-

Posts

216 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rudybob

-

"(crappy weather motivates Model Building, I think) " Yes it does

-

I concur regarding the replacement parts. I wanted to be sure I did not get a bum kit so I was waiting. My thought on computer controlled cutting is that it is only as bad as the programming and calibration allow it to be. I now have a definition for what's good enough. Yep. A critically important gap in my opinion. Everything comes off the keel so get that right. They did not. This is not billed as an advanced model this is for beginners. I have enough to learn out of the gate and one of them should not be jimmying the keel. A problem right out of the gate for those not in the know...Me :-) I can appreciate and sympathize with the work involved in moving an operation. I have done it twice. I waited two weeks for correspondence before I recontacted them. I told them if you aren't going to replace the part and what they viewed in the picture I sent is "normal" let me know and I will move on. No threats, no harsh words. Not a word back until I contacted them again. When they wrote...I dunno when. I am not angry with Model Expo but I don't mind reporting what I have experienced so others may be advised. I really like the time you took to comment. It was well thought out and fair. Thanks

-

It has been 28 days since I requested from Model Expo replacement parts. I sent three follow up e-mails. Here is what I believe will be their last response which I received today "The order for your parts has been entered, but we are experiencing parts shipping delays due to our move to a new location. I can't say when the order will be shipped. Let me know if you wish to cancel. Best Regards, Parts Dept Model Expo/Model Shipways The key component of the e-mail is "I can't say when the order will be shipped. Let me know if you wish to cancel." I think that roughly translates to go away kid ya bother me :-)

-

Looking around is what I am good at in this hobby :-) Thanks

-

I looked for but could not find Model Dromedary. Do you have a link? Thanks

-

I'm having a similar experience with them now. I am anxious to get parts that may have been poorly crafted. I won't know for certain if it's a one off until the new parts arrive and it is taking longer (3.5) weeks then I would like. Responses from Model Expo are not that helpful. Thank You for your reply. I appreciate it

-

I would like to know why you would not buy anything from Model Expo.

-

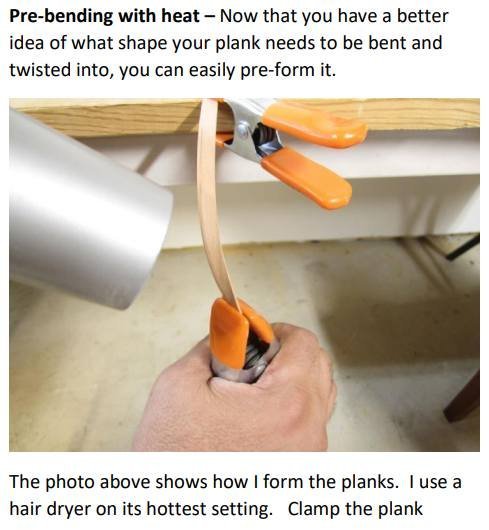

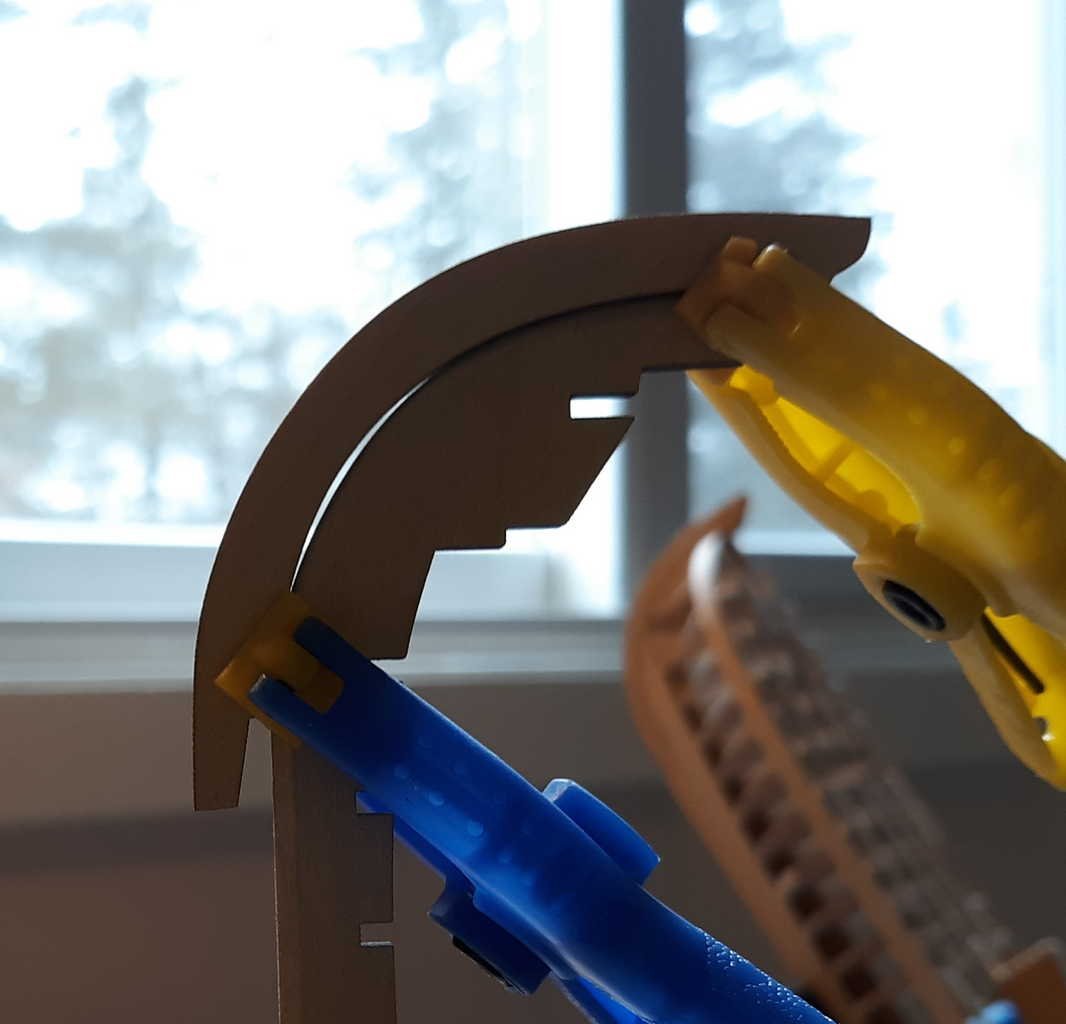

It has been quite a process. First let me state that when you read that laying planks isn't hard don't believe that. It is a difficult process. There is not only the bending which is the most difficult there are many other considerations. I read that forced clamping isn't necessary when the plank is correctly bent. Well that's true and a goal to strive for which I have. The shear on the pinnace is a very difficult bend. There is an edge bend, a twist and a curve all to be made in a short space. I enjoyed reading and trying all the methods at this forum. In my case the hardest part was to keep the shear's lower edge flat on the first 3 or 4 bulkheads as I curved it around the bow. The edge bend gets the shear to lie flat. In the subsequent process of putting in the twist and bend I have been unable to create a plank that I can get to lie flat along all the bulkheads AND keep the previously made edge bend like it needs to be. I shaped the plank to lie flat along the first four bulkheads. I also shaped it to generally follow the hulls course to the stern. After gluing down the shear on the first four bulkheads I wet the plank and shaped it to fit the rest of the way and clamped.

-

Are the notched limewood strip 1/8 x 1/8 inch? Thanks

- 156 replies

-

- pinnace

- model shipways

-

(and 1 more)

Tagged with:

-

Thank You for the reply. I agree with your first paragraph. I spent 11 years on the NY Pilot Boat and I would have dropped this build otherwise. If there was a time limit I might do better. HA!! I set schedules and am way behind on this one. I was not clear enough in my post. I can bend and trim planks and have them fit nicely. I have ticked the bulkheads. Post #30 in Blue Ensign's log, "It is the short curve at the bow that has defeated me using just water and heat; aft of the first three bulkheads the treatment works fine to achieve the more gentle 'S' curve. On your original Pinnace build, where I think you just used water and heat to achieve the shape, did you have to start the short bow curve well back in a longer length of strip to give you the leverage to form the bend?" Chuck replied, "Yes indeed....it is impossible to bend that severe a curve on the end of the strip. The curve was made closer to the middle and then the excess snipped off and discarded. " Chuck linked to his barge build and on pg 12 of the pdf is the picture I posted where the problem Blue Ensign had and I am having is addressed. http://modelshipworldforum.com/resources/Barge instructions.pdf I can make the acute bend but I cannot make the acute bend and the twist needed to go along with the lateral bending all at the same time I do not follow Chuck's explanation and was hoping someone could help me out. His planks are pre-bent (see picture 2) The planks I have are not pre-bent though I can and have bent them like Chuck's but I still am not up to speed and need further clarification.

-

Having a heck of a time coming up with the " impossible to bend that severe a curve on the end of the strip." bend. This is something I need to get right. It'll either happen or it won't. I'll keep trying. I LOL at some of my bends. On the follow up build I have formed the rabbet pretty good. Model Shipways replied that they are sending my part request to shipping. I look back on this log and I have a good time laughing at myself. I am sure there is more of that to come. I bought some tools. I seen in many build logs tools used to ensure something is straight and square. I picked up a couple 1-2-3 blocks and a machinist square. Both will be of tremendous help on this project and other crafts. For as much time as I think I have spent on the pinnace I ain't getting very far and I sure like shopping for clamps

-

The part only fits one way. There is no "turning around". I moved it for best fit the first time I made this model. Space shuttle tolerances...no. Reasonable... Yes. I requested new parts. If they say "Sure" I will see if it is just the way it is and then I will deal with "pretty good" tolerance. Thanks

-

F-86F-30 Sabre by Egilman - Kinetic - 1/32nd scale

rudybob replied to Egilman's topic in Non-ship/categorised builds

If it cannot be seen then I just don't do it. So much to hone skills on... the unseen is not one of them for me. I was going to do a Sabre but just down the Hwy there is an F-84 on a pedestal. I have driven by it many times so I picked the F-84

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.