-

Posts

216 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rudybob

-

Gluing on planks

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

I got it now Plank on Bulkhead, Plank on Frame -

Gluing on planks

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

POF , POB ? -

Gluing on planks

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

I have used the iron and the hair dryer to bend my planks but not to dry glue. This is the first I have read that. I will try it -

Gluing on planks

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

I been using a toothpick but haven't been happy with them. I will try the #11. -

Gluing on planks

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

Yes I am bending the planks. I rarely use CA. I was trying to do to many planks at once -

Gluing on planks

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

I didn't think of one at a time. I did several at a time. They are close but it's worth a try. -

Ticking off the bulkheads

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

I am going to try this tomorrow. Thank You -

Ticking off the bulkheads

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

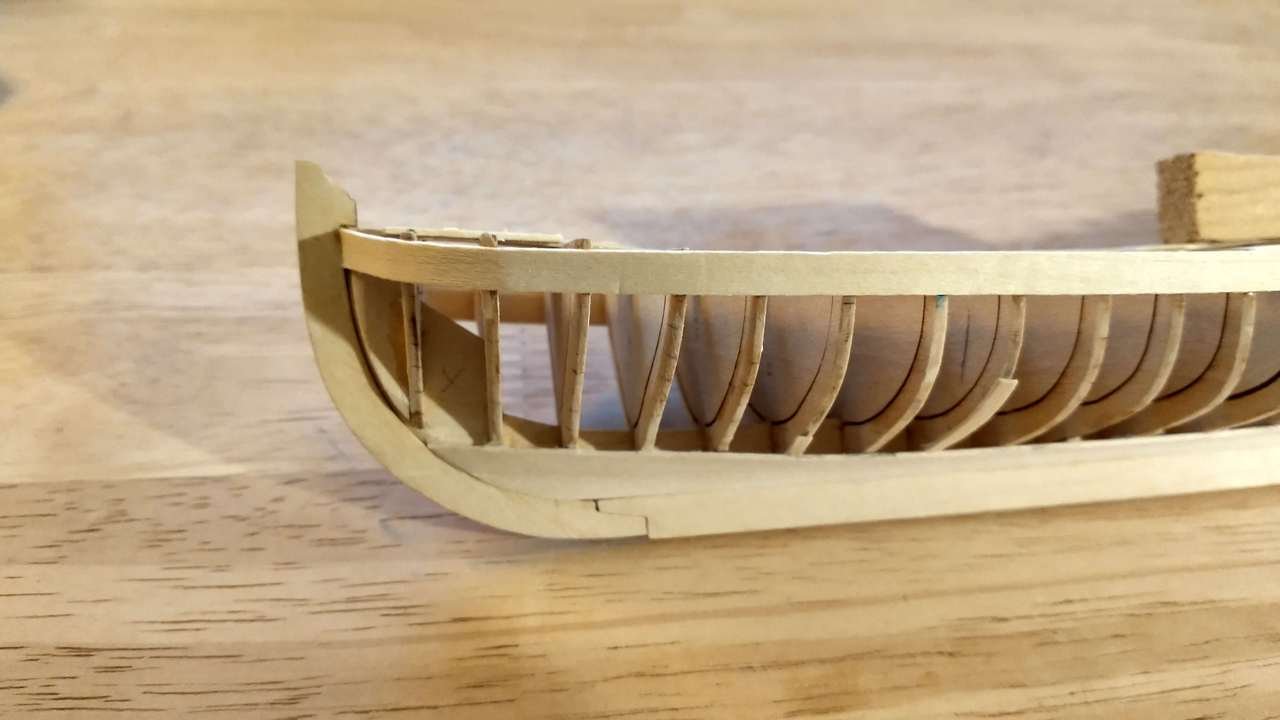

Yes. It is glued and I had to choose the lesser of two weevils. It's poorly cut and I am not the only one to get it like this. So much for laser cut accuracy. A more talented guy could have fit it by sanding or filing but I ain't that guy. It's Chuck's pinnace from our old friend model shipways -

Ticking off the bulkheads

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

Yes. It's kit supplied -

Ticking off the bulkheads

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

I'm following the tick marks I made. When I do that the garboard extends to the point in the picture. It doesn't "appear" to be riding up the stem. If it did ride up some could I compensate for that with the next strake to keep my line as straight as possible? -

Ticking off the bulkheads

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

What is the "boxing joint" ? -

Ticking off the bulkheads

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

I'm thinking about the strake that snubs into the rabbet and what difference if any that makes. -

Width in the bend

rudybob replied to rudybob's topic in Building, Framing, Planking and plating a ships hull and deck

It seems to me that as I bend them around the bow I MUST keep their width in the bend the same as the width of any planks I have not cut out ie the straight planks that came with the kit. Is that true? -

I have cut spiled planks from a flat sheet. It seems to me that as I bend them around the bow I MUST keep their width in the bend the same as the width of any planks I have not cut out ie the straight planks that came with the kit. I did so using dividers. I am working with the second garboard plank ie the one above the garboard. I know that all planks don't have to be the same width I am concerned with the bend. If this is unclear I am out of luck because I can't explain it better. Please don't suggest I look at someone's video :-) I really only need a yes or no. Thanks

-

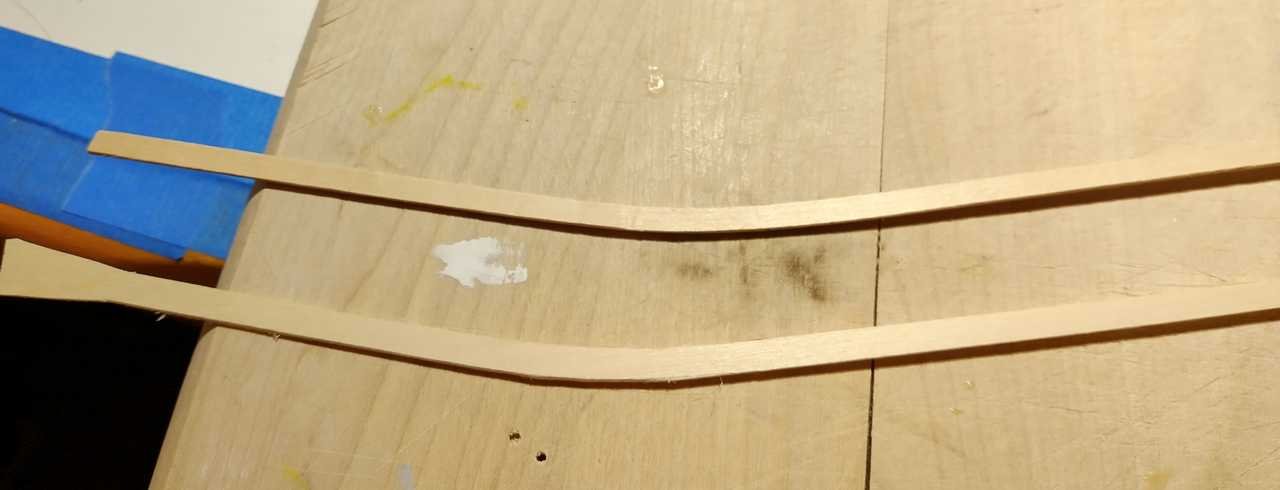

I've known for sometime that the strake above the garboard should not creep to far up the bow. OK fine. I also knew that it has to follow the curve of the garboard and fit into the rabbet. OK fine. I also see where guys install the garboard in one of two ways. With the bow curve facing up (1) and the bow curve facing down(2). I did up (3) and had bow curve really bad as someone in my log commented though I didn't see it. I decided to flip the garboard on this rebuild. OK fine. To get the curve I needed for the strake above the garboard some severe edge bending was in order. I read this: "By now you will realise that virtually all the planking will need to be cut to shape, as you cannot edge set a plank. Edge setting means bending the plank sideways across its width. If you try to do this, one edge of the plank will lift off the frame and be im- possible to attach. Well ya can't edge set without edge bending, eh ? Or can ya? I don't know. Maybe it means two completely different things. Which meant I needed to cut a strake from a flat sheet already spiled. To get the spile I needed to edge bend a strake that followed the curve of the garboard. OK I tried that with heat (iron) too extreme a curve it broke. I wasn't going to toss that strake though. I just soaked it down, got my curve, clamped it down and ironed. I did all that close to the center of a 14 inch strip. All I needed was the curve. I traced the curve onto my sheet and there it sits until tomorrow when I will "laser" cut it out. That's a joke. I will use a X-acto and sandpaper. The strake I edge bent to measure spile angle I fit to the frame. I needed to know...how I gonna do this, before I do it? Well it turned into a good day. Not because it is exact but because my procedure worked for me. Can I reproduce it...That is the next question. I had long since lined off the hull. Last night I ran thread along the tics. What I saw today while fitting my second strake was that the lining off pretty much matches the curve on the strake. Seeing is believing. I have read and heard, paraphrased...just get those two bottom and two top strakes on best ya can and tic from there..... I'm thinking after I get the two garboard and two sheer strakes attached a re-tic is in order. I didn't know if I should tic into the rabbet or stop before it. I think into it but doing a re-tic will dump that problem and give me more practice. I'm looking forward to my next sessions on this brain breaking ball buster

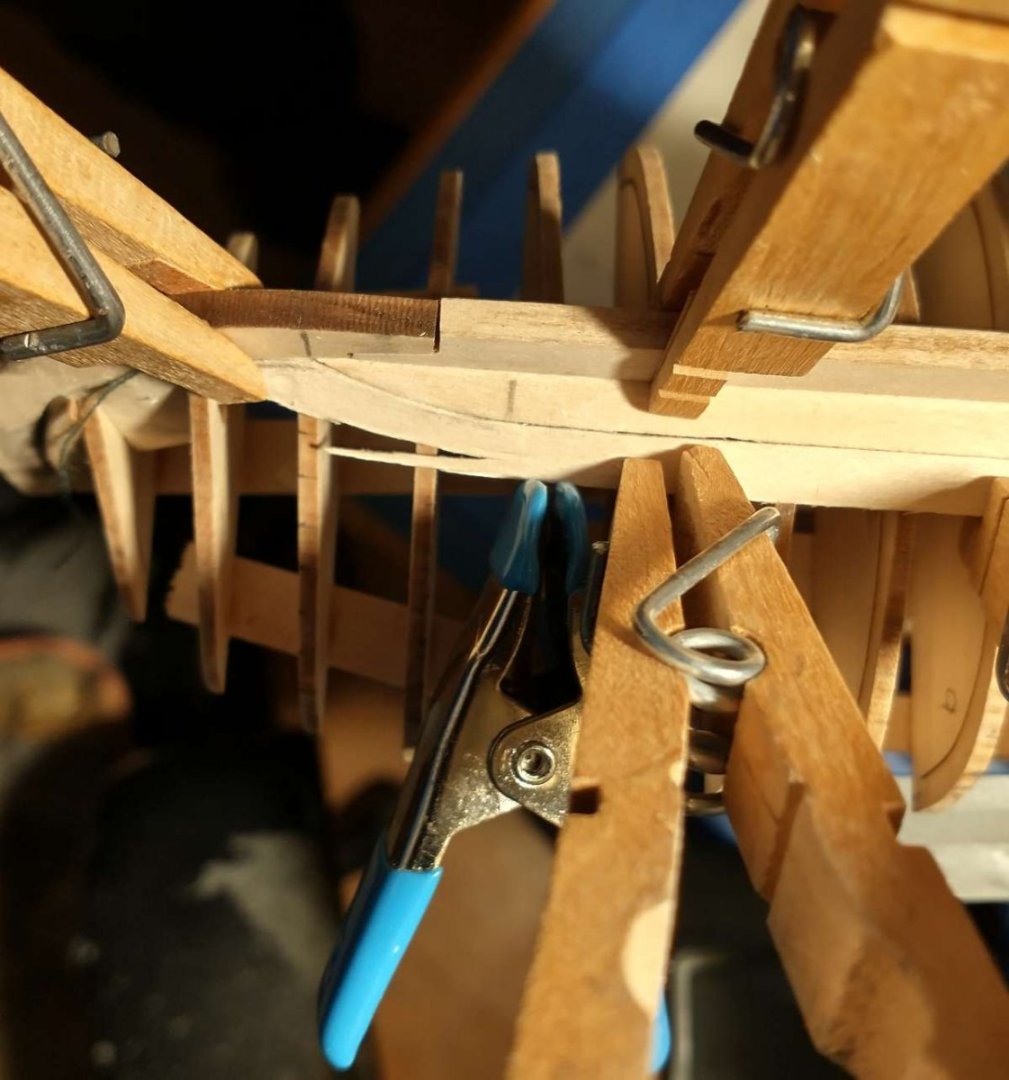

-

Now that I have the spile it was time for a bend. I dampened the strake at the spile and slid the entire piece along the top of the bulkheads until I found what I thought was the correct spot to put the curve and then the cut to fit into the rabbet. That went fine but I still needed a twist for the final fit. I tried the bottle cap scheme but that was laughable. So, I dampened it and placed the end I had size snipped into the rabbet and clamped it there. I let it dry overnight and it turned out. That made me happy. So that is some progress. I hope to repeat it for the other side. What I was looking to accomplish and did so on the top strake was to get it to lie FLAT in all it's twistyness. It does. Yahoo. I've also sized and cut the garboard planks While all that was going on I recalled that the bulkhead holders from my previous attempt had been poorly placed. They were to far in from the edge if I wanted to use them to clamp the strakes to after glue. I cut some thin ones and placed them what I hope turns out correctly. The bulkheads on this pinnace are so close I found it a super bugger trying to fit my clamps between some of them. Kits come with pre-spiled strakes and the curve must be calculated and fed into the cutting device so there is a way to get a measurement because I don't think guys sit around doing the trial and ERROR method I use but I have yet to see that discussed. Is there a formula or a method taken from a plan? Slow progress is better than I will do it tomorrow progress.

-

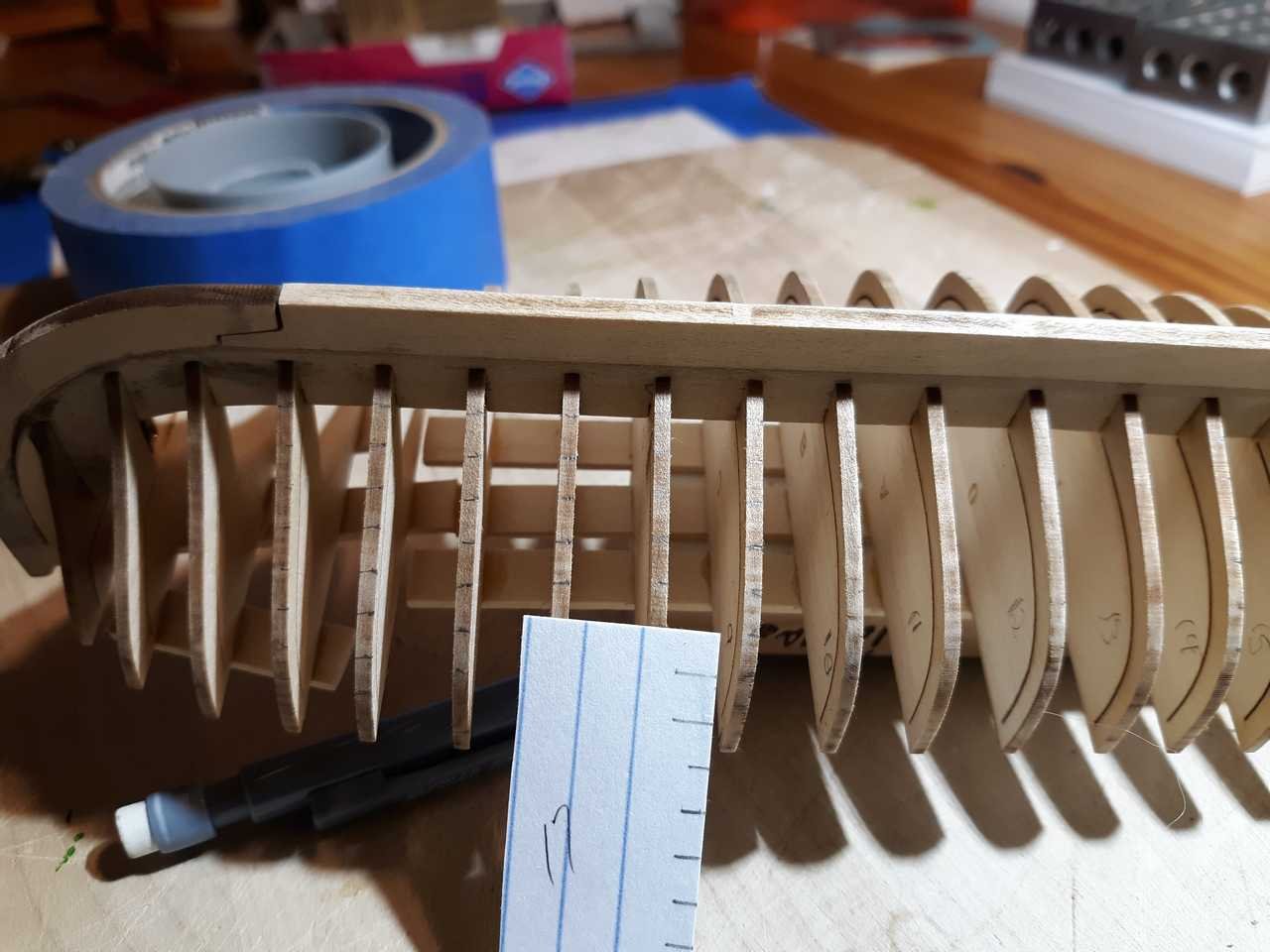

It's come down to this. I've ticked the hull on one side. I can see where it would have benefits. I don't know how my seeing that it has merit will aid me in this build though. Quite the opposite in fact. The ticks need to be accurate. I spent time and made them as accurate as I can. When I lay a strake it is easy to see where my ticking is off as I was pretty certain it would be. The tick marks can be adjusted. Tape can be used to visualize the run of the strakes before actual attachment. The tape has to be pretty darn thin. On the Medway Longboat 3/64 of an inch strips were cut. I wonder if I can cut 3/64 in strips of anything let alone sticky tape. LOL. I have 1/8 inch tape which is 8/64. I can't cut that in half, straight and true, without some severe equipment. Well maybe but I would probably remove the stick from the tape then I would need glue. LOL. I'll leave that there for now. While I have been practicing and pondering the previous I got myself back into bending planks. Even the meager three or four months I spent last year has helped for what I am doing this year. There are two main sources I am using to rise above my current understanding and skill level. One are the directions for the Medway Longboat the other is Blue Ensign's pinnace log. He does a superb job covering how he overcame his difficulties and he asked the right questions. For example ..."did you have to start the short bow curve well back in a longer length of strip to give you the leverage to form the bend?" The answer being "Yes indeed....it is impossible to bend that severe a curve on the end of the strip." OK Now I know. I tried it. It helps. I slide the strake along until I found what gave me the best results to get that tight bow curve. Of course, I have extra strake at the bow that needs to be cut off and am going to have to figure where. It will take a few strakes to solve that. Then all that will need doing is a bend at the short end into the rabbet. Yea Sure .."all that needs doing." It was suggested to Blue Ensign "...it is probably easier to find and spile the shape and then cut from a sheet." I am going to try that. Last year a huge obstacle was getting one curve good then losing it while I tried to make another. If the strip is cut spiled I could save some headache by working on only one curve in such a tight area. That's where I am at. More thinking and reading than doing but I do a little physical labor on the build daily, if I didn't I would think I putting it off. LOL

-

As usual I got a bit ahead of myself. I forgot I was ticking the hull. I came across the Medway Longboat directions and the author writes that he ticks his hull on every build for all the obvious reasons. The build is similar enough to pinnace that I can work off it to tick. It is a process that may introduce error and in my case does. The bulkheads on the pinnace are quite narrow which makes it hard for me to lay cardstock or paper along them to get each length. What I did was cut my 3x5 index cards so the laid over two bulkheads, This gives me some support for getting an accurate length and after making the tick marks from the fan getting the marks on the bulkheads. If my length measurement is wrong then my ticks will be wrong. If my length is accurate then I must get the marks drawn properly on the bulkhead. Mostly I do. Once I get it all ticked I see where some tape laid on the marks will show me how I have done. I don't know if this whole process will do any good but it will teach me something, which is nice. I recall several suggestions from previous posts regarding ticking and will keep them in mind. It's a slow process and not really to be done without good light and a mind that isn't tired. I am almost half done.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.