TheRedGnome

NRG Member-

Posts

34 -

Joined

-

Last visited

About TheRedGnome

- Birthday 06/18/1989

Contact Methods

-

Website URL

https://www.twitch.tv/theredgnome

Profile Information

-

Gender

Male

-

Location

Jonesboro, AR

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

-

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

-

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

-

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

-

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

-

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

-

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

TheRedGnome reacted to a post in a topic:

HMS Bounty by LyleK1 - Artesania Latina - 1:48 scale

-

TheRedGnome reacted to a post in a topic:

Inches or mm?

TheRedGnome reacted to a post in a topic:

Inches or mm?

-

TheRedGnome reacted to a post in a topic:

Inches or mm?

TheRedGnome reacted to a post in a topic:

Inches or mm?

-

Shipyard sid reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

Shipyard sid reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

tarbrush reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

tarbrush reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

GrandpaPhil reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

GrandpaPhil reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

TheRedGnome reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

TheRedGnome reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

Danstream reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

Danstream reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

TOM G reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

TOM G reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

Baker reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

Baker reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

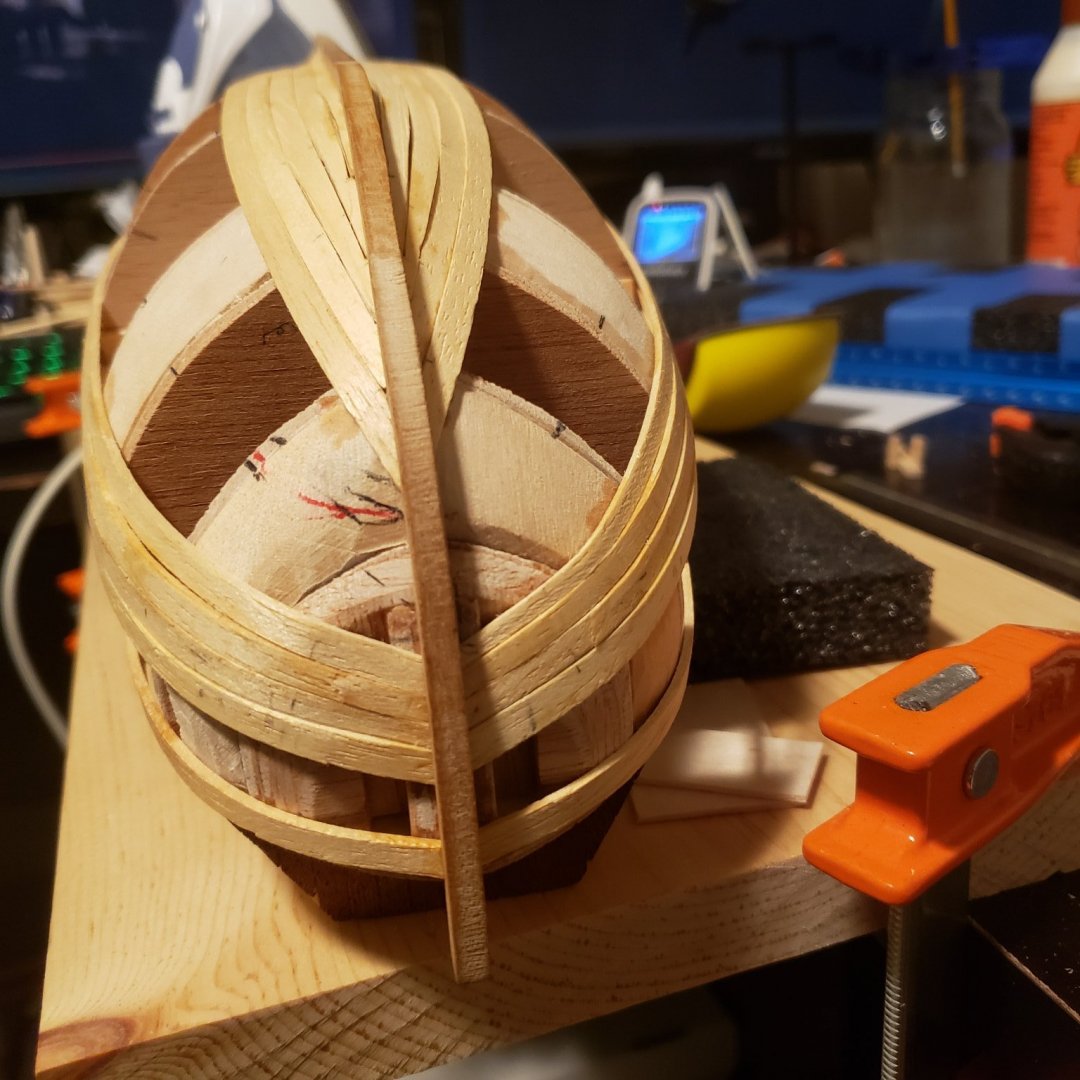

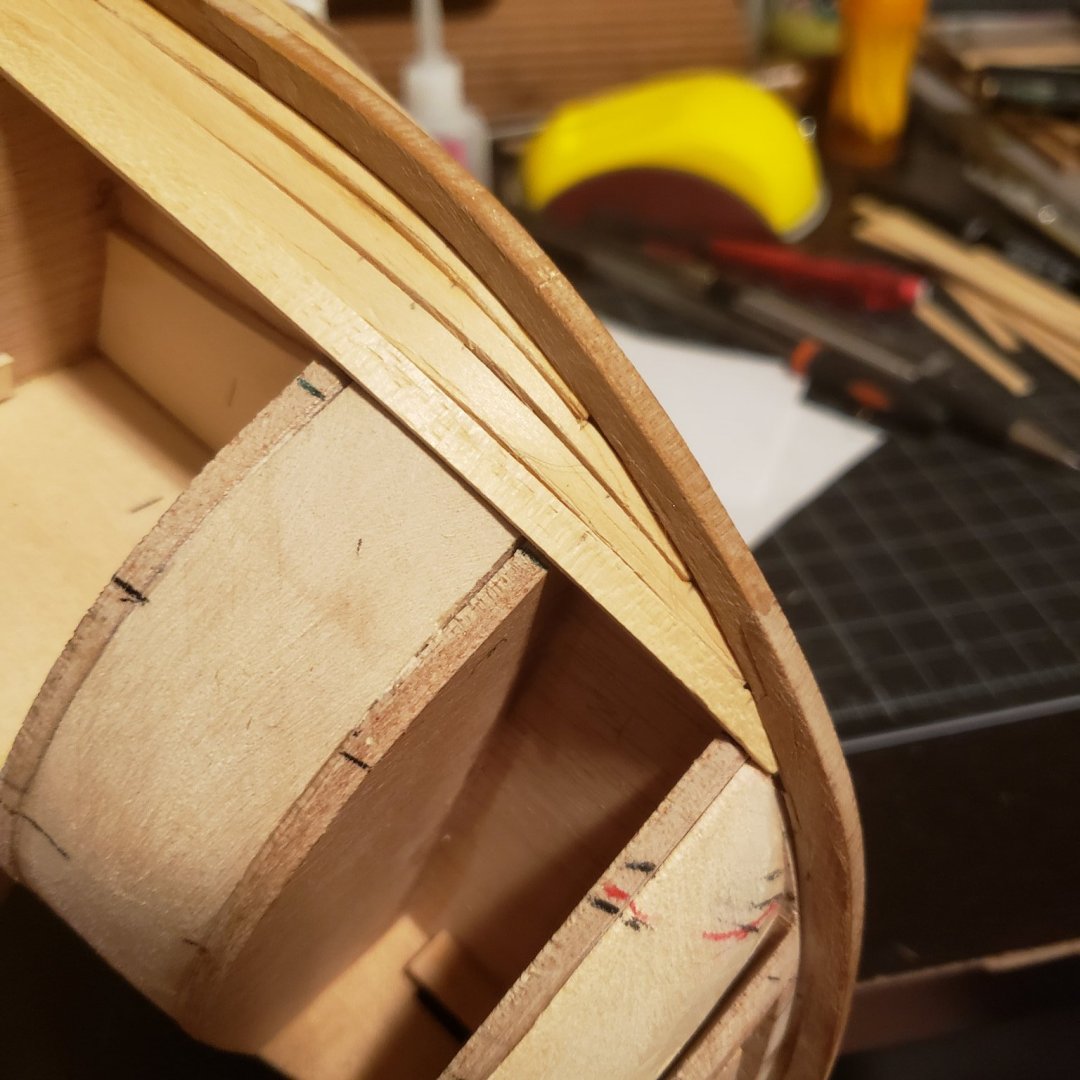

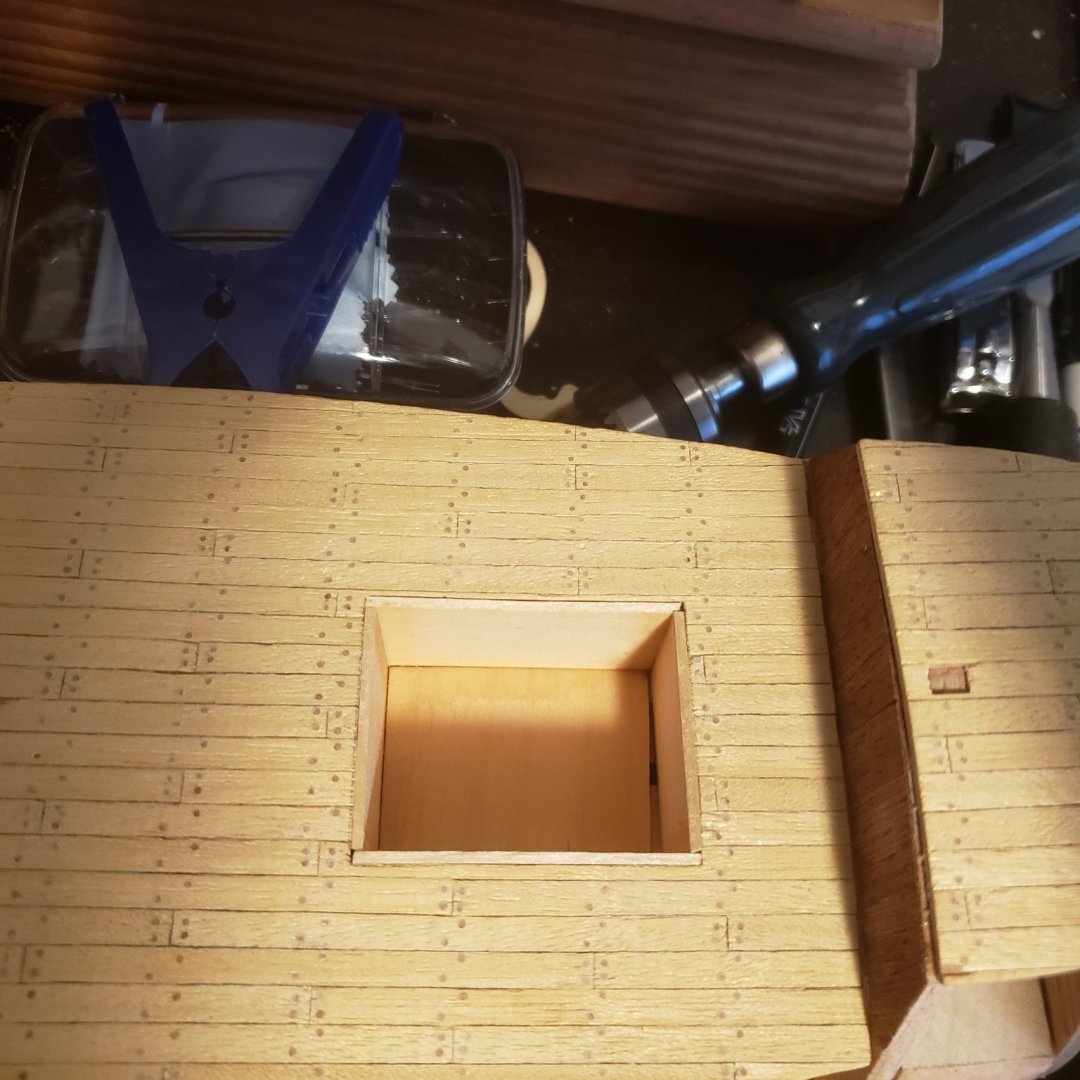

My Mayflower is still progressing nicely but hasn't had much done on it since this past weekend due to Thanksgiving, my covid booster over the weekend, and my wife's booster early this week. Fatigue and sharp objects don't mix very well so figured it was best to give building a bit of a break until the fatigue is gone. I was going to wait to post until I had a little more progression but after thinking about it and reading through various other build logs in my downtime, I think I'm at a great point for an update. One of these days I'm going to figure out how y'all are getting the images inline on your posts instead of just being massive at the end but for now it'll just be a wall of text followed by a wall of photo. Figured it out while I was actually uploading the images this time. For starters, I was trying for a while to figure out the best way to bend the plywood sheet that the AL kit contains for the planking around the decks. During this I noticed, due to not knowing any better in my initial planking attempts, that my top planks weren't entirely uniform against the bottom of the plywood. One side had a pretty sizeable gap midships that'll have to be addressed later. For bending the plywood I decided on a multi-approach of both soaking sections of it for a little bit, then using a combo of my bending iron and clothes iron to curve it. My clothes iron was used to get the broad bends in place, along with any twists it needed. The bending iron for the more severe bends near the bow of the ship. Ultimately, I'm pretty proud of the bending that I did and got them to be pretty close to sitting on the ship without any springback pressure... I then proceeded with doing the internal veneer planking that the instructions called for and started the process of gluing the now-veneered plywood to the ship.... Then things went less than ideal. I let the clamps sit on it for over 24h just to give my wood glue the max cure time. I was most concerned with 2 locations, the part that sat against the elevated deck forwardships and the part that sat against the first elevated deck aftships since those are the 2 locations with the most springback. I slowly removed their clamps... just to have them break the glue bond and pop out away from the ship. Thankfully they didn't damage the decks, just some residual glue that needed to be carefully removed. I tried some CA glue to keep them connected, which worked, but also looked extremely bad to me. After much internal debate and talking it over with the wife, I decided I'd just do the planking myself. I spent the entire next day going over ideas on what to do, using the same thought processes I use when developing & implementing the software frameworks that will be the foundation of projects over the next several years at my work. I came up with the idea of getting the deck stanchions (I believe that's what they're called? please correct me if I'm wrong) cut into the decking and glued into the existing planks, then using them as the support for laying and securing the planks that will span the gaps across the decks. I set to work cutting out the little walnut pieces that were meant to be used for this (but decoration instead of actually structural) further in the instructions. I shaped and bent the top plank for the main deck that would sit at the top of the stanchions, marked out where it's visible on the deck, and painted between the markings. The paint I used is the "oak brown" paint from The Army Painter's miniatures wargamers paint set. I did a sample piece and it's colors came out pretty close to the veneer, enough that it shouldn't be really noticeable once everything's gotten a finish coat. I then set out to cutting the notches along the decks that these stanchions will sit in. There's several spots where I cut the slots too wide (and you'll notice one of the deck boards chipped off due to my saw even though I was trying to be extra slow with it), but I'll cover them up with a toe board before everything is said and done. I glued the stanchions to their proper location on the plank, set them into the deck after the glue dried and got the correct height that they're going to be after the other 2 planking rows are applied. Currently this plank isn't glued in, but the stanchions are. I'm going to wait to glue it in until after I get the plank for the other side of the ship shaped/bent/painted/setup. Dan

-

mtaylor reacted to a post in a topic:

Jig questions

mtaylor reacted to a post in a topic:

Jig questions

-

Jig questions

TheRedGnome replied to Johnny kid's topic in Building, Framing, Planking and plating a ships hull and deck

While this has some instructions included in the pictures, it also seems to be a pretty decent build log of the jig itself so might help shed some light on the remaining bits of hardware. https://modelshipworld.com/topic/27501-building-berth-lmg-bb-09-poor-replica-of-hobbyzone-building-slip/ -

GrandpaPhil reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

GrandpaPhil reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

GrandpaPhil reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

GrandpaPhil reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

yvesvidal reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

yvesvidal reacted to a post in a topic:

Mayflower by TheRedGnome - Artesania Latina - 1:64

-

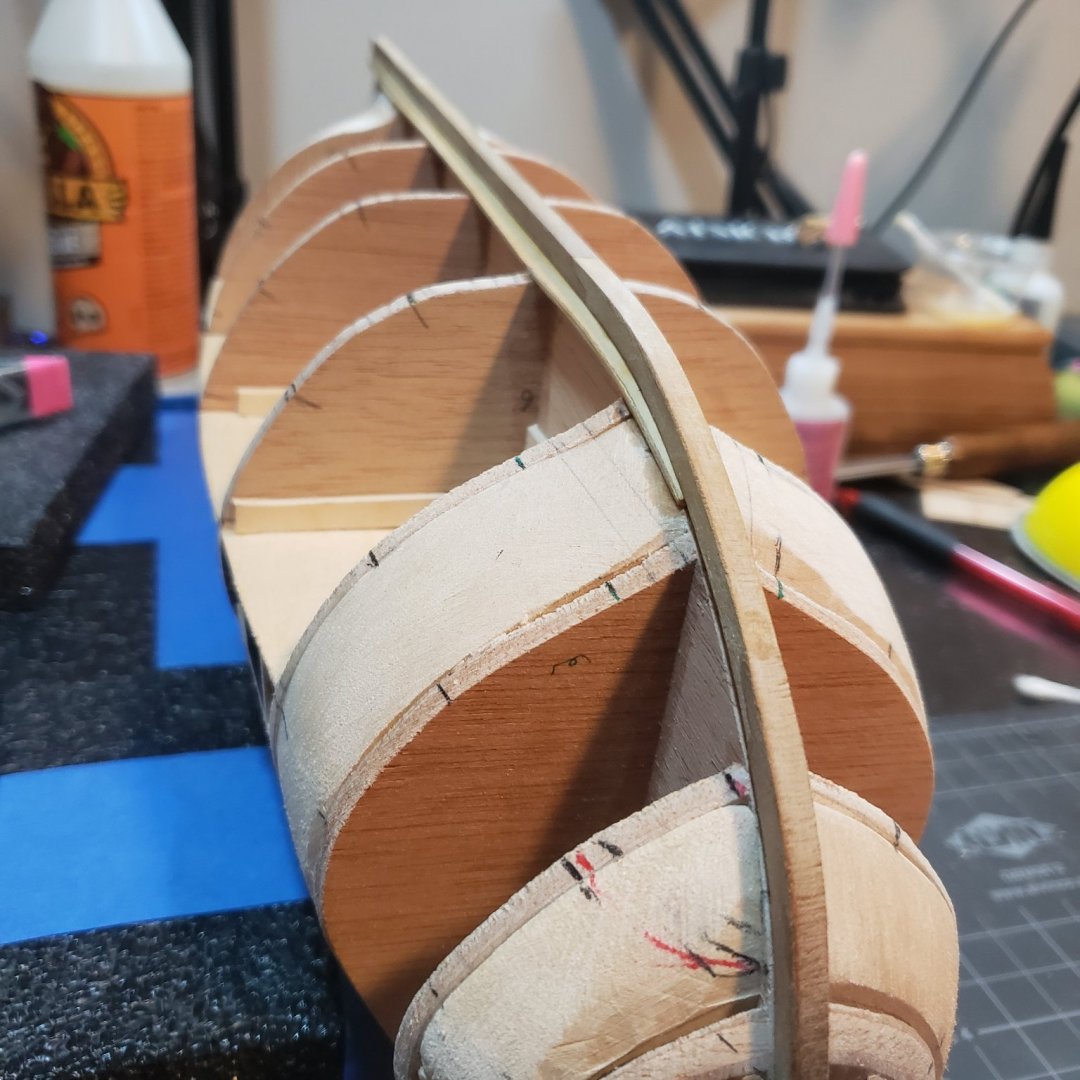

I've been a busy little bee over the last couple of weeks and have been able to devote quite a bit of my evening time to planking. I've learned a lot while doing it. The treasure trove of information on how to plank here helped in the theoretical sense, and as time went on I got a better grasp on just what people were talking about. The side of me that takes pride in my work to the point of completely scrapping something to redo it is struggling with the practical side of me that knows I can't mill more wood down with the tools that I have on-hand to replace what was used in this learning process. I know the simple solution is to just get said tools, but my wife's family has 1 absolute rule during the holiday season.... Under no circumstances are we to buy something for ourselves that wasn't a "pre-planned/budgeted purchase" from October 1st through to December 25th... so I'll just take what I've learned into my next build when I start on it after this Mayflower is finished (or when I get to rigging and need a break from small knots). For now though... the main hull is planked! I've marked where I added the proper gun port framing behind the planks so they can be cut out. I used a combination of a small clothes iron for putting the edge bending into the planks, and followed them up with my aeropiccola being held in my vise to allow both hands to manipulate the planks I was spot bending. I tried using the little clamp guide that came with my aeropiccola, but ended up running into more trouble with it than I felt it was worth. Some planks would be over-bent, some under. Some I couldn't even get the plank through due to the tension on the springs. I couldn't use the sharp curve side of the aeropiccola while using the clamp guide because of the spring tension. To bend twists into the planks, I would just use a set of precision/jewelers pliers to hold the plank if the twist position was too close to the bender. This week my main goal is to start the sanding/smoothing process for the planks that were stepped early on in my bending experience (before I set the aeropiccola into my vise to use both hands). If areas are too filled with CA glue, I have acetone on hand to soften the glue up for a more precision gluing. I also have some putty on hand to close up the gaps that formed here and there. After that, my next step is to figure out how to get this laser cut piece that's supposed to be the rails around the decks and the upper rear portion of the planking bent into shape/place. I'm still not 100% sure on how I'll manage that one... I might just do some soaking overnight in a container and use my iron to form it into shape on the hull itself. I'll search other threads that have done the AL Mayflower to see what they've done before I get too set into a process. I do know that I'm going to first shape the laser cut pieces into place and then do their interior walnut planking after I've marked what areas need to actually get planked rather than planking it first and then shaping after.

-

I've added a few more rows of planks and started working my way down the hull. There's some "stepping" in the planks near the bow, but I'm not overly concerned since the instructions show us painting things later and that can be fixed and hidden with some putty and sanding. I'm learning more and more with each row... and having a great time doing it since it's taking my mind off the day.

-

There's a shipwright that I've been following on Youtube for the last few years named Leo who's been in the process of restoring the Tally Ho racing yacht. In a recent video he had one of the people he hired for help talking about it. You can find their explanation here, from 12:45 to approx 14:11 (apologies to mods, you can remove the YT link if you feel the need to). I neglected to get some pictures last night when I was done shaping the 4th row of planks, but will try and remember to get some tonight.

-

I'll have another couple pictures ready to post either tonight or tomorrow, but I'm making sure to only bring these planks to a minimum of 1/2 their width in when it's reaching the stem (planks are 5mm so minimum of 2.5mm but I try to keep them at 3 or larger). I've been using the "nib" method for that portion to make sure I don't get too thin and toothpicky up there, hooking the next plank over it. So far I've laid 2 more rows in on both sides, averaging about 1 row a night right now.

-

Well I did it... as of last night the garboard plank is in place. I bent the planks using my aeropiccola, though the hardest part was getting the twist in without snapping the wood. I just ran it over the shaft of the aeropiccola increasing it's twist over time. They're glued in to the with some very thin CA glue with a spot of glue on each bulkhead frame. Tonight I'll get to start adding in more, but I'll just be dry shaping for now so I can go on a gluing spree later in the week. I think this was by far the most stressful portion of any build that I've had since it was my first garboard and everything that I've read talks about how it's one of the most crucial planks to get right. Hopefully the rest will be, I dare say, smooth sailing. Dan

-

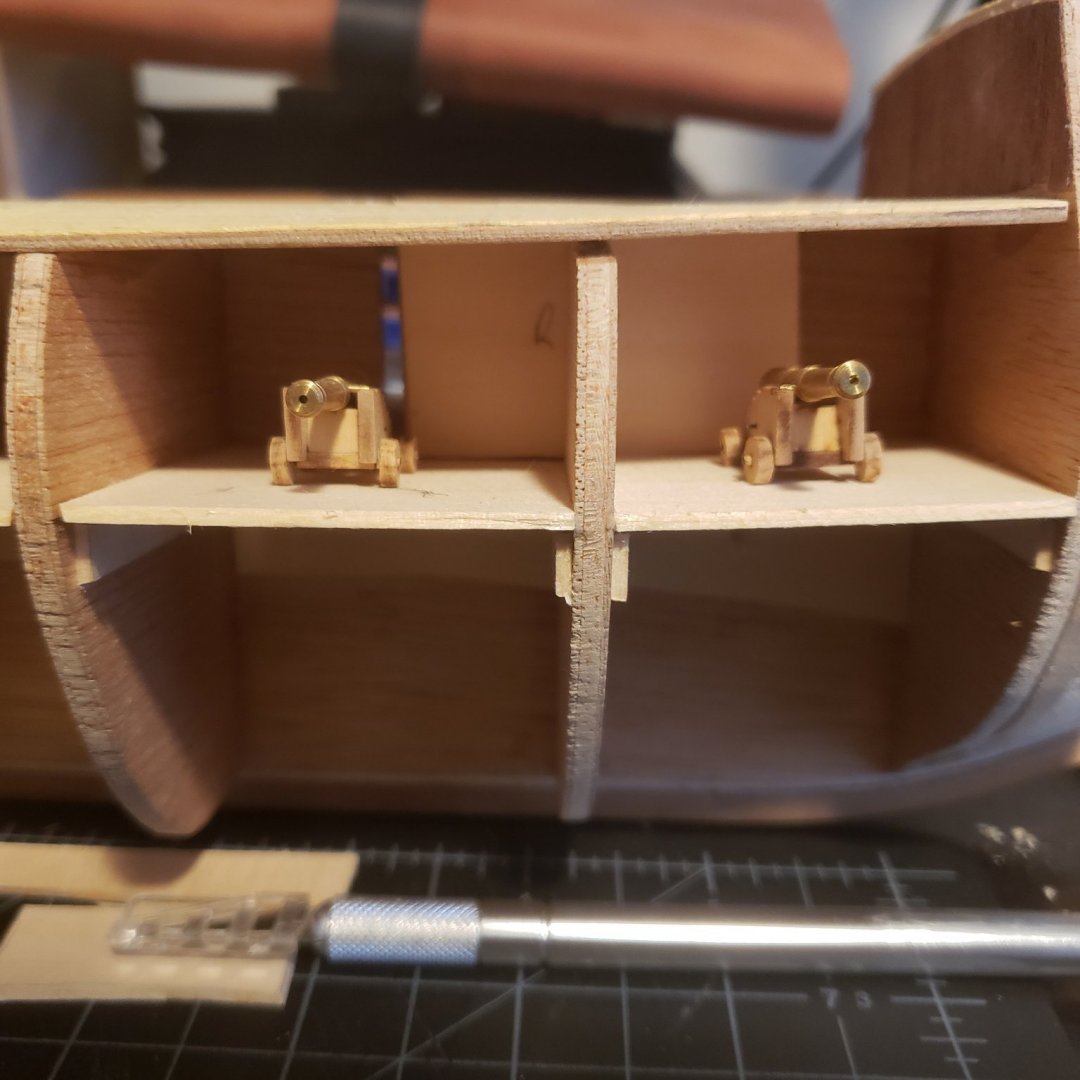

Hello everyone, long time no see... life's been, busy. I'm glad to be able to start working on the ship again after a long hiatus. Over the last several months, I've put some work in here or there but never anything substantial until this past week. Starting this past Monday, I'm able to devote a couple nights a week (Mon/Tues) to working on the ship, with more in the future, and even able to stream some of my building again. In an effort to correct the locations for the gun ports, I've made an interior gun deck for them to sit on, painted it black to give it more depth, and added some framing (which will be painted this weekend) for extra structure around the doors. You can see how the cannons will sit inside of them. I also decided to forgo a lot of the blocks I was shaping for the interior of the hull. I felt they were taking too long to do by hand and were starting to detract from the enjoyment I had with building. I'm starting the process of lining the hull, with intentions of putting my first hull planks on either this weekend or Monday evening. It'll be a bit of a picture dump, but here's a showcase of the progress I put in over the last several months, and even more of the last few days.

-

Thanks for the praise Backer. I should probably also note that these blocks currently are not glued into the hull, I'll be doing that before I do my final sanding/shaping to fully match the hull's intended shape. The box my parents made and gave to me is quite useful too, as it keeps my Xacto knife, it's blades, and my box cutter from sitting on my desk in plain view where my 2 1/2 year old's little fingers would find. I hear you on this one loud and clear. Just under 12 years ago, a blueish-gray tabby showed up on my porch, hungry and with front paws declawed. She was already on the older side of things according to my vet, half her teeth were missing. Fast forward to today, and she still sleeps next to my pillow.... so it'll be an extremely sad day at some point in the next few years.

-

Evening everyone, it's been a hot minute since my previous update. Between the holidays, and the cold arriving, the time I have available for heavy usage of tools was (and still is) very limited. We were fostering a litter of kittens that a local stray had in our garage, so I couldn't use my belt sander very easily during the evening, which left a handful of hours each weekend that I've been able to bulk-sand down blocks for filling the hull. At this point, I have most of those done and have transitioned to my Dremel (along with a flex attachment) to carve out the remaining detail into the blocks. I over-sanded one of the blocks (the 2nd block, you'll see in the following post where I upload the pictures) using my belt sander, so I'm debating on filling it in with my wood filler, or just ordering some more basswood blocks and redoing it. After I've gotten all of the blocks roughly sanded down using the Dremel, I'll be coming back over with with some sandpaper by hand to clean up the sanding job and prep them for mounting the hull planks. For Christmas, my in-laws gave us some cash due to covid restrictions limiting travel between the US (where I'm from) and Canada (where my wife's from), and I managed to snag a Aeropiccola plank bender off Ebay that was in excellent condition (even contained the original instructions & bag from Model Expo where the previous owner got it). We've found homes for all of the kittens, and just waiting for the stray mom cat to either get a home or our TNR appointment with my vet for her before I get full usage of my garage in the evenings again... so some more actual progress will be made soon. Thanks for sticking around! Dan

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.