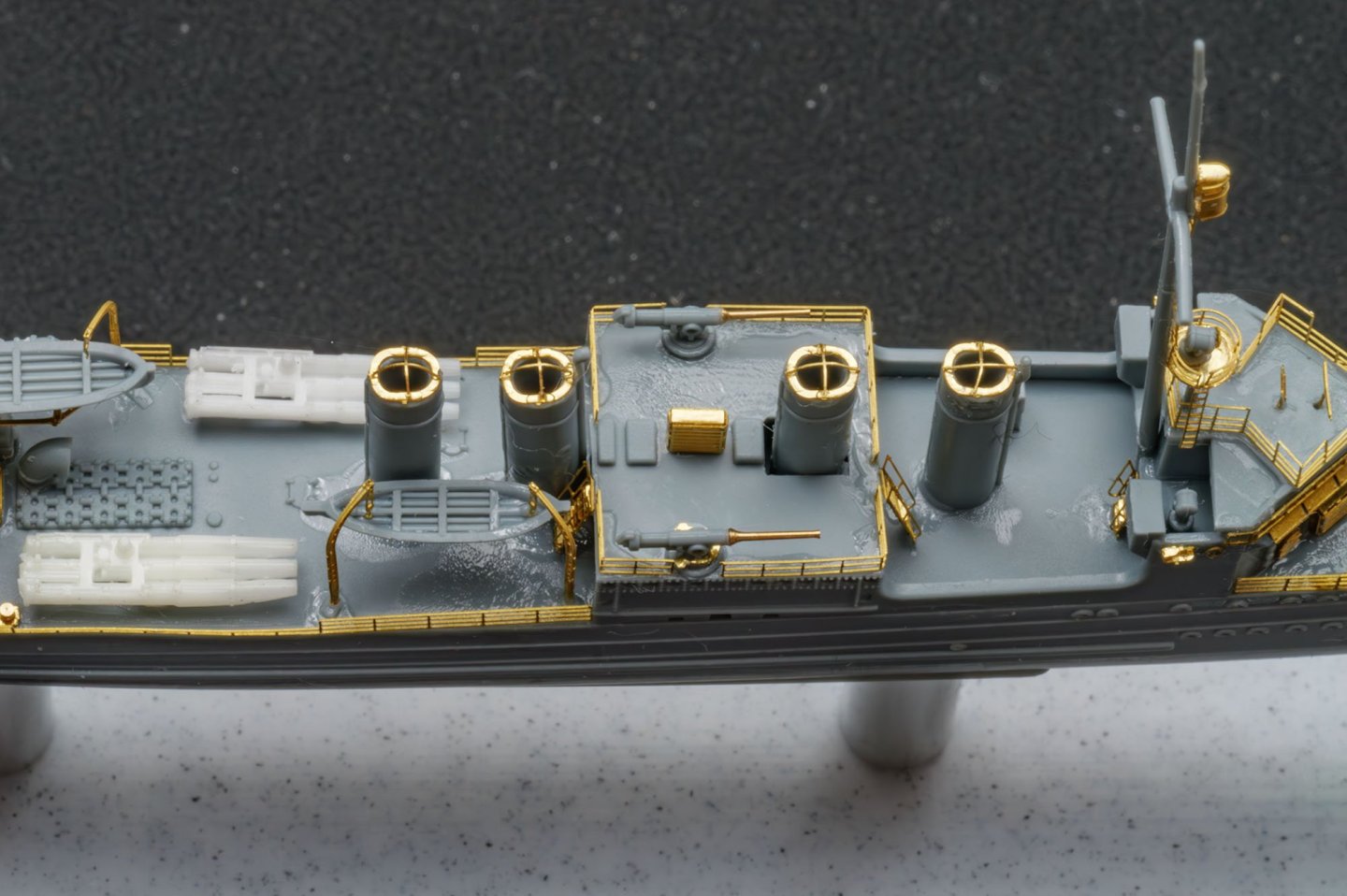

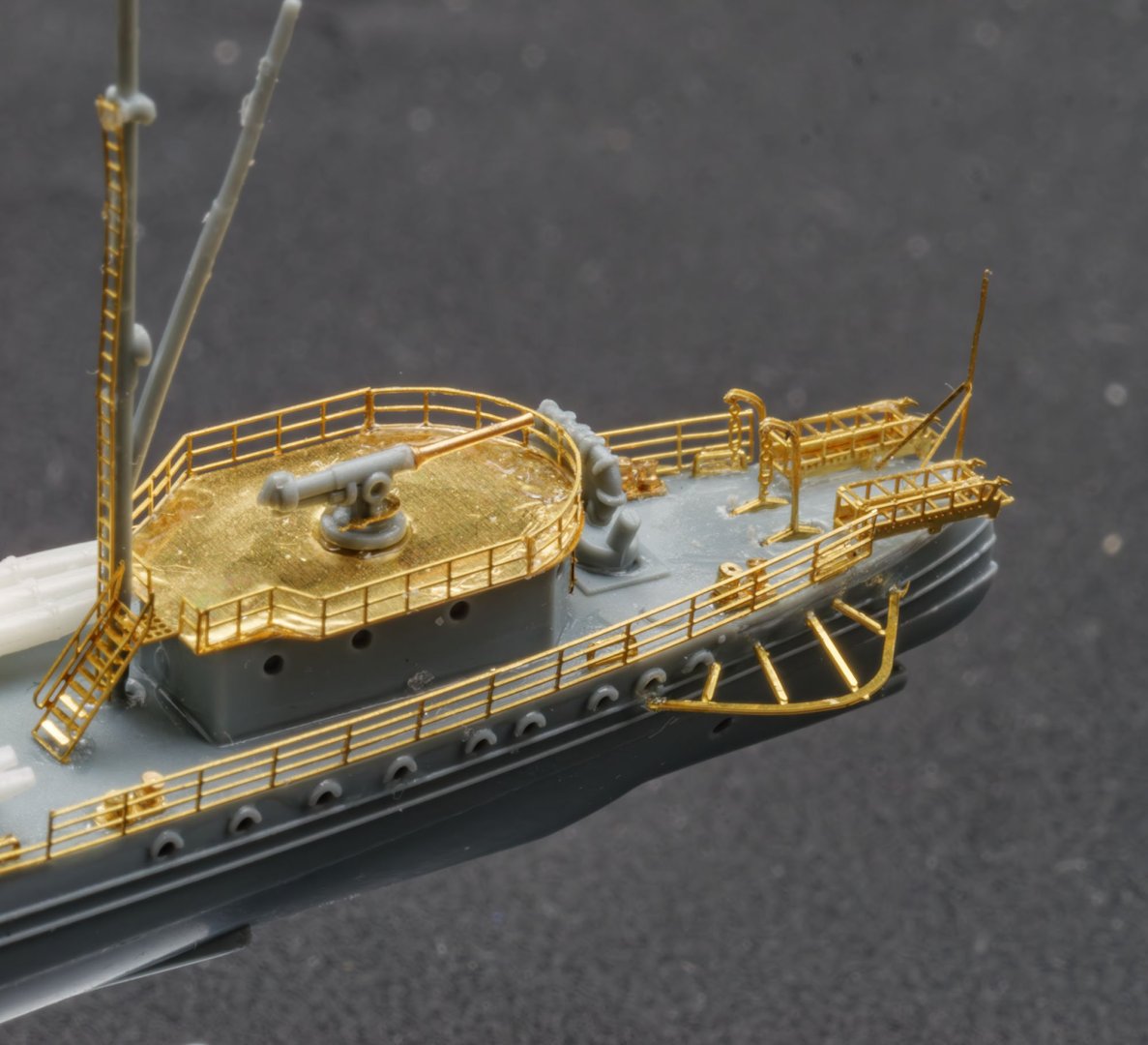

The next project is HMS Invincible 1914 from Flyhawk. The model number is FH1311S deluxe edition. When I started this project a few months ago, I wanted to build a full rigging model. I have studied the aerial antenna spacer and tried to make a 1mm (1/16 inch) long asterisk-shaped spacer. Unfortunately, my attempts didn't work for several reasons. I admitted that I couldn't build the 1/700 antenna spacer yet. This is the reason I built the HMS Naiad without any riggings. I'll build the HMS Invincible without riggings, too. Here is my personal study about WW I RN ship colors. I simply modified the 507A I've used at the Naiad. This is a pretty rough assumption and not based on facts, so please don't mind the source of my colors. I mixed new colors from the Naiad formula. This will be a simpler project because she has no camouflage pattern. Let's build a handling dock. Very comfortable and useful. 😎

- 4 replies

-

- Invincible

- Flyhawk

-

(and 2 more)

Tagged with:

-

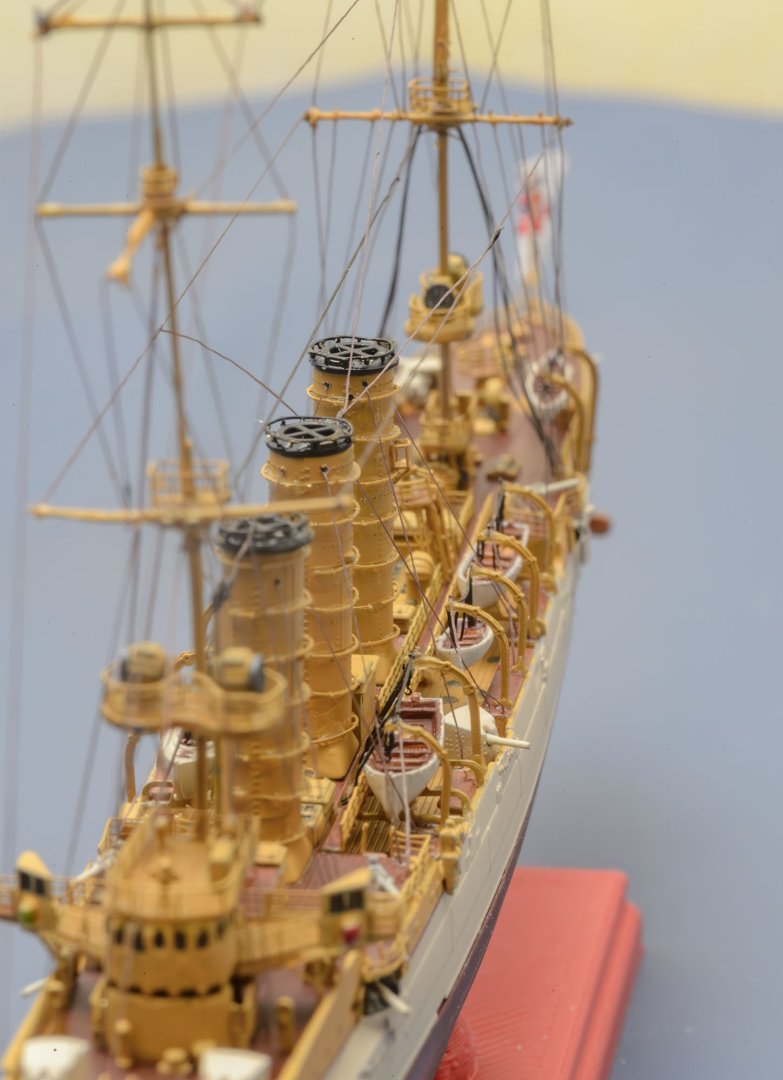

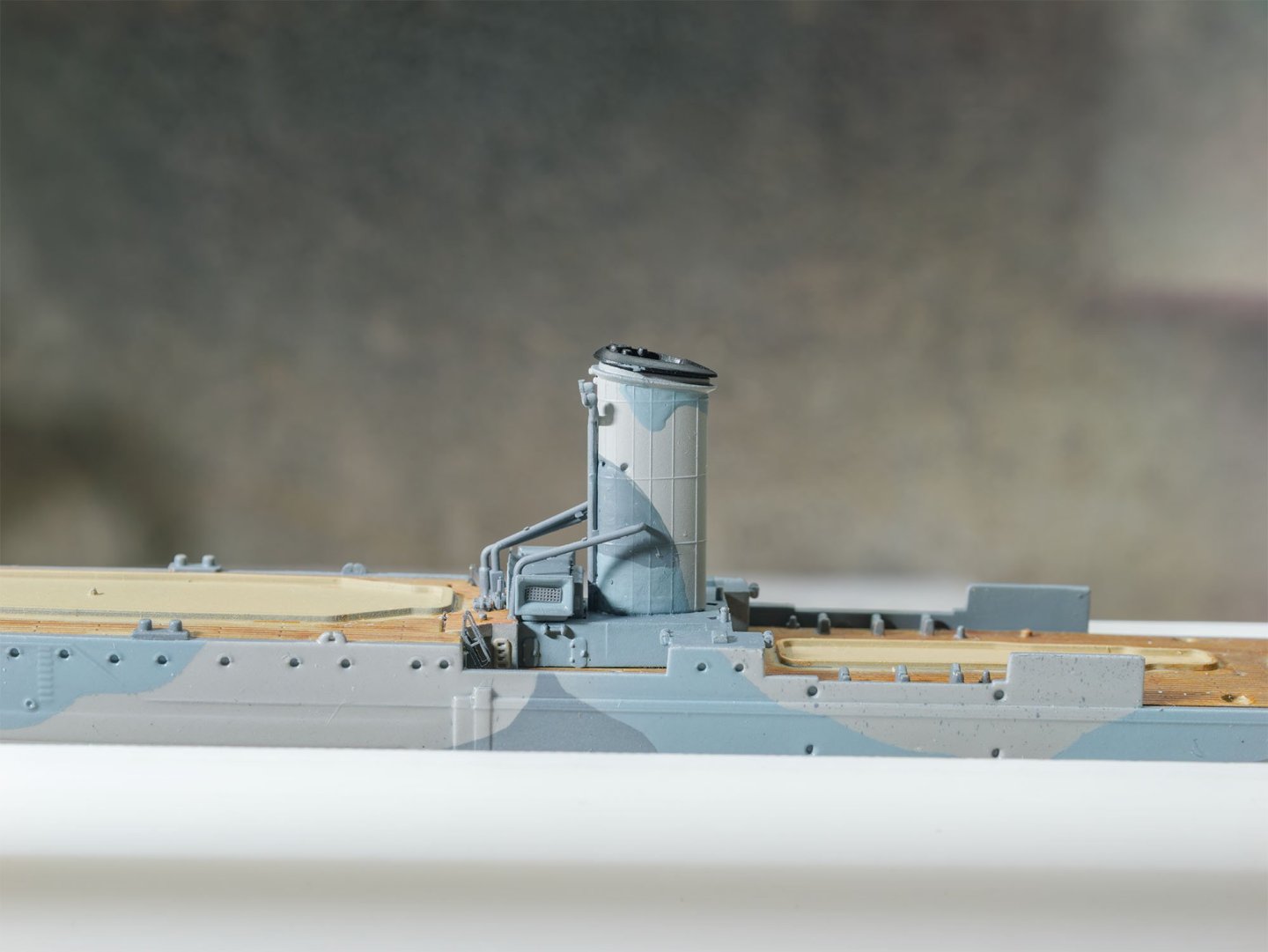

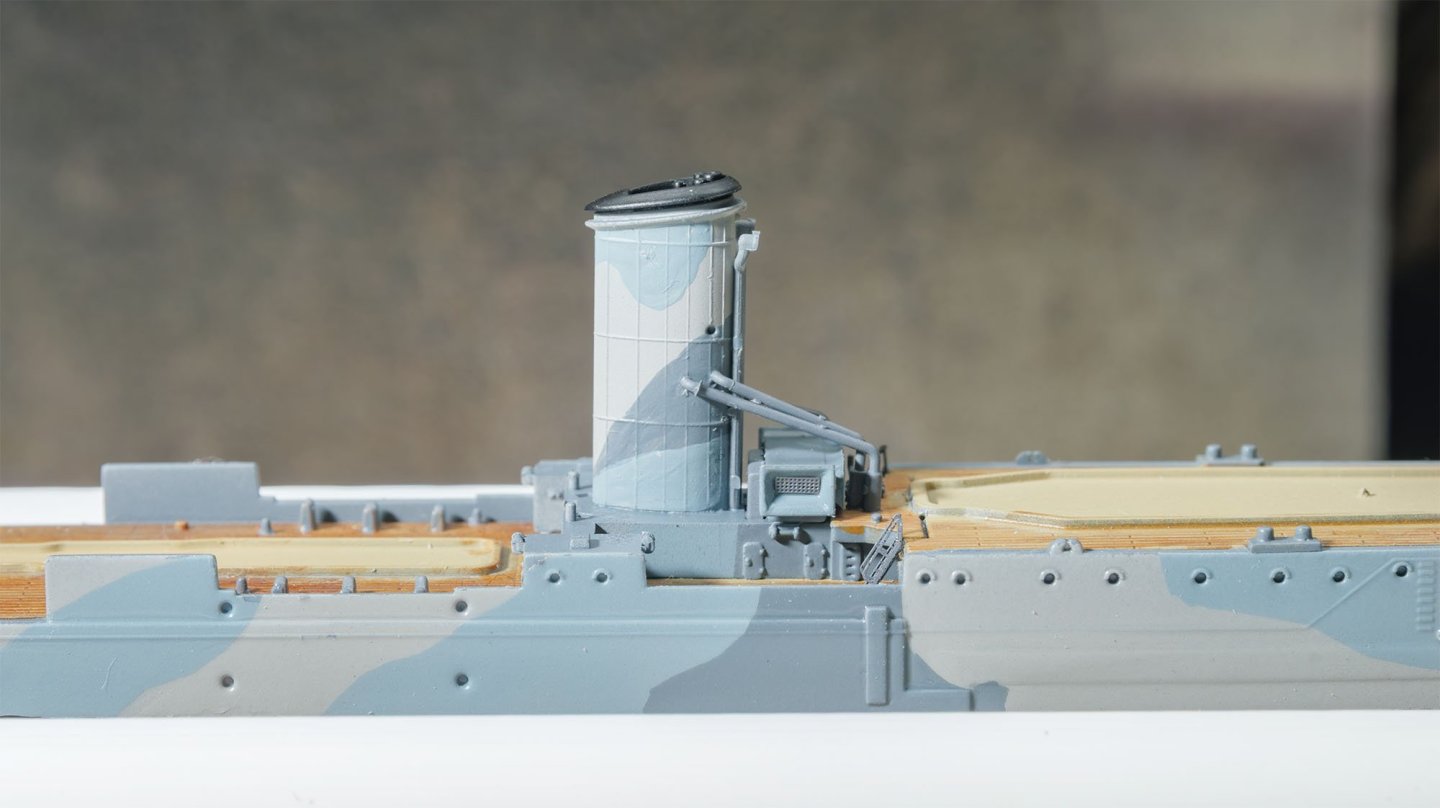

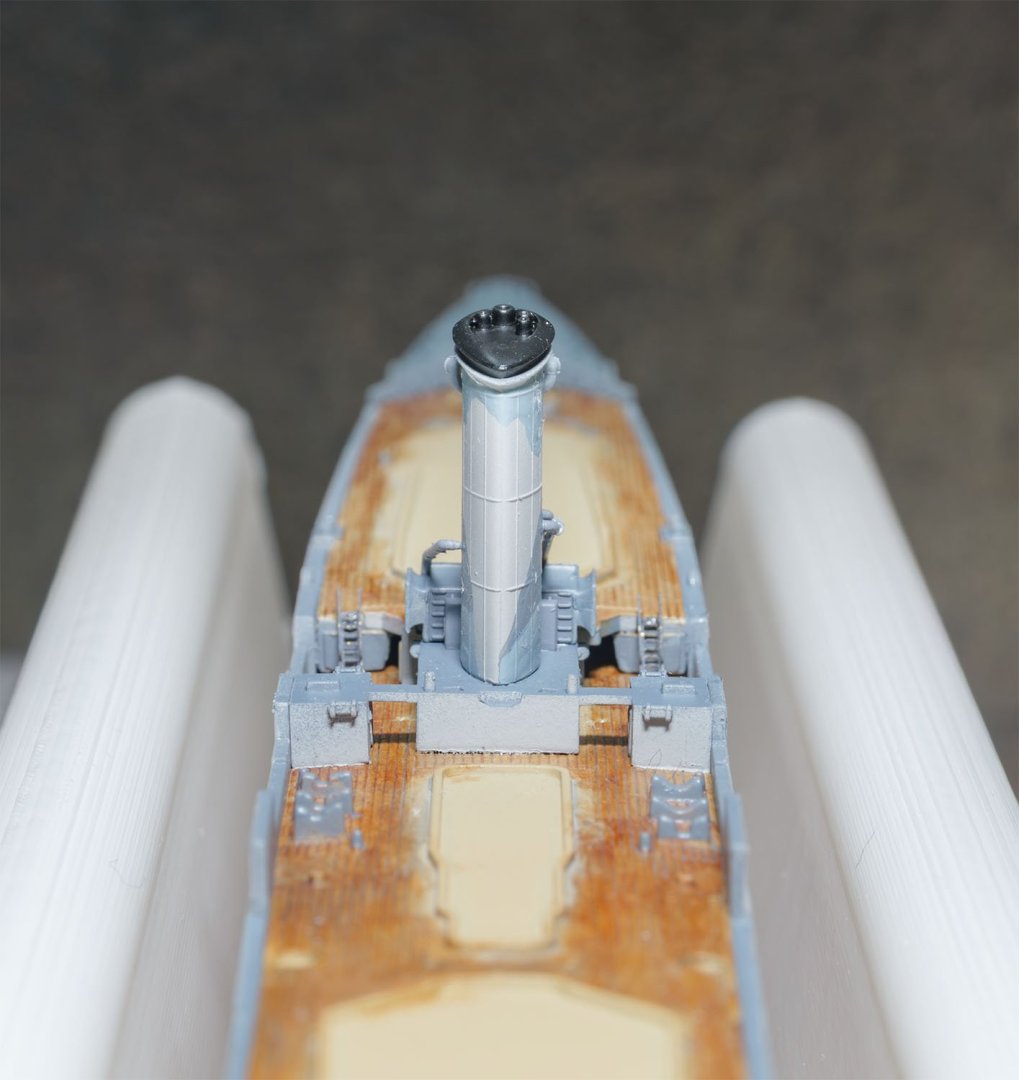

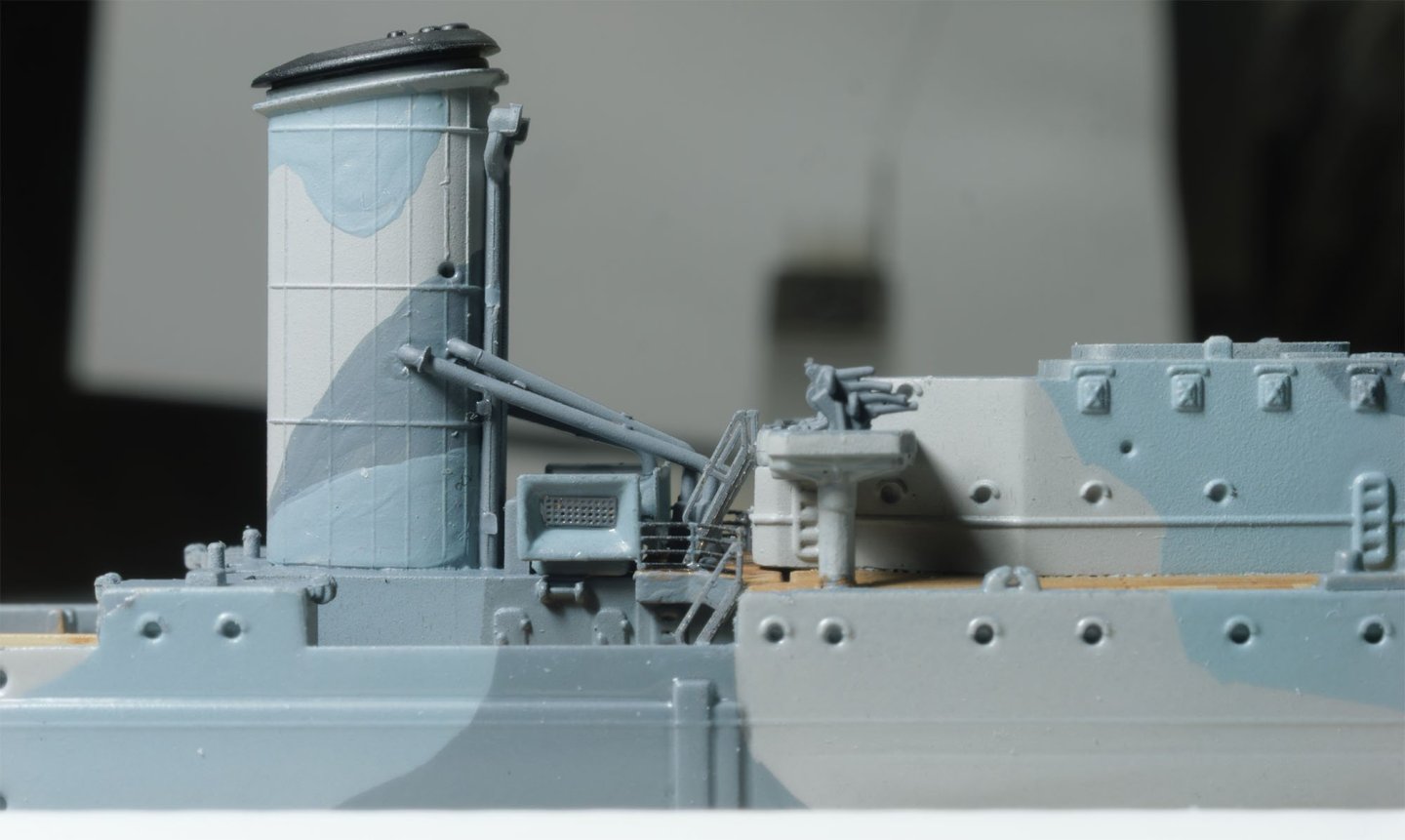

Ok... All Quiet on the first funnel. 2nd funnel. I'm varnishing the gloss surface. I'll wrap it up tomorrow.

-

!!!!!!! I made a critical mistake. The funnel was reversed !!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!! Fortunately, it isn't a model-reset fatal error. I'll buy one more kit and replace the part. The shipping will be 1~3 weeks.

-

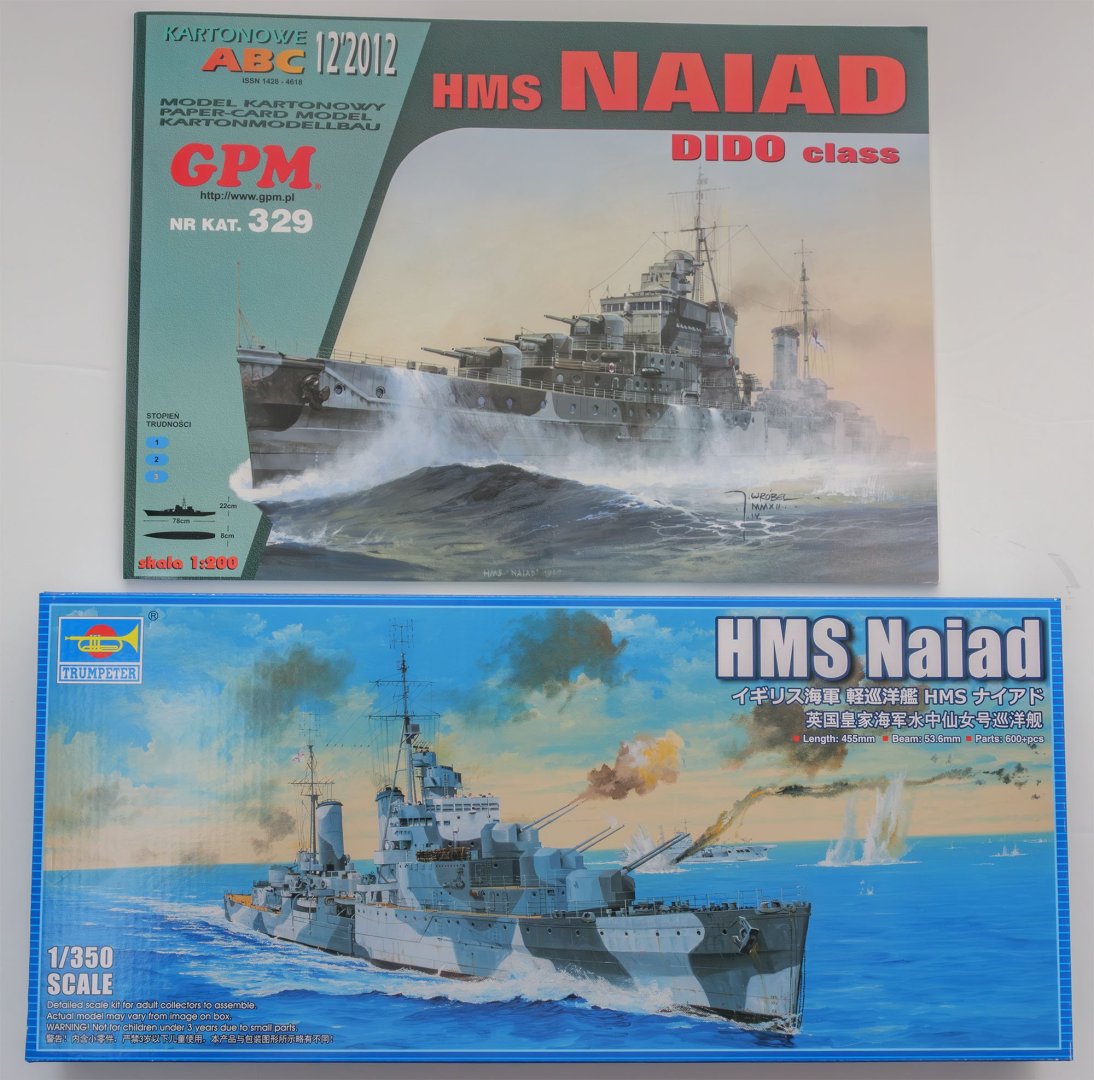

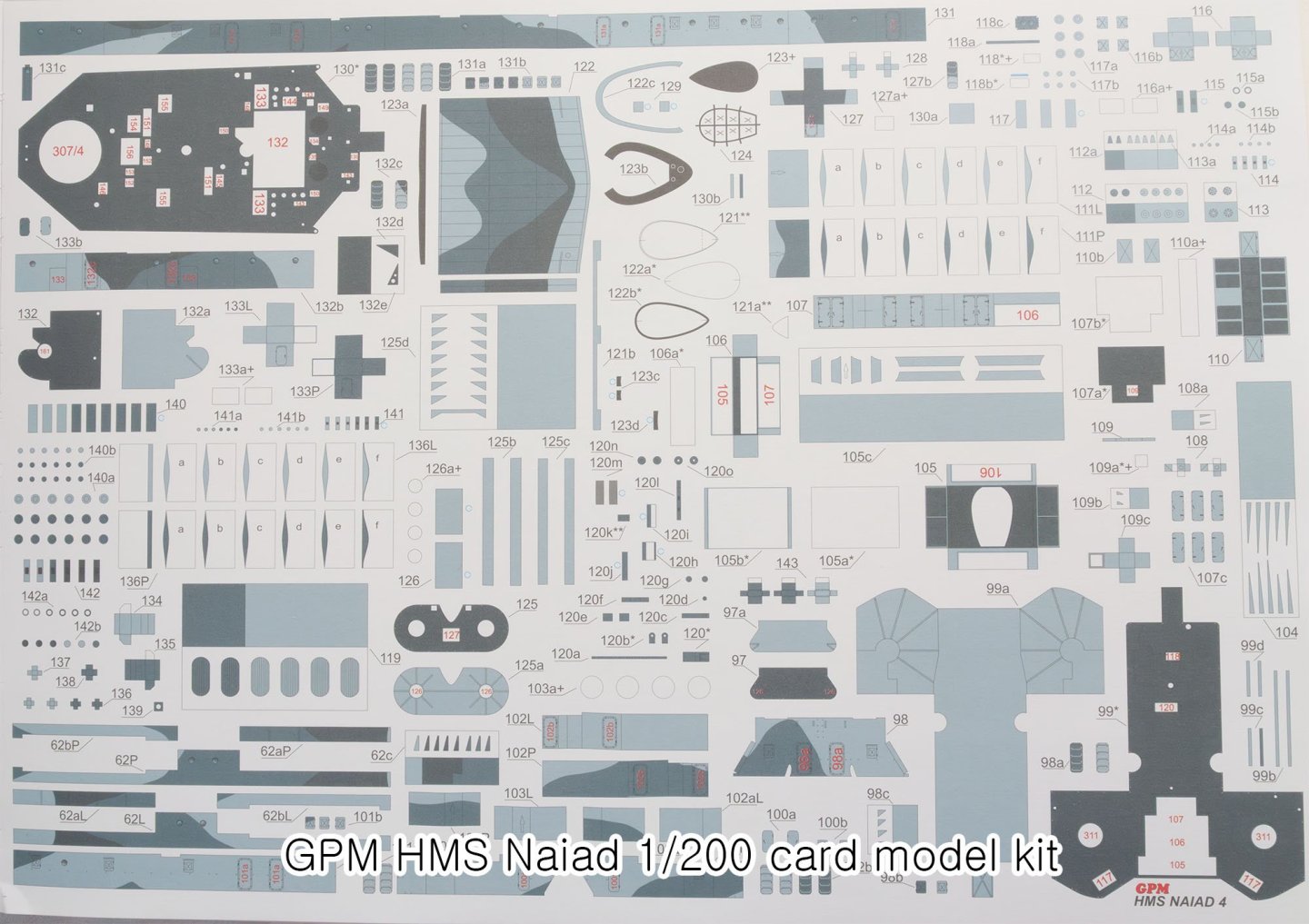

The trumpeter's painting instructions are the same as the 2012 GPM 1/200 card model kit. It is better to ask Roman Cholewiak, who made the GPM kit. Because of the geological and cultural distance between East Asia and Europe, it is difficult to follow the most recent research on the European models. Please understand that this build is for fun and fast building as a beginner. The next project (Trumpeter Naiad 1/350 kit) may be one step better than this. + Before I started this project, I found that the Di-do class cruisers are one of the most controversial topics due to insufficient data. I wanted to build HMS Sirius, but now I take a step backward and am waiting for new kit, which should throw new fuel on a Di-do fire.

-

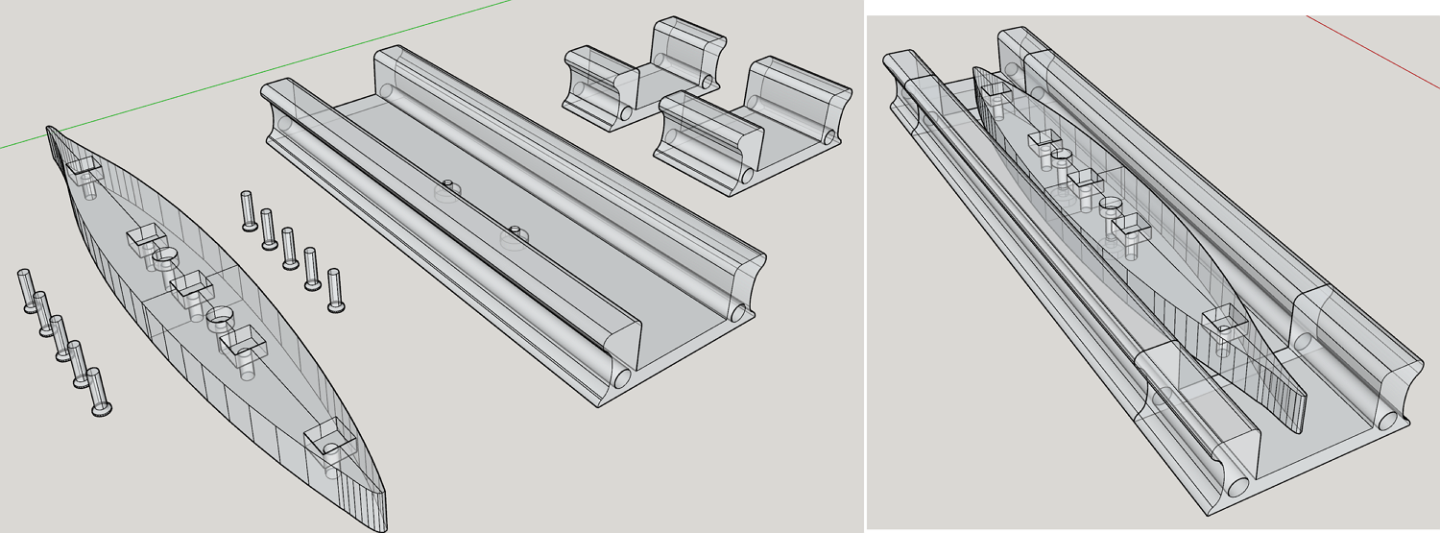

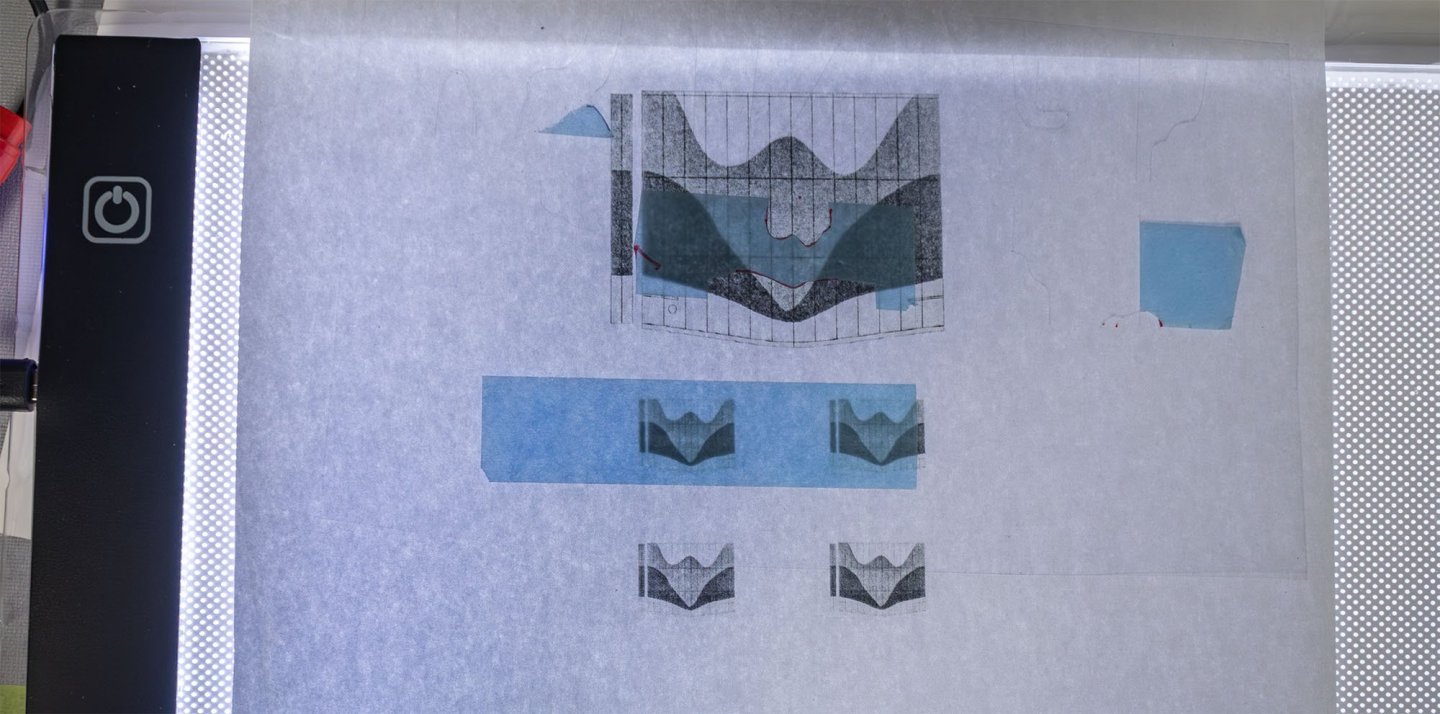

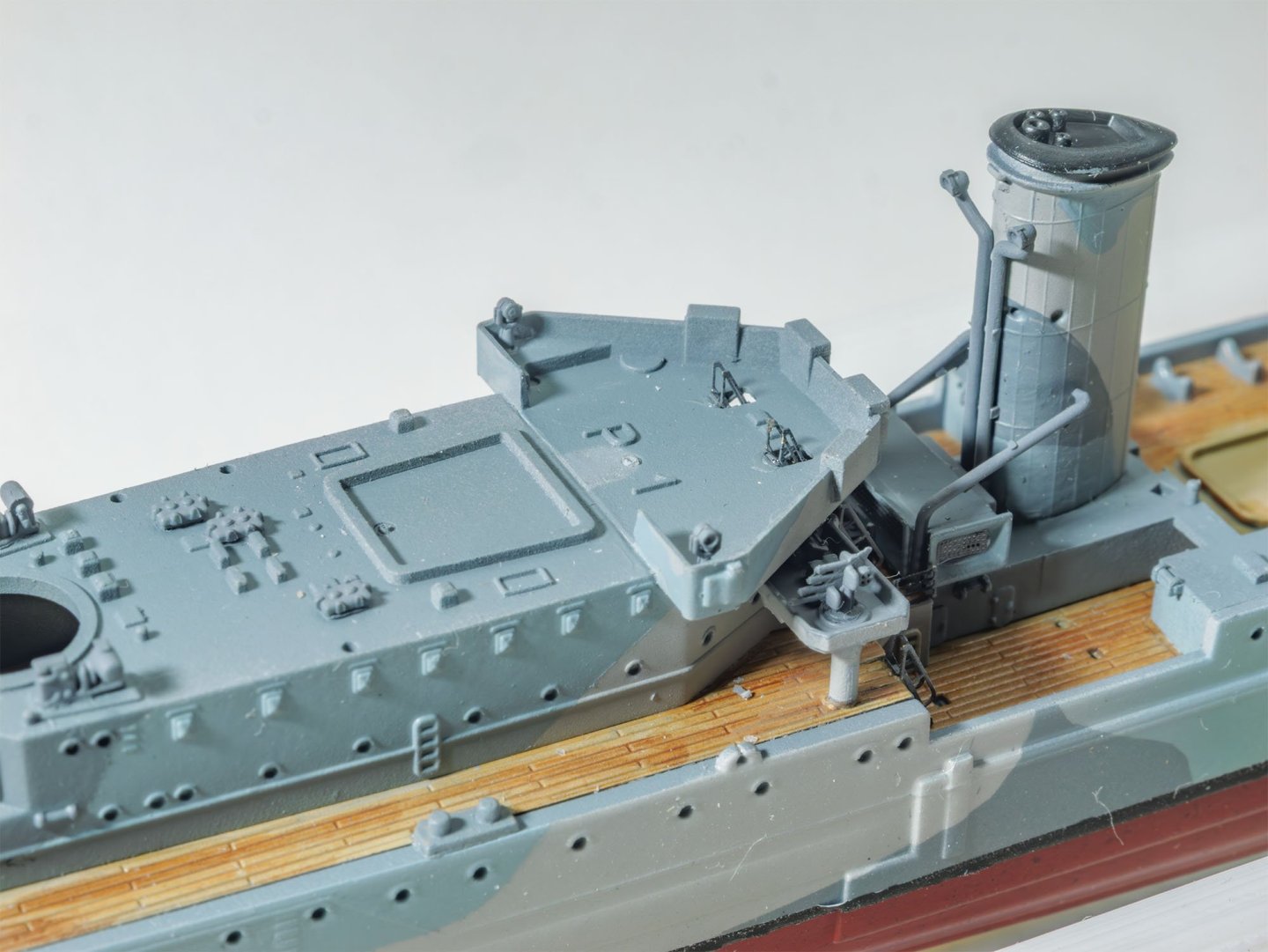

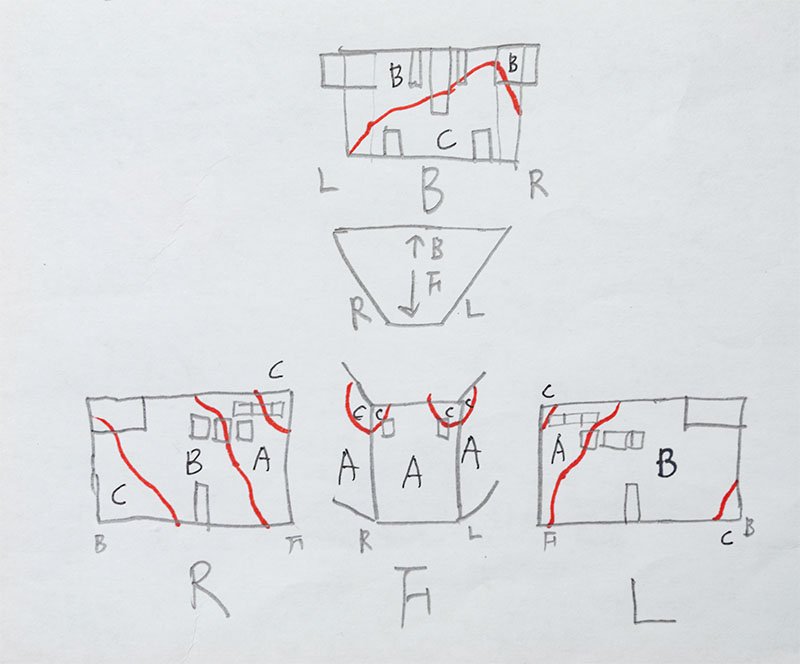

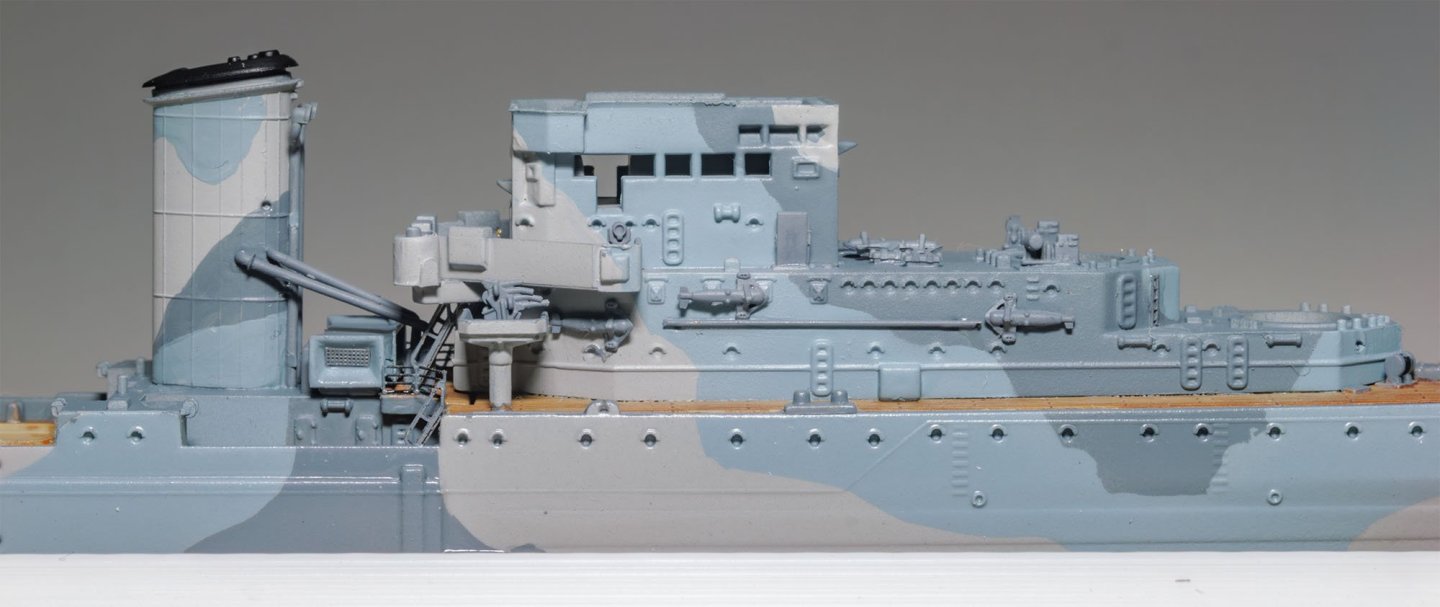

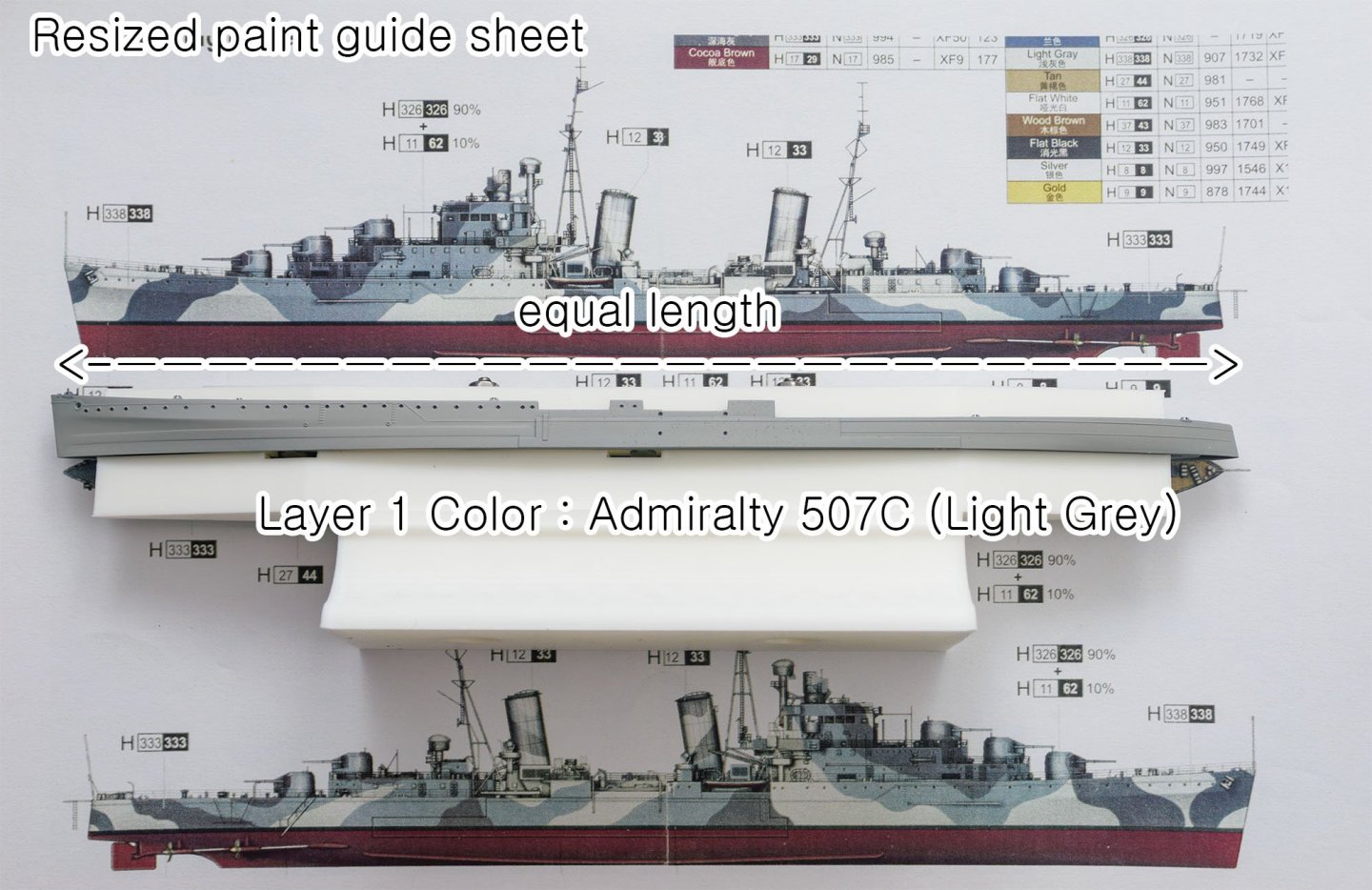

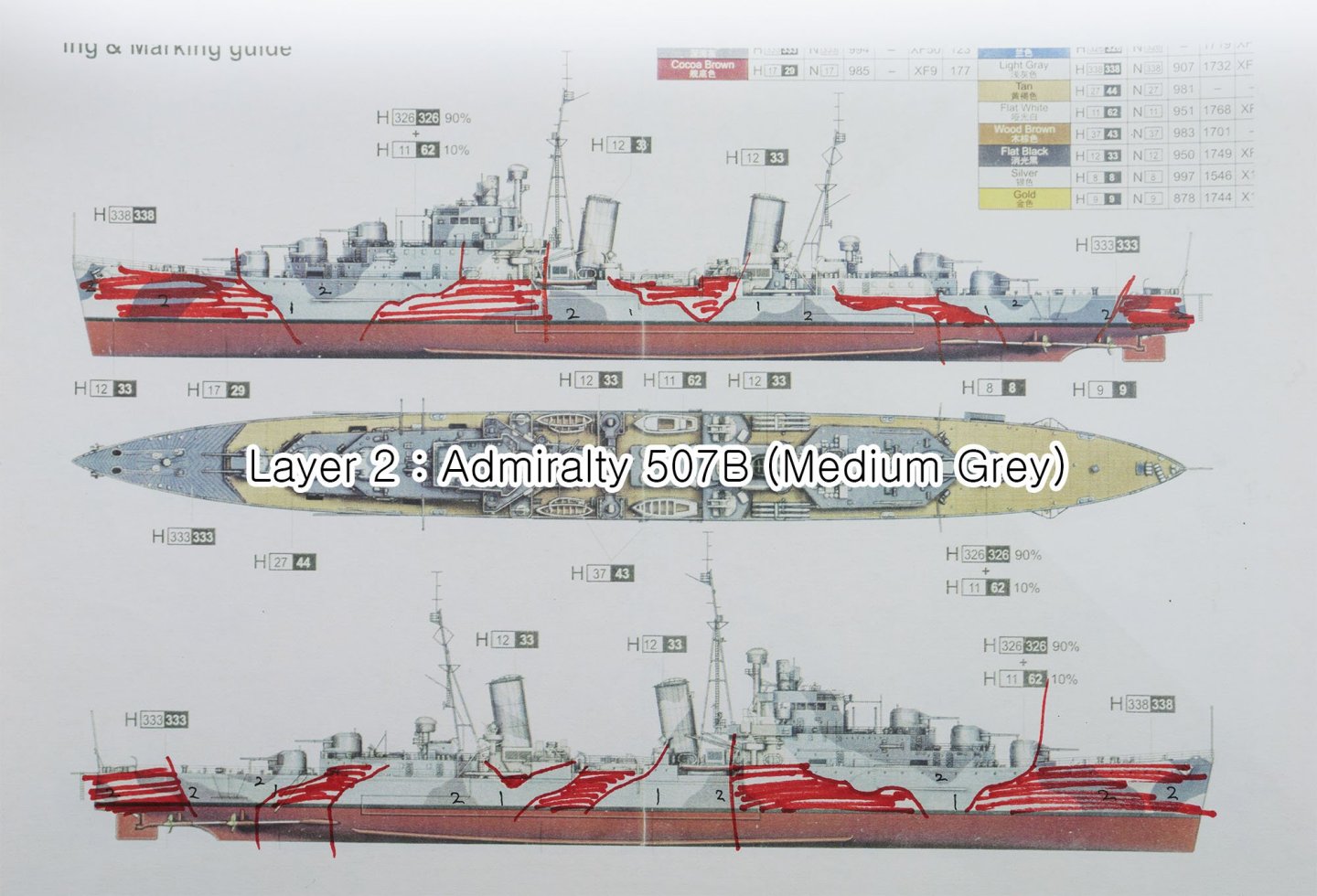

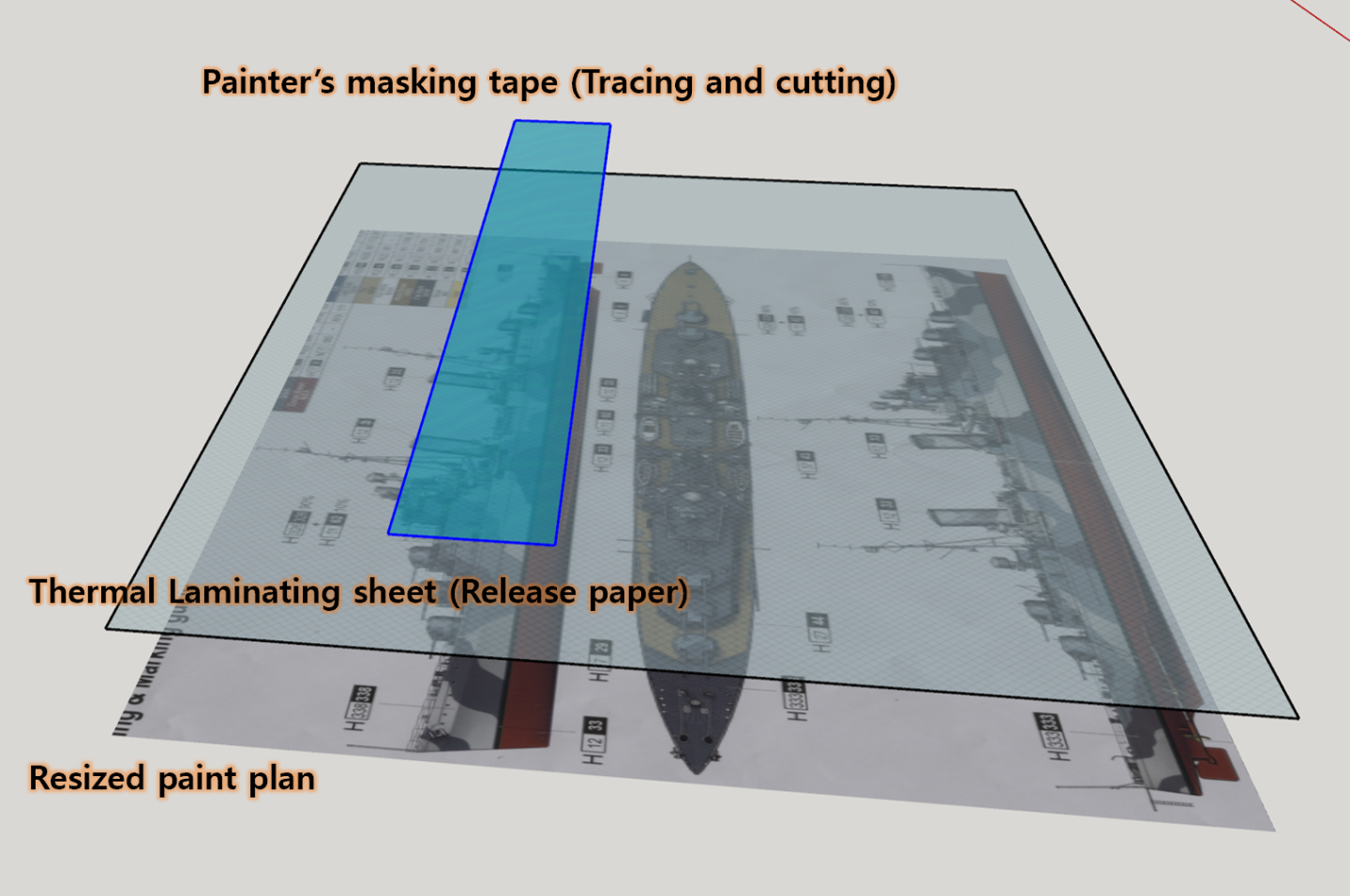

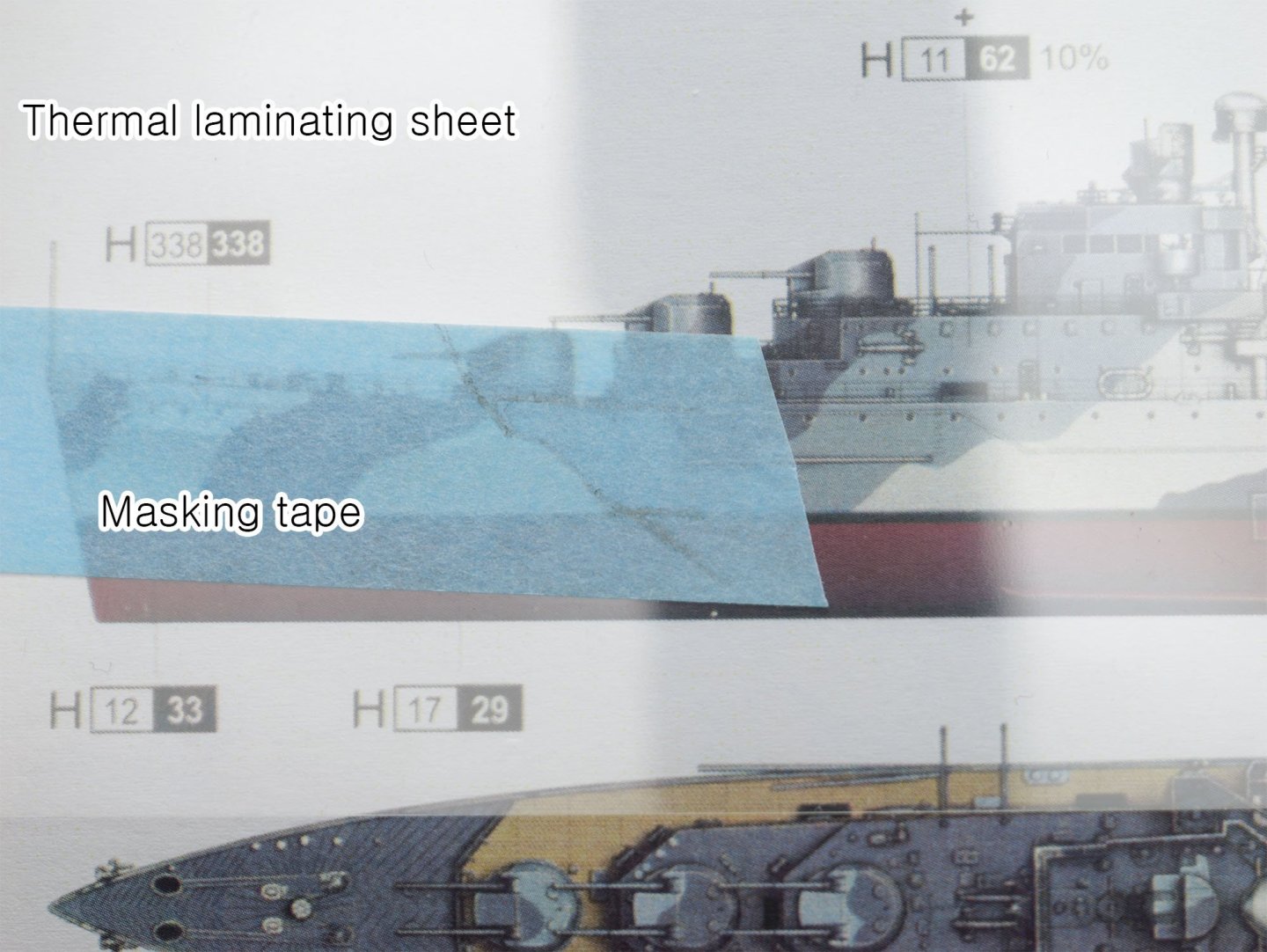

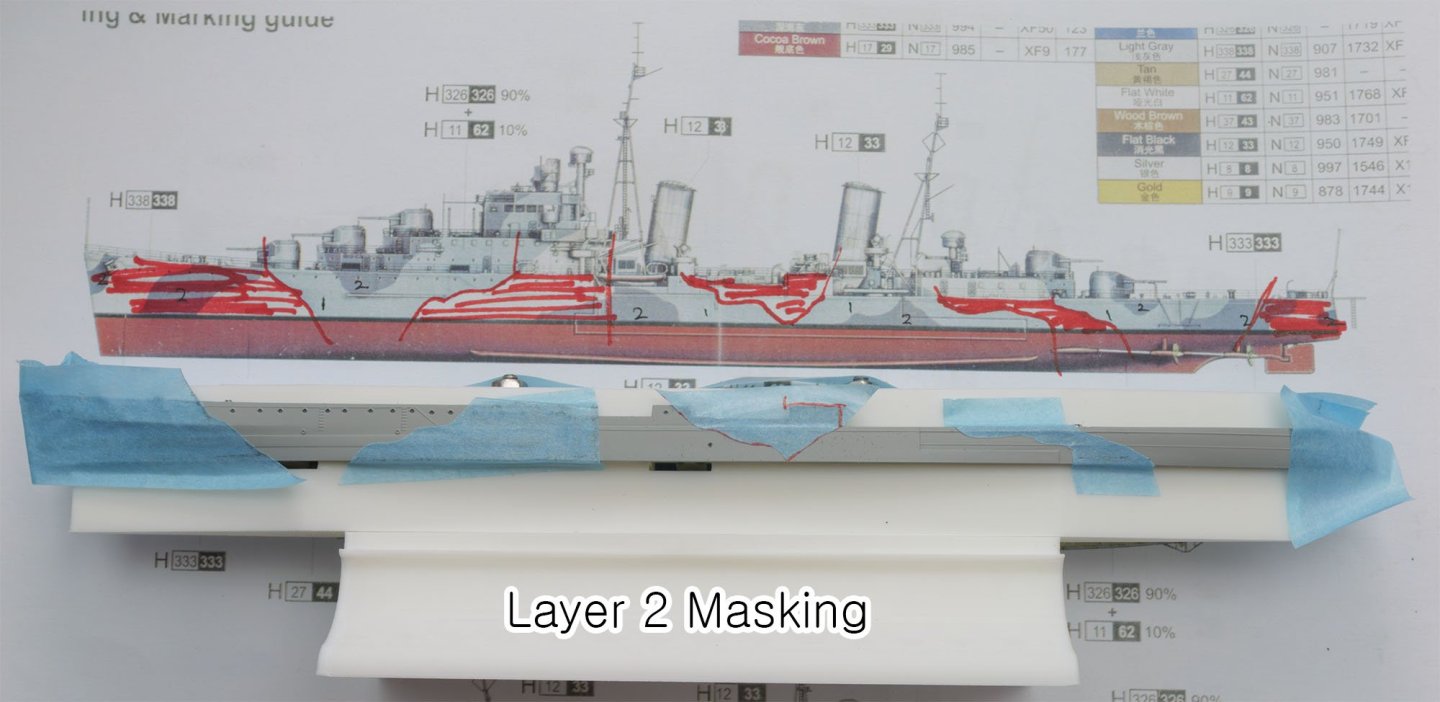

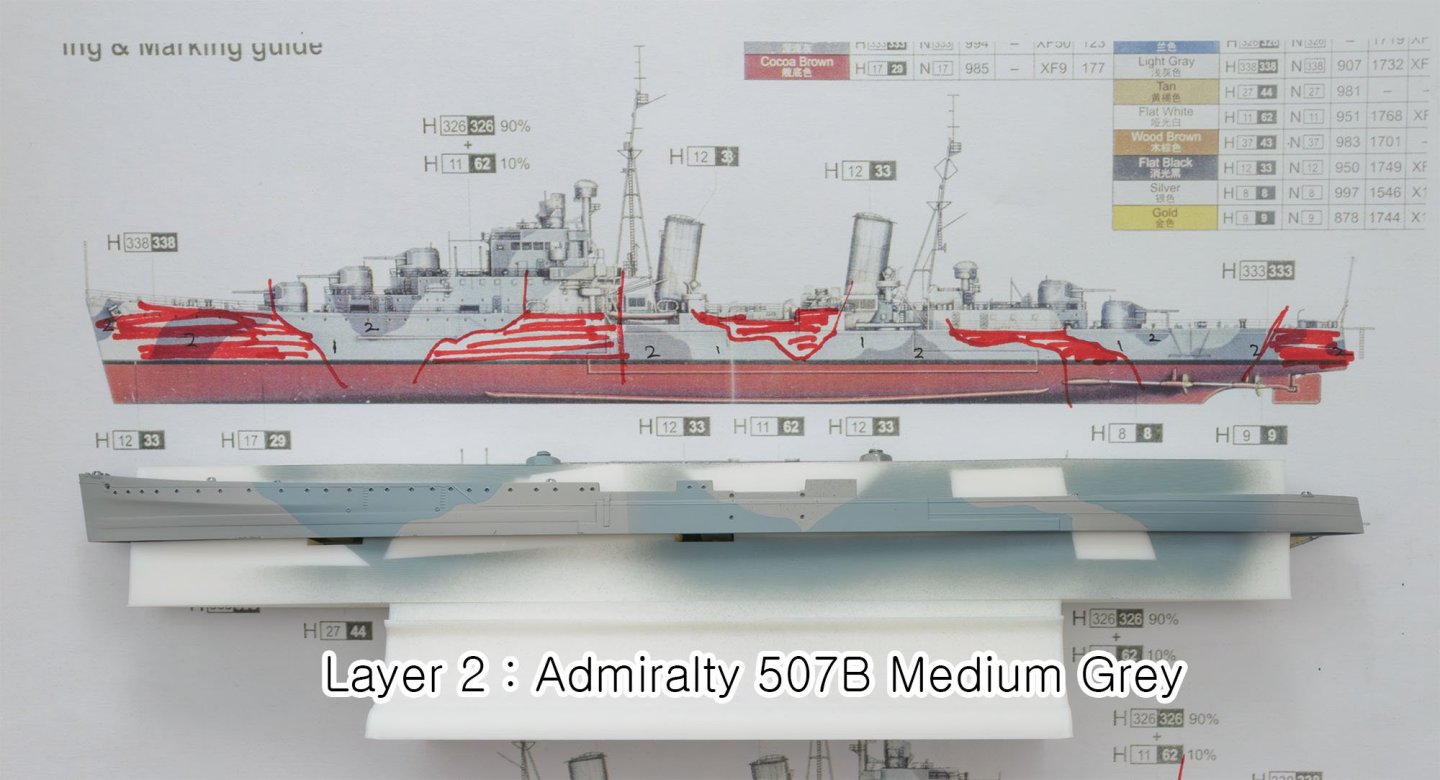

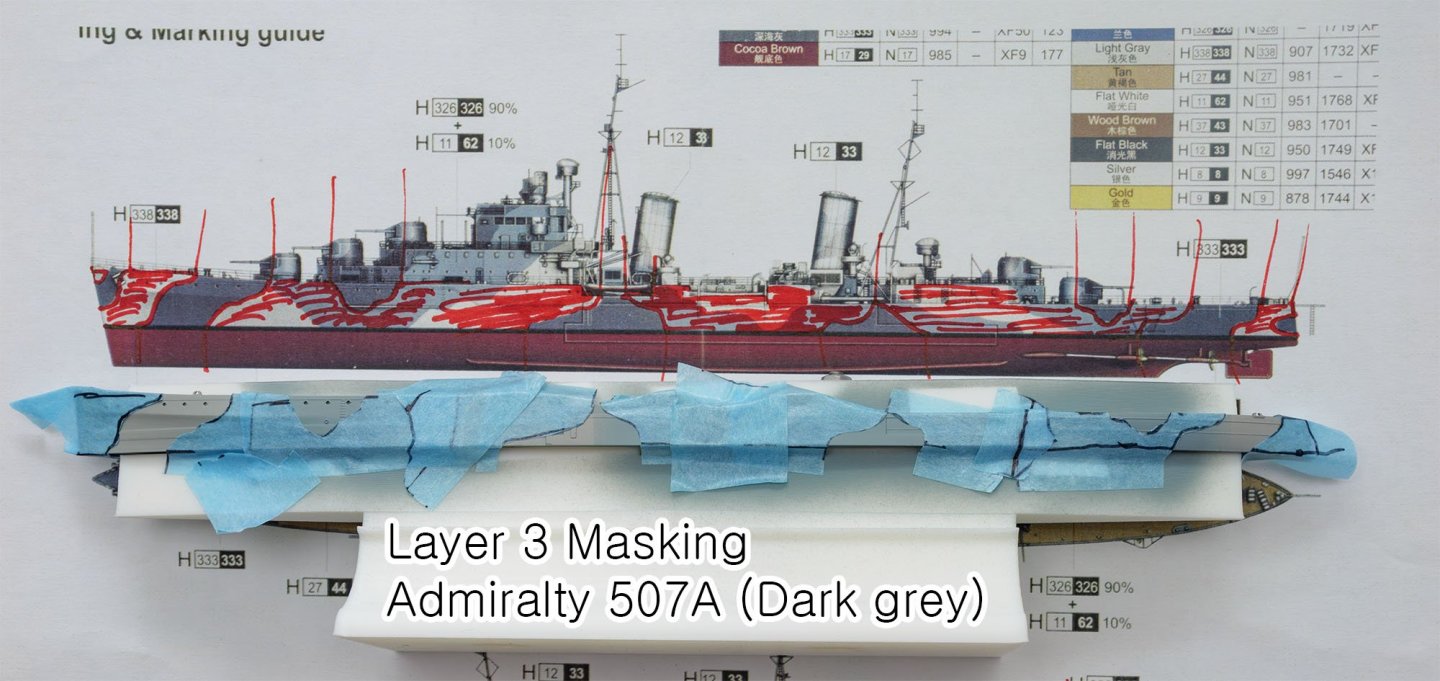

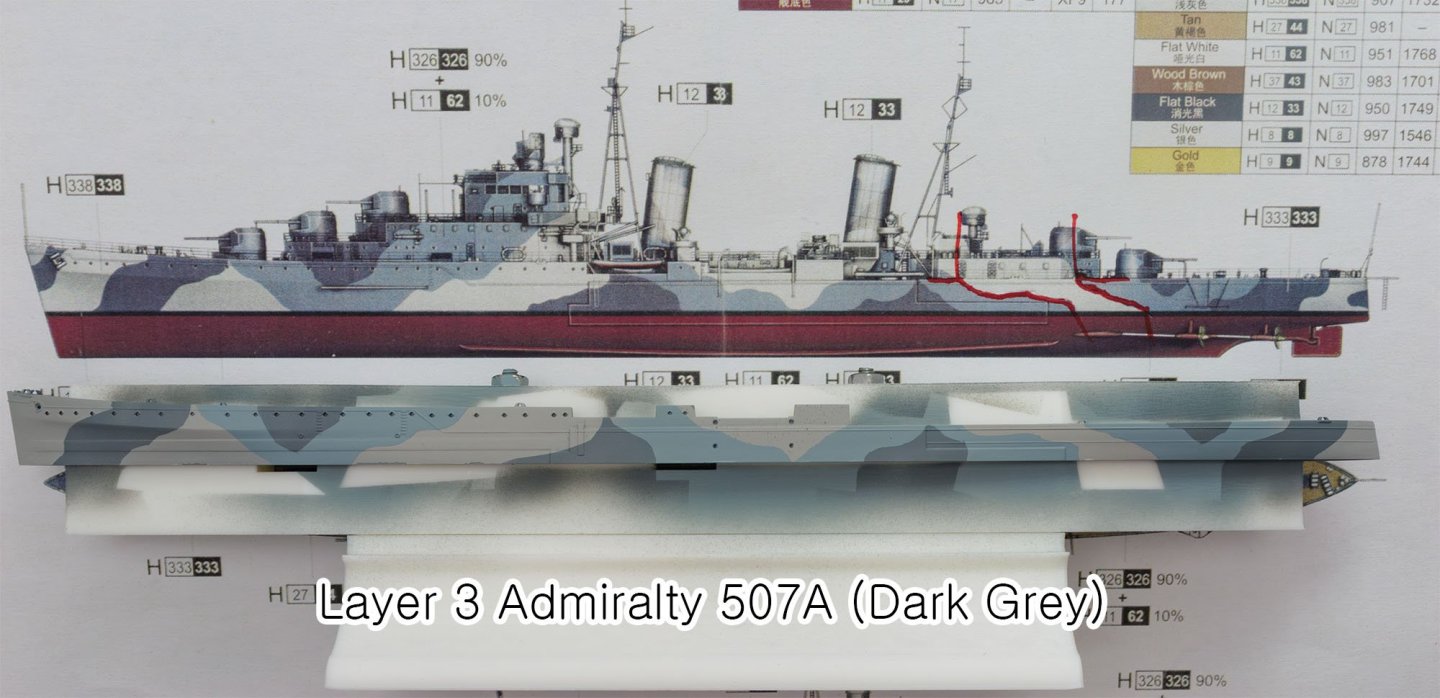

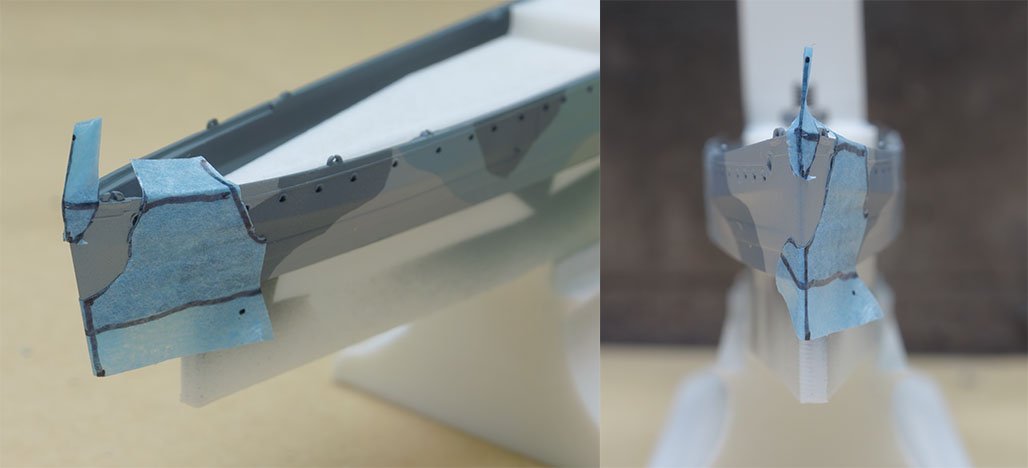

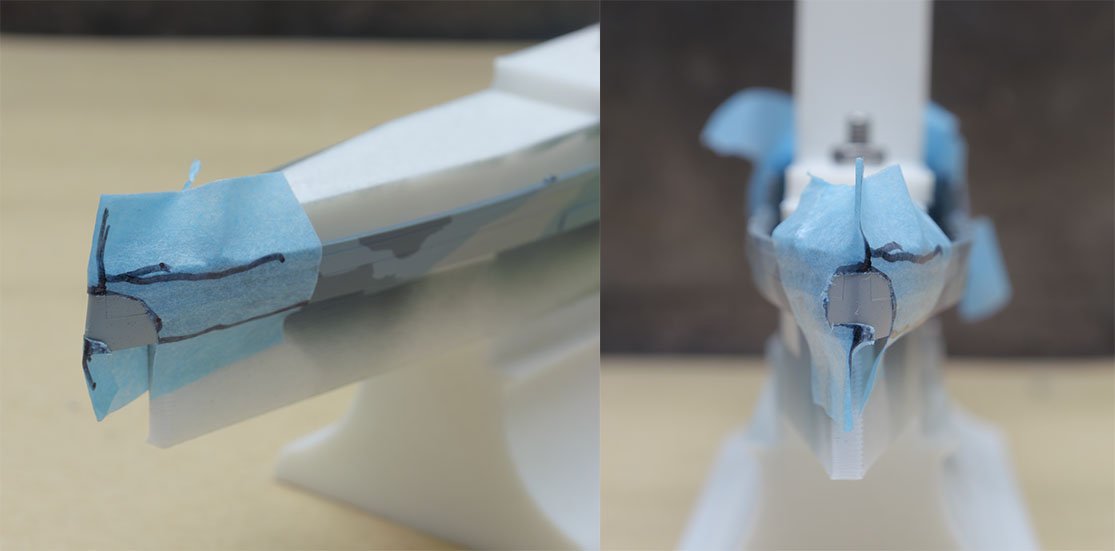

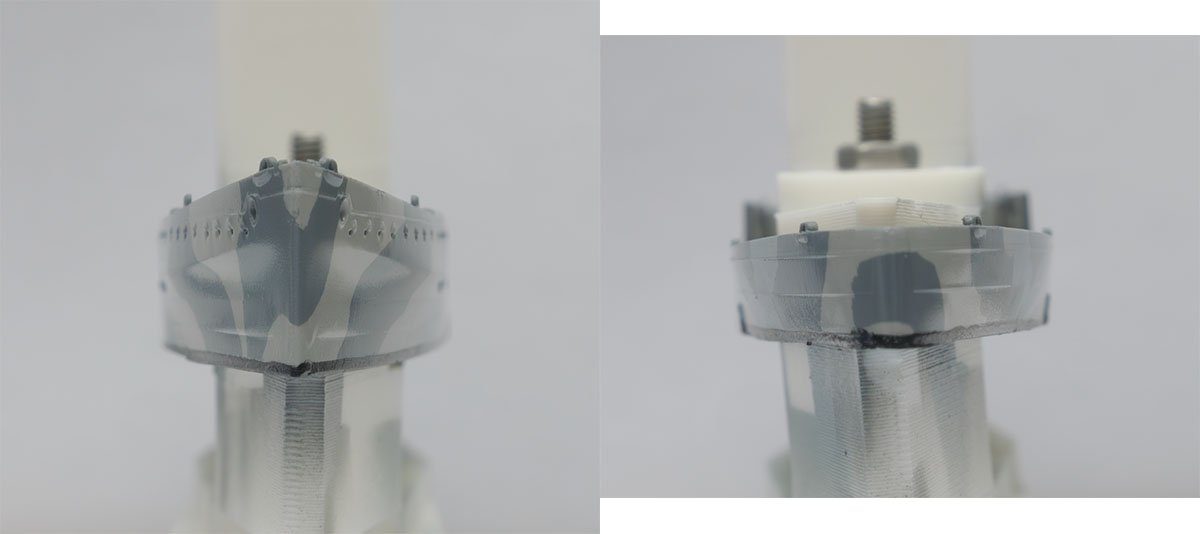

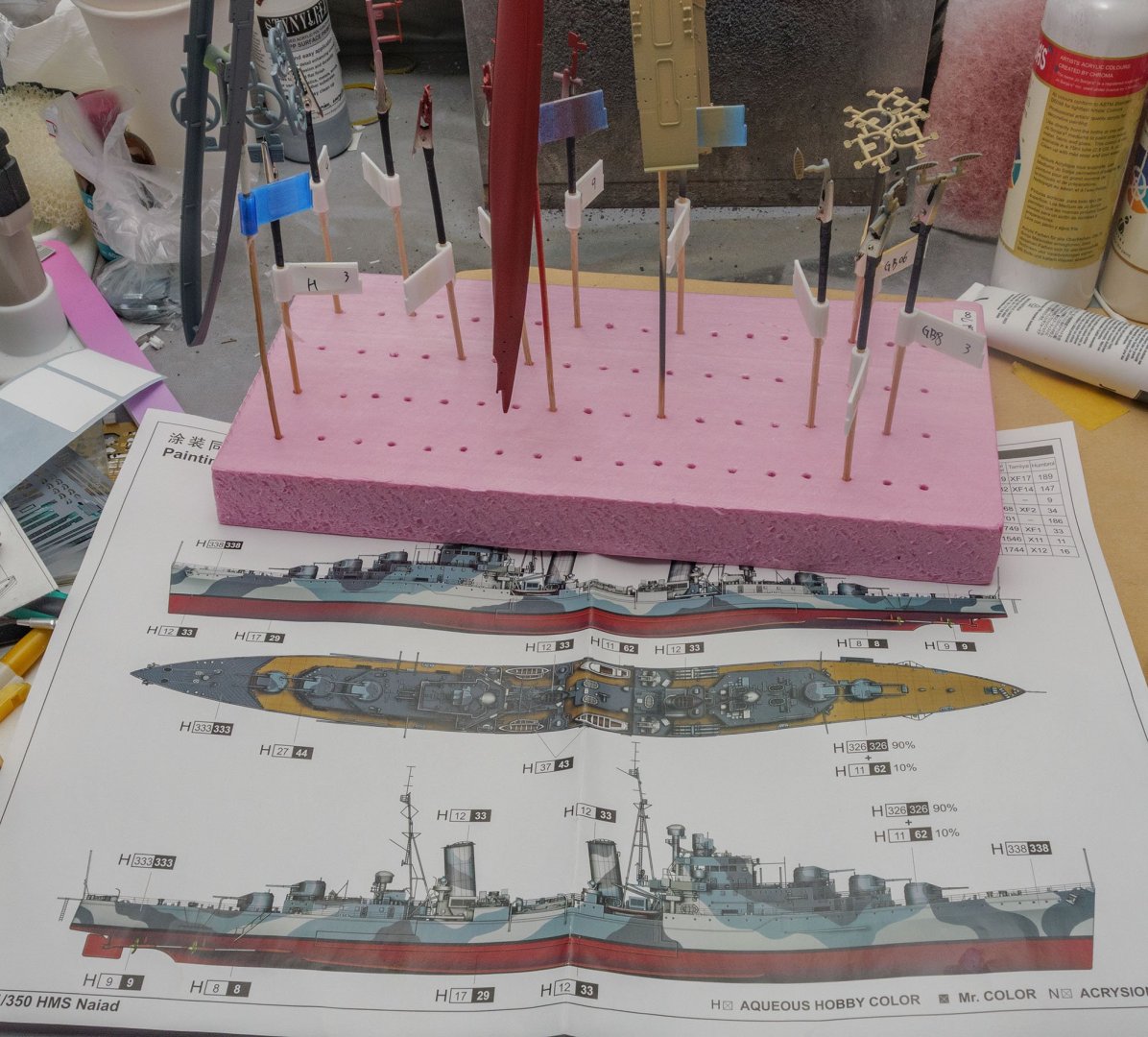

I designed and printed handling dock for painting the upper hull only. Also, I resized the painting guide sheet to trace the camouflage patterns. This method is very handy and fast. Not perfect, but 95% accurate. Here is the final result. 😎 I made a larger handling dock for cruisers. It is simply a bigger version of the 1/700 destroyer docks I've used.

-

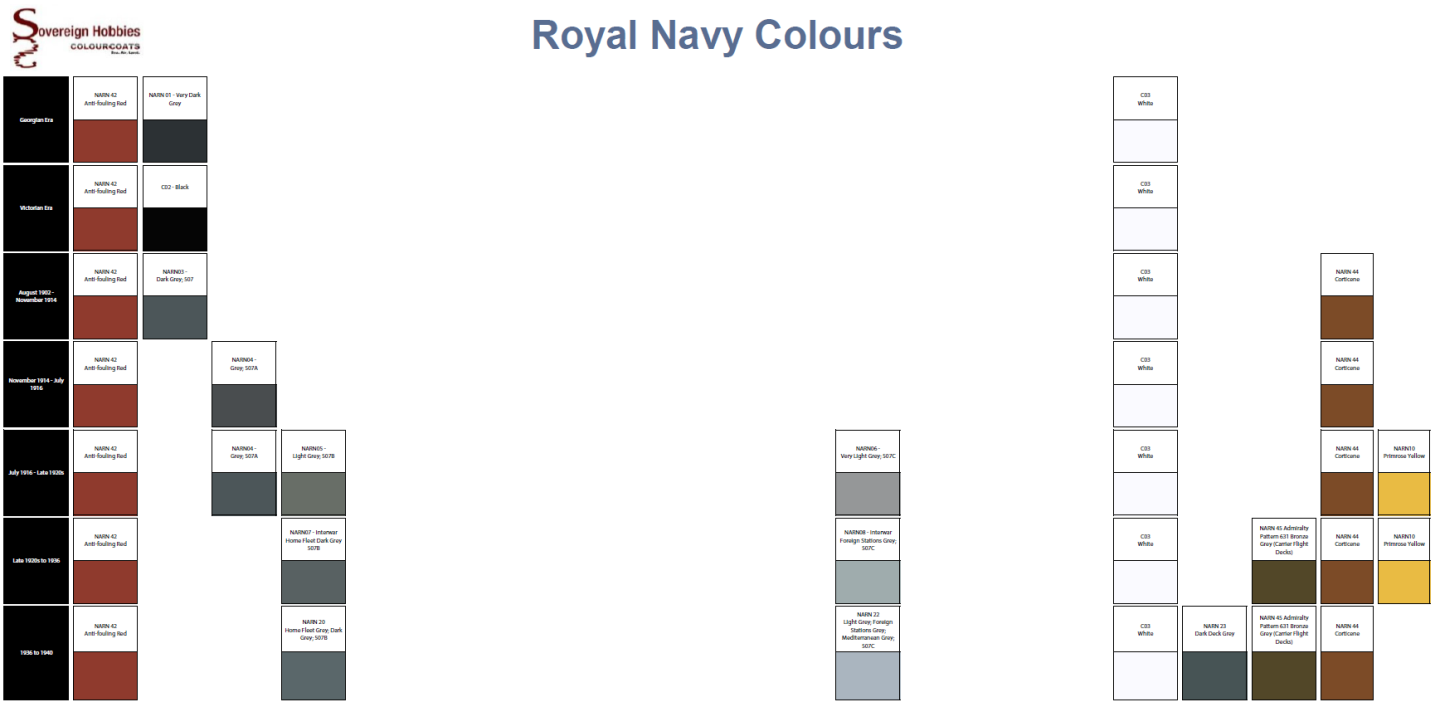

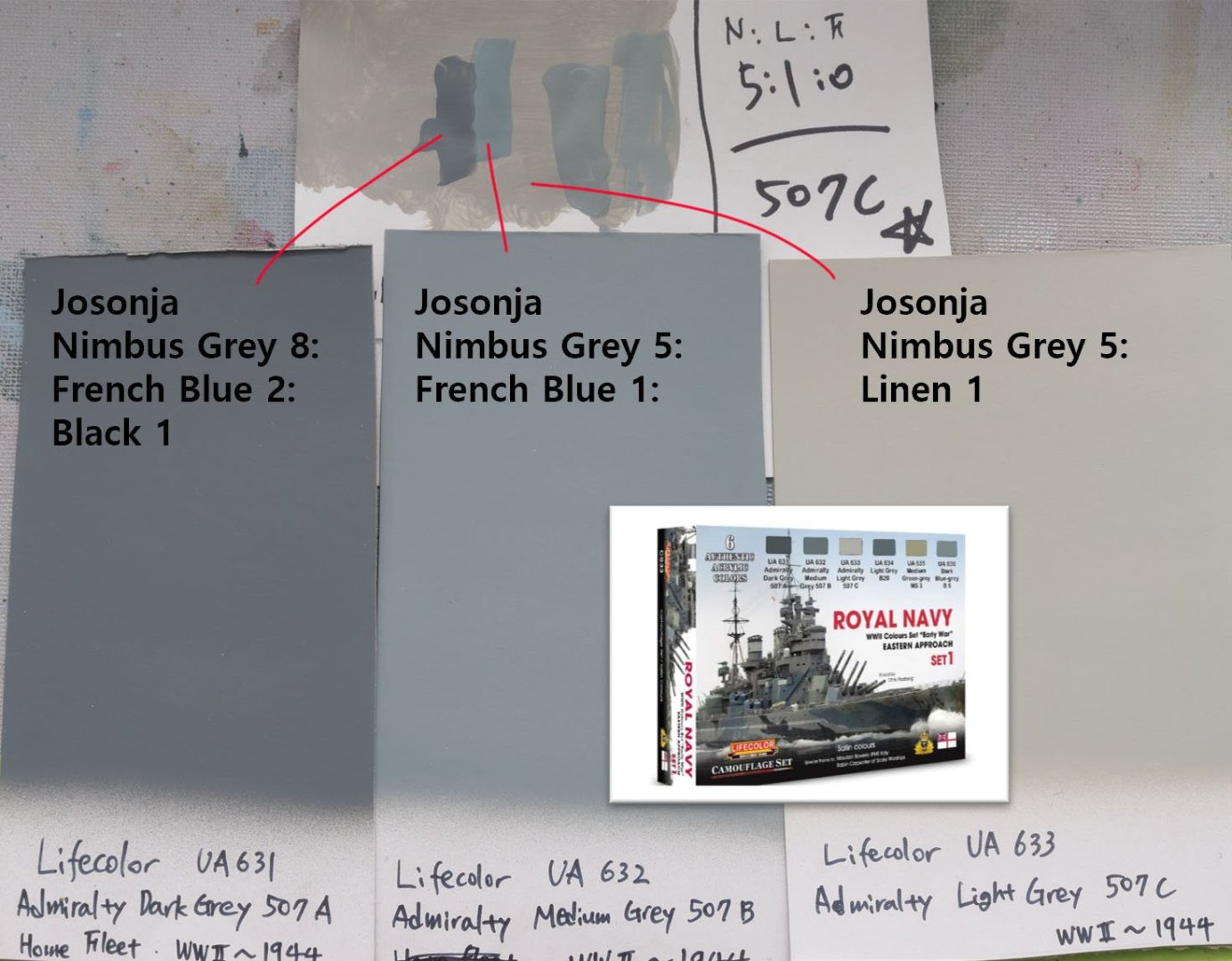

This is the first time I seriously paint the WWII RN ships. The kit is Flyhawk - HMS Naiad - 1/700 - FH1112. I used two main references to understand the camouflage patterns. The GPM 1/200 scale card model kit offers almost everything I need. Also, I mixed 90% percent accurate colors. The color reference is from Lifecolor RN set. (Source : https://web.archive.org/web/20241107004340/https://www.sovereignhobbies.co.uk/pages/royal-navy-periodic-table-of-paints ) The research pages of the Sovereign Hobby were the best of the best. I became familiar with the USS camouflage scheme at the site. Unfortunately, the Sovereign Hobby shut down last year. It is a reason I relied on the Lifecolor paint. I thank them very much. To ensure that the entire RN fleet in the future matches well, I'll use the same mixed colors for future RN kits. 😎

-

https://thenrg.org/events/workshops I found the source. There are three "Strategic detailing" online workshops presented by Chuck Bauer.

-

And Royal Navy East Asia fleets in 1910s also had similar grey color paint. I think your sources are right. It is better to follow the first color scheme in the Flyhawk manual.

-

The SMS Emden was the most successful ship in the German navy's history. She pretended to be HMS Yarmouth of the Royal Navy. Her pirate adventure and the last survivors' voyage around the world were very interesting. https://en.wikipedia.org/wiki/SMS_Emden

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.jpg.7fe72818d54539f20b09a2fcc2313c84.jpg)