-

Posts

302 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Rock_From_Korea

-

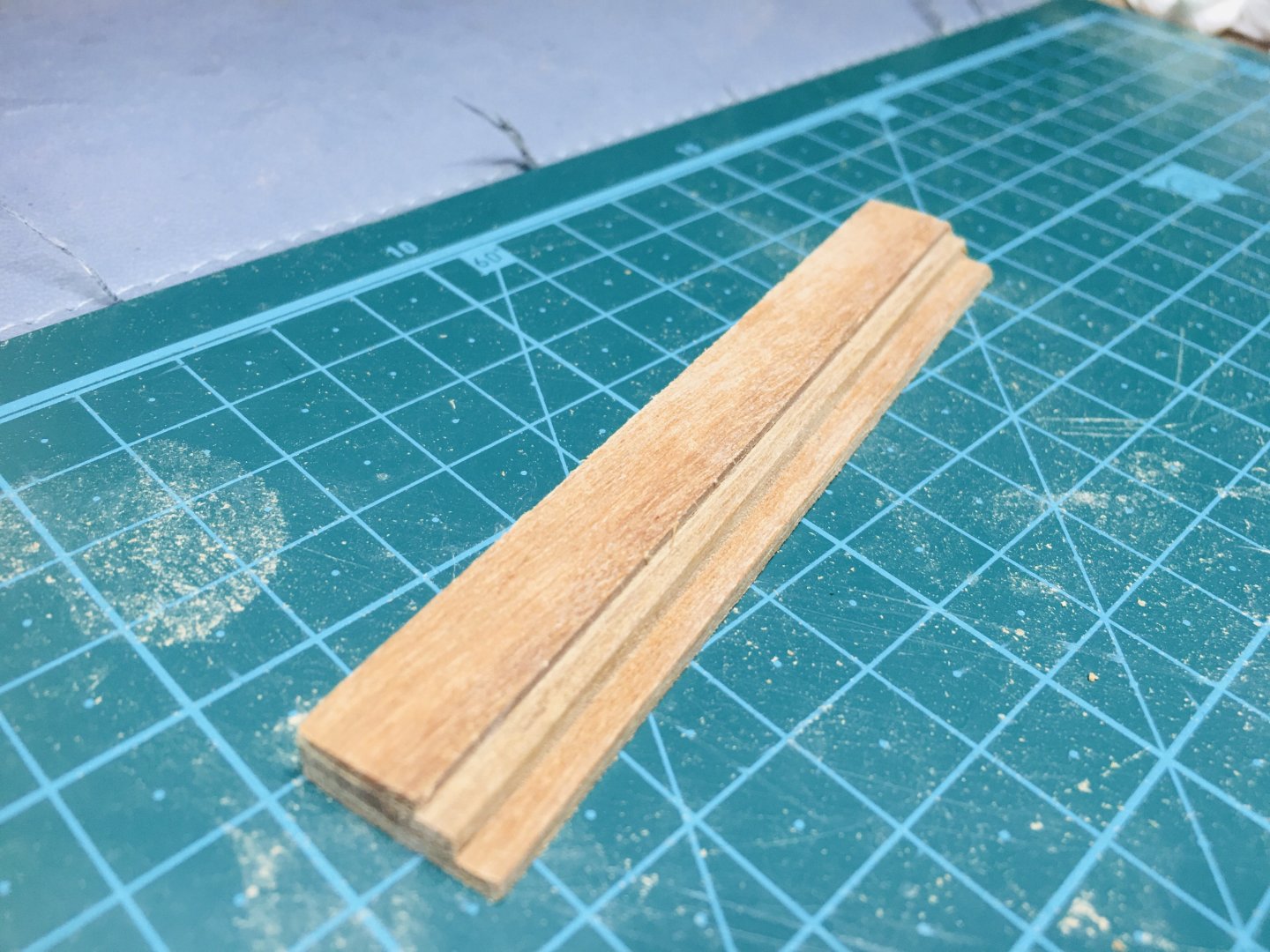

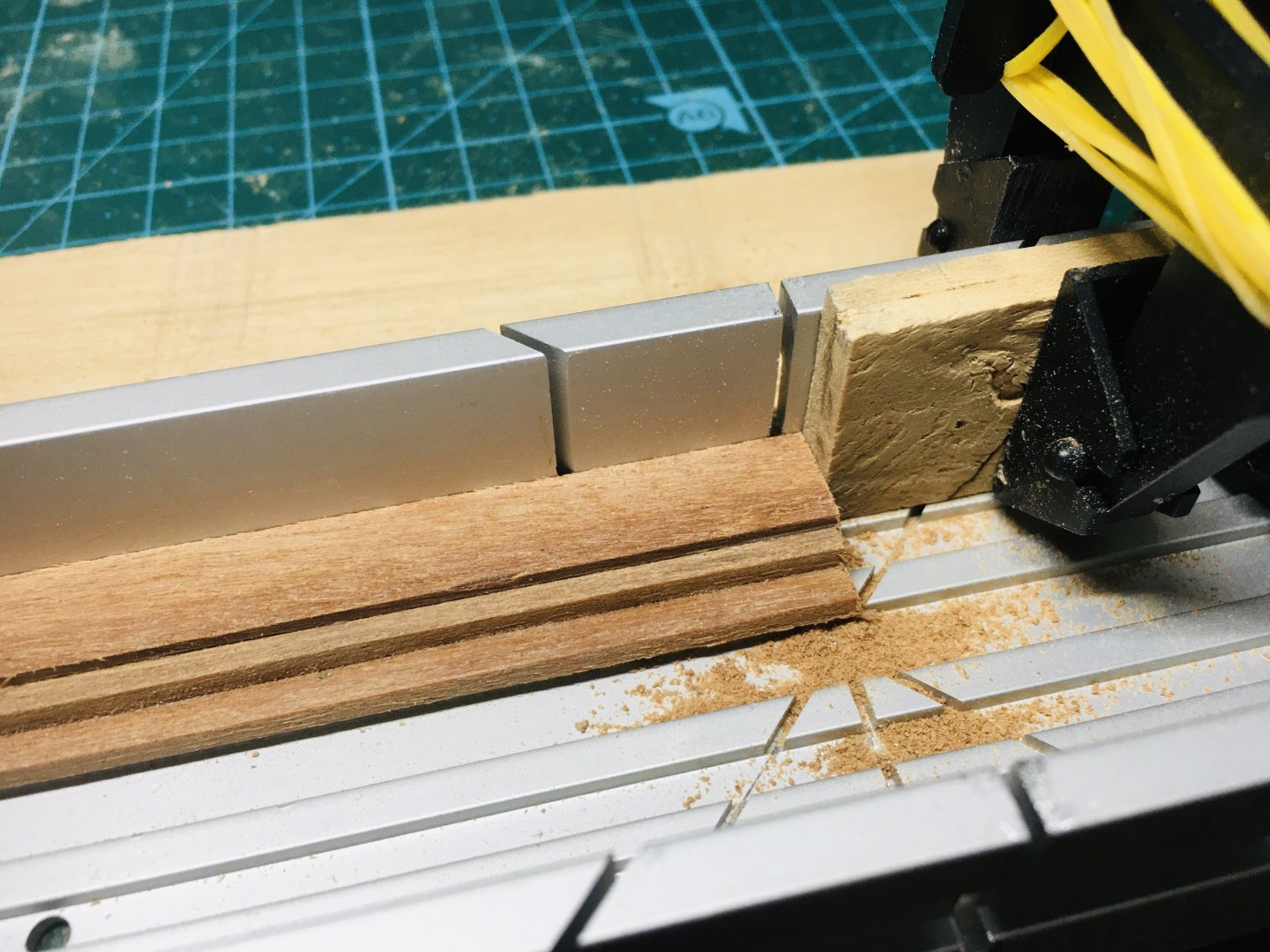

Now the progress pictures - I took pictures only on the works where I applied different (from GH1) methods, styles and/or materials. I am applying darker colours in GH2 - the grating has been dyed with walnut colour (vs. no dye, light wood colour in GH1), gun port rims also dyed with walnut paint, cannon carriages also used darker wood with different methods (smaller). GH2 overall theme would be darker colour, less decorative painting, slimmer design and etc. My next interim report may also take some time as I plan to report only on those areas where GH2 differs considerably from GH1.

-

Hello All~ It has been really long since my last update on GH1. I have been working on GH2, but progress has been extremly slow as it has been quite a busy half year at work. I originally planned to post the progress report on GH2 at one go, with all the hull/deck related work finished. However, I think that would make my next progress report due sometime around the end of the year. Therfore, I decided to put forward an interim report on GH, just highlighting the different methods/styles that I am applying to GH2. First, the GH2 pictures that show the progress level before I began working on GH2 again at the beginning of this year. I have posted these pictures in this thread sometime in 2022 (I think). But, to make things easy for everyone (including myself), I am reposting here.

-

Roter Löwe 1597 by Ondras71

Rock_From_Korea replied to Ondras71's topic in - Build logs for subjects built 1501 - 1750

Looks amazing! -

Happy New Year~! I have finished all the hull & deck related work last week. Instead of starting the mast & rigging work on GH1, I decided to work on GH2 for a while - plan to finish the hull & deck work on GH2 before resuming work on GH1. I plan to apply different style, deck configuration, colour schemes and etc for GH2. I will be posting the work on GH2 only on the areas that do not duplicate the previously posted work streams. Below are some pictures taken from the last hull & deck work on GH1. Also posted are some pictures with unfinished masts put in place.

-

Hi Robert~ Thanks for your comment! I blackened them chemically. I usually put the chemical in a small plastic holder and put it in a bigger container that has hot water in it. This way, the chemical process happens almost instantly and I can save time and the amount of chemical to be applied. Hope this clarifies~ Rock

-

The cannon work begins with single blocks (without hooks) being attached and rigged to the cannon carriage. There will be no hooks attached to these single blocks as there are not enough space to have hooks on boths ends - won't have room for tight rigging. The double blocks that are connected to the inner hull wall and to the other end of the rigging have been constructed with hooks. The demi-culverins are installed in a slightly different configurations - 2 cannons fully deployed, 2 cannons on a stand-by positions.

-

Hello shipmates! I am nearing the end of 1st phase (completion of hull structure) of the GH1 construction. The only areas left for the hull work are the installments of cannons and the main mast knighthead. I have included just a few pictures of the main mast knighthead as there were ample pictures presented during the fore mast knighthead construction. The main mast knightheads are not fixed to the deck as final fixing to the deck will be done after the cannons are all installed.

-

Hi Allan, I am sure that they did NOT use belaying pins during the 16th century! As I mentioned at the start of the belaying pin work in the forecastle area some time ago, I originally planned to use no belaying pins. However, looking at the sheer number of rigging that I need to do later, I decided to use some belaying pins. Just a bit of compromise between historical accuracy and ease of work on rigging. After trying this particular method for GH1 and if I figure out a way for tackling all the rigging without help from some belaying pins, I will definitely apply it to GH2 and beyond. Regards, Rock

-

I still feel a little bit clumsy with my left index finger. And as such, work is not as satisfactory as before. Anyway, for the whipstaff house, I just chose a simple (but robust) design. The end result is kind of cute and quite strong structurally. Below are the photos on this endeavor. The whipstaff house is not attached yet to the deck as I will need some space to work on the mizzen mast area and etc.

-

Continuing on grating and some work on the quarterdeck knighthead(? not sure if this is the right jargon). My beloved IKEA drill is broken..... So, until I get a new IKEA drill (I intend to get another IKEA drill!), some work that requires drill will need to wait - some refinement to be done later on the quaterdeck knighthead(?).

-

Hello All~ It's been a long time since my last update! I had to take time off from the shipyard due to minor injury on my left hand. Now fully functional again~ So, I have restarted on where I left off. Continuing on the quaterdeck grating and whipstaff house. First, below are some pictures on the quarterdeck grating.

-

Hi all~ It's been a while since my last visit - have been tied up with something. Anyway, work on the upper decks continued. I tried walnut color stain for the ladder and it tuned out quite OK. Belaying pin racks are once again done using decommisioned hard wood chopsticks. Below are some progress pictures.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.