TimC

Members-

Posts

109 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by TimC

-

Looks like we’re around the same portion of the build. Yours is looking wonderful so far and the planking looks very clean. I like your idea of the capstan step and the mast partner! best tim

- 82 replies

-

- Fly

- Victory Models

-

(and 2 more)

Tagged with:

-

Thank you starlight! Great to have another beginner on here. I would love to discuss things together as we go forward. I’ll be checking your build out as soon as I reply to this as well so that I can follow along tim

- 164 replies

-

- fly

- Victory Models

-

(and 4 more)

Tagged with:

-

Thank you Richard and Spyglass! The reassurance is very helpful that I’m on the right path. I’ll get going with more beveling on the rear portion...I was hesitant to take too much off. im hopeful to soak the gunports tomorrow and get them fitted properly so I can start planking this weekend if I have the time. Very nervous for that! If you have any helpful tips about lining the hull or figuring out plank tapers I’d be very grateful! I have a bunch of references but more can never hurt Have a great night!

- 164 replies

-

- fly

- Victory Models

-

(and 4 more)

Tagged with:

-

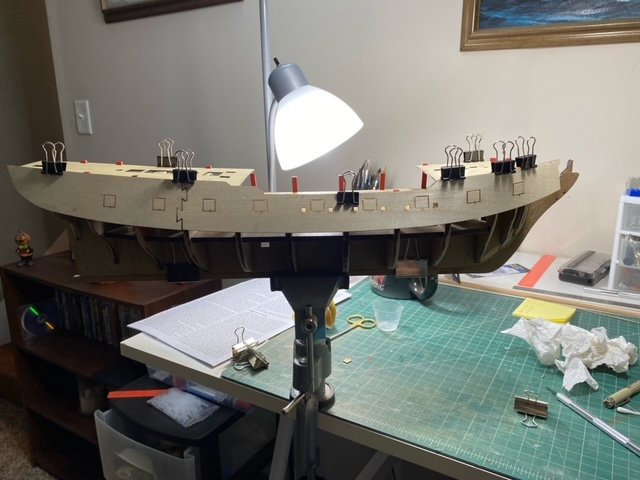

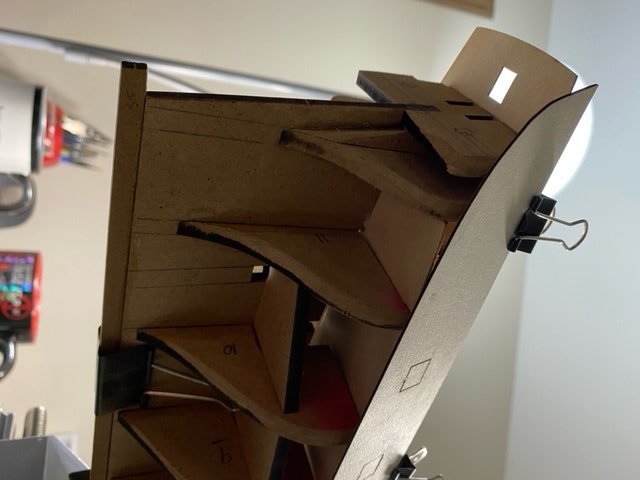

Hi all, Lots of pictures on this one, apologies in advance I got a good bit of work done today. Just got back from hiking in Shenandoah Valley (Appalachian Trail) the past few days with my girlfriend and our 3 pups so being up and about wasnt on the top of my to do list. Anyway, I was able to get the main deck planked, except the portions on the mid ship where the ends of the bulkheads will be removed later on. I think it came out pretty good with just a layer of varnish on top of the raw wood--room for improvement next time though...or even on the upper decks when I do them. I dry fitted the support beams along with the upper decks fore and aft. I used this to start getting my lines to shape the frame of the ship which seemed to work out well so far. I then started to use the gunport strips to help with planning the beveling for the planks. I was very unsure of how to approach this so I just went with the idea that as the plank bends around the frame, it should lay as flush as possible wherever it contacts the bulkheads--this seems to be what most videos and forums say on the matter--please correct me if I have this incorrect. Very unnerving being the first time, but it looks pretty good holding the limewood up to it with a light bend. I also used a piece of the deck planking to check the flush-ness of the fit since that bends much more easily. Getting the limewood to bend will be an experience I'm sure. I have not attached the stern counter patterns yet. From placing the rear upper deck, if I were to glue them in line with the pre-cut rear bulkhead, it would extend laterally out past the end of the rear upper deck. I angled the attachment sites of both pieces to allow a flush fit against the pattern of the rear upper deck---I think that was the right move. I spent a decent amount of time trying to figure how much to bevel the stern portion to make planking easier for me there...everything I see on here is that you need to take more off than you'd think to avoid a massive bend. I'm happy with it right now, but i guess i can take more off as I go. I still have to taper the rear portion of the keel (deadwood??) to accept the width of the planking against the rudder. I assume I should have done this earlier, but here we are! 🙃 Thanks for reading this novel, the sequel will be out shortly Tim

- 164 replies

-

- fly

- Victory Models

-

(and 4 more)

Tagged with:

-

Decided to use the mostly hidden areas of the lower deck to practice some planking techniques...figured if I messed up I could act like it never happened ;) I went with 120 mm cuts at 30 mm breaks in a 1-3-2-4 pattern with thread between the planks. I think the contrast there looks nice and I couldn’t get a decent marking with a pencil on the edges of the plank. I decided to use Zap medium CA since the pieces are so thin and won’t have stresses on them. I then applied a thin coat of matte medium on top to slightly darken the colors and apply a mild protection (not sure if this seals the wood too?). Any objections or words of caution using CA vs wood glue? For all hull planking I’m planning on wood glue (titebond 2) since I’ll use clips and hold them there for a bit. I think I will use the same deck pattern for the main decks as well. I like the look of it. side note: I’m not necessarily going for full historical accuracy on this one. I want to make it visually appealing to my eye and use it more as a “learn the techniques” process thanks for looking in! Tim

- 164 replies

-

- fly

- Victory Models

-

(and 4 more)

Tagged with:

-

Thank you Rob! Any and all help would be greatly appreciated

- 164 replies

-

- fly

- Victory Models

-

(and 4 more)

Tagged with:

-

Hi all this will be used as a log for my build of the Amati HMS Fly. I have never built a wooden ship and have only built plastic ships for about a year so most of this is very new to me, including the terms—which I will hopefully learn along the way. I will likely move very slowly because I’m nervous to make a mistake, but please offer any and all advice you have. I’ll gladly accept it all. Forgive me in advance for my dumb questions I’m sure I’ll ask. I haven’t don’t much yet, but I started to dry fit the keel and bulkheads. I will hopefully start the beveling process soon. —Tim

- 164 replies

-

- fly

- Victory Models

-

(and 4 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.