Riotvan88

Members-

Posts

120 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Riotvan88

-

Your model looks museum quality to me, that's an amazing finish and a fair bit better than my effort I'd say. This is my 1st wooden boat coming from plastic 1/350 scale kits previously. I'm thinking of doing a scratch build next and will apply the many things I've learnt so far. Hopfully I'll get closer to a museum quality model next time. But for this current build I've got to move on to the next stage or it's never getting finished.

-

-

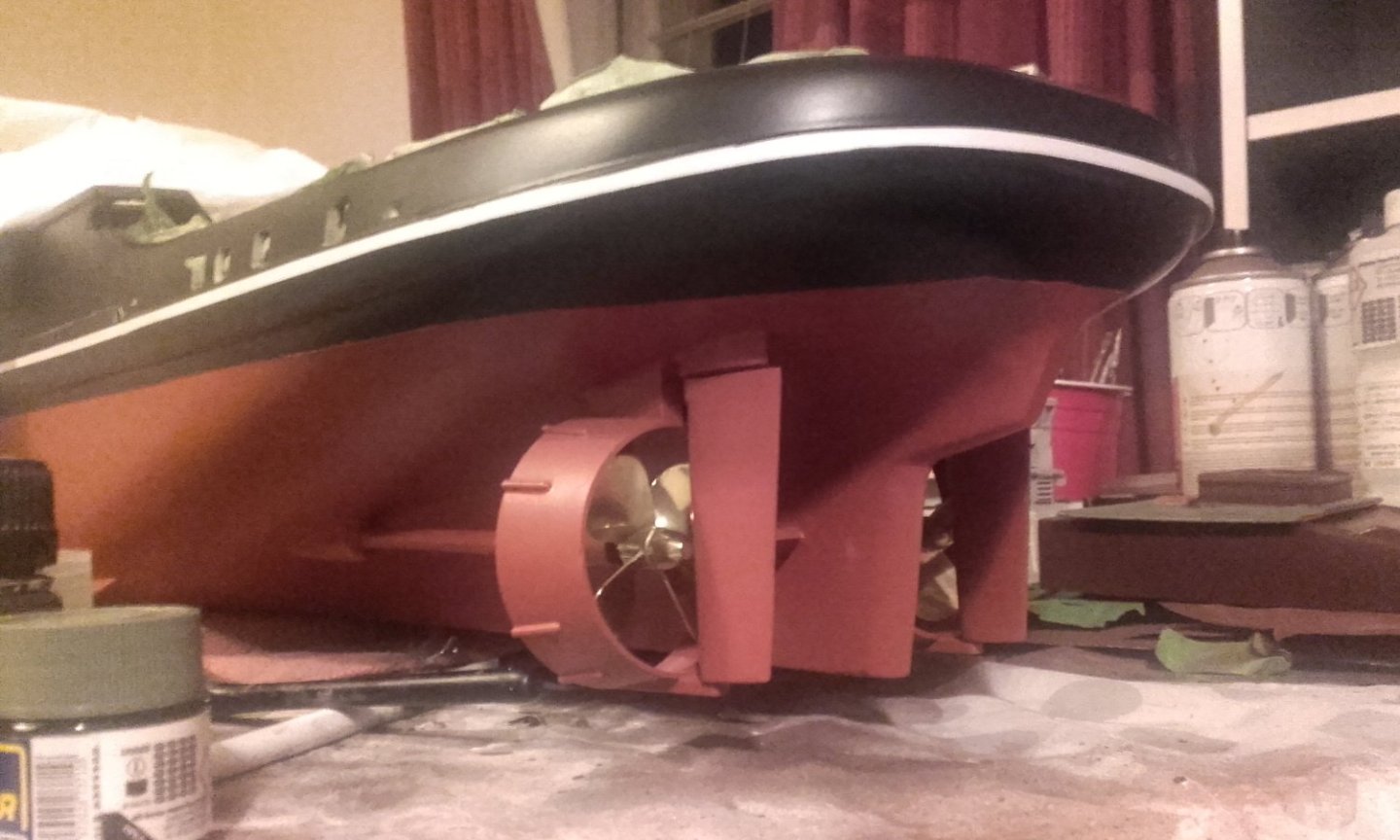

I've been building a smit Rotterdam kit and have painted my hull now onto the super structure. I used epoxy to seal the wood and get an even surface. Then used primer. The hull looked great until actual paint went on and I could see flaws everwhere. So sanded it back till it looked smooth paint again and still flaws. Sand paint sand paint....fast forward 5 cans later and I'm finally happy with the result. Here are my results Surely I've been missing some key tricks here? Is there a way to get a good finish without using a million cans and hours of sanding?

-

After some rumaging around I've found the empty tins of everything I've used. The complete schedule is Several coats of CPES 1X coat WS Gflex with water barrier additive 1X coat WS Gflex with fairing additive 2X full cans automotive high build primer 2X full cans plasticoat outdoor trade paint Black above waterline 2X full cans plasticoat red oxide below water line The boat looked smooth but each time I put paint on I'd spot flaws which is why I've used so many cans. Paint, sand paint, sand. Anyway I plan to add plimsol markins with decals and so will add a top coat to seal them in. Thus the top coat need be water proof to protect the decals. Hopfully the end result will be a matrix of layers that will keep her dry.

-

Drafting

Riotvan88 replied to mangulator63's topic in CAD and 3D Modelling/Drafting Plans with Software

Still relevant. In Aerospace we still use isometric, 1st and 3rd angle projections. We don't draw them anymore we model parts/assemblies in a 3D program that then spits out whatever drawing is required. In fairness one must understand geometry to create the 3D model in the first place. -

Drafting

Riotvan88 replied to mangulator63's topic in CAD and 3D Modelling/Drafting Plans with Software

I'm an Engineer when I was at uni in 2010 our teacher made us learn to draft on boards before we could go into CAD. I liked this approach as you actually use alot of the basic skills even in CAD especially true if using a parametric tool that uses sketches to create 3D objects. Contrary to popular belief CAD dosn't do it all for you it is simply a digital board that renders a 3D model from 2D infomation. A user still needs to be able to produce that 2D info properly for the system to generate a 3D visualization. You are correct however that drafting on a board is more of an art. At work I've occasionally though rarely had to work from drawings as some of our older products are pre CAD and still need modifying/upgrading. CAD certainly speeds up the design process as you can go through multiple iterations of a design rapidly on a CAD and detect clash easier. You can rapidly design multiple parts in assemblies and check fitment, tolerance, maintainabilty issues etc. From a user perspective as a tool to do a job CAD wins everytime. The 2D drawings produced from CAD programs do lack any artistic flair IMO and are bland. I occasionally design things for personal projects on my A0 Neolt drafting table using rotoring isograpgh pens and agree it is definitely satisfying to add line weights, stippling and little details to make the drawing really pop. Such things a CAD produced drawing lacks. But to be fair I end up using fusion 360 for 90% because it just makes the design process so much faster not to mention ability to 3D print mock ups and the like -

That's a great idea, I have taken pictures along the way but I've not really recorded anything down. A bill of materials would be a good idea next time.

-

I know what you mean especially with varnish. I definatley didn't sand the epoxy off generally but it's possible certain spots might have been sanded though I can't really remember. I did lots of primer layers sanding between coats and occasionally sanded back to the epoxy layer in spots. I do remember mixing up small batches of epoxy to patch areas I suspected a sand though might have ocured but always a chance I missed one or two. That's the problem with an on/off project. Can't remember half of what I did to build it.

-

I see the problem with future expansion/contraction etc and I do wish I'd used glass now just for piece of mind. I'm semi tempted to strip paint and glass it but at same time I really really don't want to. That said the Gflex is used to seal full sized dinghys and day sailor boats. It has a much higher elasticity than polyester according to their website it's designed to create structural bonds in wooden constructions and does mention it's ability to accept flex and expansion. Didn't many older models simply use sanding sealer or varnish and do fine?

-

Cheers Bob I did two coats with Gflx one with water barrier additive and a final with fairing additive. The whole model was done in CPES as well as Gflex including decks and superstructure albiet only one coat of Gflex for those areas. Outdoor varnish was applied to all inside surfaces My concern is during all the priming, sanding, painting (done over months) I may have sanded through in some spots without realizing. Probably not but impossible to know now. I plan to give several coats of satin lacquer at the end which should also provide an additional waterproof barrier as well. I've made some small test hulls one with paint and topcoat only to simulate a potential sand through area and one with CPES, Gflex and paint to simulate the the hull generally. I'm going to place these in water 24/7 to see how long these coatings last.

-

I have built two small test hulls each the size of a matchbox one with the paint system only and one with the epoxy coating only. Will build a third with epoxy + paint to be truly representative of my hull. I'm going to float these in a bowl to see how long the coatings last.

-

Thanks for the reply. I coated the whole hull in epoxy atond payed special attention to all hull penetrations. Then several coats of automotive primer and costs of paint. Inside has been varnished but could add epoxy to it as well. Boat will be on water 6-12 times a year summer only.

-

Hi thanks for the reply. I think you may have not understood the problem. I did not use any glass at all. I treated the wood with a penetrating epoxy then 2 coats of marine epoxy only no glass. I did this based on some recommendations (seems others have done it also) My worry now is that without glass the model is only suitable for display. Interested to see what others think.

-

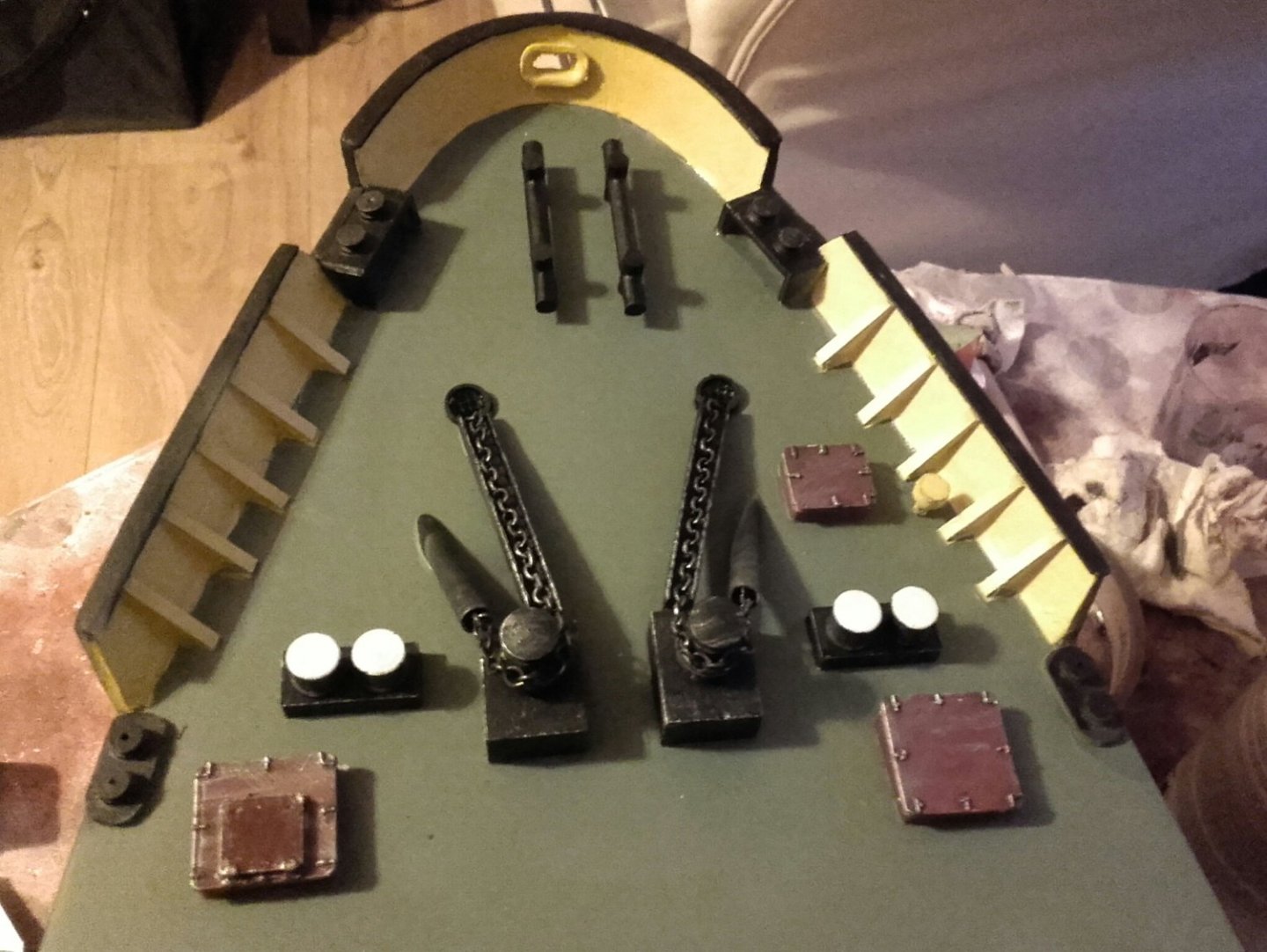

Hi all seeking some advice I have built a smit Rotterdam kit. Intention was always to make it RC. Here is current progress However I am now deeply concerned I have made a huge error. When looking for advise on glassing the hull I was advised I could use epoxy resin only (no cloth) with additives 422 Barrier Coat...see thread below This was recommended by a couple of people so I went down this route and ended up painting the hull with Smiths penetrating epoxy sealer then did two coats of west systems Gflex epoxy with 422 barrier coat additive added. I'm now worried this was wrong and now the boat is unsuitable to be RC. This epoxy is what they on full size yachts and dinghys. (Used it myself to fill damage on an Enterprise dinghy) Any thoughts? perhaps I'm worried over nothing? would appreciate any wisdom on this. Future builds I'll definitely use glass. I just hope I haven't limited this to a static build.

-

Can anyone identify this model/kit

Riotvan88 replied to Riotvan88's topic in RC Kits & Scratch building

Do you mean the fender? What's wrong with it? I've seen plenty of real yachts with a bow fender like that -

Picked up this RC model sail boat second hand. Seller didn't know anything about it. I really liked the look of it and bought it. Its a fiber glass Hull with wood mast, decks and superstructure etc. The Hull looks exactly like a Revell Inga IV but the superstructure is totally different as well as the rig. It also looks like it either had 2 masts at one point or possibly the kit had the option to fit two masts. Perhaps its a custom design using an Inga Hull or modified Inga. Can anyone identify it?

-

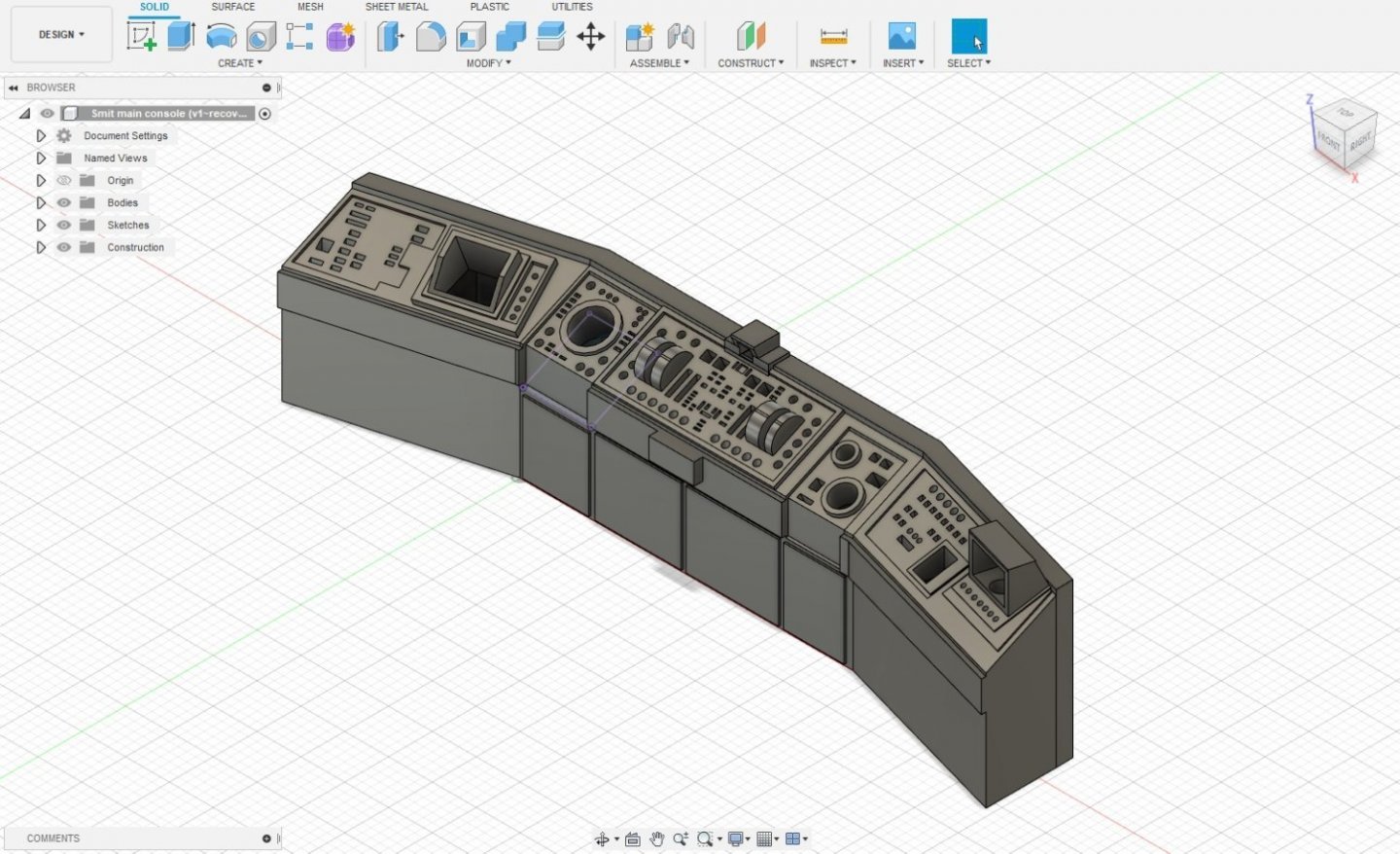

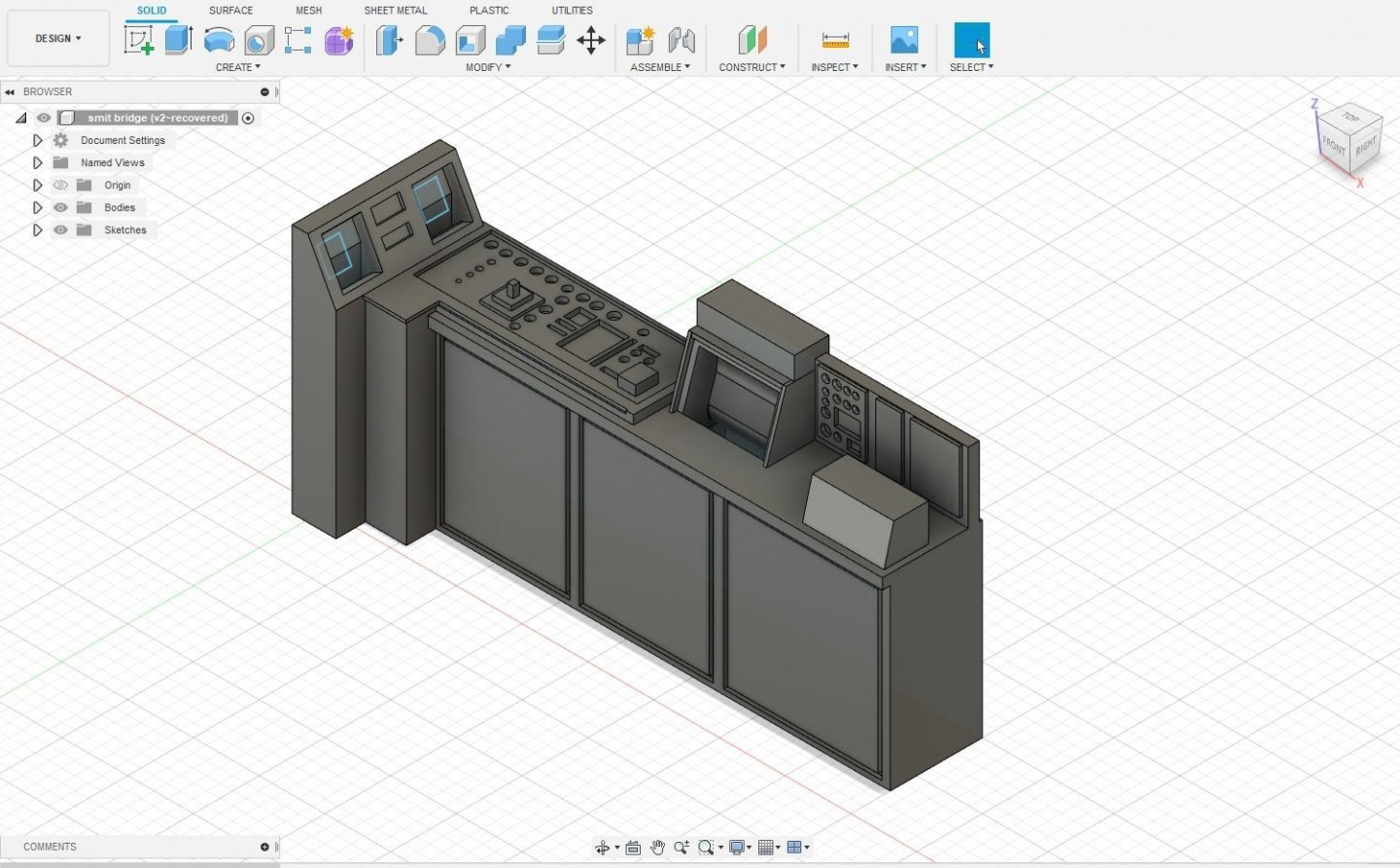

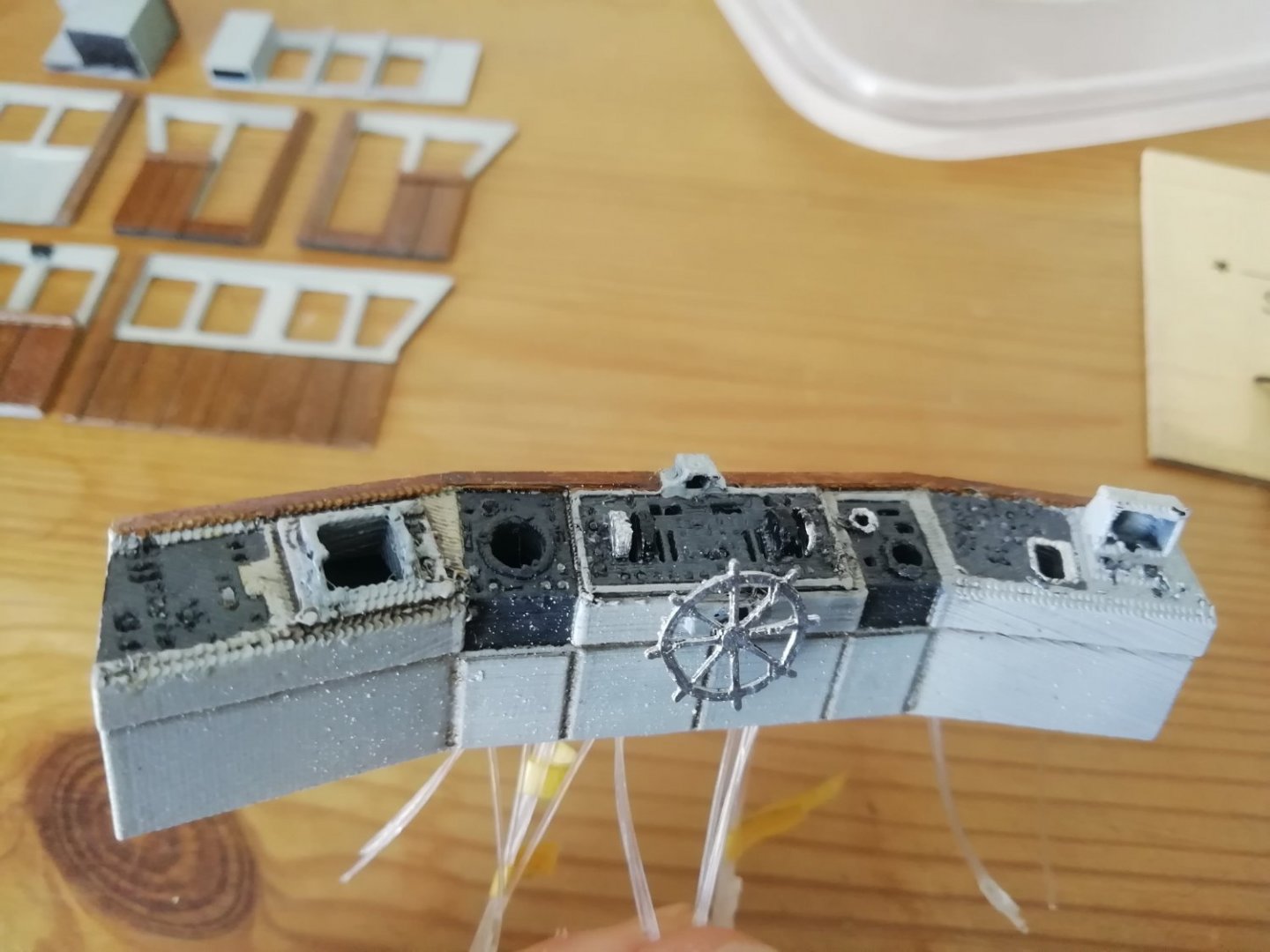

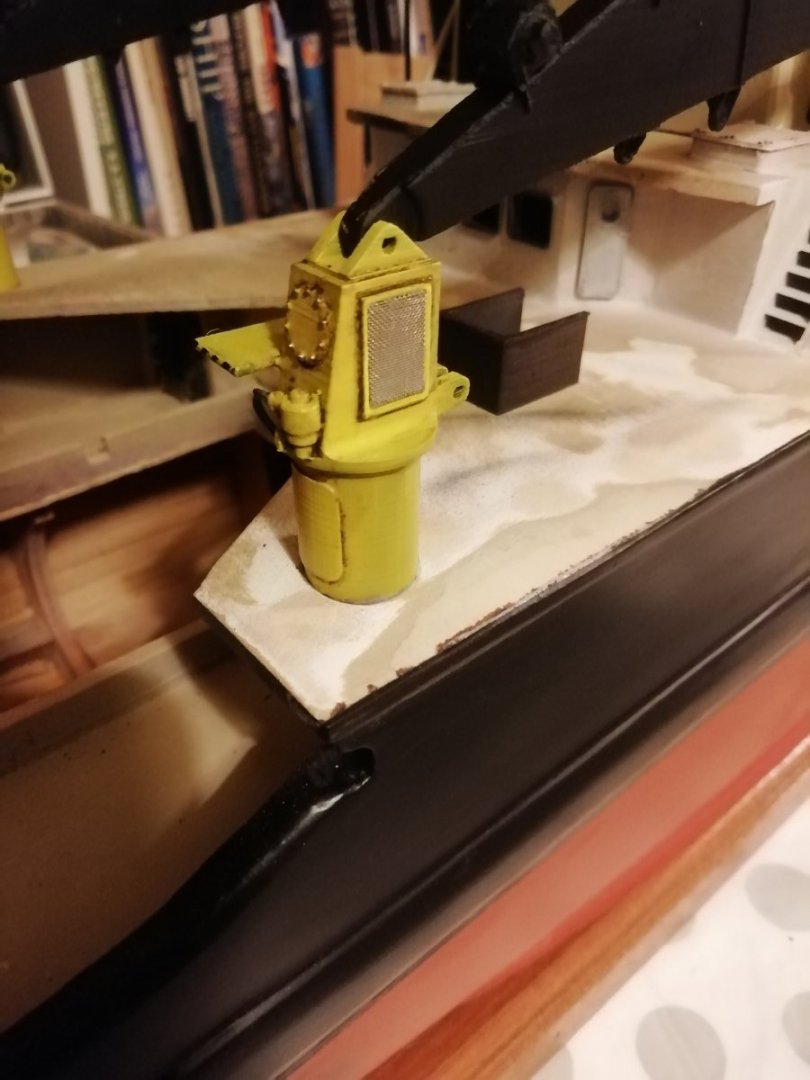

Hi Jan. No this kit is the old version so the interior is very basic. I have made my own interior based on photos I found online. It is made in a CAD program and 3D printed into pannels that I painted and will assemble into the bridge. I've added fiber optic wire to the main consoles as I'm going to light the control panels. I've tested this with everything lose fit and it seems to work quite nicely.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.