Steve20

NRG Member-

Posts

168 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Steve20

-

HMS Victory Renovation - Outer Planking Removed

Steve20 replied to Steve20's topic in Nautical/Naval History

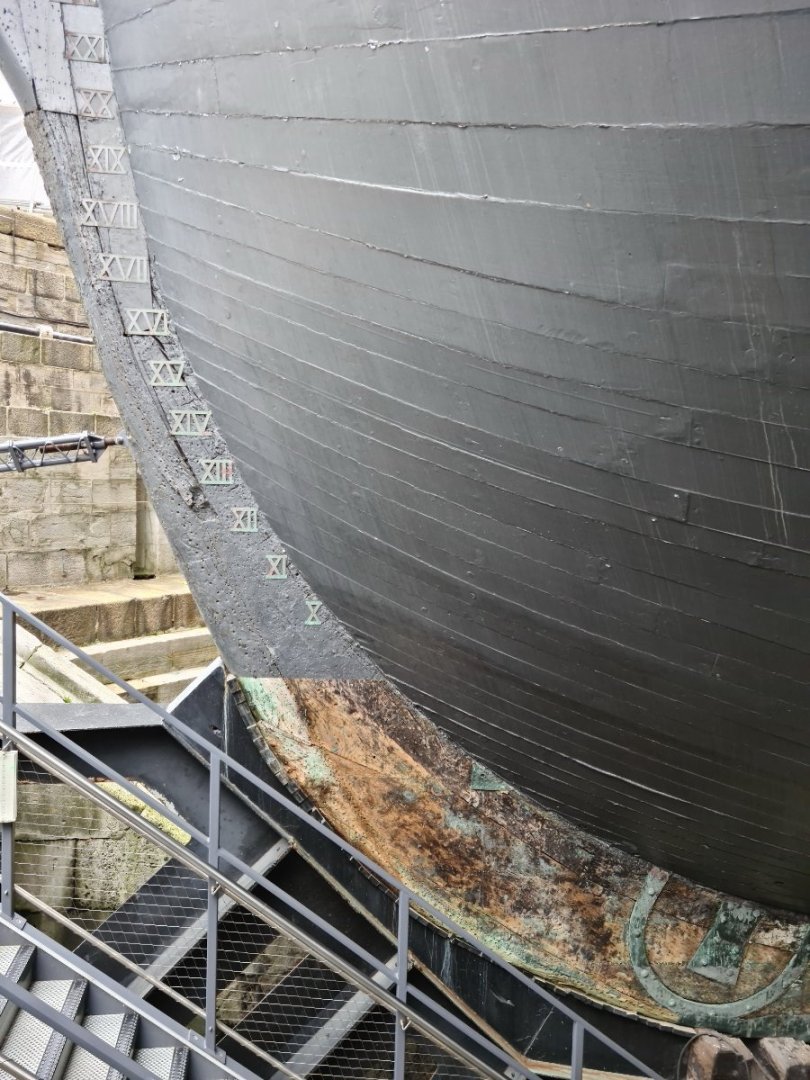

The below pics show elements of the bow, keel and stern, which I believe date from the 1800’s and perhaps even earlier. (I've since found out that they date to the time of launch in 1765 - Steve) -

HMS Victory Renovation - Outer Planking Removed

Steve20 replied to Steve20's topic in Nautical/Naval History

-

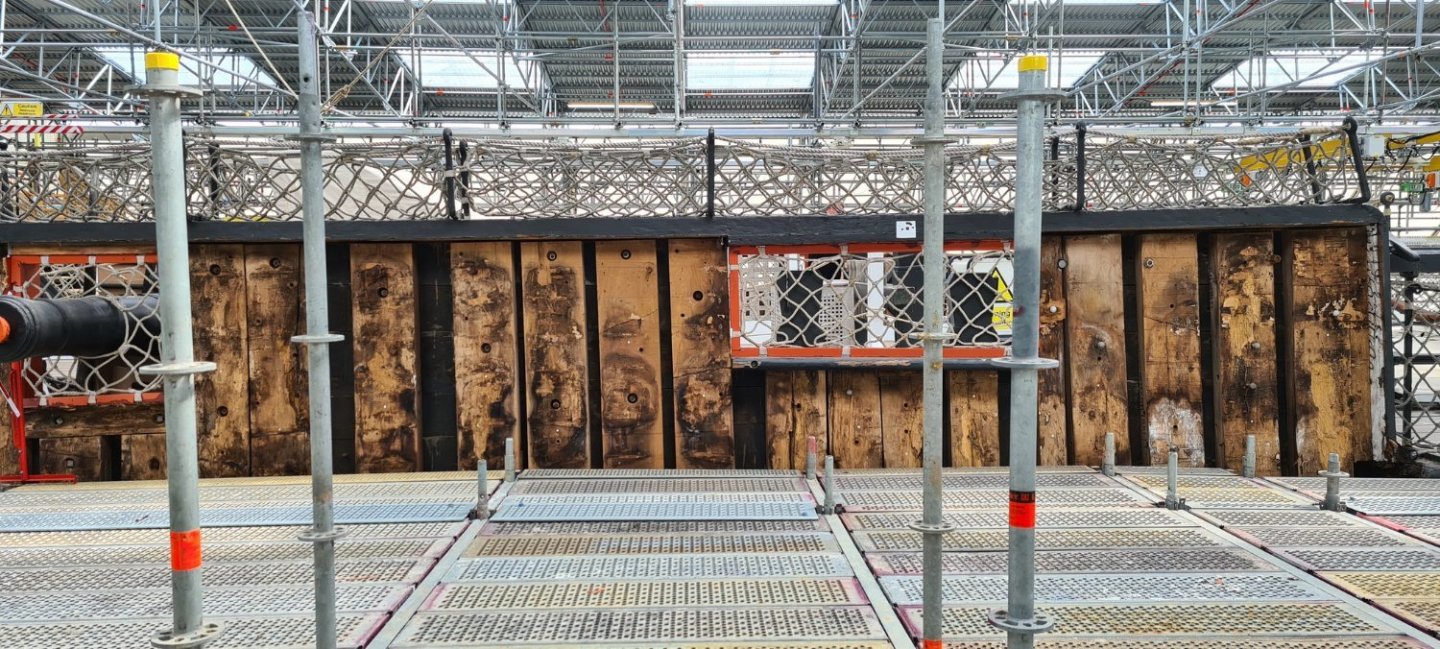

HMS victory is currently undergoing a £35 million (GBP) renovation and outer planking is being removed to access and replace frames that are damaged by moisture, fungus and pests. Below are a few photos I took a couple of days ago of frames on the starboard side. I believe these date from a renovation carried out in the 1900’s.

-

Very nice work. So detailed and precise.

- 642 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

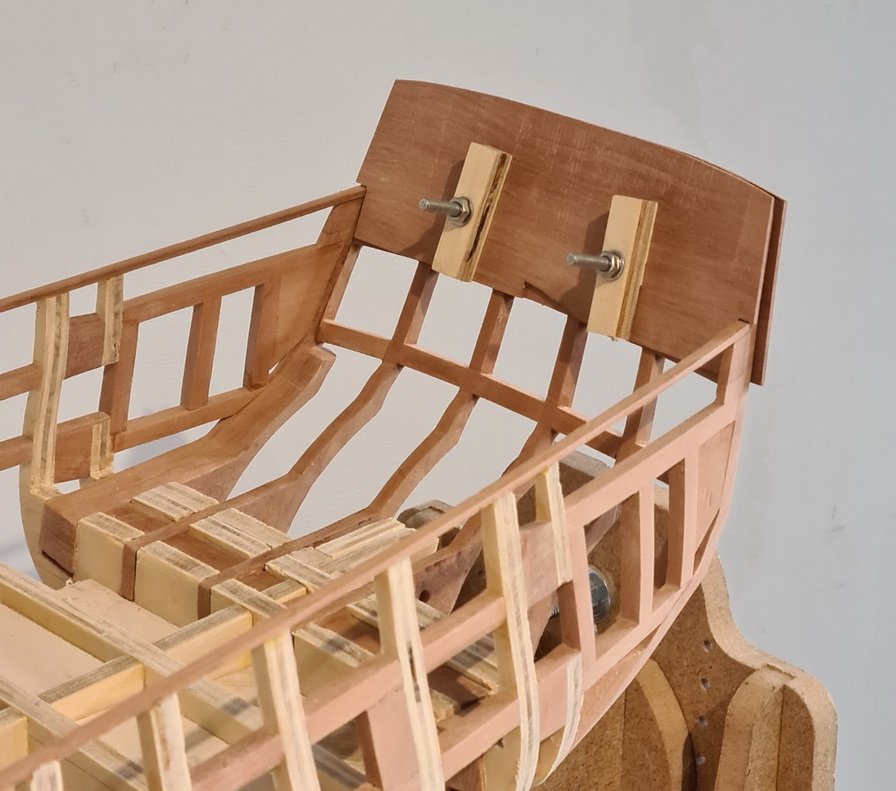

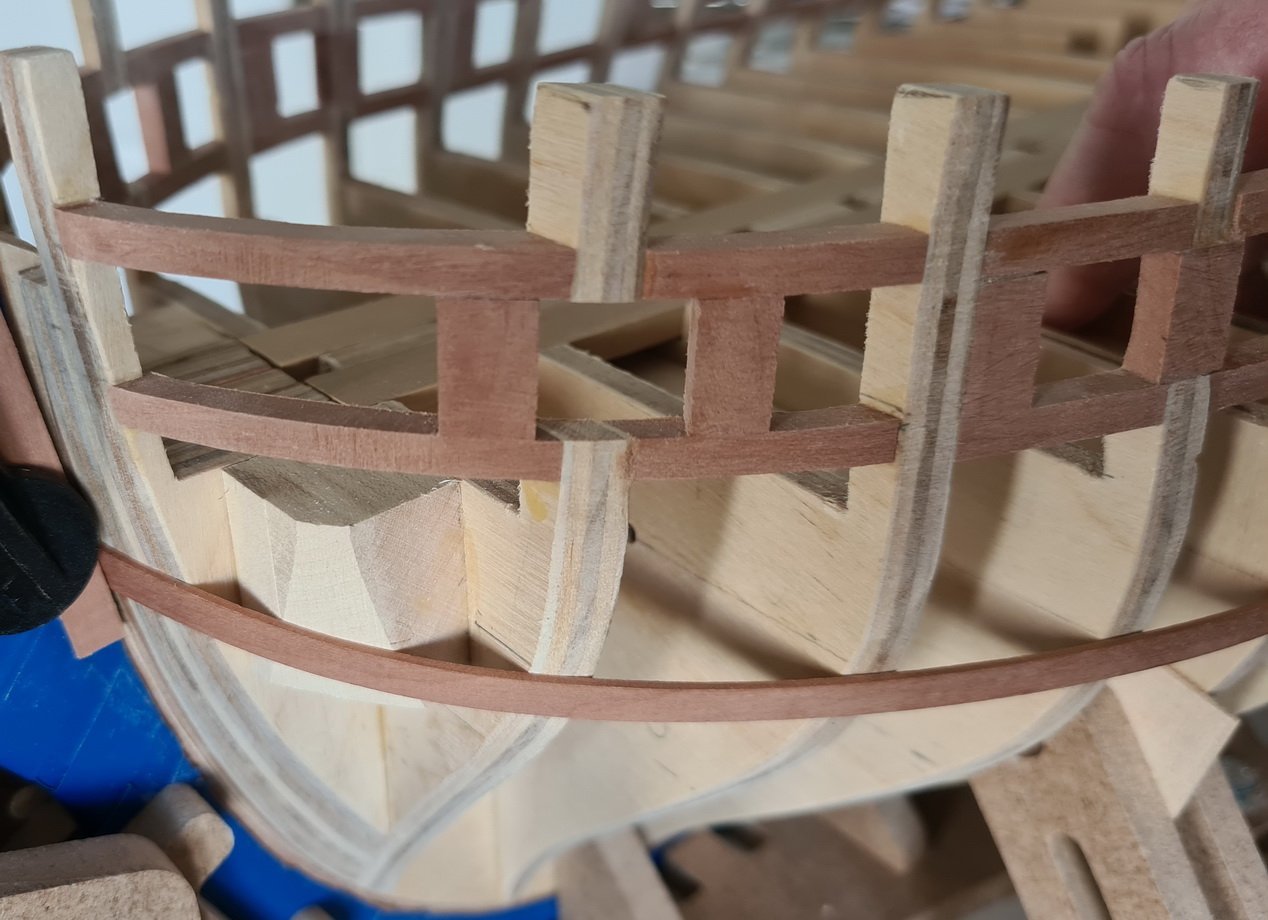

The upper part of some waist frames were a bit ragged and the height needed to be built up in two or three places, but I decided it would be better to sand them all down to a uniform level and place a 3/64” plank on the top. I now need to sand the top plank down just a little (I’ve left a small plus margin for error) but I’ll leave that until I’m ready to plank this location. I’ve been sanding the inside and most excess is now removed but I won’t sand any further until the outer planking is laid. However, I do have some fairing to do outside and there are a few places where I still need to add padding - you can see a couple of these in the photograph.

-

A lot of effort there and the results are really good.

- 840 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

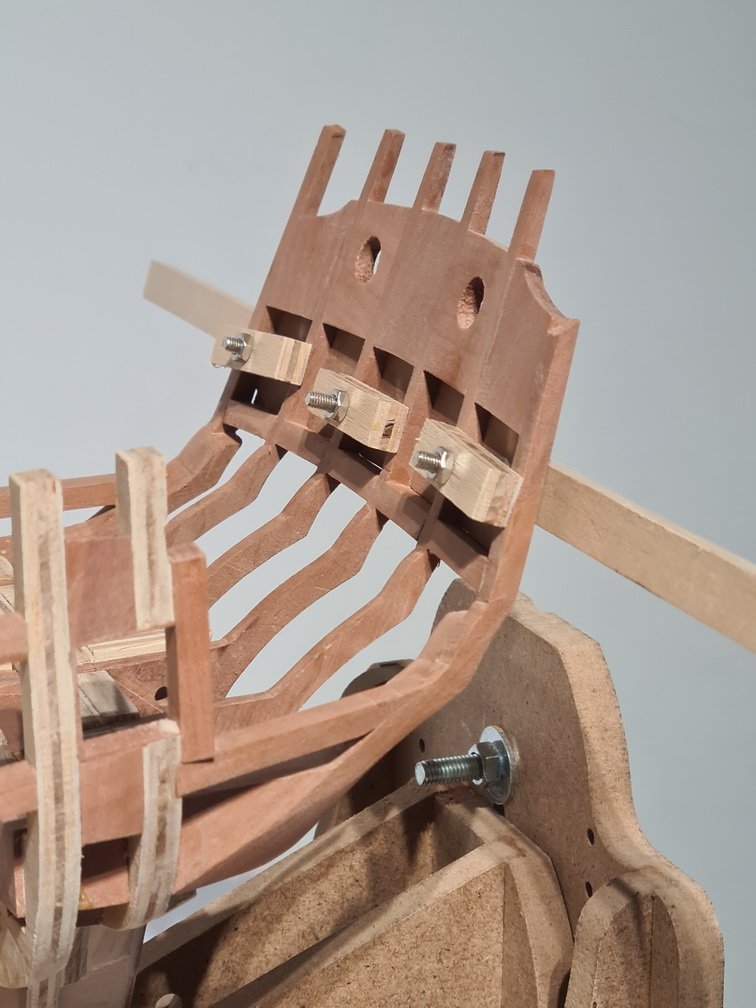

I’ve now moved on to the quarter gallery framing and to make things easier I provided one fixed point for each successive piece to land upon. I started with the forward end of the lower longitudinal by taking the upper side to keel elevation from the A0 drawing and cutting a slot at this height in bulkhead 28 for the longitudinal to set into. I cut the longitudinal a little over length, shaped the after end to fit the stern, and sanded the forward end until the after end dropped to the right elevation.

-

Good idea for the gunport lid assembly, Ben. Finished lids look very good.

- 399 replies

-

- winchelsea

- Syren Ship Model Company

-

(and 1 more)

Tagged with:

-

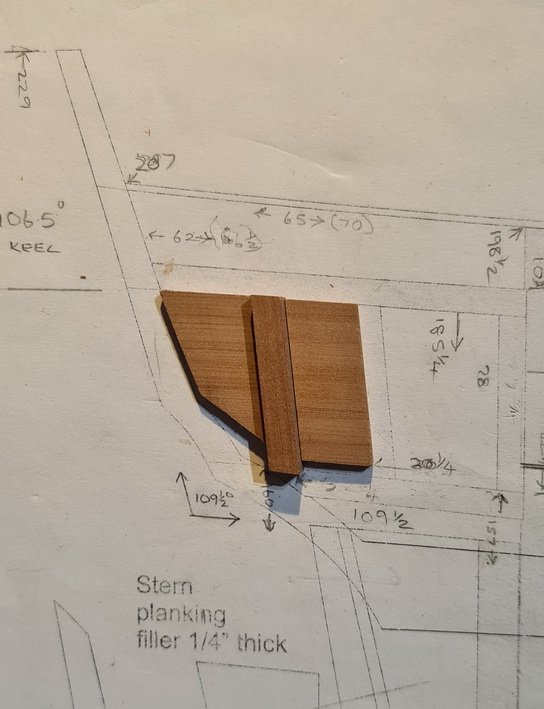

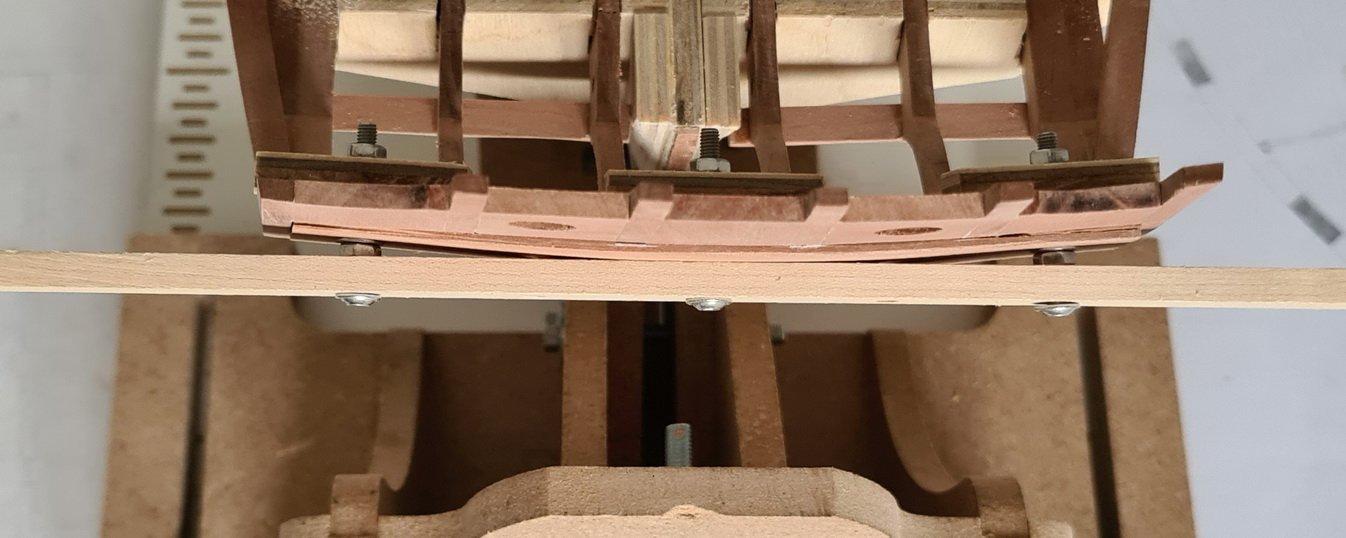

I had an error to correct on Bulkheads 27 and 28 as they rake aft because I did not cut the false keel joints properly vertical. These were the first pieces that I’ve cut, so I was trying-out printing to adhesive paper after removing sticky labels, then transferring the image to the plywood using pressure. This method didn’t work well for me as the transferred image was not very clear, so for the bulkheads I switched to pasting paper cut-outs on to ply with a glue stick. Anyway, I really messed up with the image transfer as I must have let the adhesive paper shift. However, as the fulcrum is near the top of the bulkhead former it only throws the bulkheads back just over 1/16” at deck level and I thought I’d get away with it by compensating with the stern framing placement. Reading ahead to Chapter 4, though, I was reminded about gunport placement so now I’ve shaved the bulkhead down to correct the distance between the last two pairs of gunports.

-

The stern frames are in place and I’m now sanding the transom down to 3/32” at the upper sill top edges as it’s currently about 1/8”. Whilst doing this I’m working on the quarter galleries. I did mange to break the top of the port ‘C’ frame, but I will not repair this until I’ve finished the quarter gallery framing.

-

That’s my big concern, Glenn. The stern frame positioning is not so easy and a mistake here will really mess things up later-on. I find Chucks drawings are excellent, though, both for detail and for accuracy. I verified a lot of measurements to get my badly cut bulkheads and frames correctly positioned, and although these were made from the printed A3 and A4 drawings, when each is properly lined-up, dimensions are always exact to those I check against the A0 drawing.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.