Rick310

NRG Member-

Posts

837 -

Joined

-

Last visited

About Rick310

- Birthday 06/30/1953

Profile Information

-

Gender

Male

-

Location

Belfast, Maine

-

Interests

Flying, model ship building and maritime antiques and history

Recent Profile Visitors

-

Canute reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Canute reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

hof00 reacted to a post in a topic:

Flying Cloud 1851 by hof00 - Mamoli - 1/96 - American clipper

hof00 reacted to a post in a topic:

Flying Cloud 1851 by hof00 - Mamoli - 1/96 - American clipper

-

Ryland Craze reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Ryland Craze reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

thibaultron reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

thibaultron reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

thibaultron reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

thibaultron reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Jared reacted to a post in a topic:

Flying Fish by Jared - FINISHED - Model Shipways - 1:96

Jared reacted to a post in a topic:

Flying Fish by Jared - FINISHED - Model Shipways - 1:96

-

Keith Black reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Keith Black reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Congratulations Jared!! Really well done!! I refer often to your and George’s blog as I progress with my build! Can’t wait to get finished! I have been telling everyone for the last 3 years that I have 2 more years to go! Rick

- 434 replies

-

- Flying Fish

- Model Shipways

-

(and 2 more)

Tagged with:

-

I’ve had really inconsistent results with blackening, either Brass Black or Liver of Sulfer. I’m always having to touch the pieces up with paint, although I like the look of blackening when it works. Rick

- 204 replies

-

- Flying Cloud

- Mamoli

-

(and 1 more)

Tagged with:

-

Canute reacted to a post in a topic:

USS Pillsbury DD-227 by michael.denigan - BlueJacket Shipcrafters - 1/96

Canute reacted to a post in a topic:

USS Pillsbury DD-227 by michael.denigan - BlueJacket Shipcrafters - 1/96

-

hof00 reacted to a post in a topic:

Flying Fish by Rick310 - Model Shipways - 1/96

hof00 reacted to a post in a topic:

Flying Fish by Rick310 - Model Shipways - 1/96

-

lawrence101 reacted to a post in a topic:

Albert Baldwin c. 1890 by Steve Harvath - Granite sloop

lawrence101 reacted to a post in a topic:

Albert Baldwin c. 1890 by Steve Harvath - Granite sloop

-

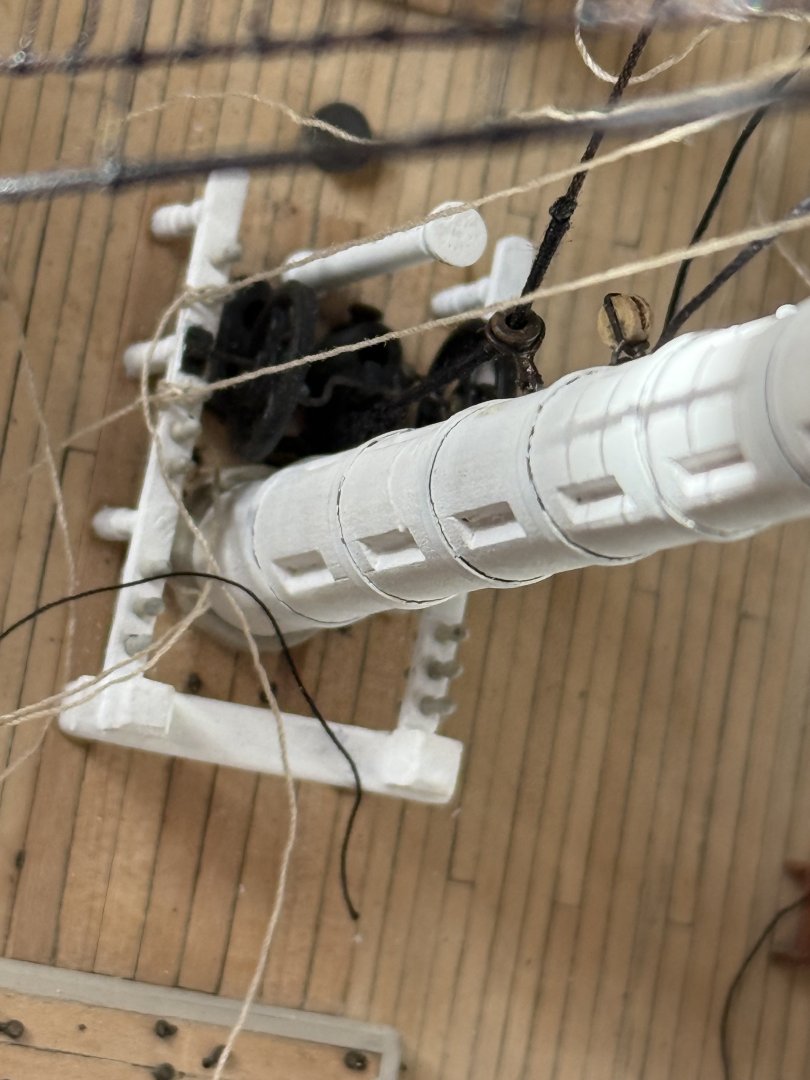

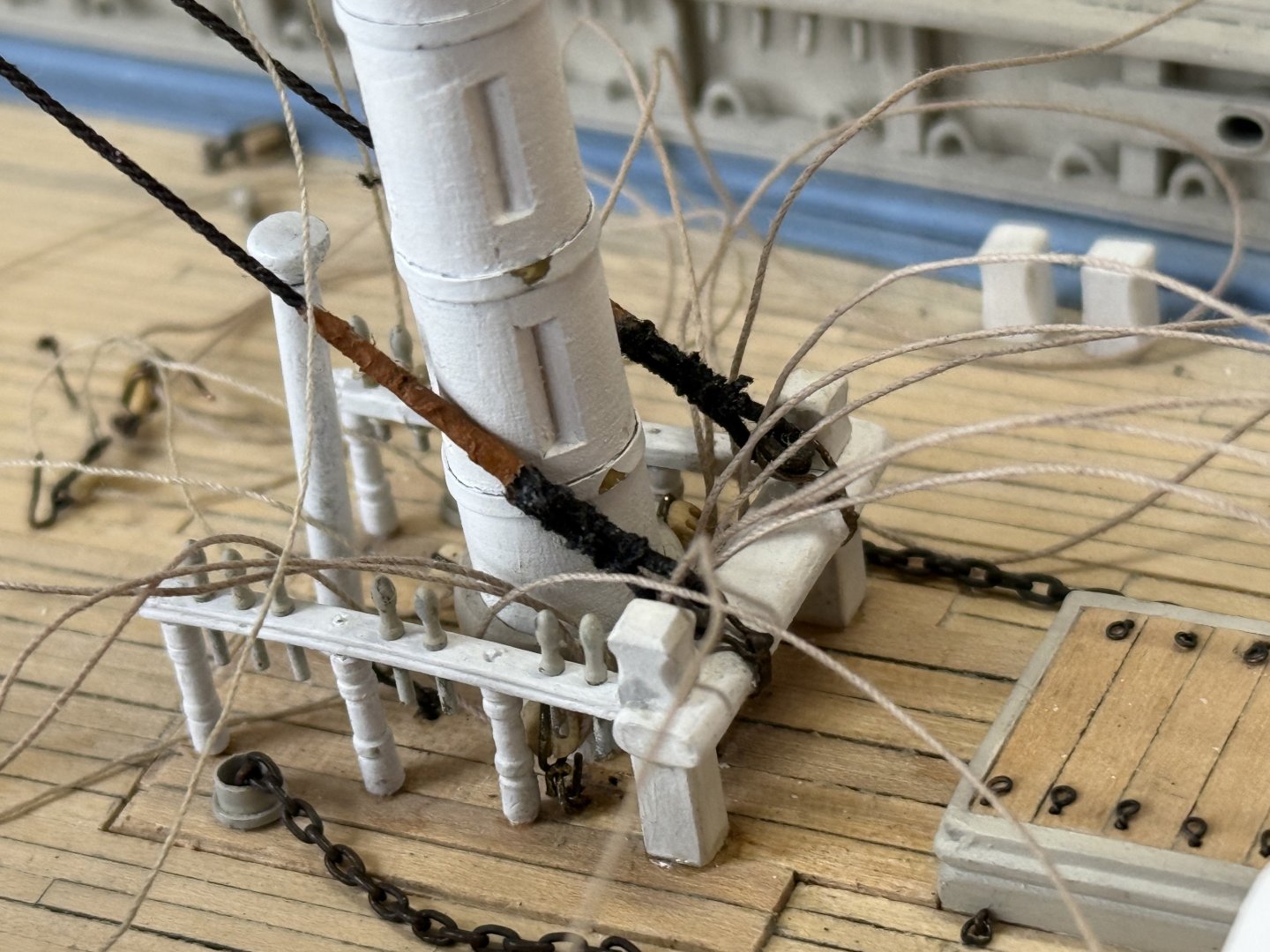

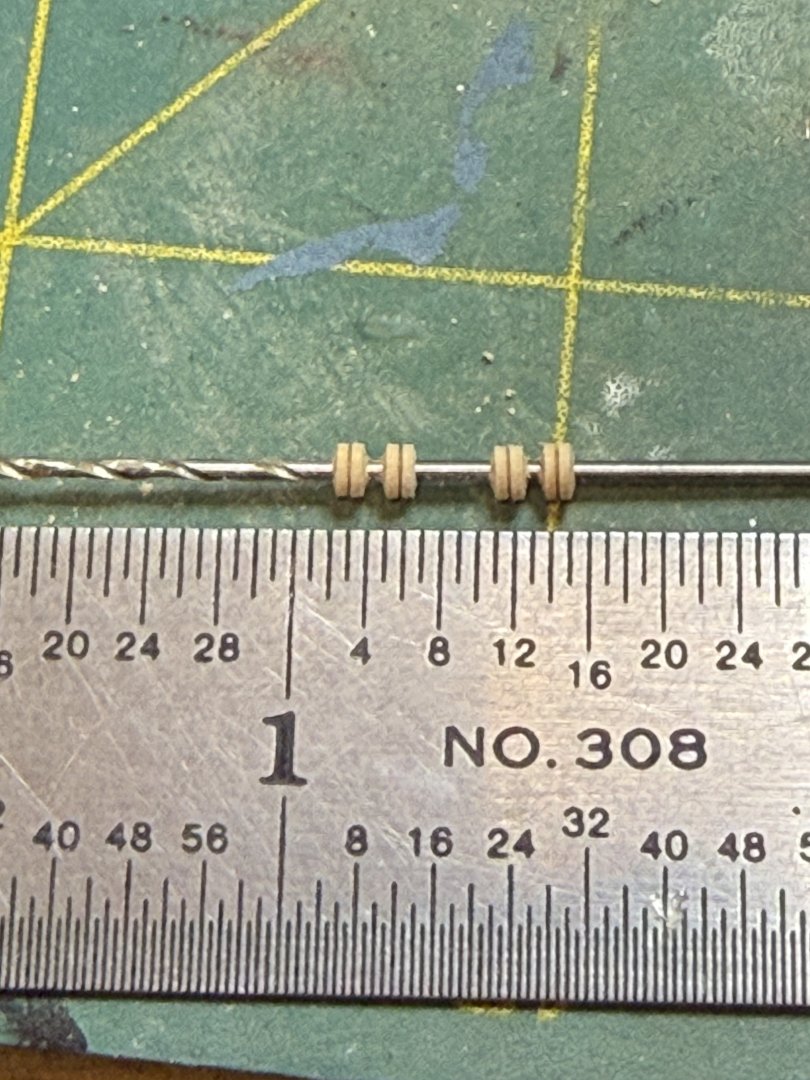

Well, another self inflicted wound as I broke the fore topmast attempting to push the futtock band on. Spent a day remaking it. I thought about trying to repair it but feared it would break again at a worse time and it was safer to bite the bullet now. Fortunately I was able to rig the tackles for the main and fore TG and TS chain sheets inside the main and fore fife rails. Hope I’ll be able to untangle the lines when I attach them to the chain sheets I also turned the TG bullseyes for the TG shrouds from boxwood.086 dia. and the holes #71 drill bit. The futtock shrouds are 26 ga. Brass wire for strength. Since then I’ve been finishing outfitting the TS yards, attached the stunsl booms which were shortened to half the length of the yard. The blocks at the end of the booms are 2mm blocks from Syren. Beautiful but small!! Lost several blocks trying to strop them with thread, never to be found again. It was nice to finally attach the cloverleaf blocks and run the sheet chains through them. Also attached the halyard chain tackles. Next up, place yard on topmast, add futtock band and TG cross trees. Rick

- 360 replies

-

- Flying Fish

- Model Shipways

-

(and 1 more)

Tagged with:

-

Rick310 reacted to a post in a topic:

Gary Thomas by J Snyder - 1:16 - William Atkin 25 foot Sloop

Rick310 reacted to a post in a topic:

Gary Thomas by J Snyder - 1:16 - William Atkin 25 foot Sloop

-

Very nice!! I struggle making rivets out of copper wire, how do you do it? Rick

- 53 replies

-

- William Atkin

- Sloop

-

(and 1 more)

Tagged with:

-

Just amazing Keith!! Really love it! My father was from Pittsburgh and my brother has 2 Stobart prints of the Pittsburgh water front circa late 1800’s, early 1900’s. Billy fits right in!! Rick

- 394 replies

-

- Billy

- sternwheeler

-

(and 1 more)

Tagged with:

-

Your hull is incredible! Beautiful! Rick

- 60 replies

-

- Endeavour

- j-class yacht

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.