Paul Le Wol

NRG Member-

Posts

1,062 -

Joined

-

Last visited

About Paul Le Wol

Profile Information

-

Location

Mount Hope, Ontario

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Paul Le Wol reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

-

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

-

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

-

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

Paul Le Wol reacted to a post in a topic:

USS Tennessee 1869 by Keith Black - scale 1:120 - Wood Hull Screw Frigate - ex Madawaska 1865

-

Paul Le Wol reacted to a post in a topic:

Columbia 1835 by Glen McGuire - 1/400 - BOTTLE - Steam Packet

Paul Le Wol reacted to a post in a topic:

Columbia 1835 by Glen McGuire - 1/400 - BOTTLE - Steam Packet

-

Canute reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Canute reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

thibaultron reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

thibaultron reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Keith Black reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

Keith Black reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

John Ruy reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

John Ruy reacted to a post in a topic:

Billy 1938 by Keith Black - FINISHED - 1:120 Scale - Homemade Sternwheeler

-

Keith, congratulations on completing Billy! Amazing detail on this little guy.

- 401 replies

-

- Billy

- sternwheeler

-

(and 1 more)

Tagged with:

-

Keith Black reacted to a post in a topic:

Gjøa 1872 by Harvey Golden - Roald Amundsen's Cutter built at Rosedahl, Norway

Keith Black reacted to a post in a topic:

Gjøa 1872 by Harvey Golden - Roald Amundsen's Cutter built at Rosedahl, Norway

-

JacquesCousteau reacted to a post in a topic:

Gjøa 1872 by Harvey Golden - Roald Amundsen's Cutter built at Rosedahl, Norway

JacquesCousteau reacted to a post in a topic:

Gjøa 1872 by Harvey Golden - Roald Amundsen's Cutter built at Rosedahl, Norway

-

Harvey Golden reacted to a post in a topic:

Gjøa 1872 by Harvey Golden - Roald Amundsen's Cutter built at Rosedahl, Norway

Harvey Golden reacted to a post in a topic:

Gjøa 1872 by Harvey Golden - Roald Amundsen's Cutter built at Rosedahl, Norway

-

lawrence101 reacted to a post in a topic:

North Carolina Oyster Sharpie by Paul Le Wol - FINISHED - 1/24 - from plans drawn by Thomas Pratt

lawrence101 reacted to a post in a topic:

North Carolina Oyster Sharpie by Paul Le Wol - FINISHED - 1/24 - from plans drawn by Thomas Pratt

-

lawrence101 reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

lawrence101 reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

-

lawrence101 reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

lawrence101 reacted to a post in a topic:

Muscongus Bay Lobster Smack by JacquesCousteau - Model Shipways - 1:32 - Rescaled and Modified

-

Great looking planking John. Have fun at your reunion!

- 53 replies

-

- William Atkin

- Sloop

-

(and 1 more)

Tagged with:

-

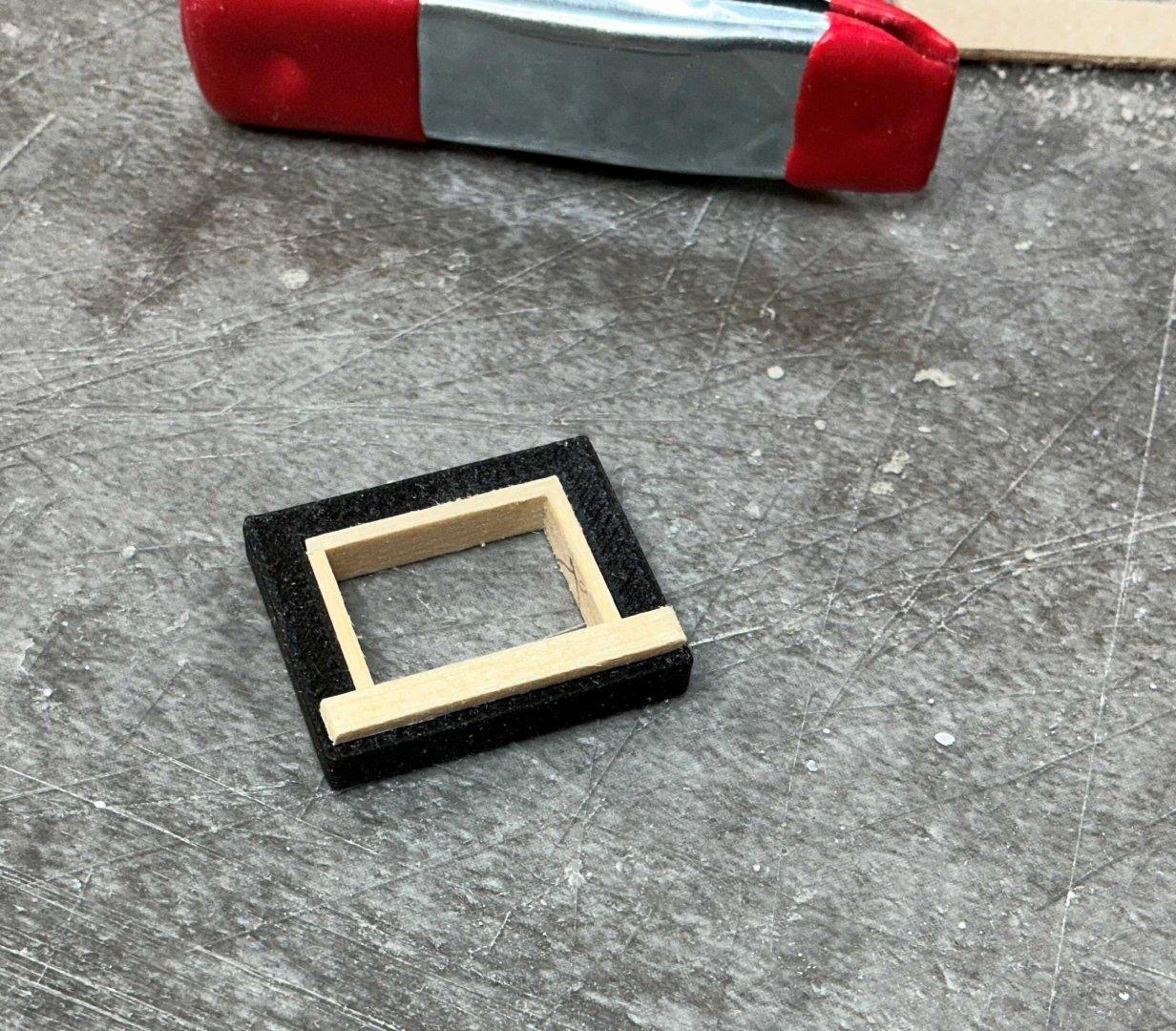

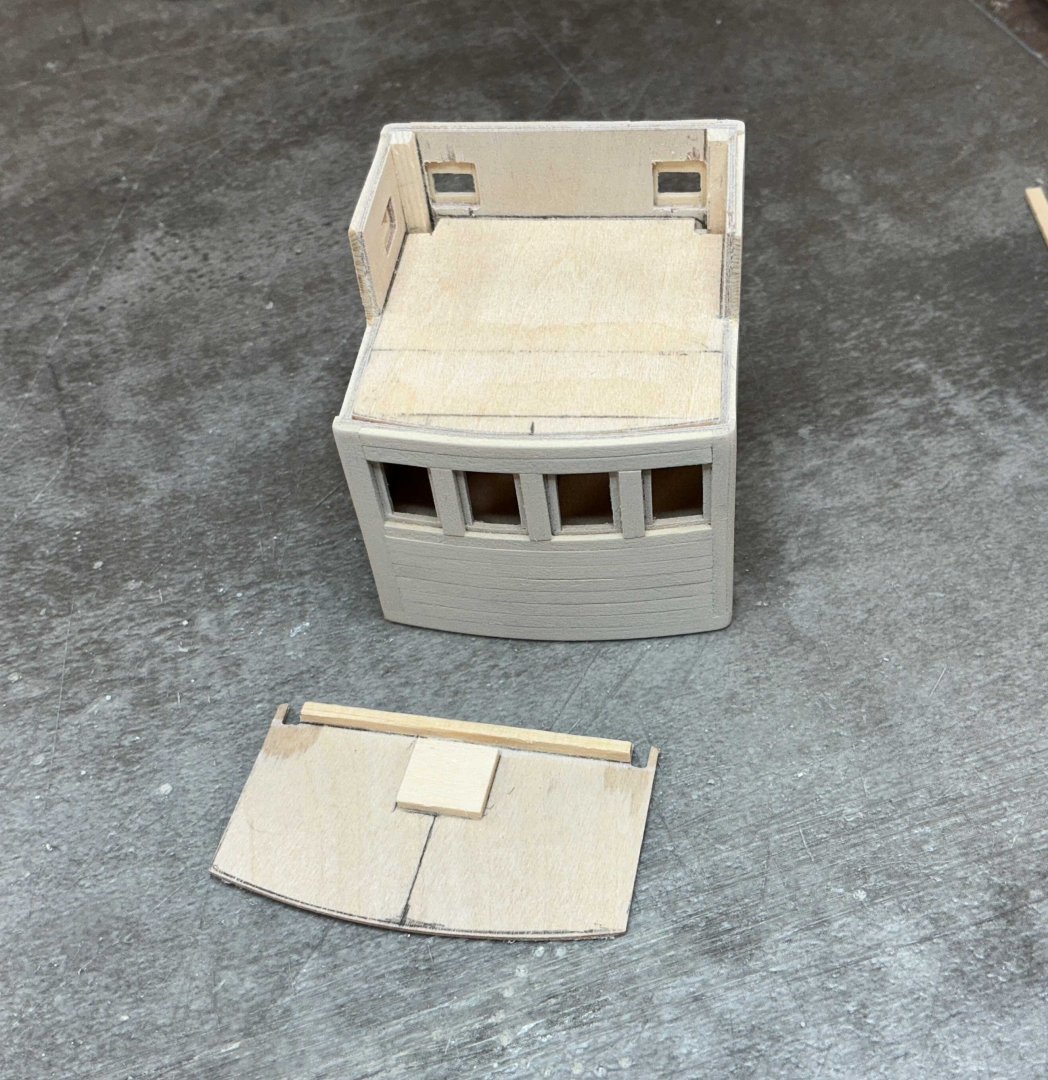

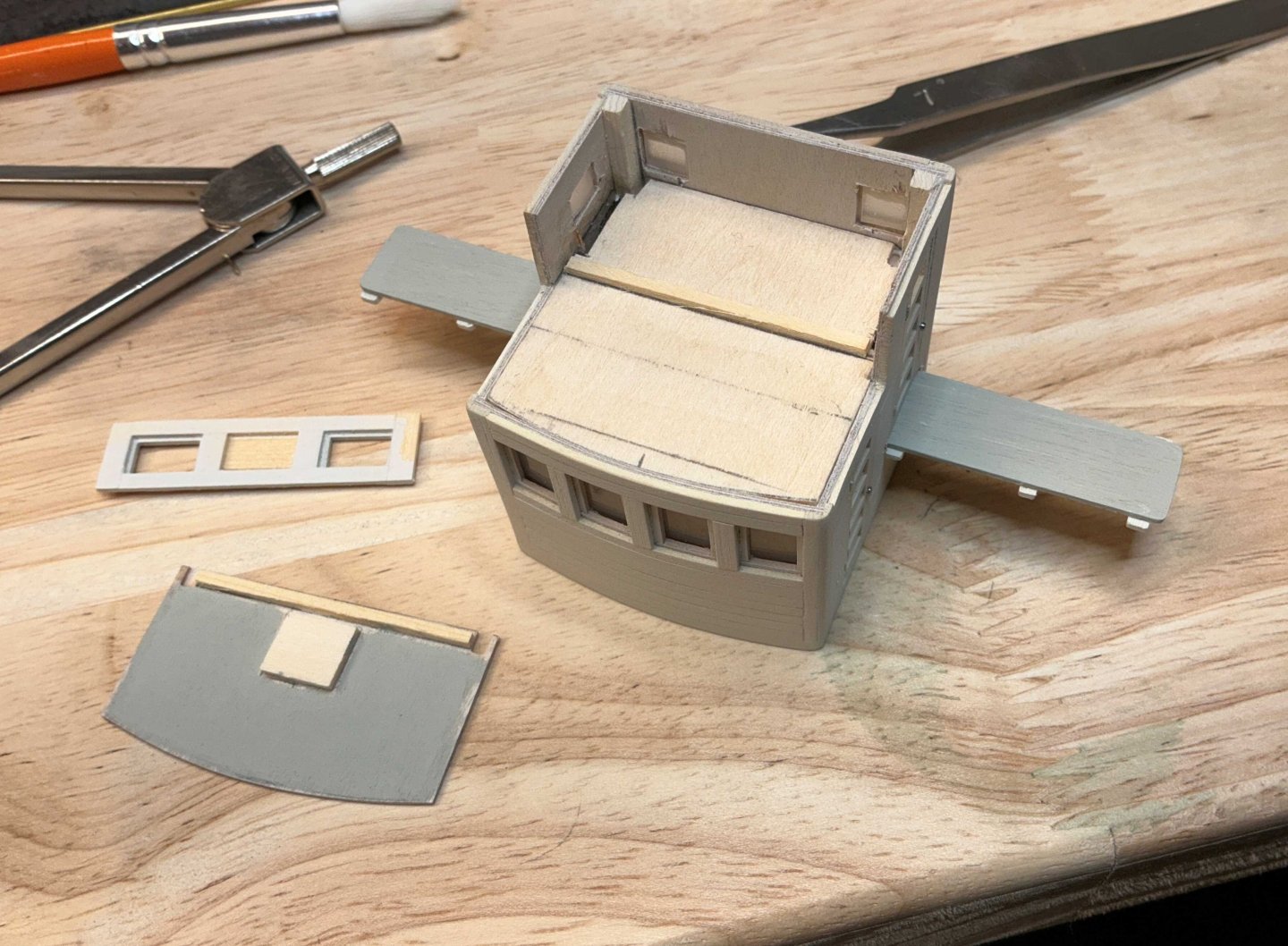

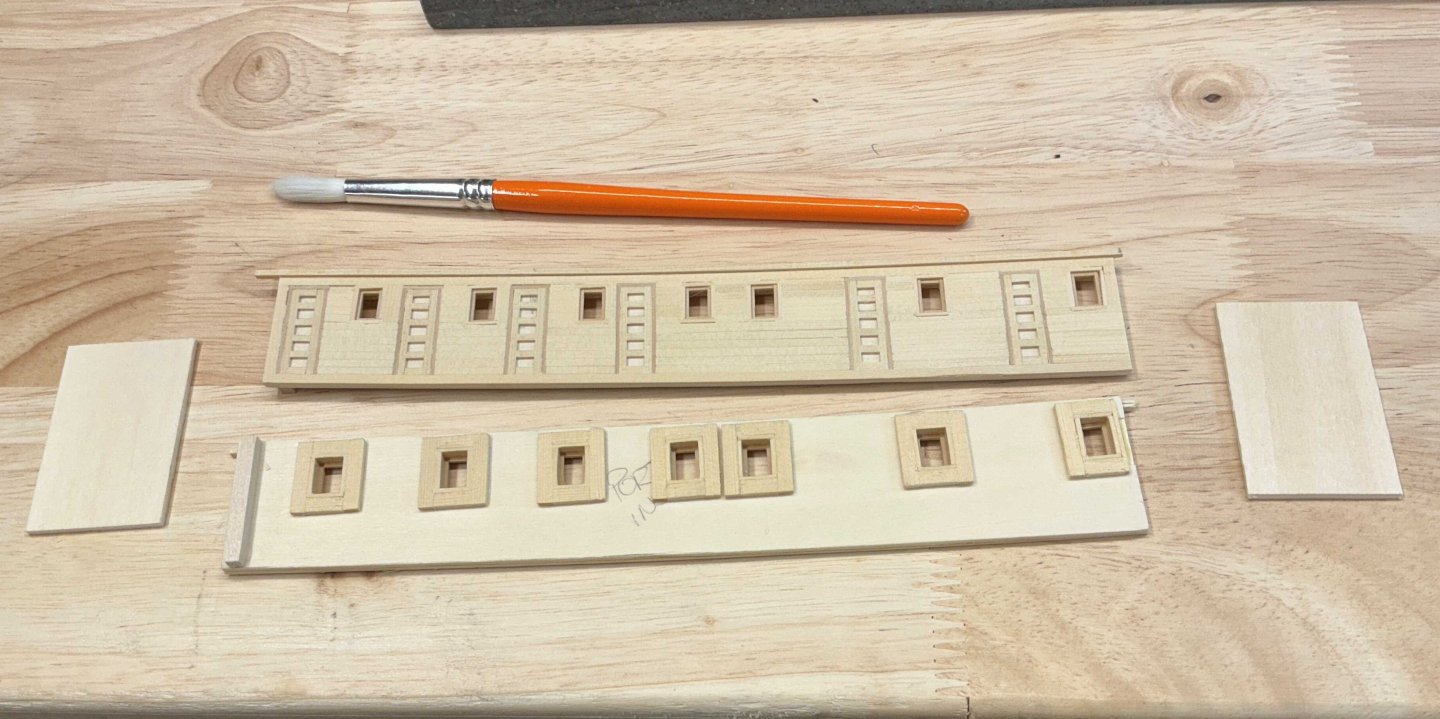

Hey Everyone, I hope you all managed to stay safe in this weather. Luckily only had a 6 to 8 inch dusting of fluffy snow here. I have a Creality K1C 3d printer all fired up here so I made a couple of jigs to help build the coamings at the top of the ladder way on the boat deck. They are dry fitted until the railings can be attached. The Wheelhouse/ Pilot House was given a coat of paint and the windows were glazed. A 1/16" piece of plywood was used to support the roof of the wheelhouse and to keep the structure square. A 1/32" piece of plywood sits on top of it. Before they can be attached the bridge wing(s) have to be glued into place. The pilot house windows were framed, painted, and glazed. Then the roof of the pilot house was installed. While this was going on I sided the cabins and assembled the parts. After the fore and aft bulkheads were sided it was painted and the windows were glazed. Strips of 1/8" square basswood were glued to the subdeck to keep the structure in place while gluing. Pieces of 3/4" square balsa wood were glued to the inside of the end bulkheads with holes drilled in them to accept #4 wood screws. The wood screws were screwed into the subdeck to hold down the cabins while the glue dried. I apologize for the finger in front of the lens And of course I had to throw on all the parts on it that were laying around to make it feel like there is progress. Now it is time to finish planking the boat deck. Hope to see you soon!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.