-

Posts

881 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by rfolsom

-

-

Fantastic work, as always... Is your microscope for sale?

-

Anybody recommend a good brand of micro torch?

-

Welcome to the Niagara Fleet; this Girl's just as worthy as any Ship of the Line...

-

Hello, Larry!

I haven't checked into you fine build for awhile; (been working on another..) I'm not sure if I'm able to help you with your problem, but I installed my main rail in my Cutty Sark after lightly sanding the bulwarks to an even shape. I believe I did the same for Niagara, but I haven't installed the rails yet.

I always worry about the topgallant railing after all the hull planking and bulwark detailing is complete; it can become lopsided... I believe the topgallant rail shows the final look of any ship's lines, and should be taken seriously..

Looking forward to your fine work;

~Bob

-

Dale;

There is slack in the chain plates, in the picture you see, because all rigging was removed. The channels only held lateral forces away from the side of the ship; they were not designed to hold or support tension forces (ie the stays) in any way but a small component of the tension forces. The chain plates transmit the tremendous loads from the; wind-->sails-->yards/masts/standing rigging/hull; and the primary structural and inflexible load bearers in this area are the chain plates.

Hope this helps.

~Bob

-

Welcome, Steven!

I also completed this kit when I was in my teens. It is a wonderful plastic model, and I look forward to your build.

All the Best,

~Bob

-

-

Thanks for the kind words everyone; my stomach flu was 3 days of misery, but that was a couple of weeks ago, and I feel fine now. (So no excuses for lack of progress, right, Nenad

?)

?) Thank you for the Shumadia tea recipe, Nenad; I must try it out soon as it is starting to get colder here, and It sounds like a good warmer-upper. Not sure if I can find plum brandy where I live, but then again, I've never looked...

I did spend a little time last night fashioning some bolts, and affixing a few to the rudder, as well as doing some measurements and experimental work with the bulwark sheaves that Nenad has just completed, but nothing photo-worthy yet.

Seeing everybody's progress will soon light a fire under my @%%, and I'll be good to go once again...

-

Eyebolts are looking great, my Friend, as are the sheaves; I am still working on my rudder, but I think I need to start doing multiple side projects in order to overcome the "mental block" I am facing right now...

.

.Cheers,

~Bob

-

-

-

Keith; Your old log is still up and running; and I blindly checked in and about had a heart attack! Maybe relabel the title as to "former log" so we see your great work without the loss....

~Bob

-

-

Very nice work! I coppered my rudder about a year or so after the hull; there is a slight patina mismatch, but all one has to say is "the rudder was lost at sea, and a new one affixed at port"

-

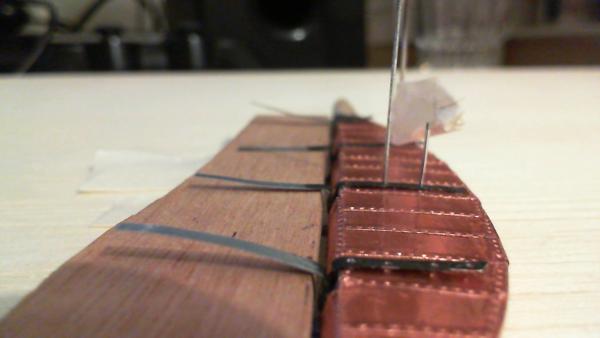

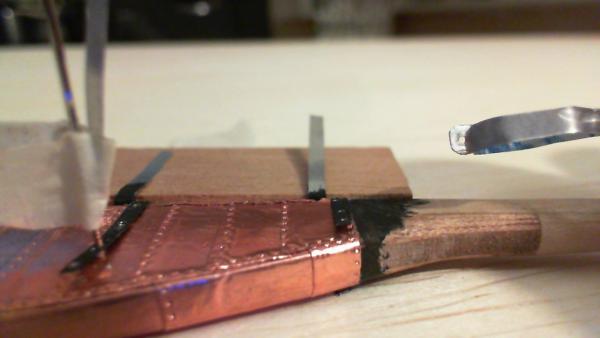

Ok, Nenad; Not a lot of progress, but this is where I'm at. The rudder is loosely mated with a piece of scrap wood in order to drill the sternpost sides of the gudgeons, which still have to be cut to size. The rudder side of the gudgeons have all been drilled, and you see some wire in place that will eventually be cut and shaped into the holding nails. In the last pic I'm holding the bracket for the rudder retention chain (I'm using the terms loosely) that will be affixed to the rudder stock.

- canoe21, NenadM, CaptainSteve and 4 others

-

7

7

-

-

Wonderful work, my Friend; You have definitely delved into the "microscopic realm". These four sheaves are all different sizes, and at different angles; will you be reproducing all of this?

Eagerly awaiting....

~Bob

-

Hello, Achuck!

If you measure your hull from tip to tip, and the distances between your fore to main, and main to mizzen mast centerlines, I'll tell you your scale.

Nice to see another Cutty build; I'm looking forward to your progress!

~Bob

-

-

Thanks, Nenad and Marc.

I feel much better indeed...

After three days of eating hardly anything, I made pork and cabbage eggrolls last night. Admiral ate one, I finished the other eight. I then cooked the remaining pork (close to a pound) and ate that as well (!) Also had breakfast this morning; I never eat breakfast!

...the runaway pig has been outdone...

Nenad; even though I'm pretty much over this bout, I'd be interested to see your recipe.

~Bob

-

Thanks Keith, I will definitely put a dab of ca into the holes...

Thanks for the advice Marc.. hinges are already glued, but the material they are made from is very flimsy aluminum from a can, so I think they will lay ok when I finally get the courage to affix them. (I may be wrong, hence the "courage" part)

I did a little work tonight, but I'm coming off a mild case of stomach flu (about three days worth) so I've been out of the shipyard. Hopefully tomorrow will be producing results....

-

-

Hello Peter; This is the exact same kit I am building; a used Billing #459 from the early '70's. Mine was purchased off ebay unstarted, but incomplete (the sheet with the main deck and the instructions were missing) with no fittings kit included. It will be great to see how a more experienced builder than myself tackles this kit.

-looking forward to seeing your posts...

~Bob

-

Keith; I have found copper tape, with a ponce wheel, works quite well. They are more fragile, but very easy to replace. Caldercraft, and other companies, make excellent tiles, but are usually very expensive, and one has to use a lot of CA to affix them. A roll of copper tape from Model Expo is about $13, and a ponce wheel about $8. I like the look of photo-etched plates, but could never justify the cost, nor the extra labor of affixing them.

In my Humble Opinion..

Cheers!

~Bob

CUTTY SARK by keelhauled - Mantua - kit bashed - First wooden ship build

in - Kit build logs for subjects built from 1851 - 1900

Posted

Hey, Marc; It's so good to see you back in the build again; you've given me much inspiration over these couple of years; and I'm looking on to your fine build.

Cheers, and best wishes always,

~Bob