-

Posts

582 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by cabrapente

-

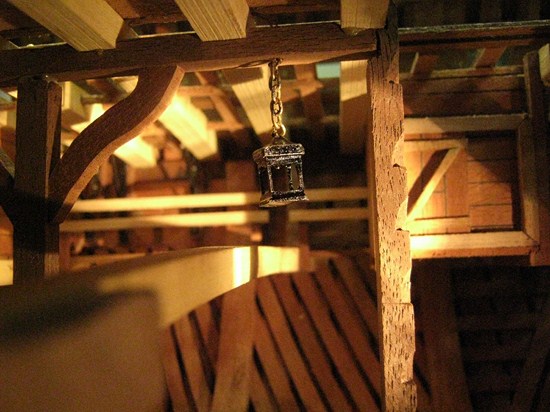

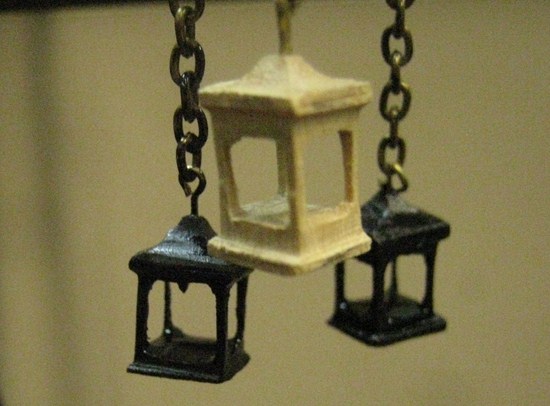

thank you very much for your help Richart. this occurred in January 2011 la belle, the finished failing to put the candles. I am copying the record, with all the problems I had already had it in another forum. cabrapente greetings

-

ROYAL CAROLINE 1749 by Doris - 1:40 - CARD

cabrapente replied to DORIS's topic in - Build logs for subjects built 1501 - 1750

Hello Doris. beautiful boat. Could you give us more information about the diodes? thank you very much. Cabrapente- 883 replies

-

- royal caroline

- ship of the line

-

(and 1 more)

Tagged with:

-

you're right Martin G. Thanks to this work is so perfect, we (the trainees) improve every day a little more. fantastic work

- 662 replies

-

- bonhomme richard

- frigate

-

(and 1 more)

Tagged with:

-

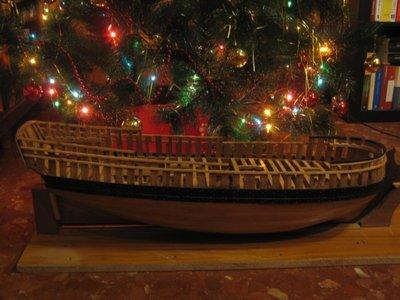

ancre Le Fleuron by cabrapente - FINISHED

cabrapente replied to cabrapente's topic in - Build logs for subjects built 1501 - 1750

- 332 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

ancre Le Fleuron by cabrapente - FINISHED

cabrapente replied to cabrapente's topic in - Build logs for subjects built 1501 - 1750

- 332 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

ancre Le Fleuron by cabrapente - FINISHED

cabrapente replied to cabrapente's topic in - Build logs for subjects built 1501 - 1750

- 332 replies

-

- le fleuron

- 64 gun

-

(and 1 more)

Tagged with:

-

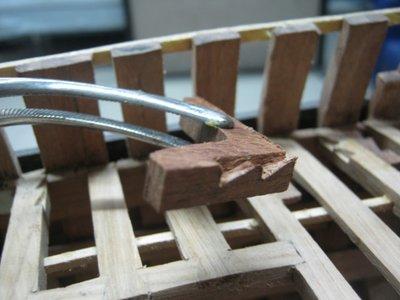

was just 4 brass rods, and the starboard side, I spent three and a half. while I buy more, I've messed with the stern.

-

Anyone can guide me? I have fear of damaging it while I finish it. What do you do when you finish the hull sanding, wax, oil, varnish, ...? thanks

-

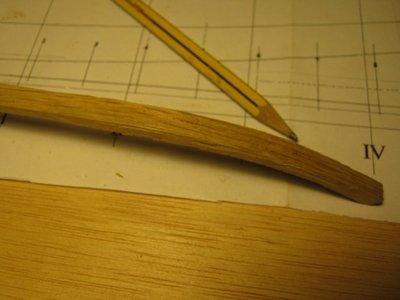

The colored lines were because I was wrong, and to start over, change color. and no one can see clear no (heh heh heh) Now do the strakes to calculate, and copy the opposite. pins, are steel. but when I'm removing the glue dry, and after the sanding, the compressor and blow the holes are back. then I'll put the final nails.

-

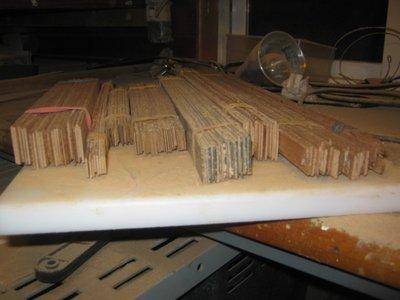

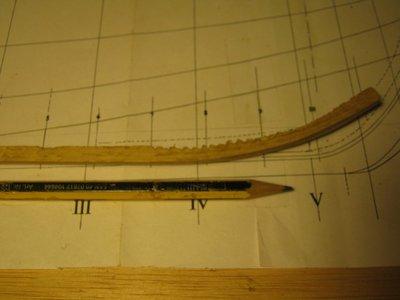

Good afternoon, I have not touched the boat. but I rapasado all strakes, iroko, cedar, oak and cherry. I've changed the sand twice. but it was too much. I could pull the nails, with just damage.

-

to see if anyone can give me advice. strakes as I can not brush them with the thicknesser, for being very thin, I'm standing with cutting band saw. let thick with many changes. inside, I put wooden nails (hygienic chopsticks), but they are too fat, and ugly. so I bought copper nails and bronze color and a nail is driven. but to sand them, change the color of iron, and bulk changes if you lose your head. if the strakes amount without nails and lijo all, where would the nails, how do you do? Thank you.

-

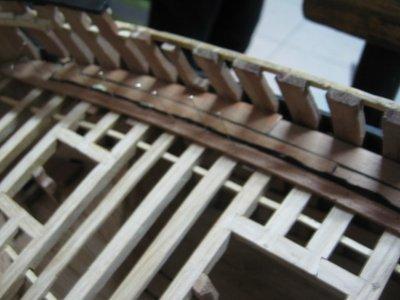

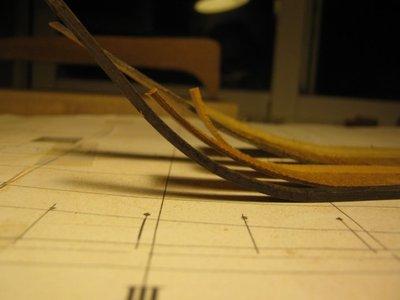

I start the shell with cherry. curving strake is a great invention. dry, and in less than a minute, you get the curve to give the strake. seriously awesome.

-

I tested with different woods. all functions. even ebony. this is oak, with a greater thickness. more breaks, but outside is fine.

-

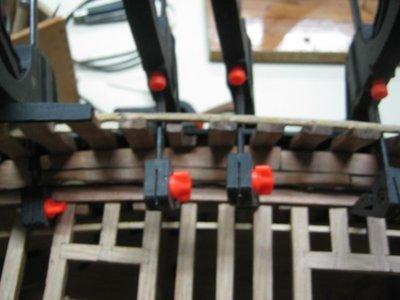

continue to gradually lined. I built a cold bending strakes. I came to see a device that crushes lemons, to prepare caipirinha. I've done testing, work well. this is oak, and very wide. curve less, but the good side does not suffer.

-

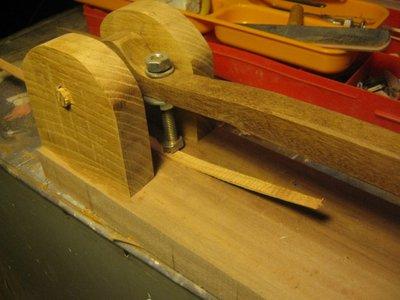

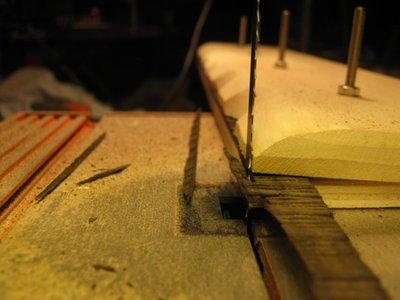

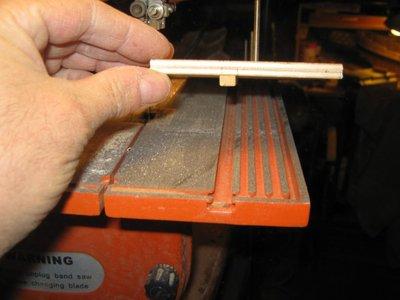

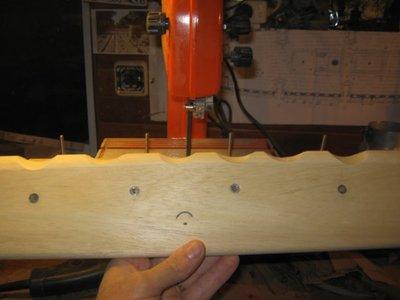

looking for a place to weld the sheets, I found a site where they are made. are larger and stronger, the cut is not as fine. but cut straight, fast, and I'm encantado.mucho better than the originals. best price ..... 7.50 euros each. have manufactured a tool, which serves to cut straight strips that do not have uniform edge. Basically, they are a couple of tables guide, with four screws, imprison within the ribbon cutting. to see the reference line to the table above, I made notches, through which you can see and align the ribbon.

-

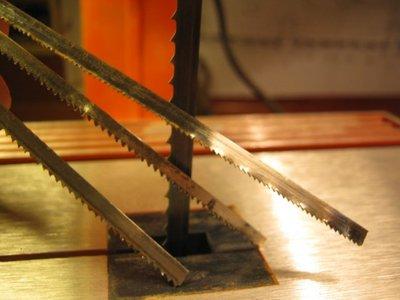

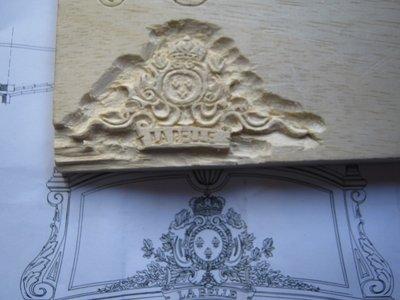

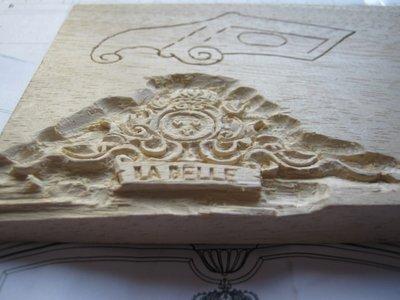

well then broke the two sheets of the band saw, and tried to make the figure of the mirror. faithfully tried to copy the picture. but even in pencil, on paper, could not. so I've done a bit modified. but I like how it looks.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.