-

Posts

794 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by moreplovac

-

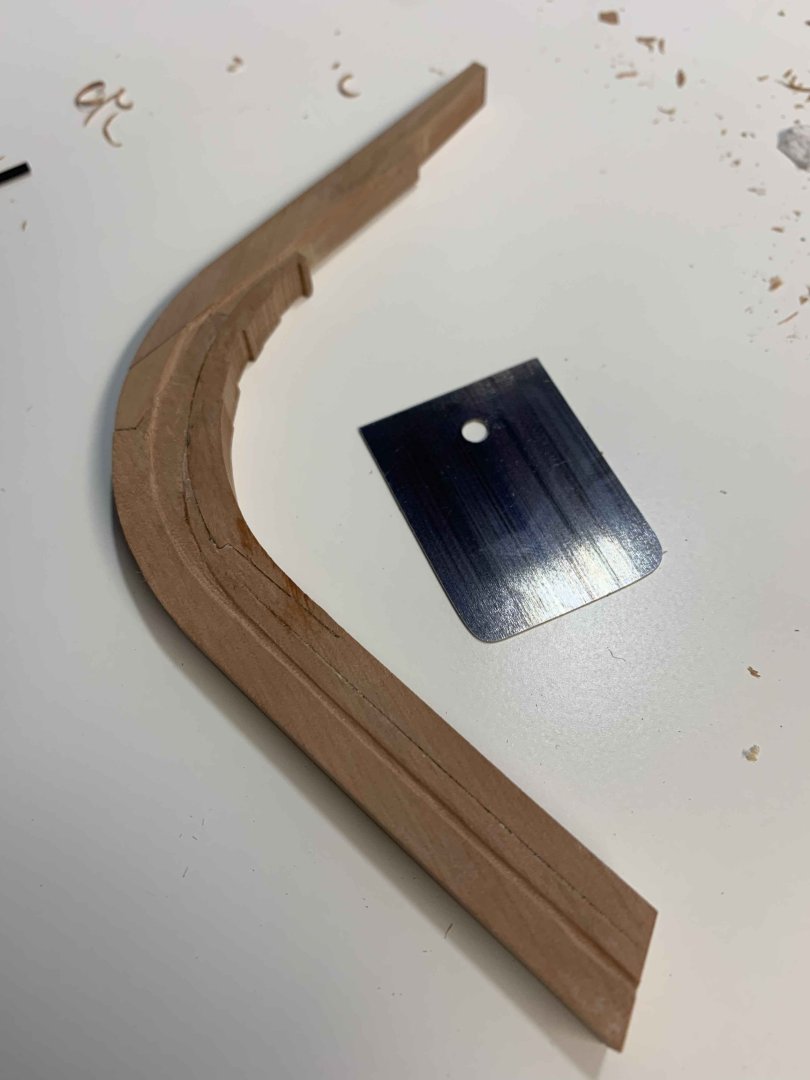

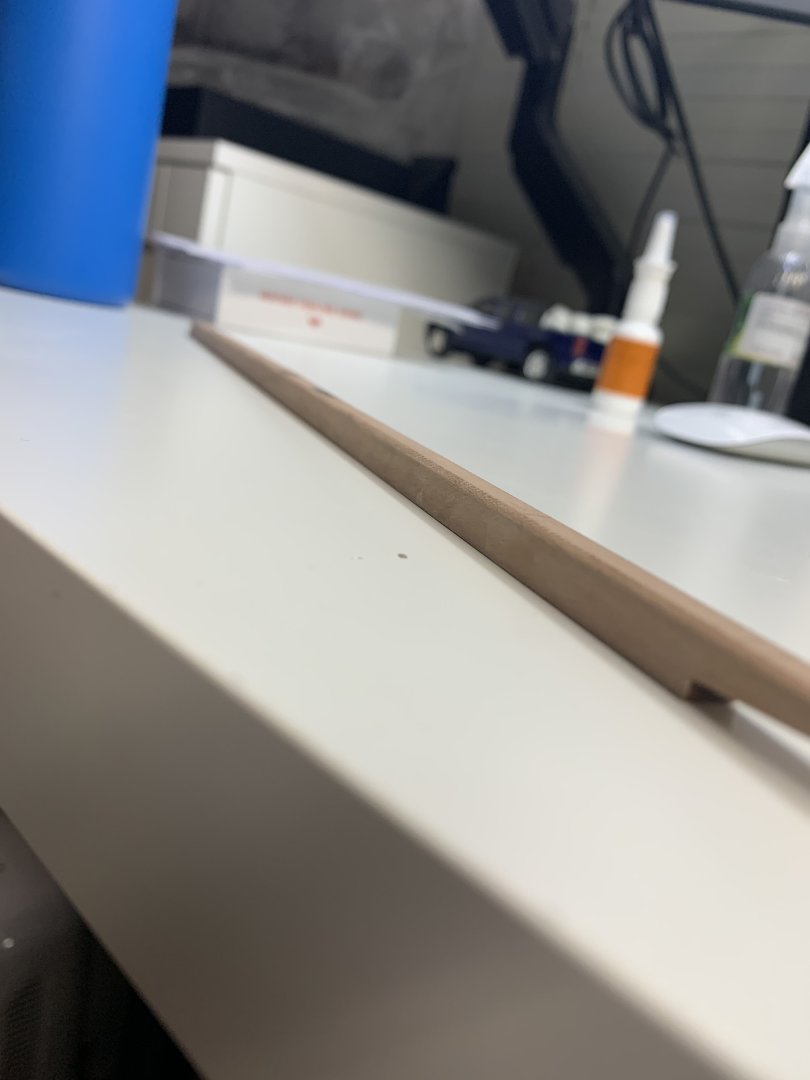

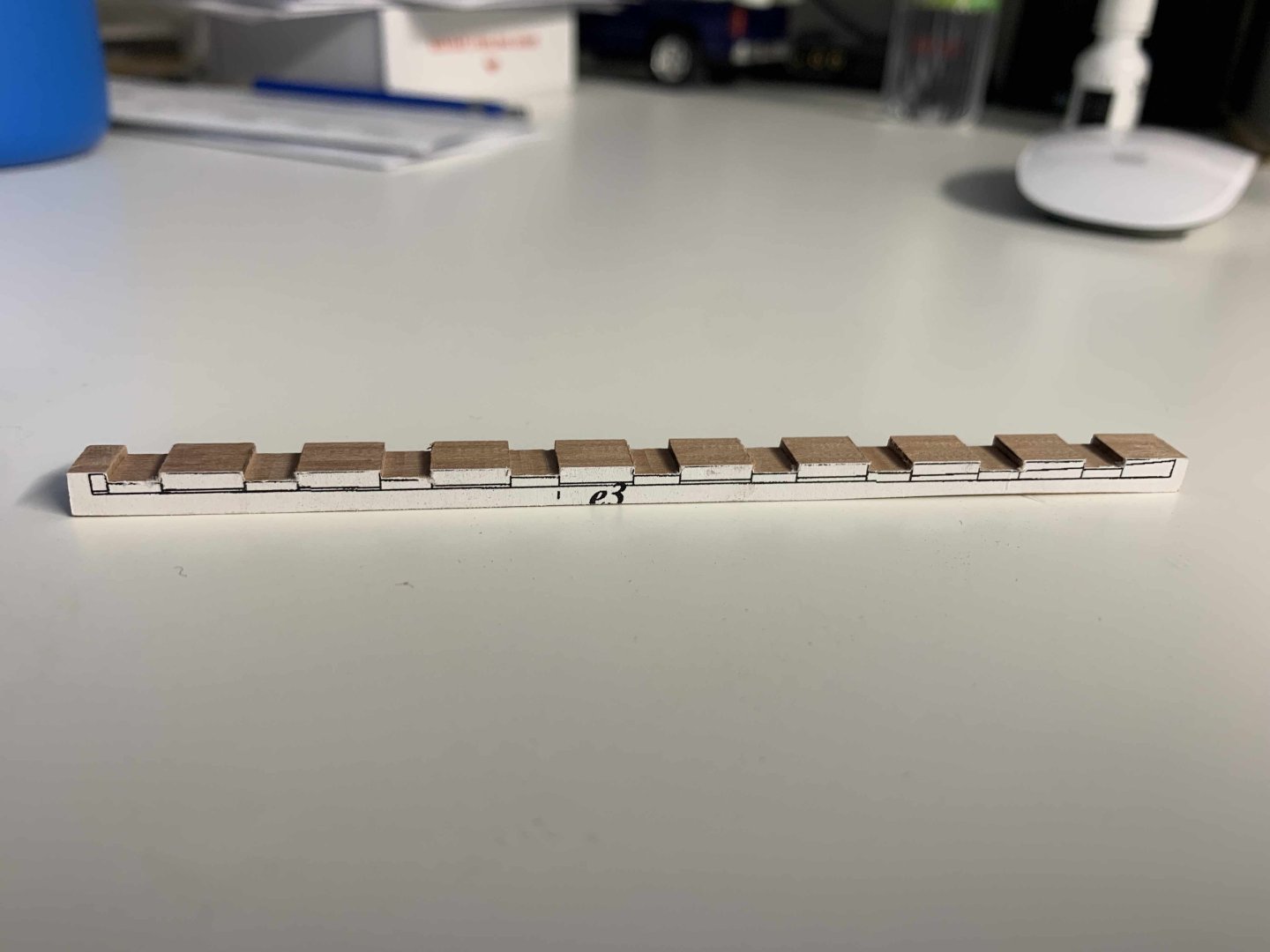

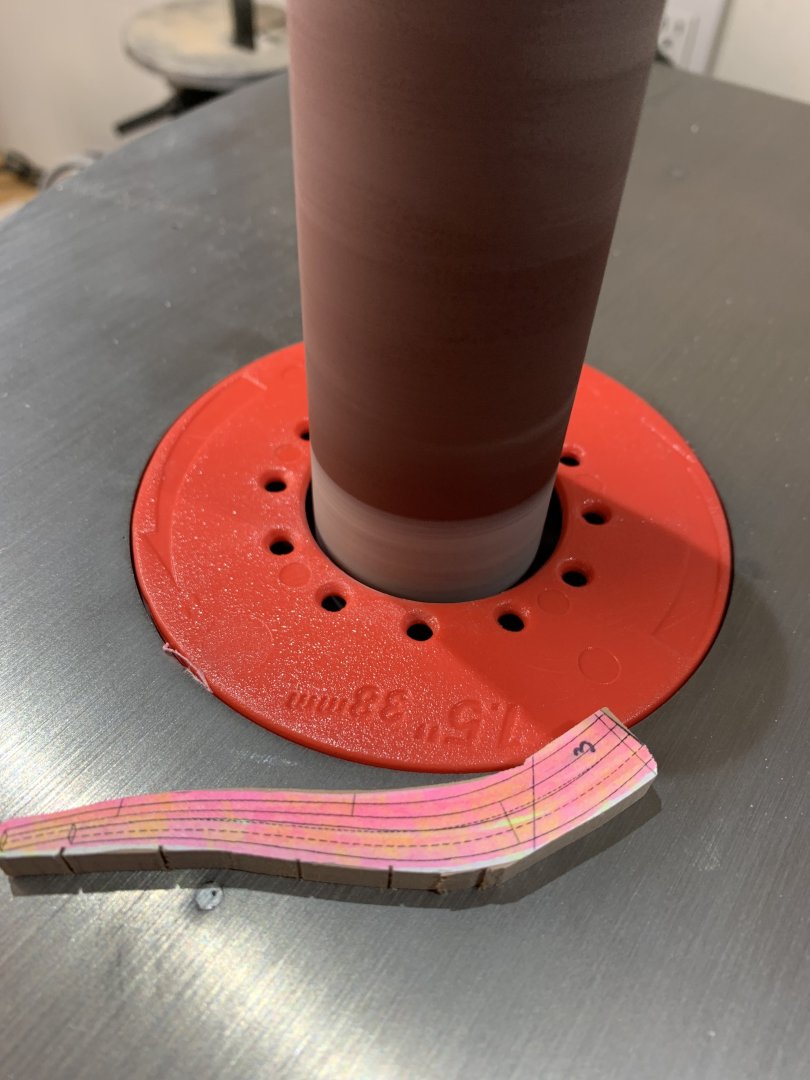

After few attempts, I managed to get one done; I will leave it as-is and adjust if needed more in the further steps... it took me really much of effort to get it done, understand the curvature and how it supposed to look, what tools to use for carving, etc... Anyhow moving forward... Few attempts discarded after different failures... All work was done using chisels and scrappers.. This is it, just need to glue the last piece, already sanded and ready.. Happy modelling... I think I might update this to "Happy modelling - patiently" Cheers

-

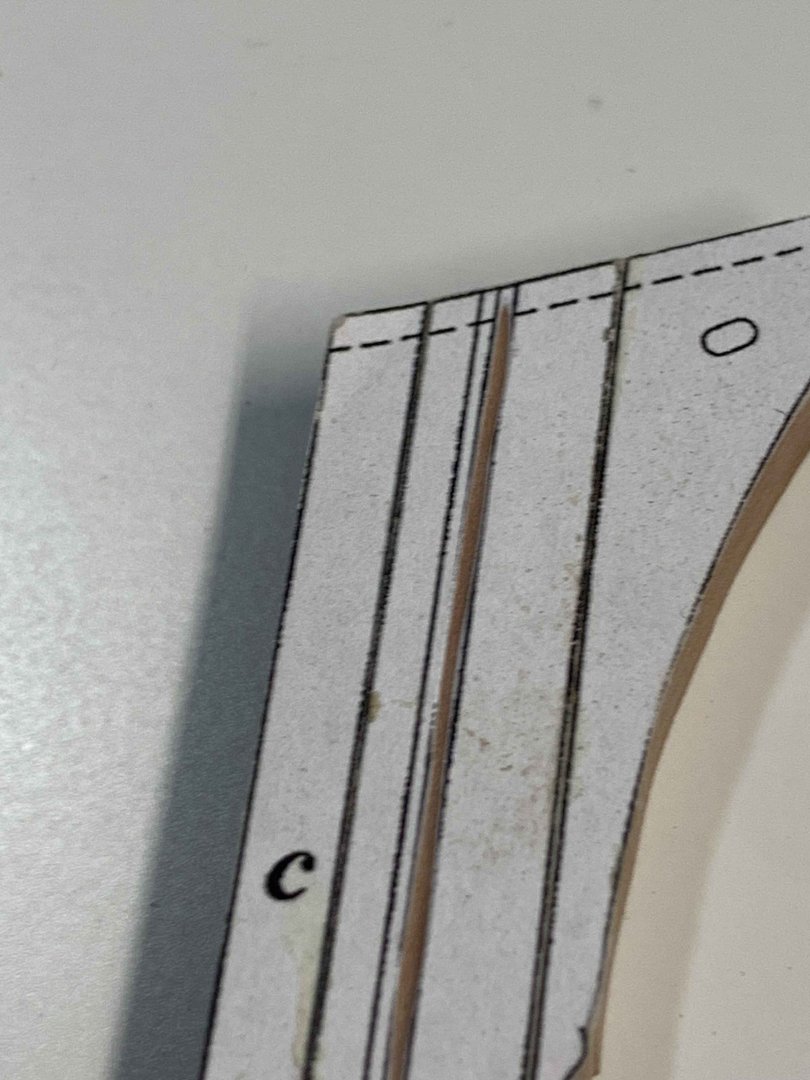

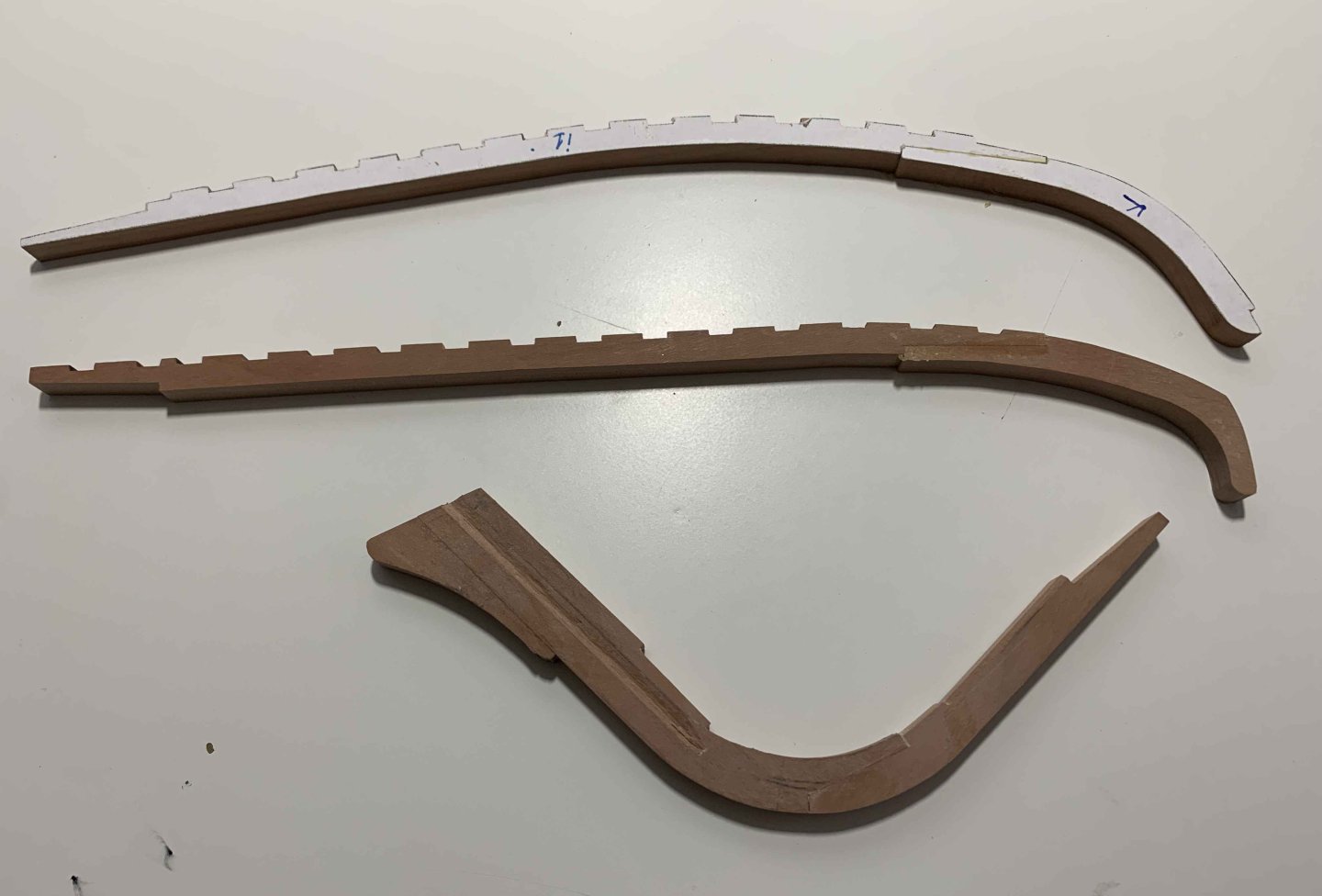

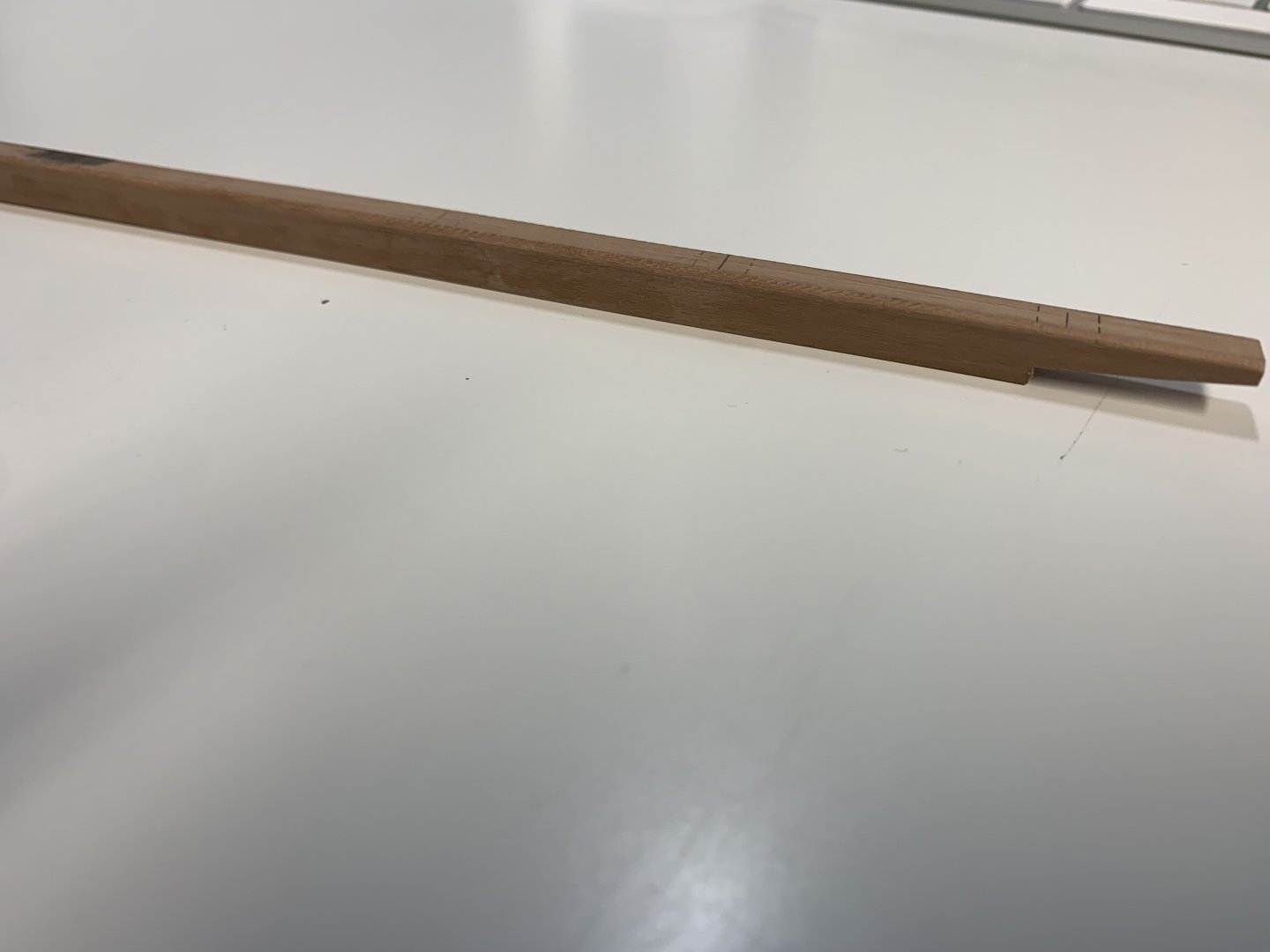

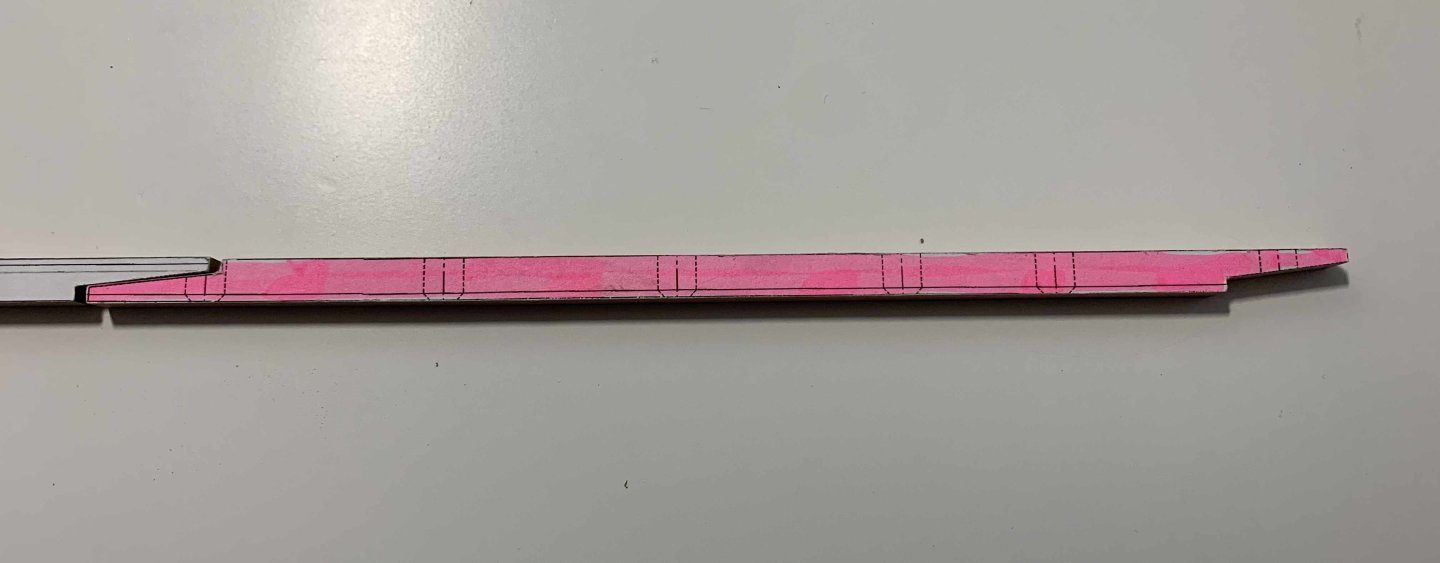

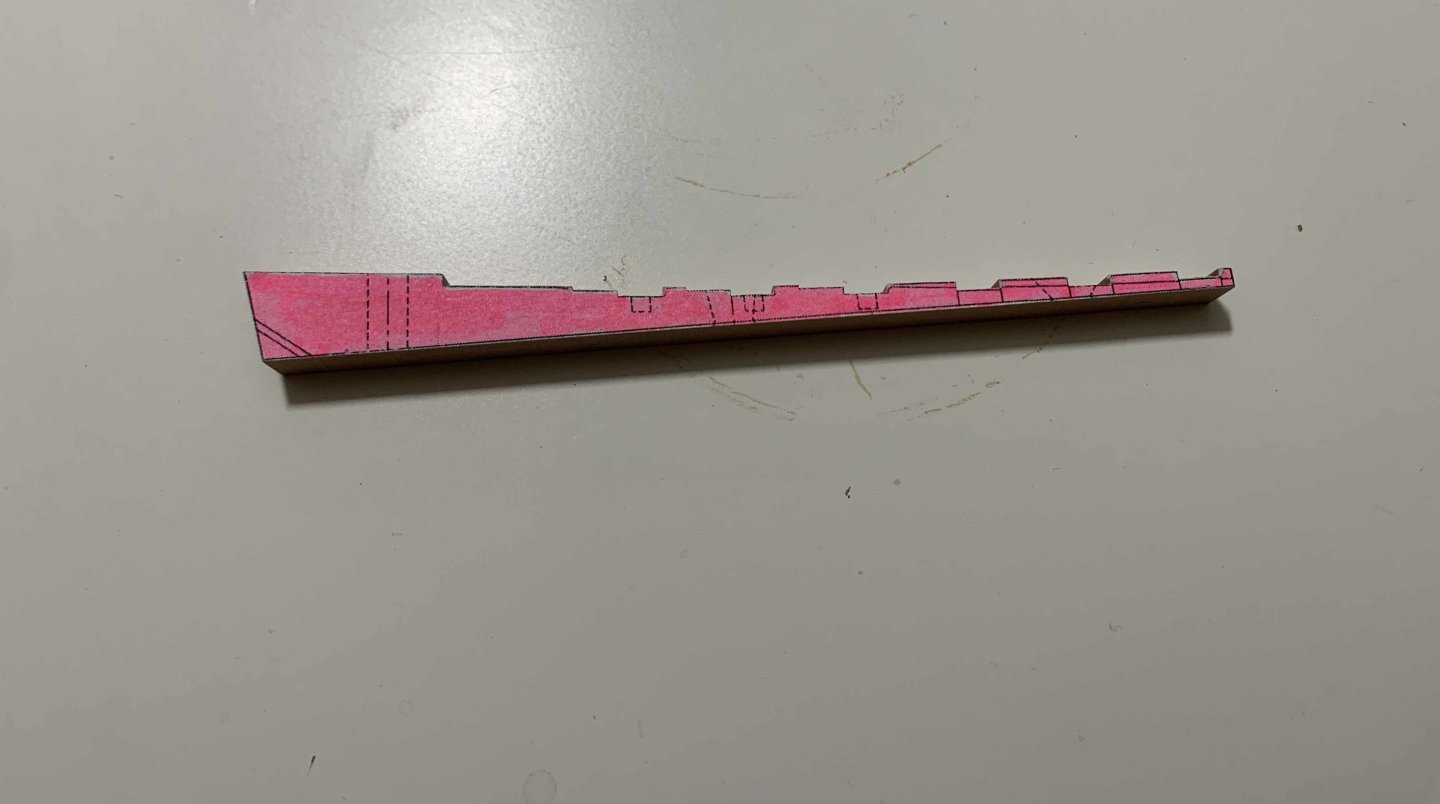

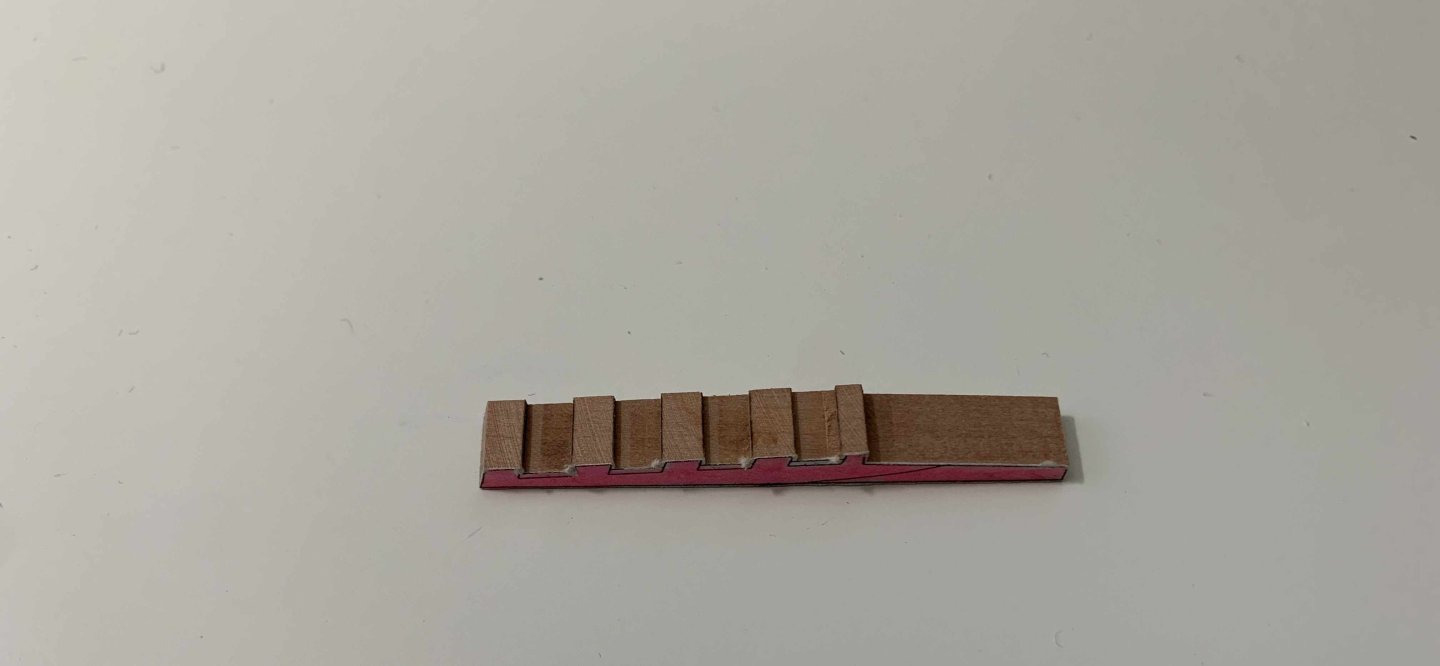

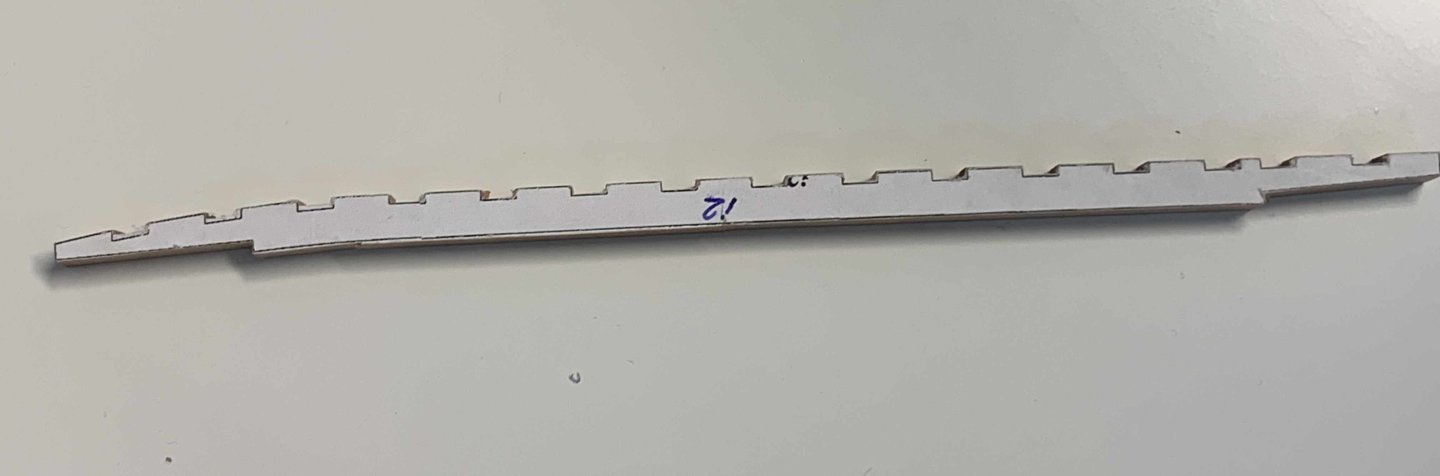

Third time - luck.... hopefully learned something from my mistakes... First one - broke the part above its potential repair.. Second one - too hard push with a chisel caused rabbet line to go sideways.. above potential repair... So now it has to be a good one, since I don't have more lumber available... Happy modelling..

-

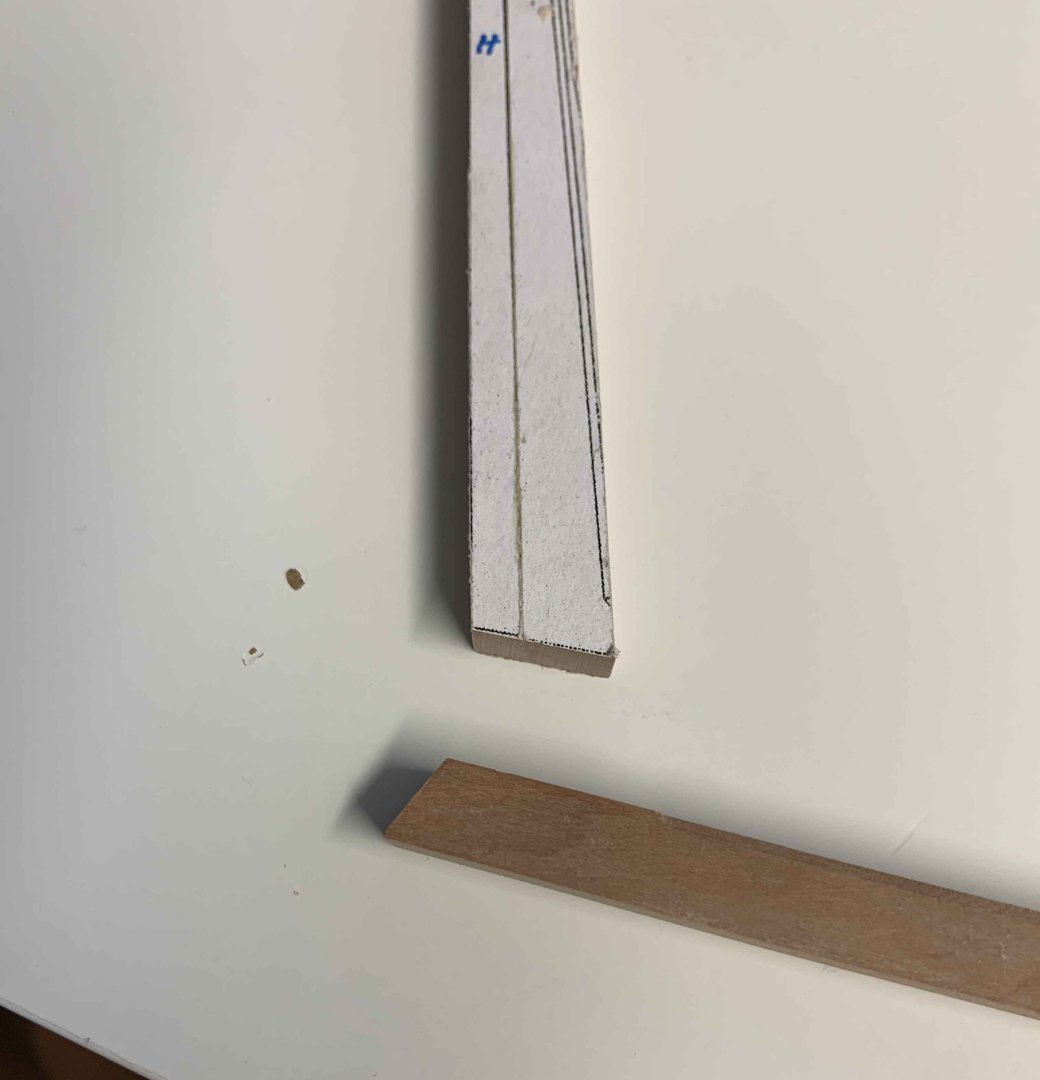

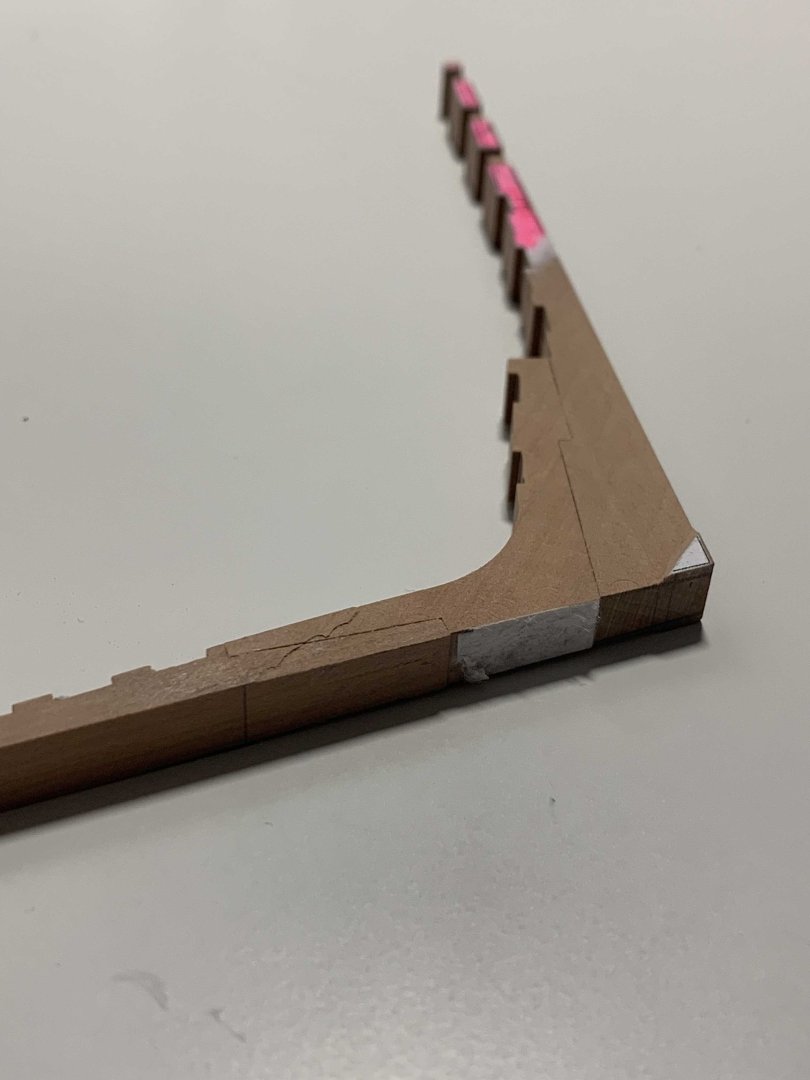

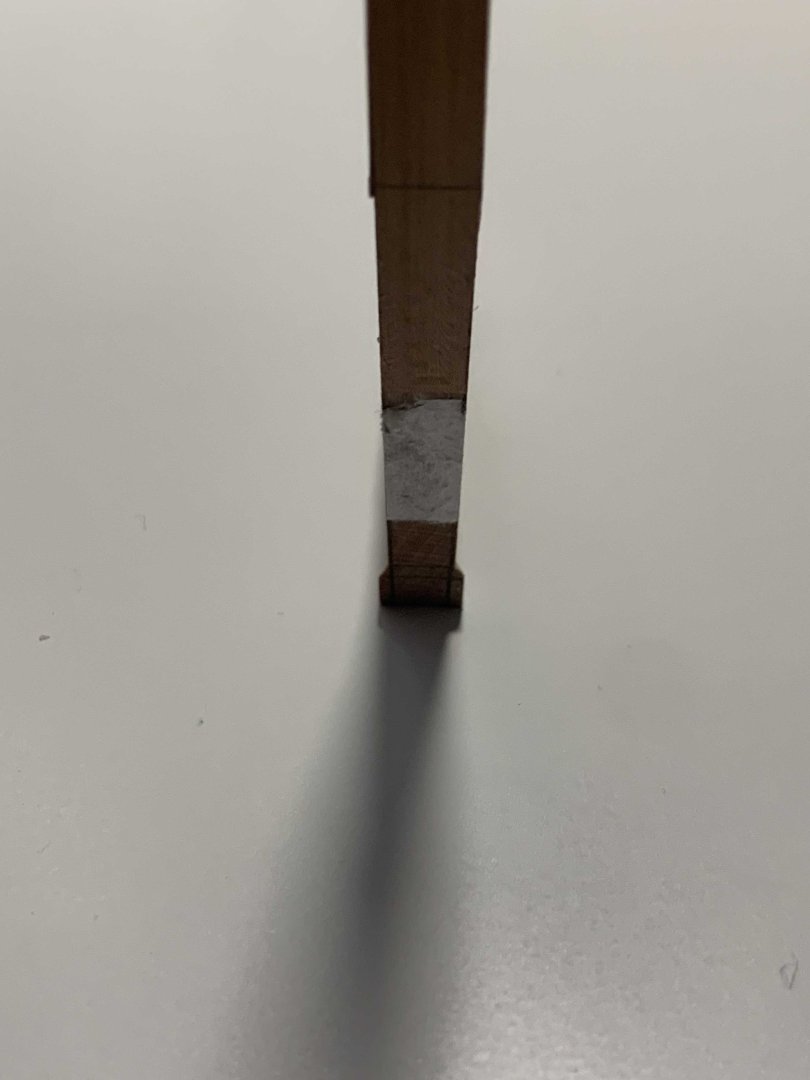

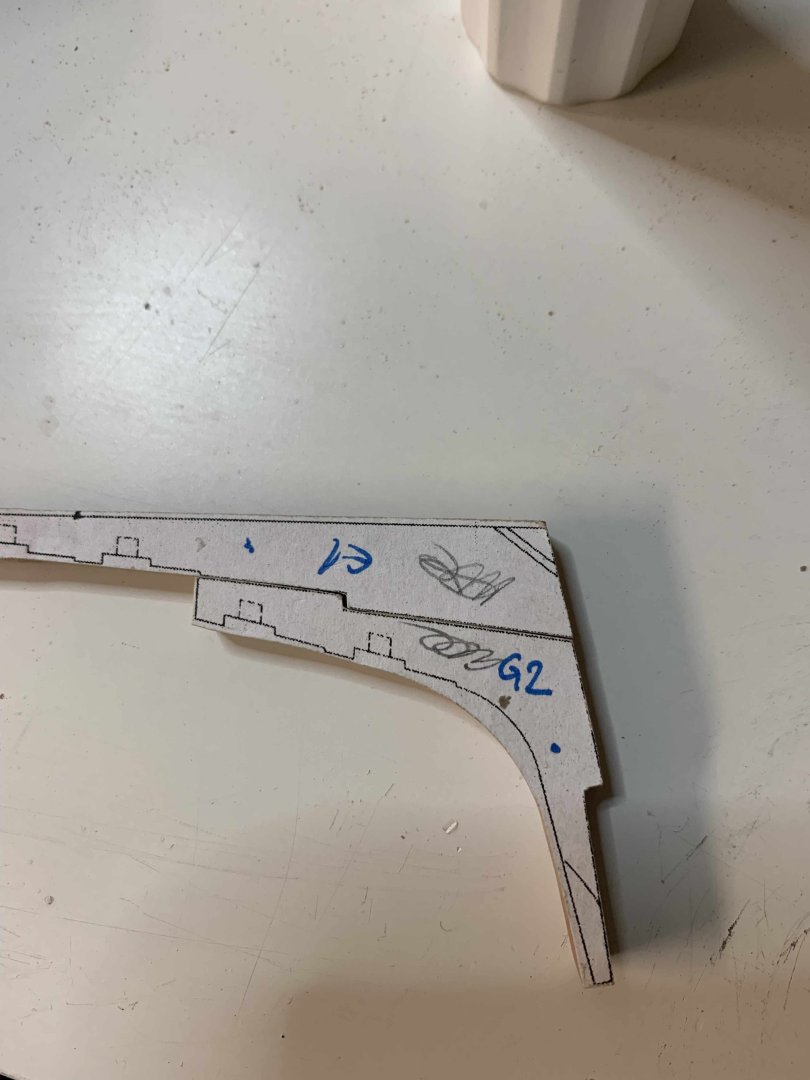

Work on a bow continues. Few peaces cut and sanded not completely but enough to test assembly and some of the to be glued together... Now I need to find a way to transfer all rabbet lines on the other side of the part, most likely will use transparent paper and mirror image if original part... Happy modelling...

-

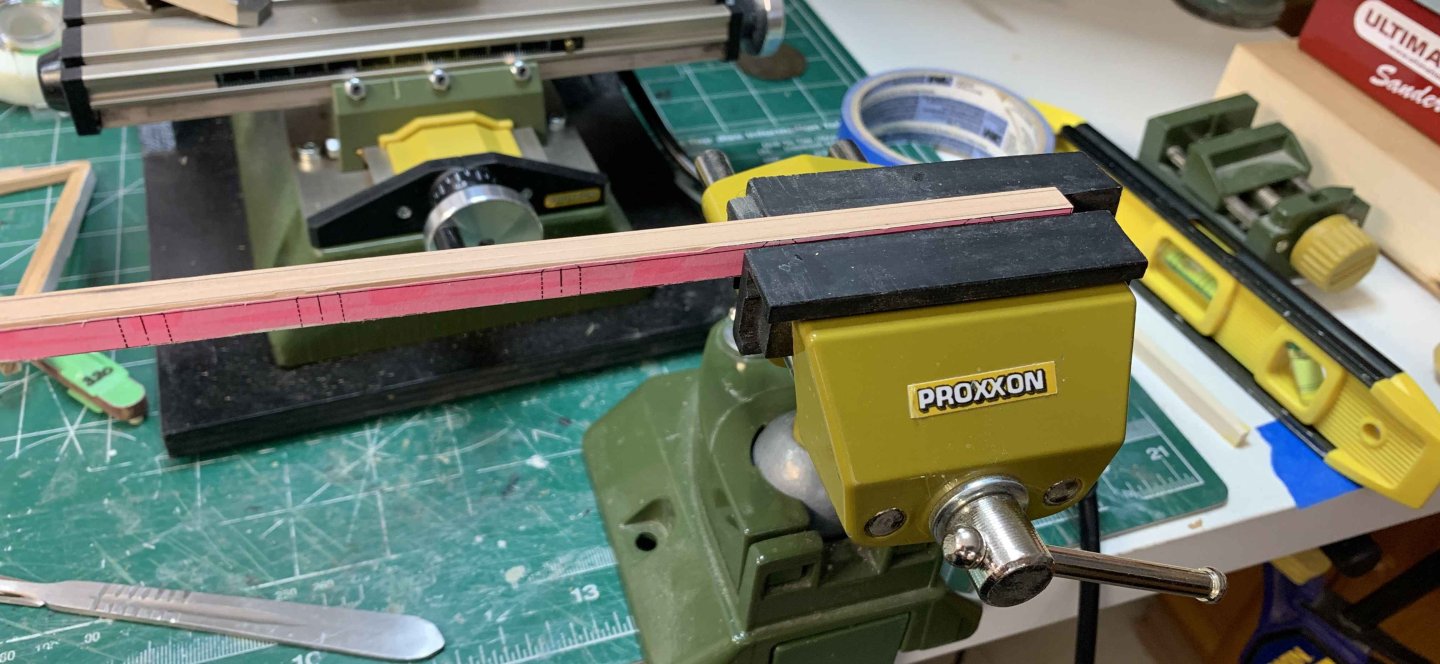

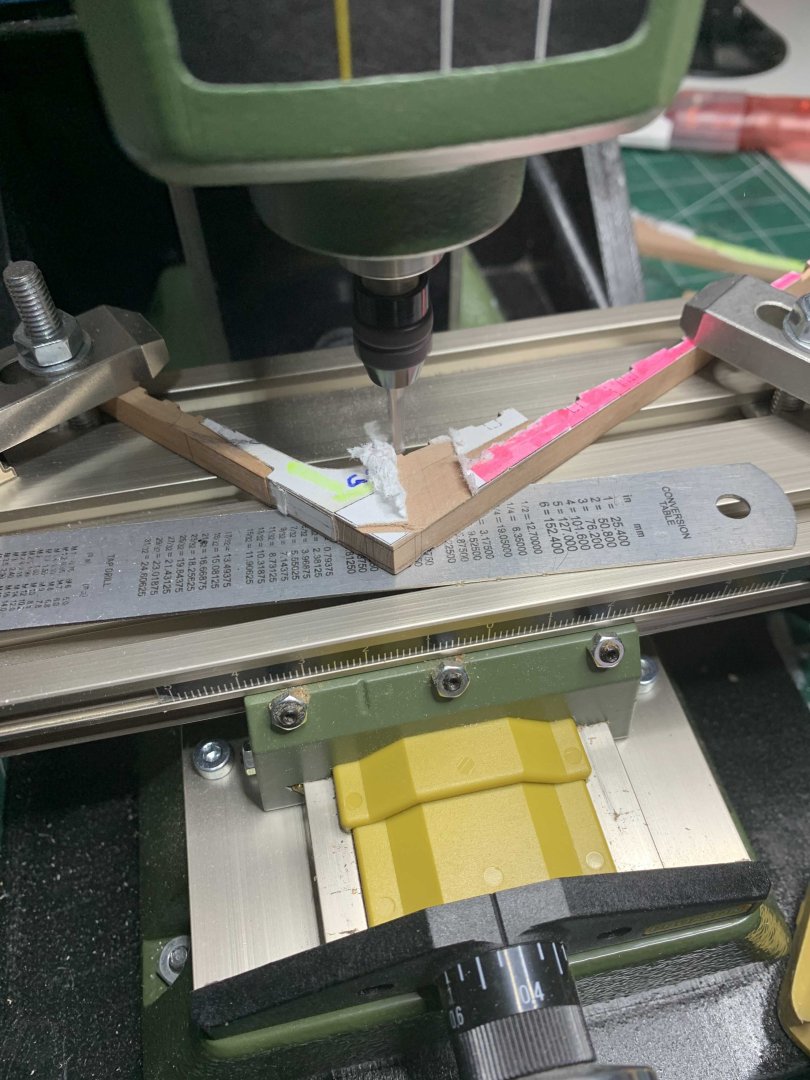

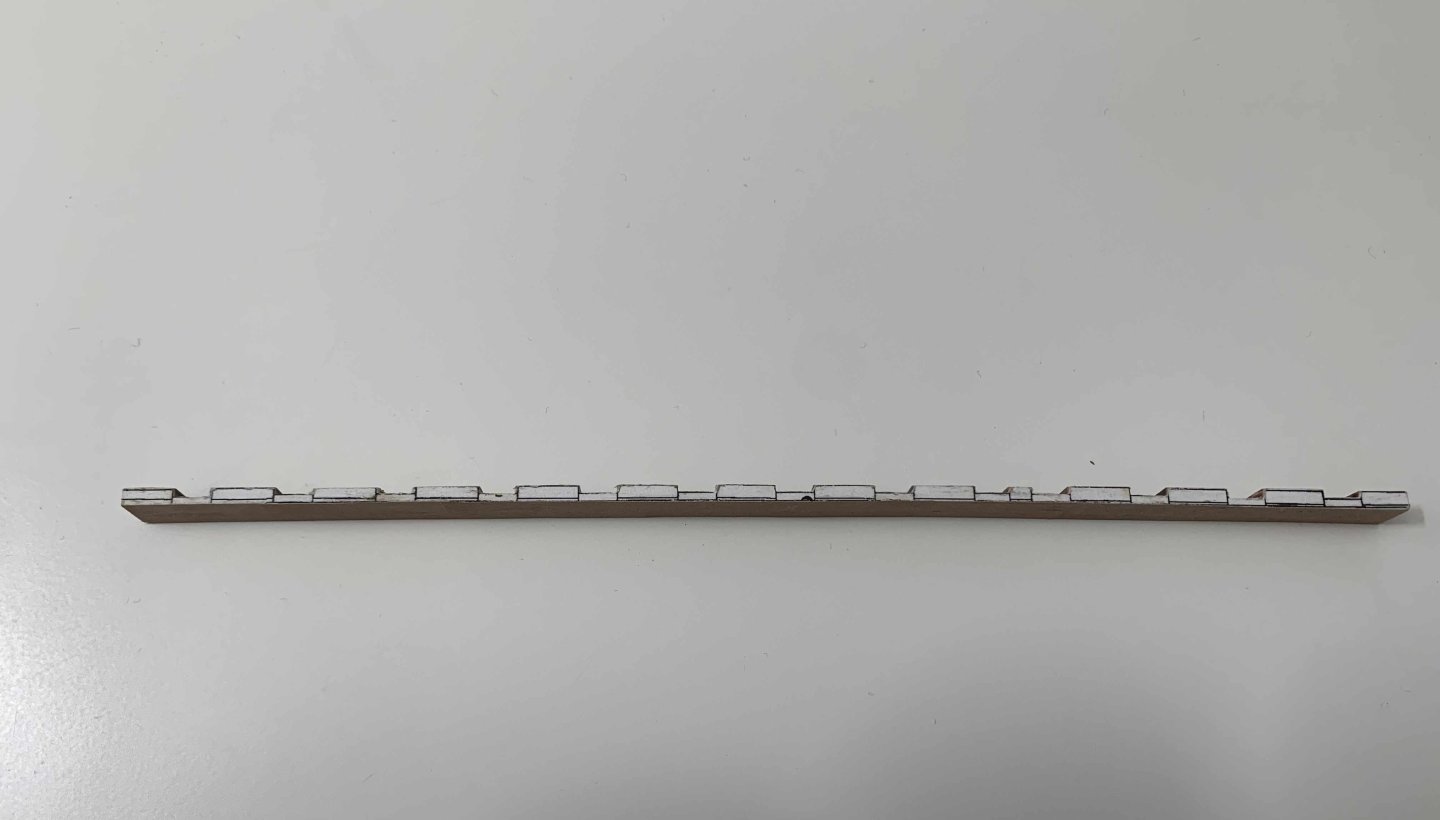

The build continues with assembling few parts, including keel... Also, I have cut the angle on the keel with a knife, file and sanding so will see end results.. Keel parts were glued together but was noted some curving on the keel so had to reassemble and glue them again with mora usage of wise and heavy objects.. Both parts done... Happy modelling...

-

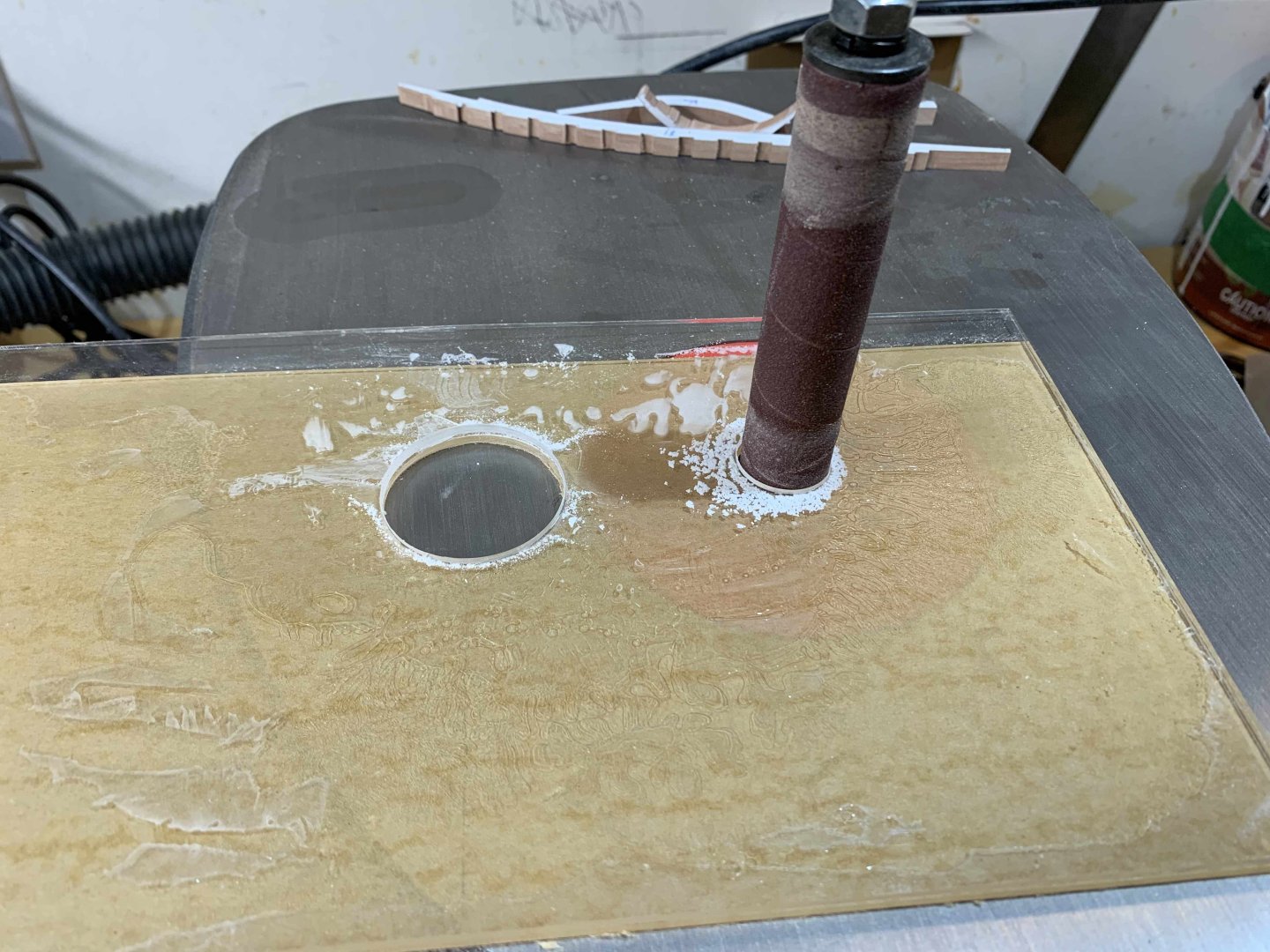

A little table addition to bridge the gap between sanding paper and sanded part... just a two piece of plexiglass, glued together for thickness and two holes matching diameter of a sanding cylinder.. suction action of an attached vacuum, keeps the plexiglass very tight... On the bench.... during action... All parts are almost done... Hard to find some hobby time during Euro24... Happy modelling..

-

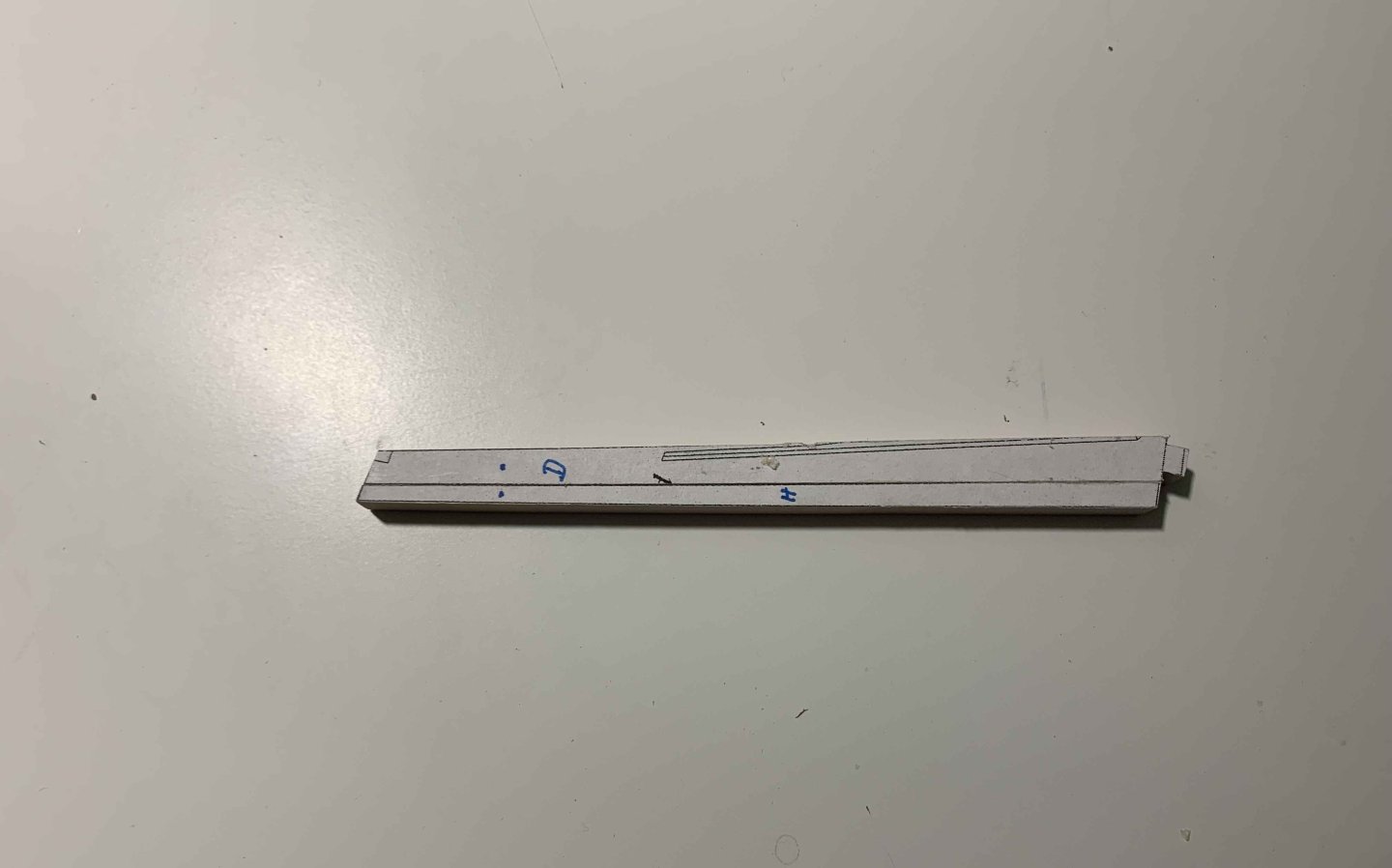

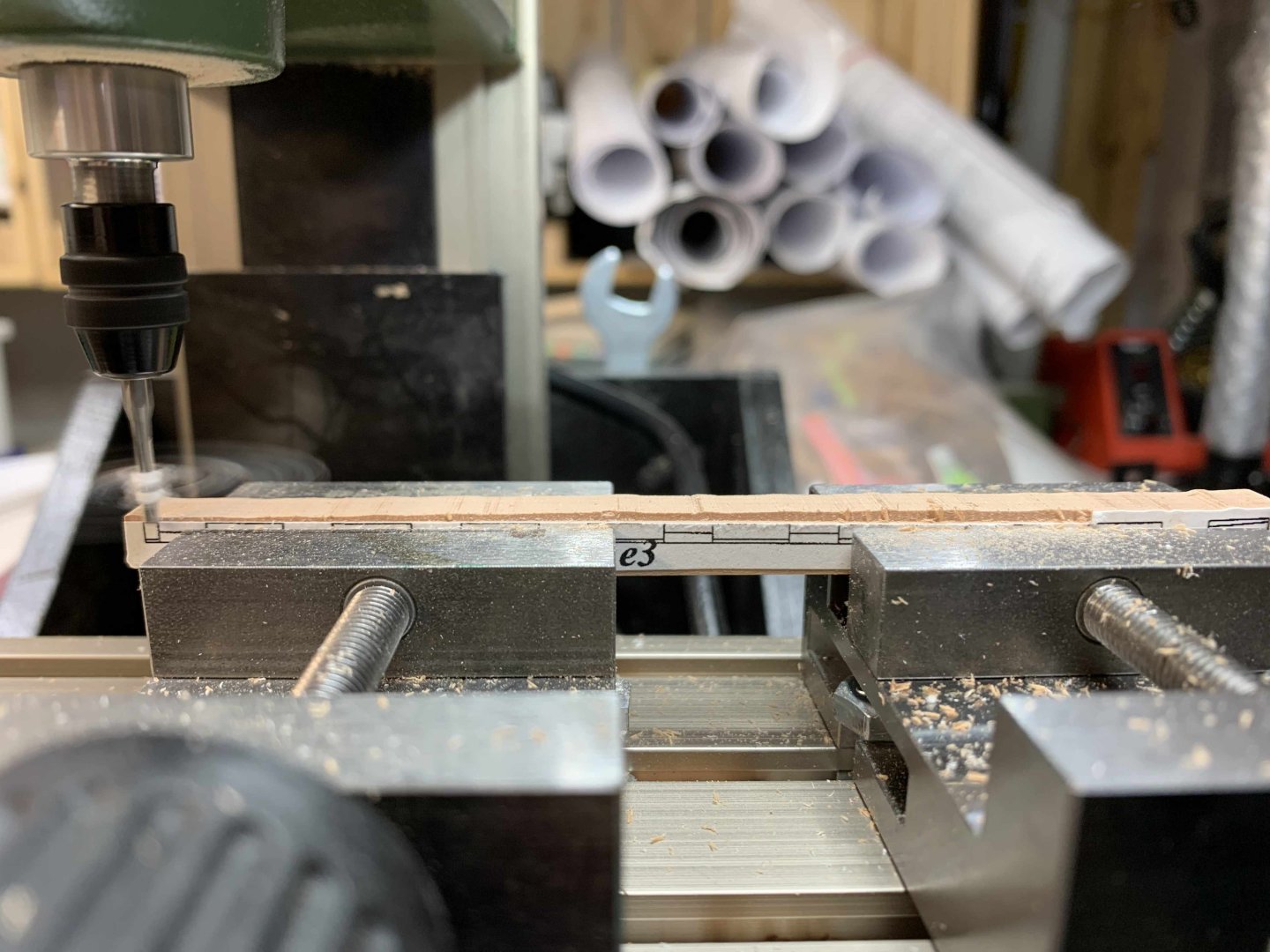

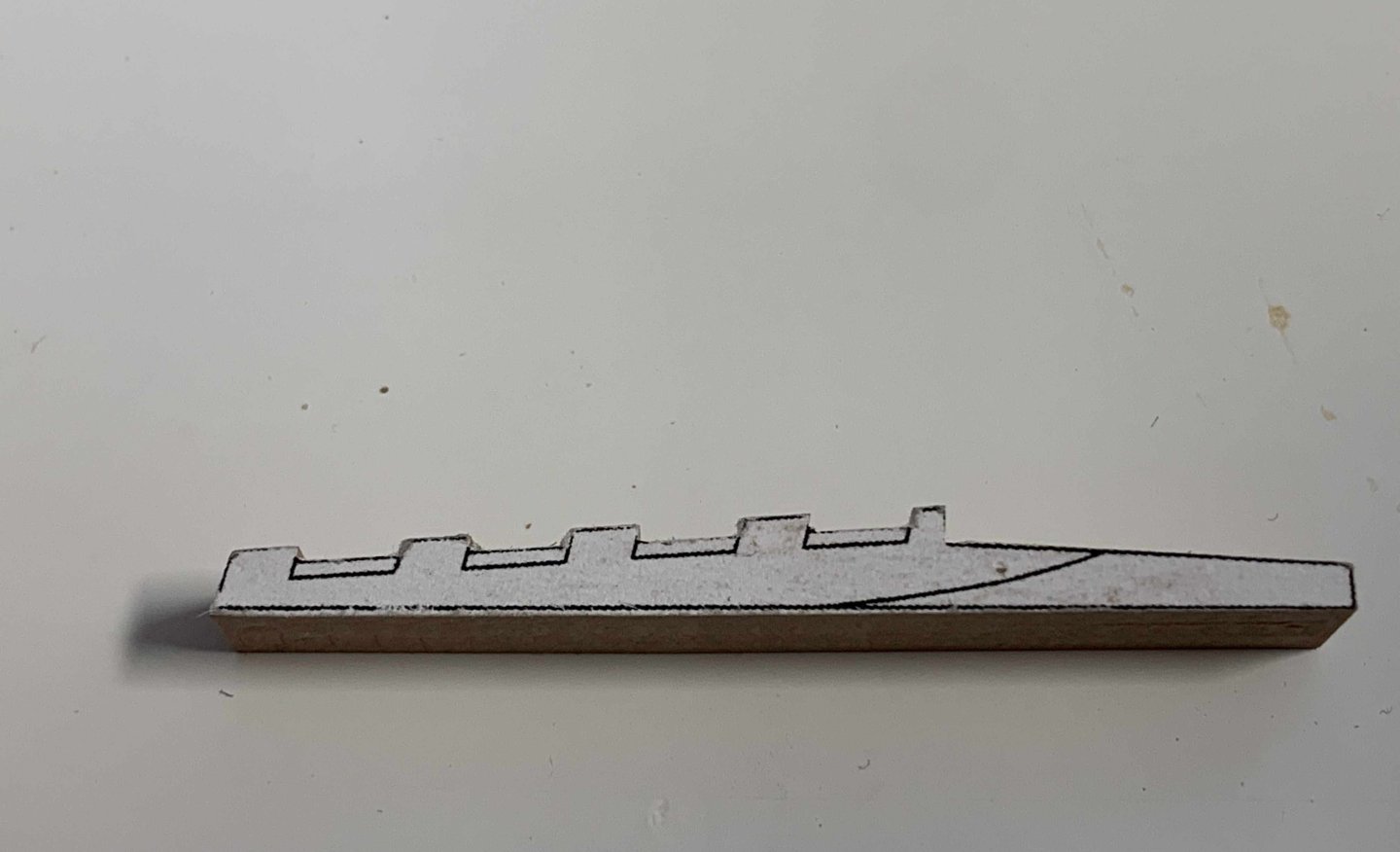

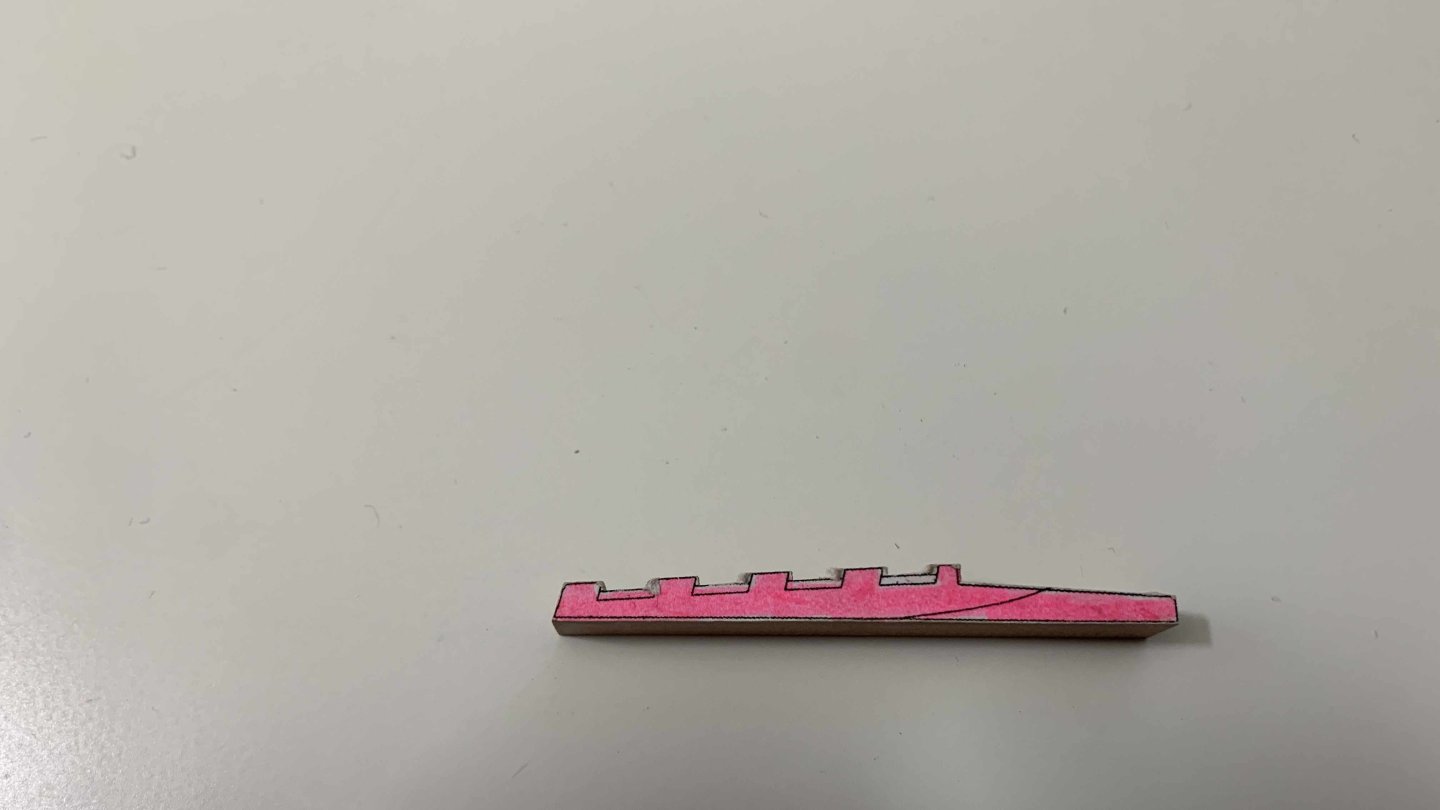

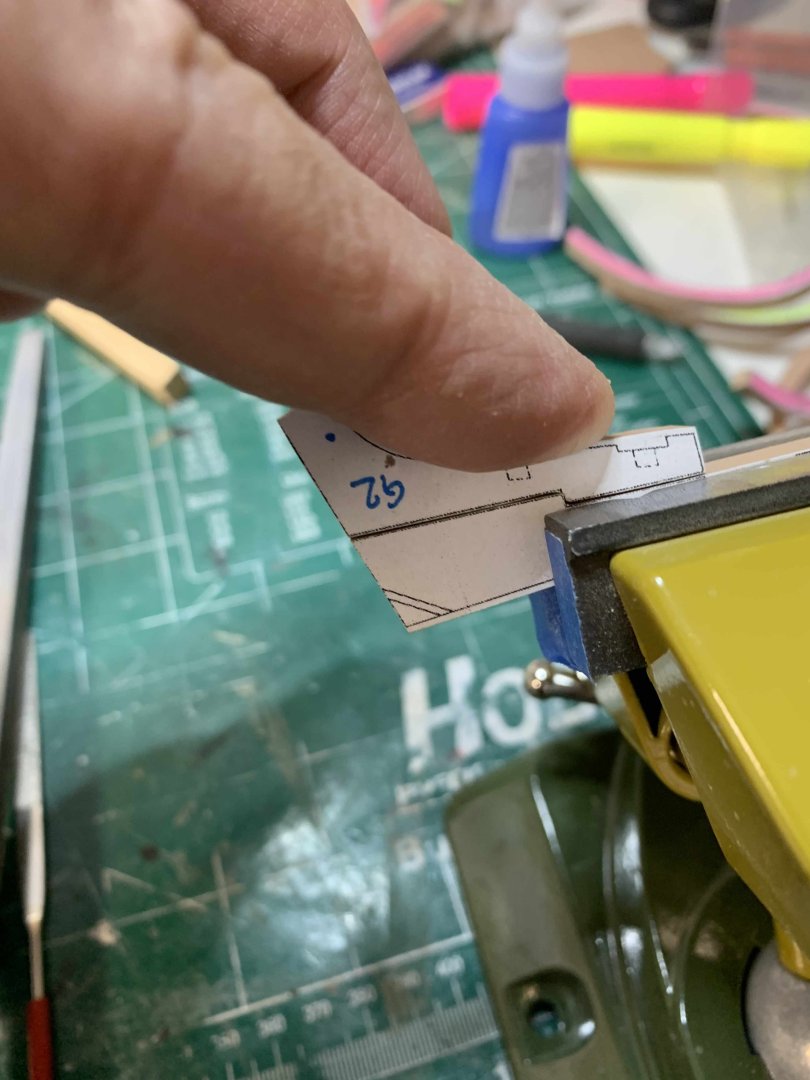

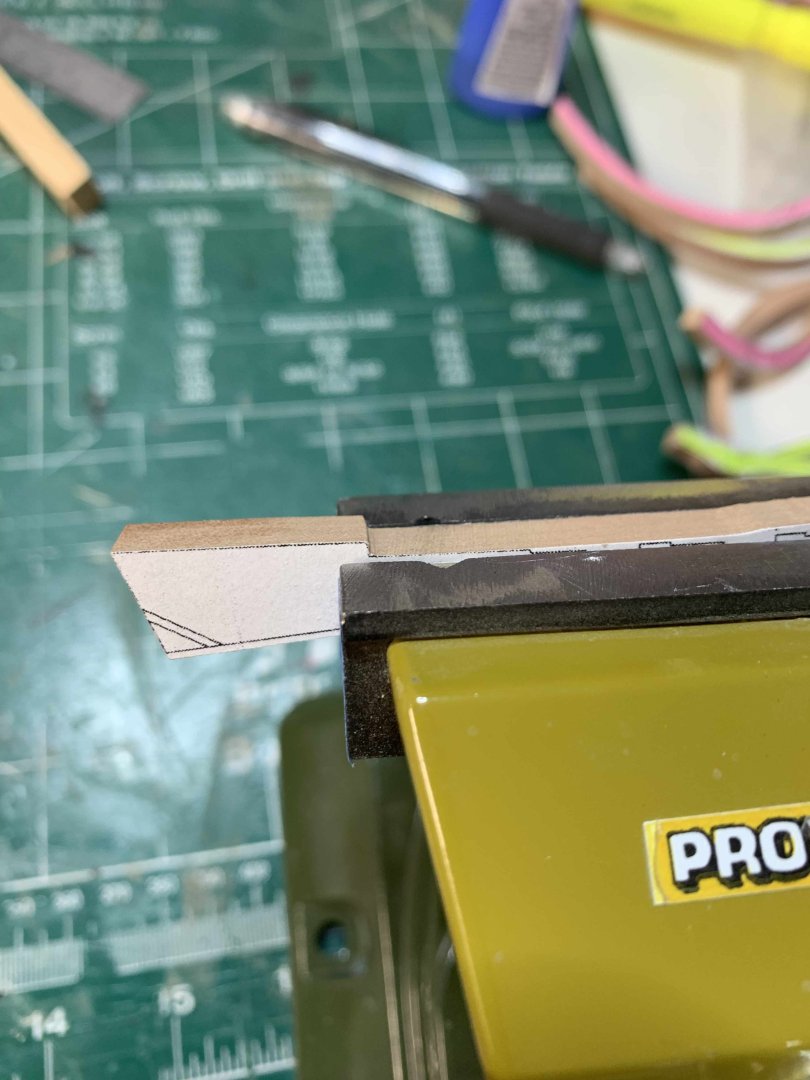

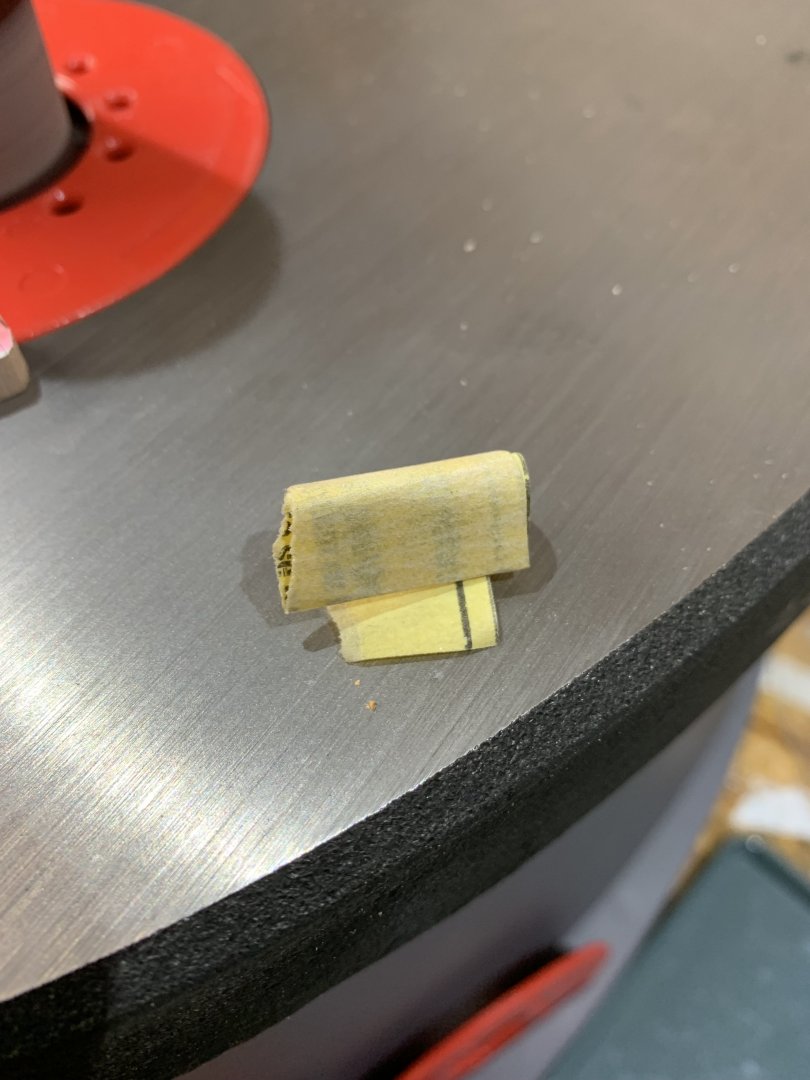

First attempt to make some keel parts... Rough sanding then some more controlled sanding using a file. Challenge here is to keep straight position of the file and not allowing it to wobble up and down during sanding.. Will need to build few sanding disks in the size of the keel parts to assisting with flat sanding... a bit afraid of damaging my Proxxon wise with sanding to the template line and keeping those metal wise parts as a border... Ok, looks OK... testing OK still looks good... And lets rotate to the side with no paper.. Hmm, not quite there... Yeah a bit over sanded somewhere... Time for a new part.. Happy modelling..

-

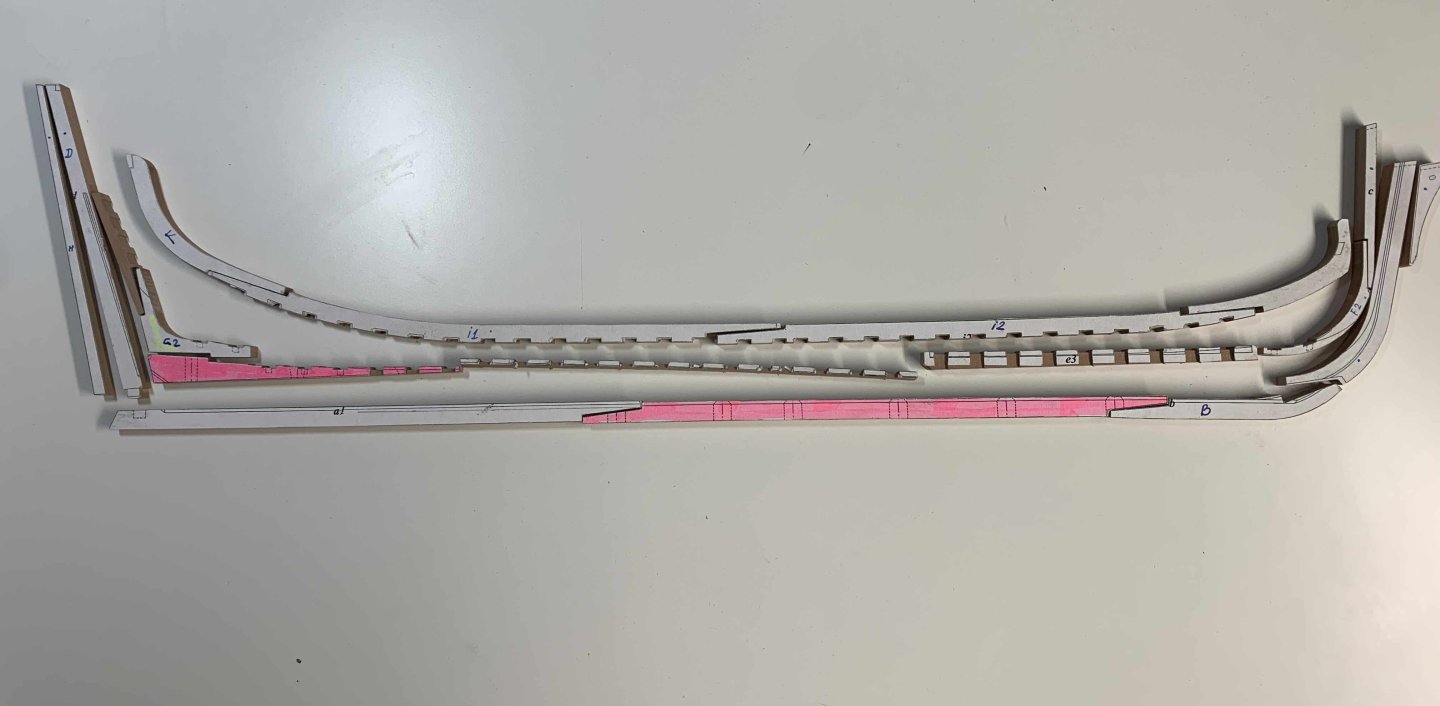

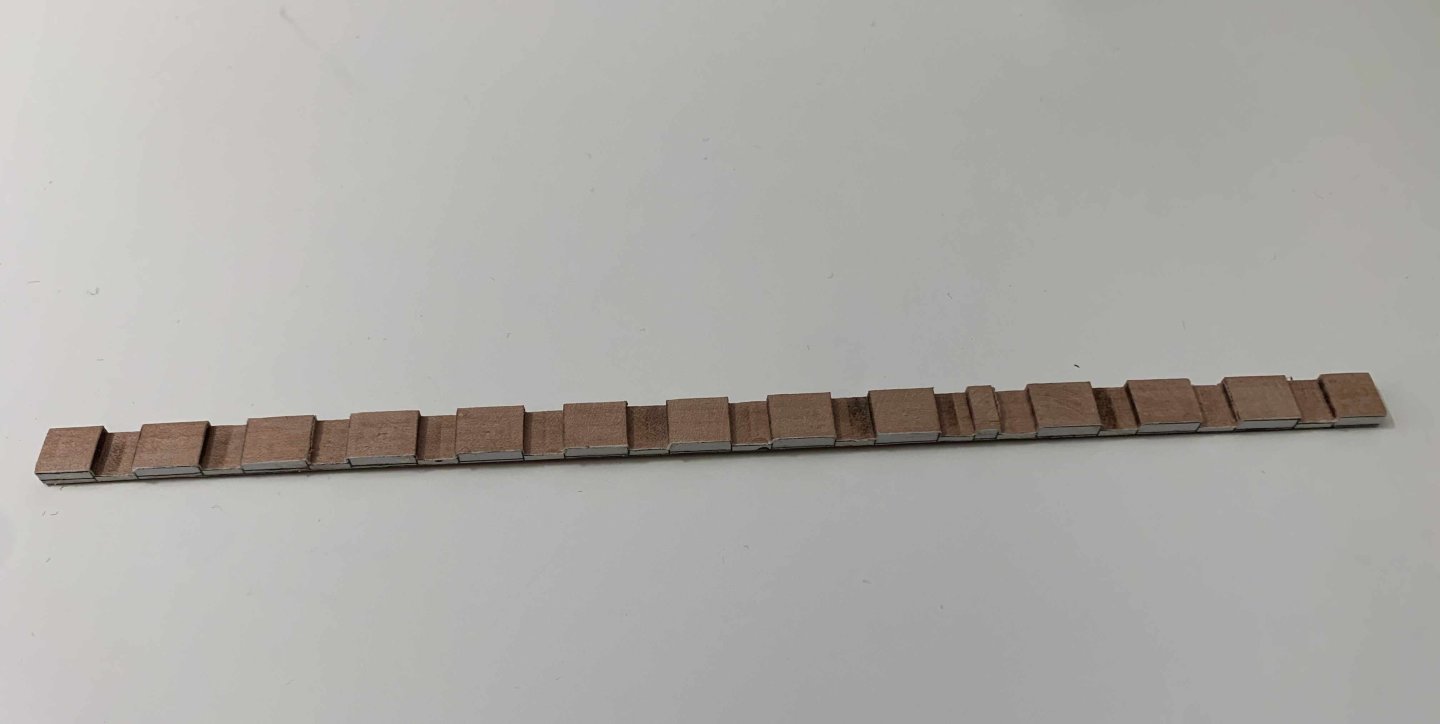

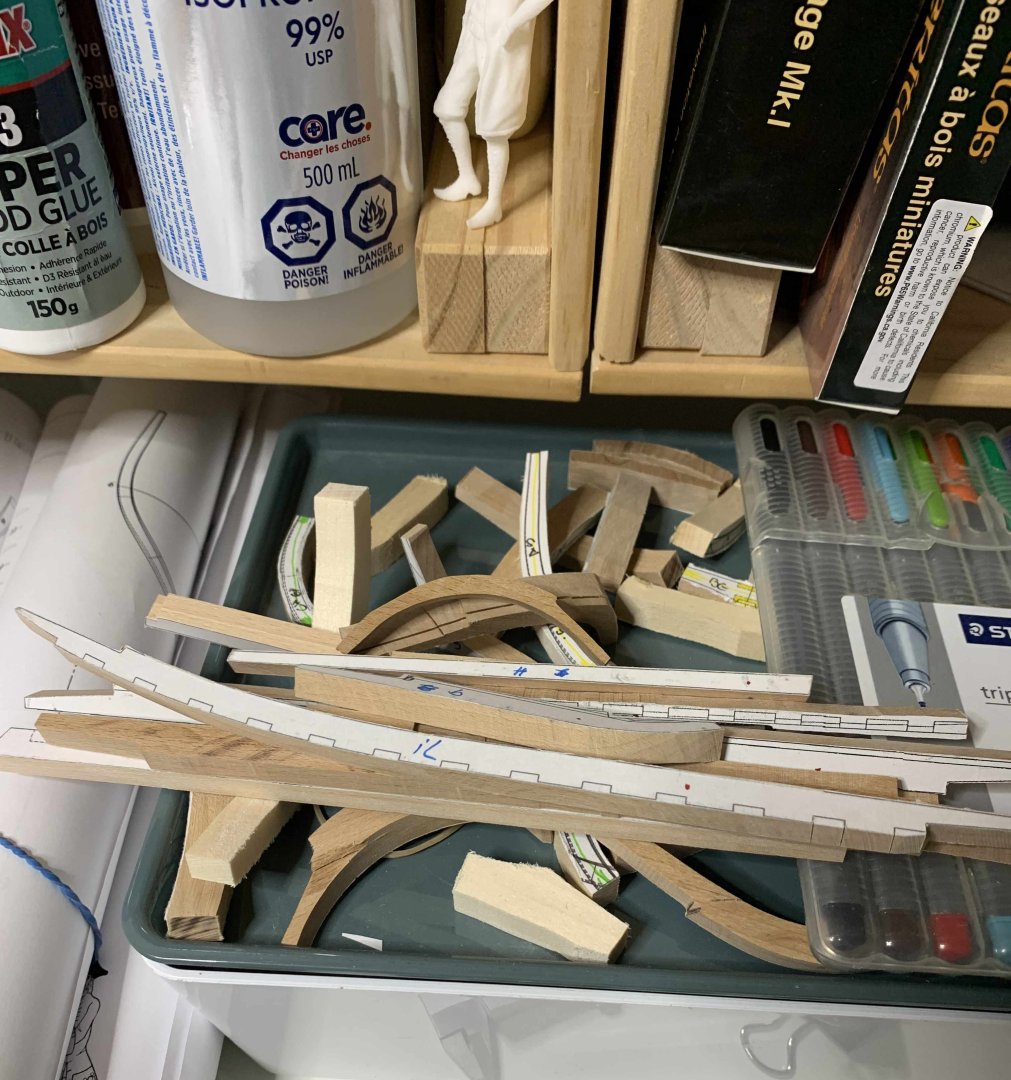

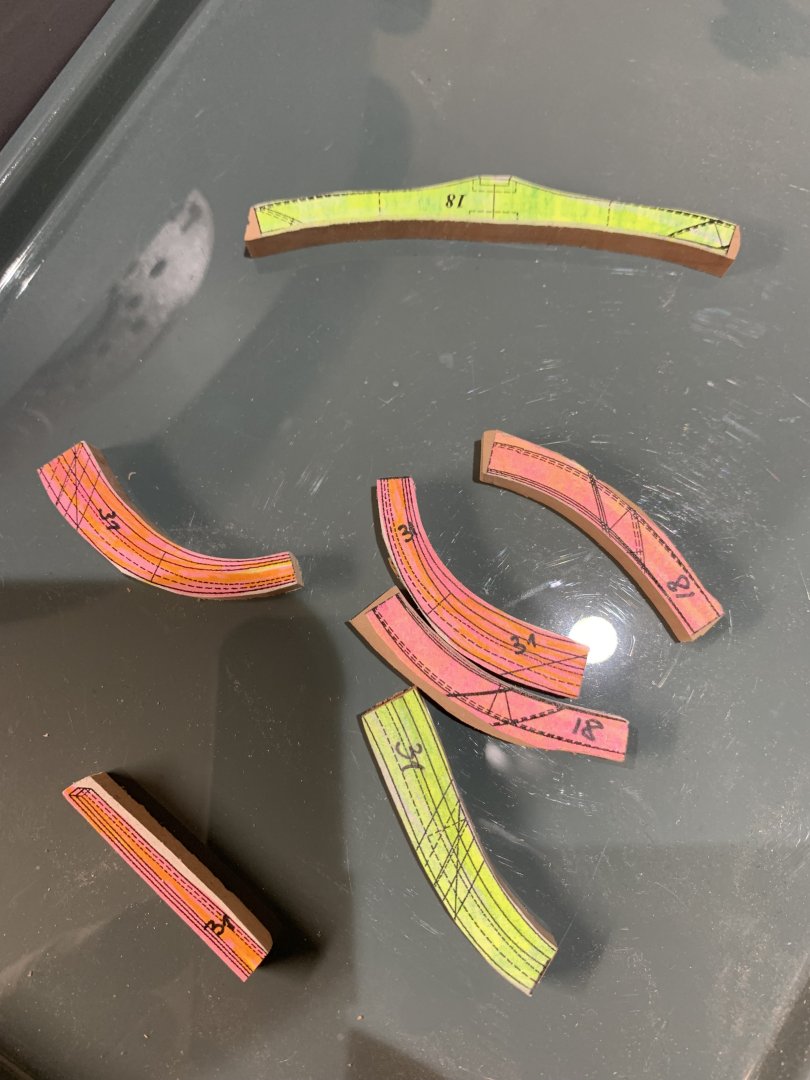

This is my pile of cut and rough sanded frame parts, ready for assembly and final sanding... I do have a bout 10 frames not marked with a number I would need to match during assembly process.. I also made few frames, completely copied from the plan, in one piece to be used as a visual representation of frames and frame orientation towards the bow/stern... this way takes more wood than cutting individual frame pieces but it is easier for testing purposes... This is my current "good" pile of keel parts.. And this is my pile of testing parts... The keel parts in above picture are done from wood that is thicker than needed and I planned to saw it down to the correct thickness but I had some challenges with the process and at this moment no much fundings to buy proper sander so will try to stick with the wood that has little deviation of required thickness... And of course under the watchful eyes... Happy modelling..

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.