Daniel Kimmer

-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Posts posted by Daniel Kimmer

-

-

-

- Canute, RossR, mnewsholme and 1 other

-

4

4

-

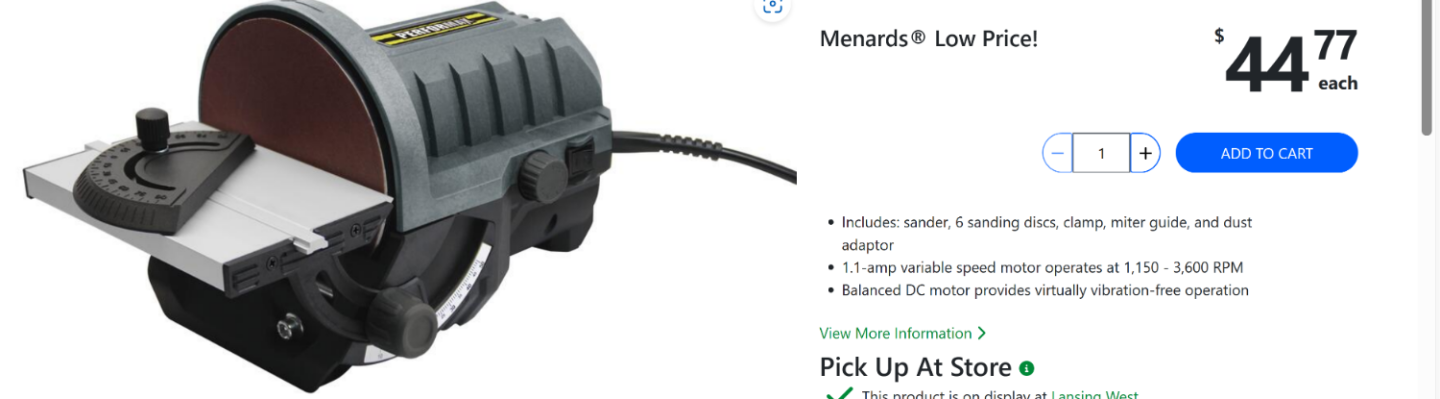

I purchased one of these from Menards for real cheap money and it serves me well for years until I purchased the Byrnes Model Machine 4 inch variable speed. It depends on how much you think you will use and need a sander. The Byrnes sander is nearly 9 times the price and it is worth the money but again how much do you plan to use the sander.

-

Is there a way to change out the center post to obtain some additional height? The use of an x y table would be nice for the possibility of some precision when drilling wood deck fittings. Currently with it only being 7 inches in height there is not sufficient room for a table unless I misunderstood the dimensions of the drill press. I can see where a small micro drill press would be useful but I would still want an X Y table. I also use very small bits and if this would help with the breaking of the bits it would be of help.

-

Yes I'm interested in purchasing a small hand operated disc sander. I've been trying to find a 4 to 6 inch (100mm to 150mm) size. Something that would fit easily on a work bench or desk to allow fine sanding and trimming up tp a line or creating a controlled angle or just a perfect 90 degree cut. If it is high quality I'm willing to pay a good but fair price.

-

You are a builder after my own heart, you have at least three ships going at the same time, and you appear to love building the hulls. I currently have four that I'm building. I seem to not be able to bring myself to start the rigging on any of them. I look forward to following your build log.

I see you are also from Michigan, have you found any good hobby shops in the state besides Riders in Flint and Grand Rapids, and J Bar Hobbies in Tecumseh? Slim pickings for a good hobby shop other than what is on line.

-

Wow, some great ideas in this string of post on how to store spare planking and lumber, sure beats the couple of small barrels I use. I like the cardboard tube idea. I have some spare PVC short plumbing pieces that were from a major replumbing of a 1900 built home and I think I may try to use them. I'm thinking if I cut the PVC to the same angle configuration as the cardboard and use end caps to secure them to a board I could make a pretty good storage system. If I'm successful and if it does not look too bad, I'll post a few photos.

-

Go to the Xuron website Xuron Corp, they have an excellent assortment of small pliers with 1.5 mm and 3 mm width heads. They work great and for me work far better than tweezers.

-

Question for you: Do they hold the #11 blade extremely tight so it does not loosen up under pressure? My current #11 blade holder by Exacto loosens up under stress when cutting. My #11 blade holder from Excel also loosens up with stress. The Fiskars barrel handle for the #11 blade does a pretty good job staying tight but I could use a handle a little larger. The ones you have look very nice.

-

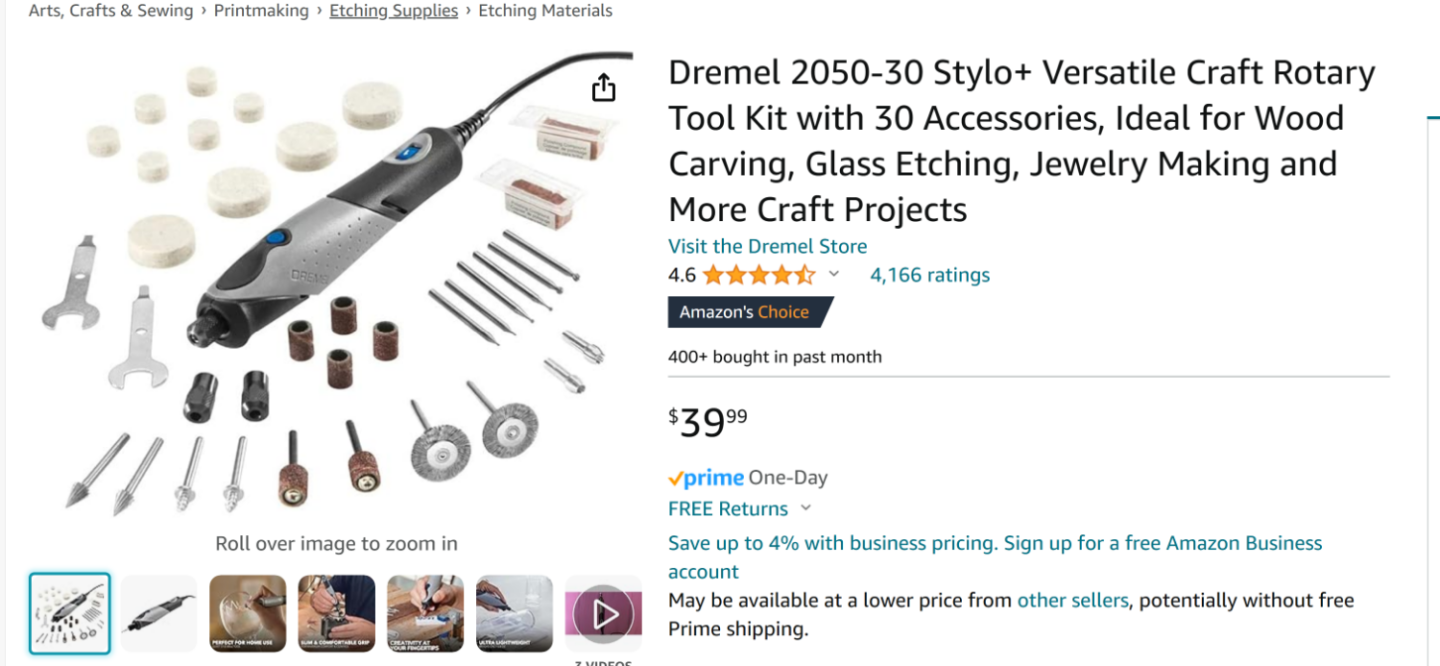

I have two of them and they work very well drilling into wood or thin brass and copper for model ship building. If I need to drill something that requires a lot of torque, I use my Foredom with a number H30 Handpiece with a chuck or the H44 Handpiece with a collet. I find the Dremel Stylo to work very well for very small drill bits.

-

-

I just received mine from UPS (Early X-mas present to myself, saves my wife from shopping). What a fantastic machine. I'm left handed and I really like the reverse feature. I purchased mine with the extended miter bar and several spare metal removable disc. The disc are two piece and can easily be changed out by removing three screws. My plan is to keep a different grade of sanding paper on each of the four disc.

When checking out the sander what I like most is the ability to turn it down to a very slow speed and still have the ability to sand without bogging down. The motor, for the size, is very powerful.

I ordered the variable speed sander off the website 11 days ago. The box and Styrofoam packing blocks kept the sander safe during shipment. The Styrofoam blocks will be used to make a building cradle for laying the hull on its side while building. I would hate to waste the blocks. Really nice firm Styrofoam.

My hat off to Model Machines for the quality of the sander.

-

-

I use the Dremel Stylo, very small, corded tool with speed ranges from 5000 to 15000. I make a small indention with a pin tool to allow the drill bit to find its' location and use cheap Hardor Freight drill bits and they work great. I use the tool on the low speed and let the tool do the work. I wear a pair of 2.5 reading glasses so I can see the impression in the wood the pin made prior to drilling.

-

Video Library – Foredom Electric Company also is an excellent resource that is on thier website

-

Try contacting the Foredom company online or calling them. They are an excellent company that will assist you with any questions. Contact information:

Emailcustomerservice@blackstoneind.comI have contacted them several times when ordering replacement parts. Very helpful staff and efficient company. There website is excellent and contain a huge amount of information. Try using the serial number off the label on your machine in the search box or use it as a reference when calling them. There tools last for decades but you want to make sure you order the proper insert for the flex line. I wish you luck, I love my Foredom tool and look forward to using it when I can. I even purchased the Vanda-lays Acra mill plus to use with the tool to give it better options for control. Expensive but it allows the full use of the tool and they sell a clamp set yp that works with the Foredome # H.30 and H.44 handpieces. -

Lathe Question

in Modeling tools and Workshop Equipment

Posted

I have both the sherline lathe and the mill and love them. A friend of mine has the Taig and we often argued which is best. We reached the consensus you would never go wrong with purchasing either. We both tried the others mill and lathe and agreed they were both very well designed and worked great. His Mill was larger that the Sherlines but I could pick mine up and move it where I wanted (35 pounds compared to the Taig weighing in at over a 100 lbs)) The Taig mill was larger and could handle larger items compared to my Sherline. I found I wanted the ability to move mine if needed (on and off the work bench). I also found a lot more accessories for the Sherline mill and lathe than what the Taig had available. I think the Taig mill could handle larger items and harder metals that the Sherline but for model making the Sherline works great.