-

Posts

689 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by moreplovac

-

Amazing and inspiring work. Much appreciated all effort put in providing a very useful build log and how-to guide. Cheers

-

Absolutely, that is a must; I already have La Rochefort from the same source for my other project.

-

Perfect build.... I do have a kit for this famous ship but your build makes me thinking to go scratch build from the plan, and forget the kit... Thanks again..

-

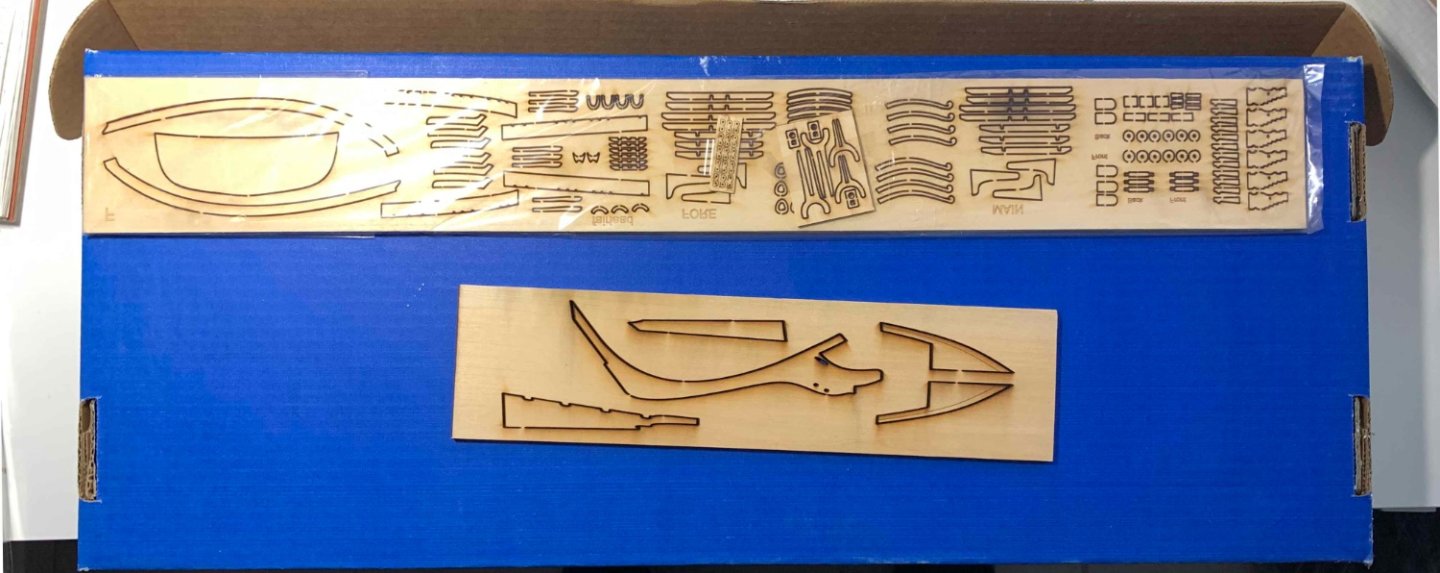

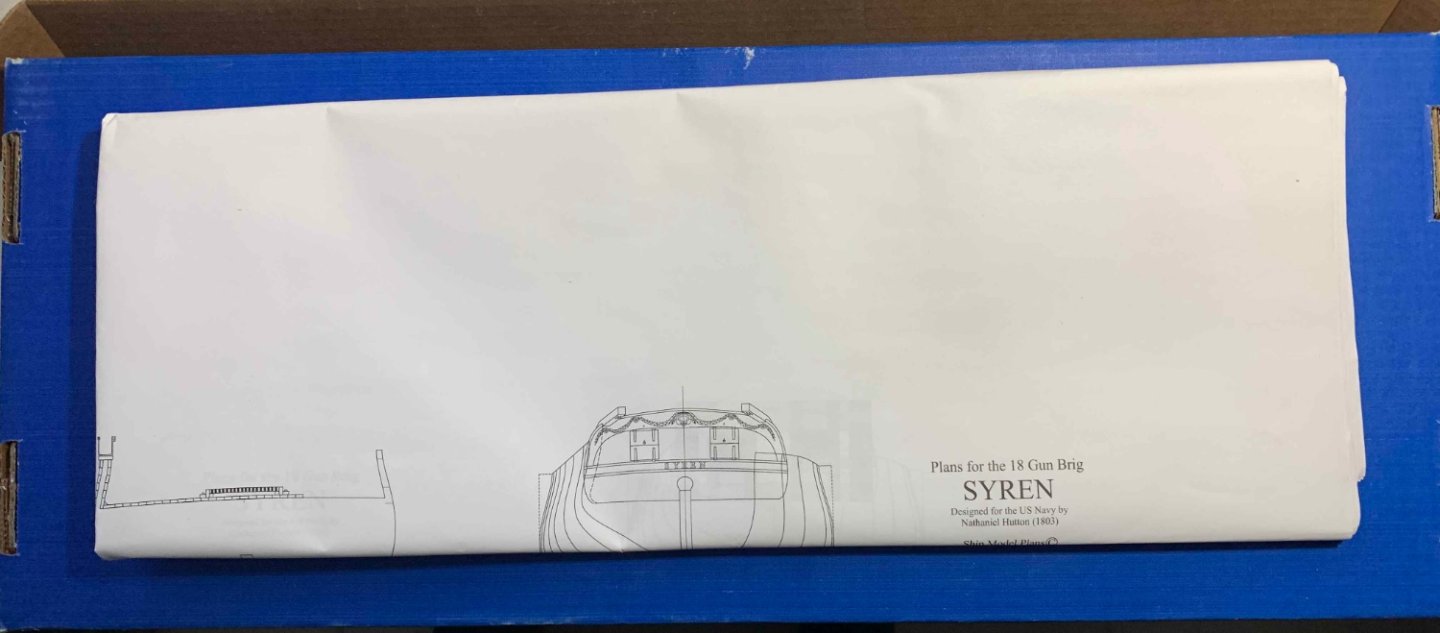

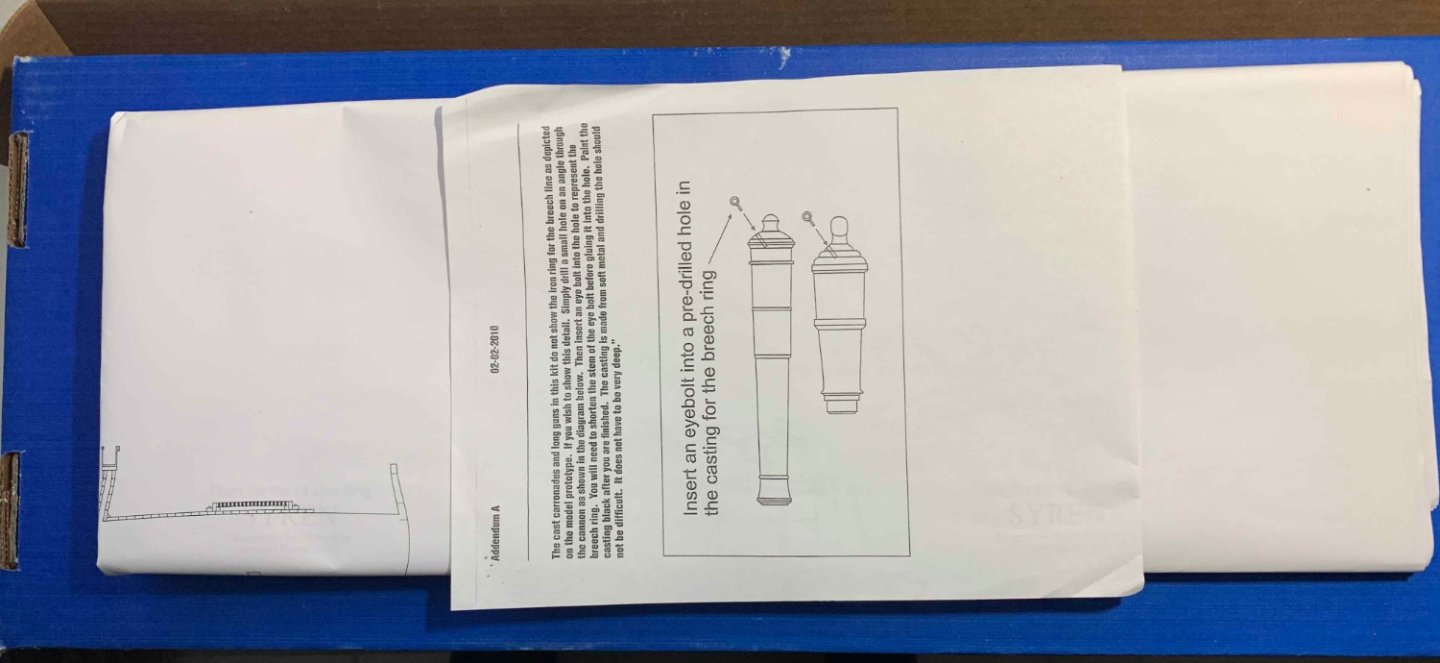

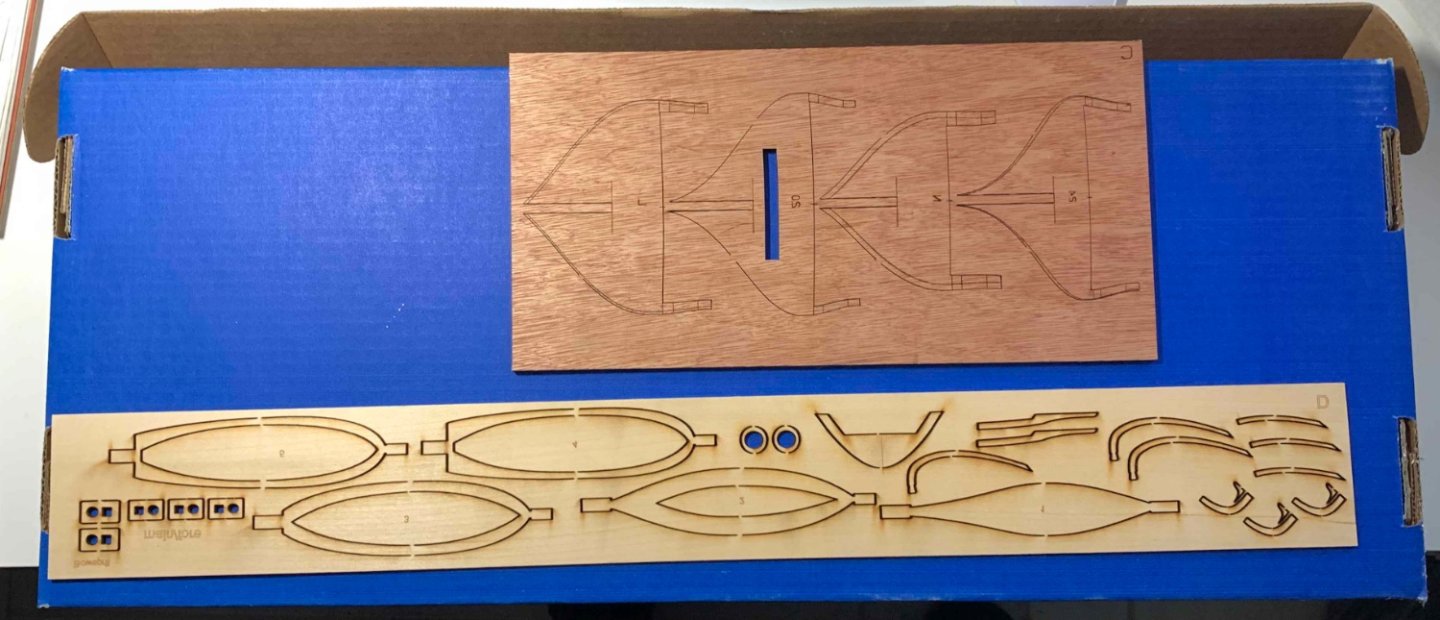

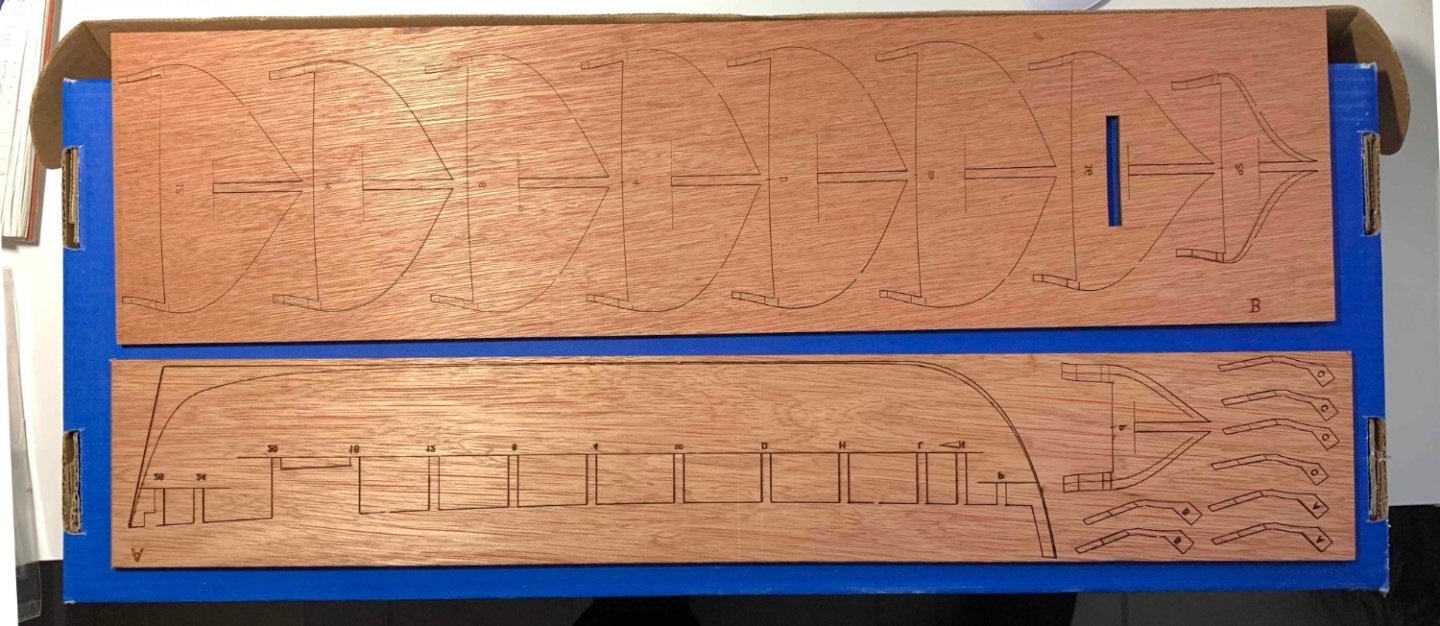

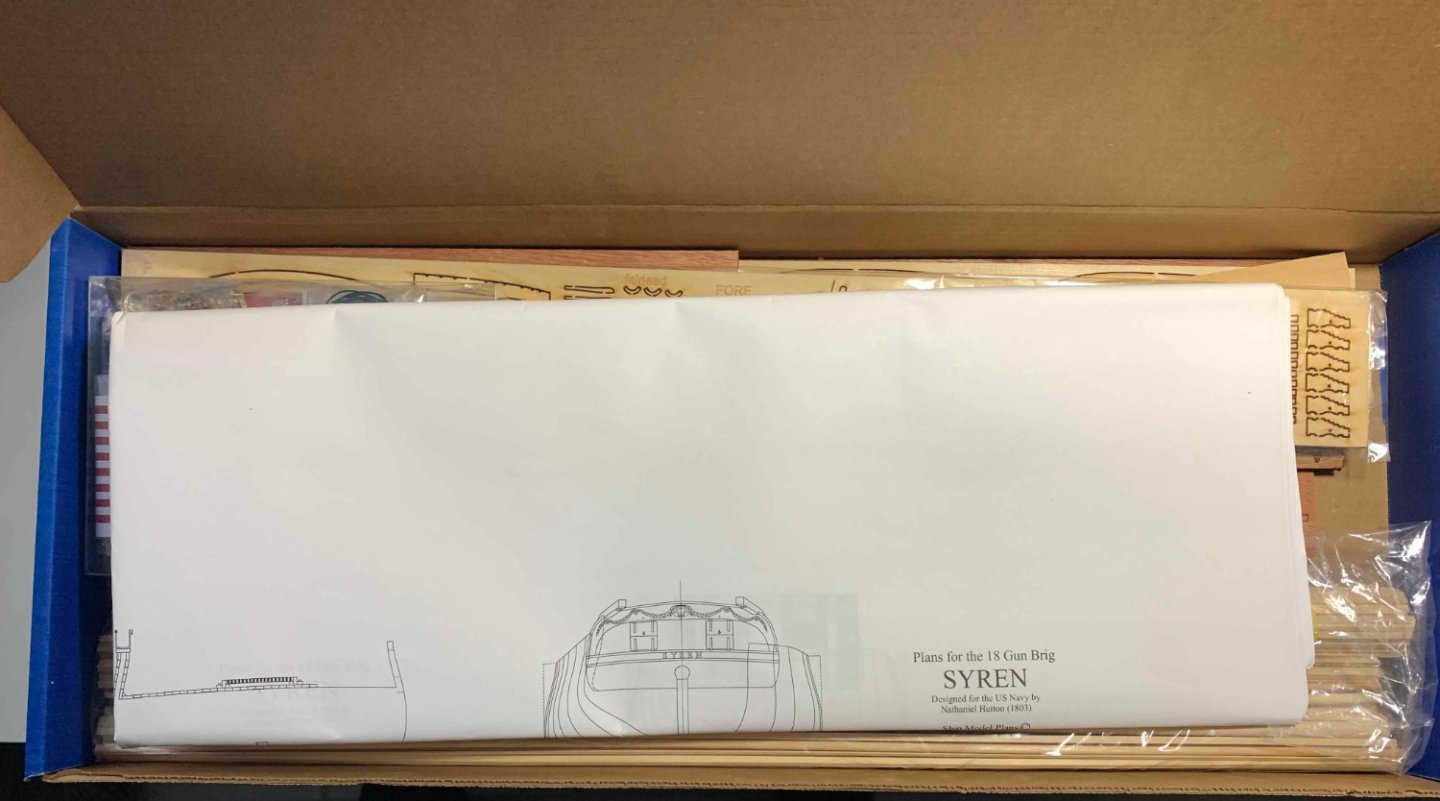

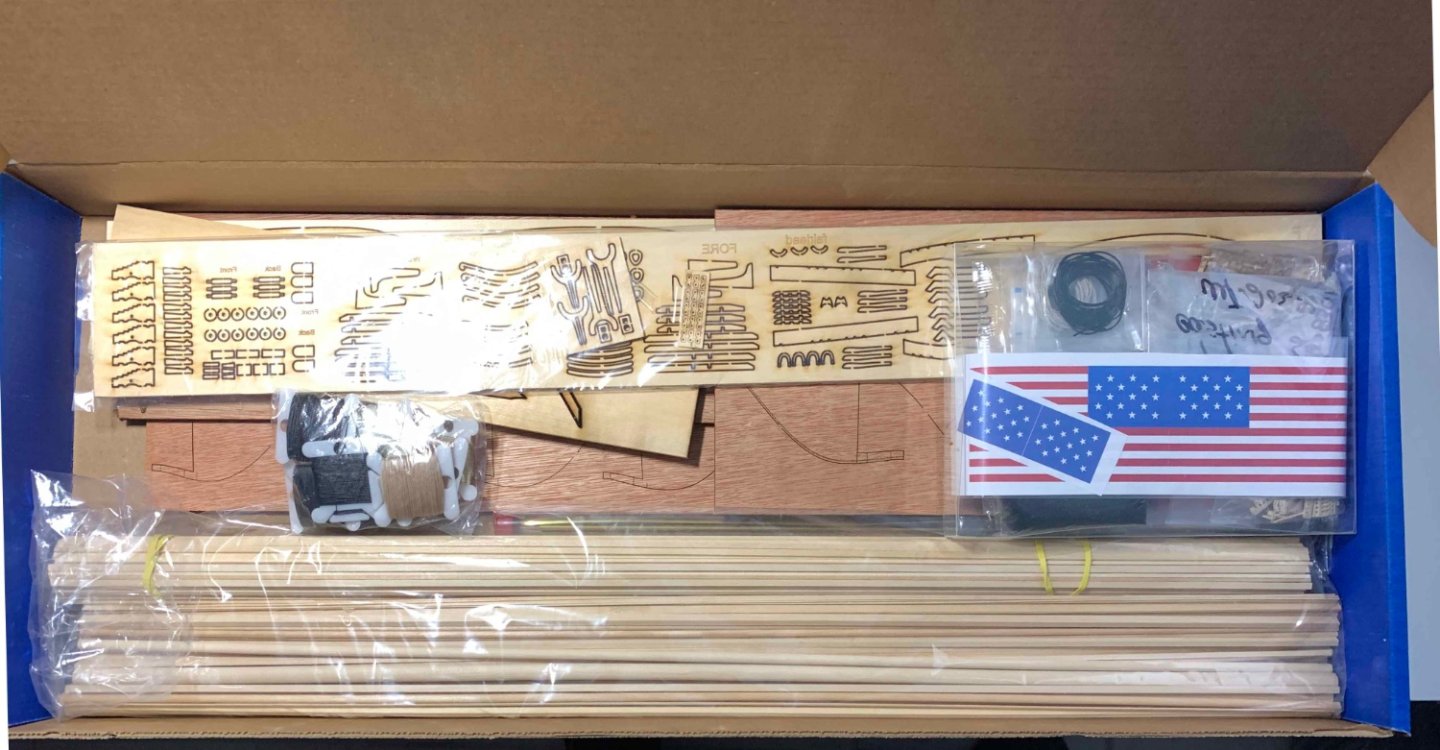

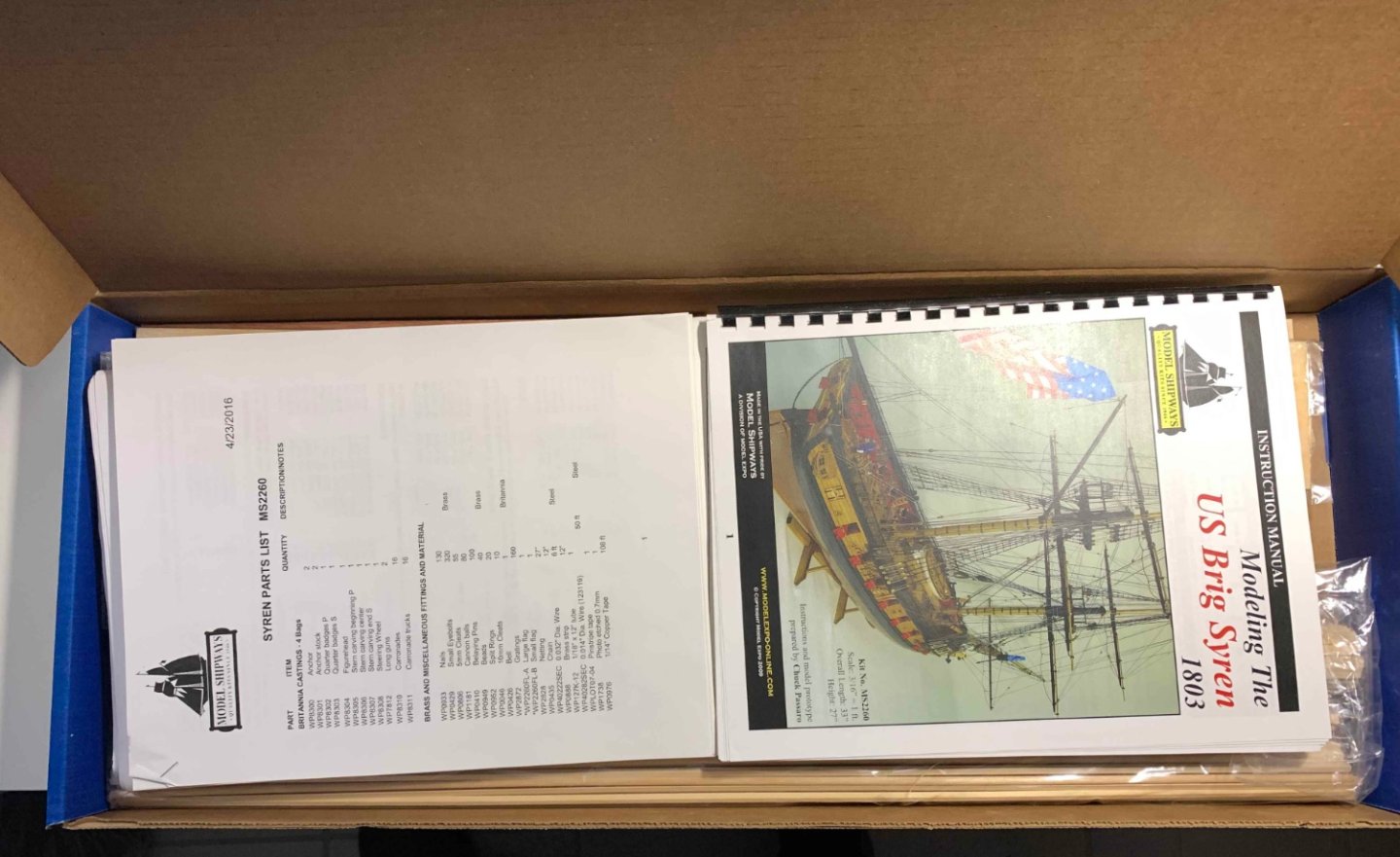

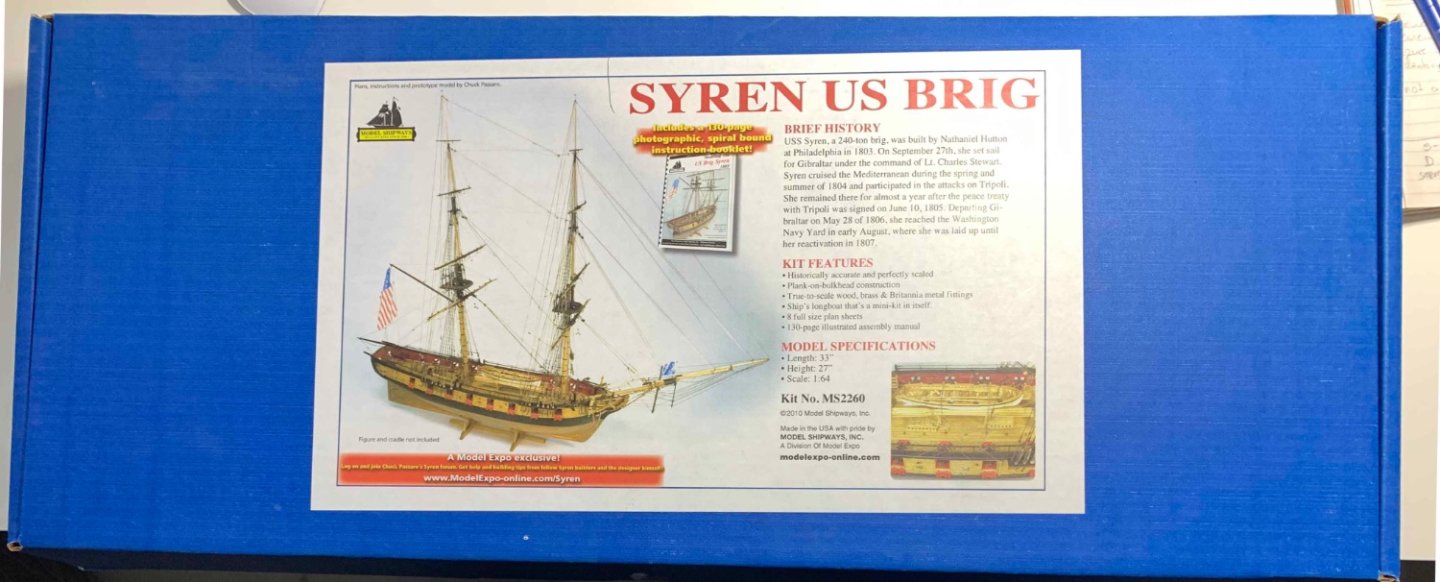

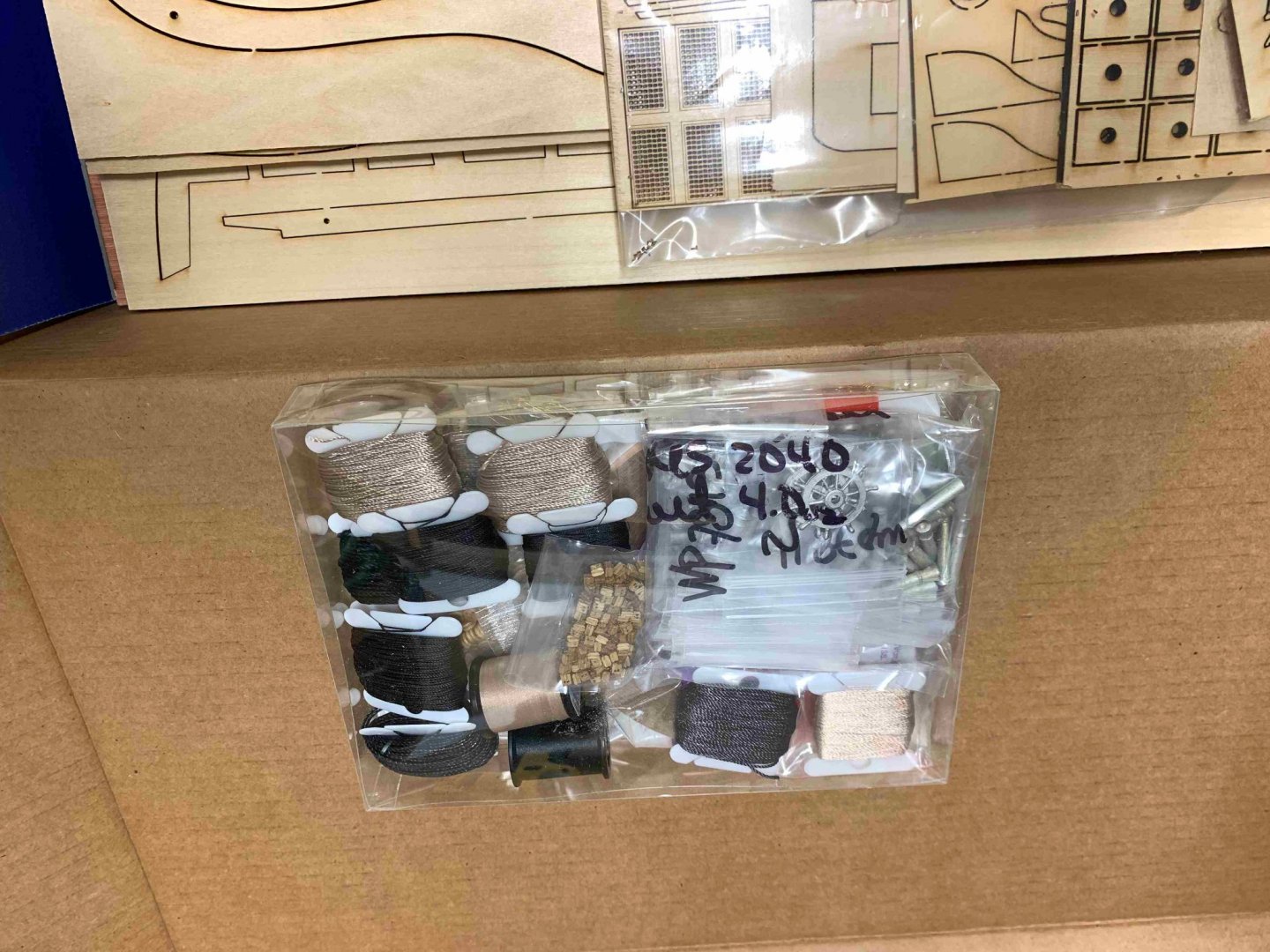

It is never late for a shopping. I am selling brand new kit, opened to take a picture of what is inside. Here is description of a model, taken from the manufacturer' web site: USS Syren, a 240-ton brig, was built by Nathaniel Hutton at Philadelphia in 1803. On September 27th, she set sail for Gibraltar under the command of Lt. Charles Stewart. Syren cruised the Mediterranean during the spring and summer of 1804 and participated in the attacks on Tripoli. She remained there for almost a year after the peace treaty with Tripoli was signed on June 10, 1805. Departing Gibraltar on May 28 of 1806, she reached the Washington Navy Yard in early August, where she was laid up until her reactivation in 1807. During her service in the War of 1812, she was captured by the 74-gun HMS Medway after an 11-hour chase. Designed by master modeler Chuck Passaro, Model Shipways' kit is authentic to the last detail. Basswood keel and bulkheads are laser cut foreasy assembly, and framing templates help you build a perfect hull. We supply several sizes of basswood strips for deck and hull planking, plus self-adhesive copper tape for plating the hull below the waterline. An abundant fittings package includes photo-etched brass detailing, brass eyebolts, Belaying Pins, nails, gudgeons and pintles, over 200 wooden blocks and deadeyes, gratings, plus dowels for masts and spars. Several sizes of tan and black rigging line, netting, printed flags and grating are supplied as well. Armament consists of 16 precision-cast Britannia metal carronades and two long guns on wooden trucks. The model carries a ship's longboat that's a mini-kit in itself. Actual sized plans are on 8 sheets, and 140-page spiral bound instruction manual shows all stages of construction. KIT FEATURES Historically accurate and perfectly scaled Plank-on-bulkhead construction True-to-scale wood, brass and Britannia metal fittings Ship's longboat that's a mini-kit in itself 8 full size plan sheets 130-page illustrated assembly manual MODEL SPECIFICATIONS Length: 33" Height: 27" Scale: 3/16" = 1 ft. The price is US $299.00. Shipping will be calculated depending on the destination, desired shipping options and will be added to the kit price. If you are close to Vancouver, BC, we can arrange pickup. Thank you.

-

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

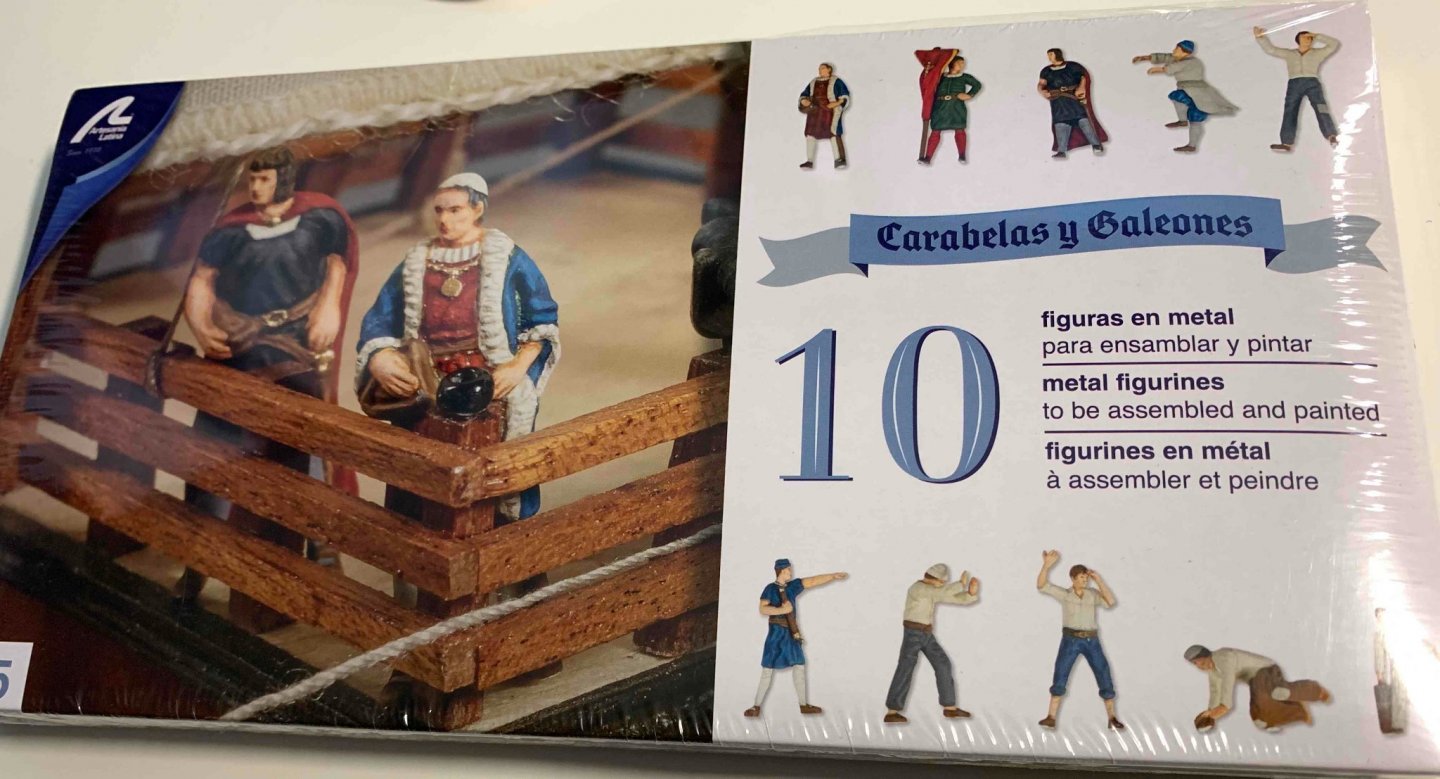

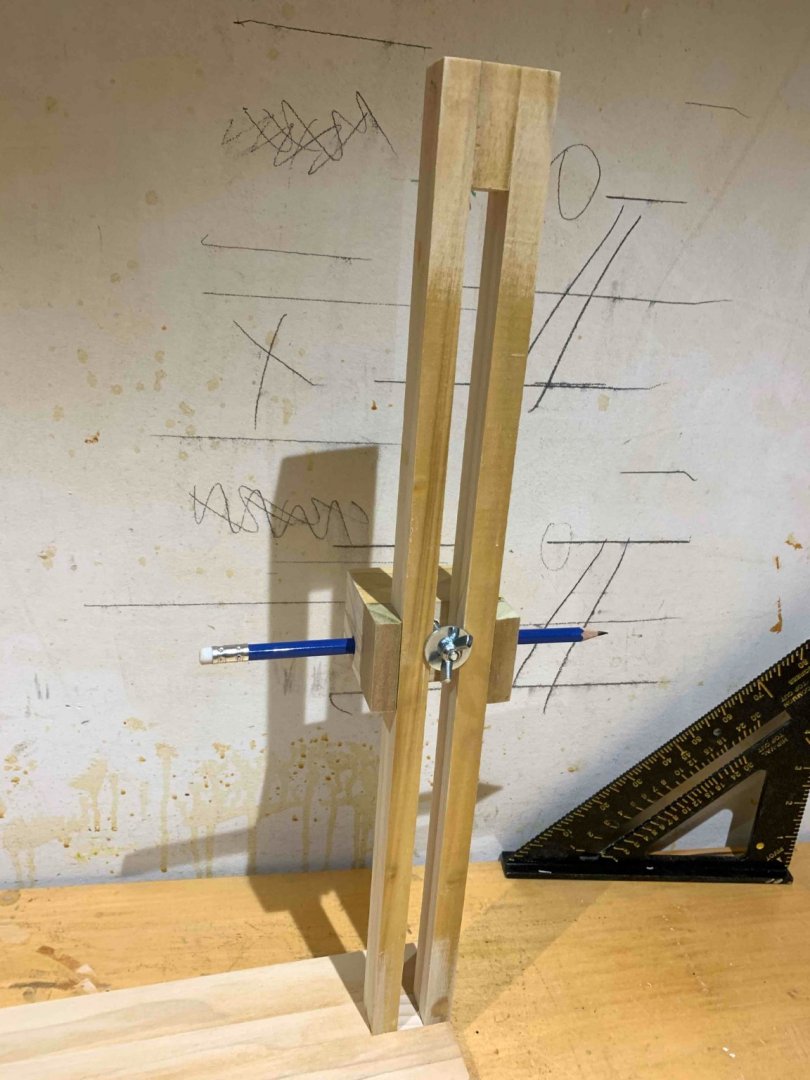

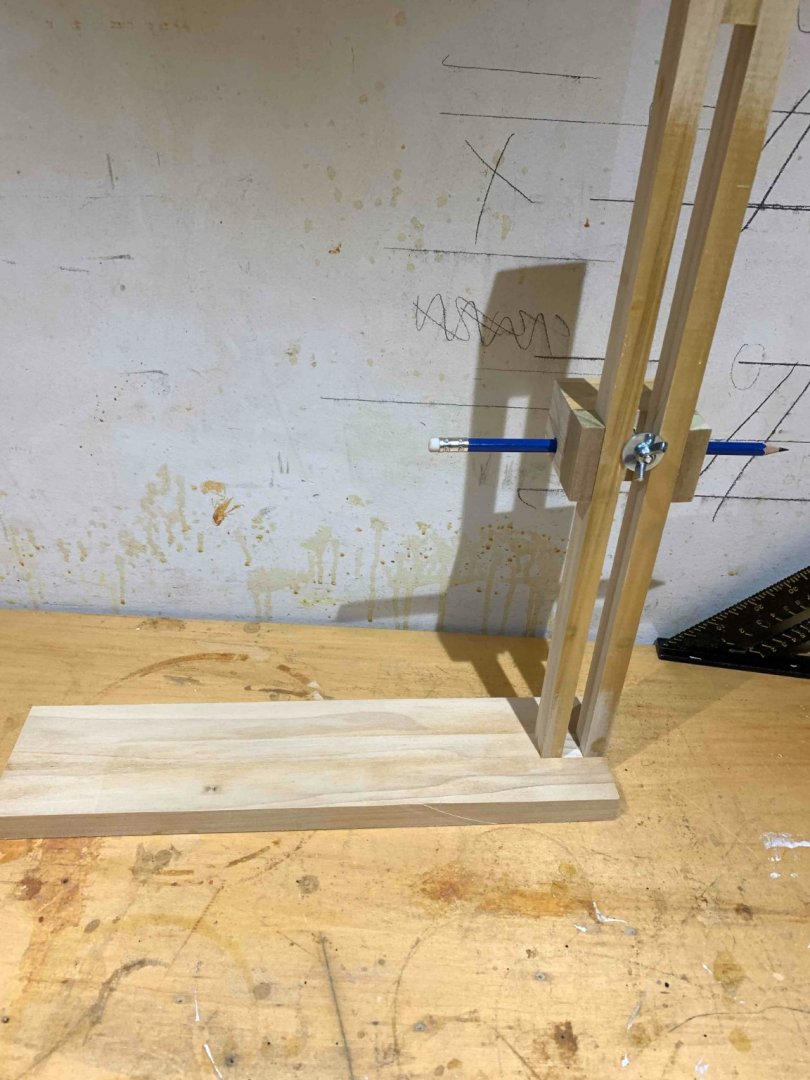

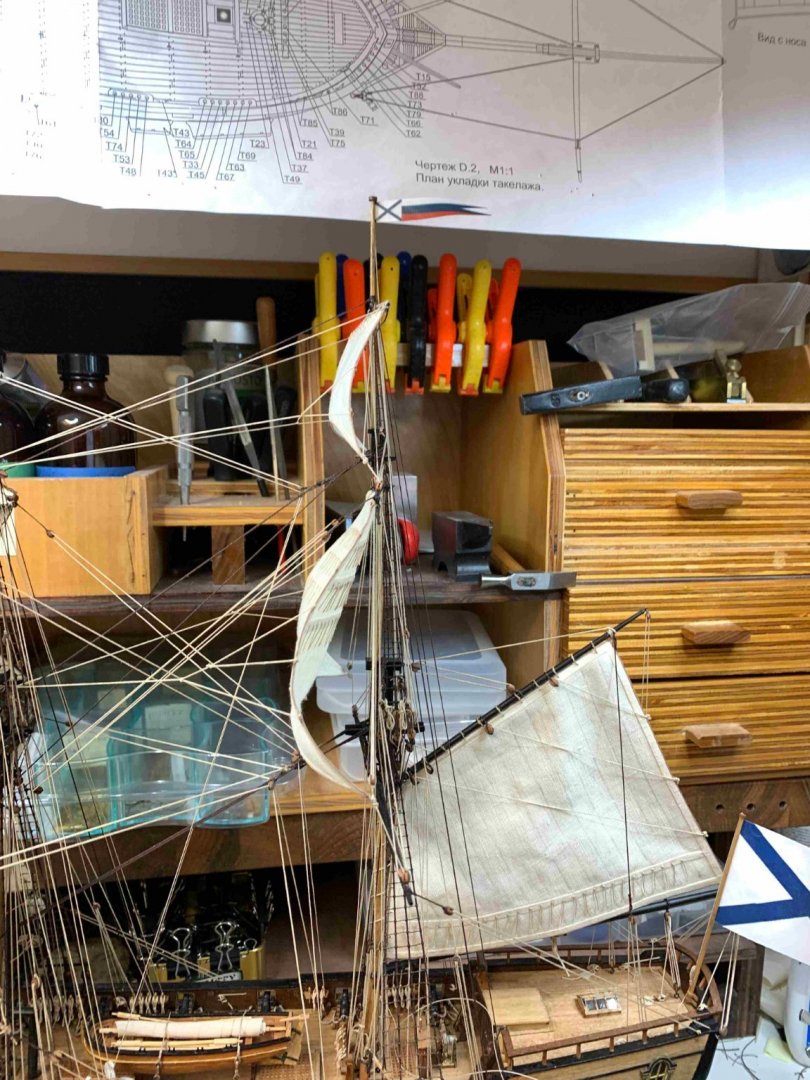

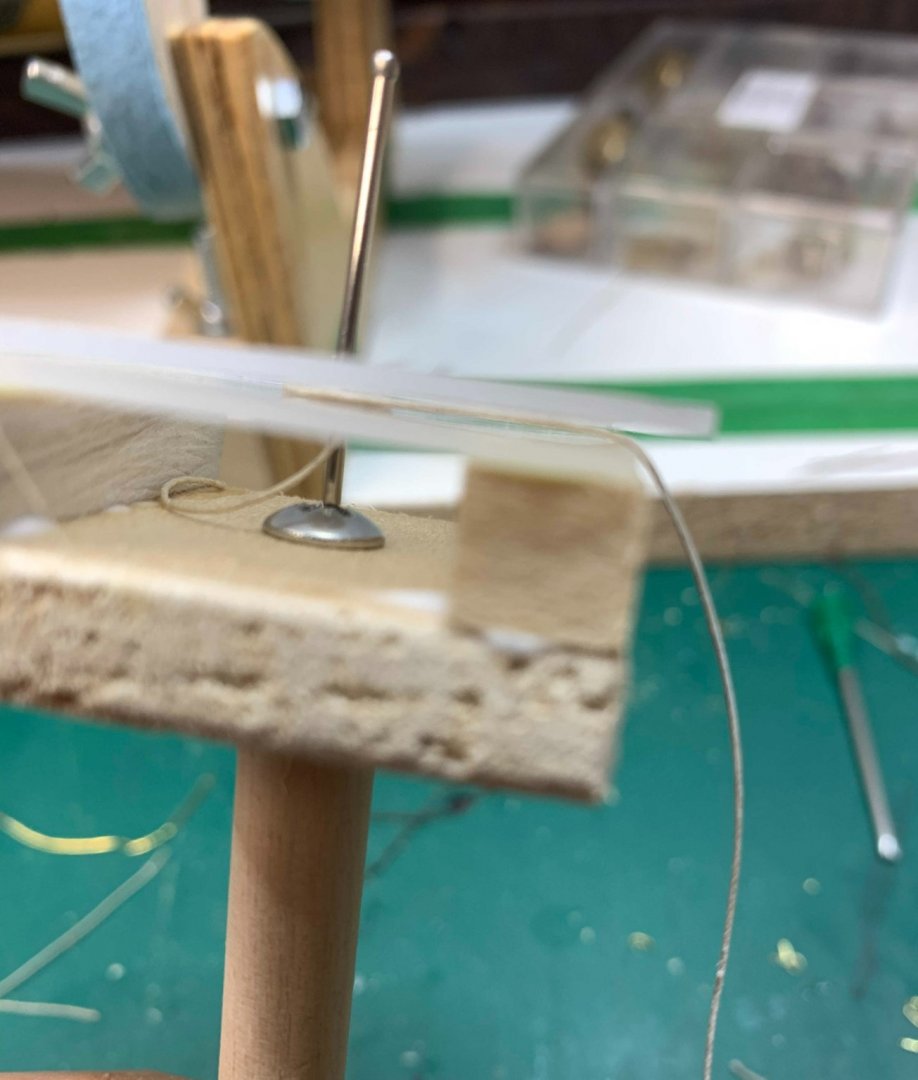

While waiting for a plexiglass to arrive (it will be used for ship protection), made waterline tool... And new little friends arrived... Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

The stand is made out of some scrap poplar located in my workshop... traced the hull ... and transferred on the wood. Then cut the shape with a saw, run the bottom board thru planner few times and ... Then i put a coat of oak stain but did not like the end result and finished with a matt black layer. Extra holding parts are made out of brass tube and a 2mm steel rod which replaced the screw on the picture. Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

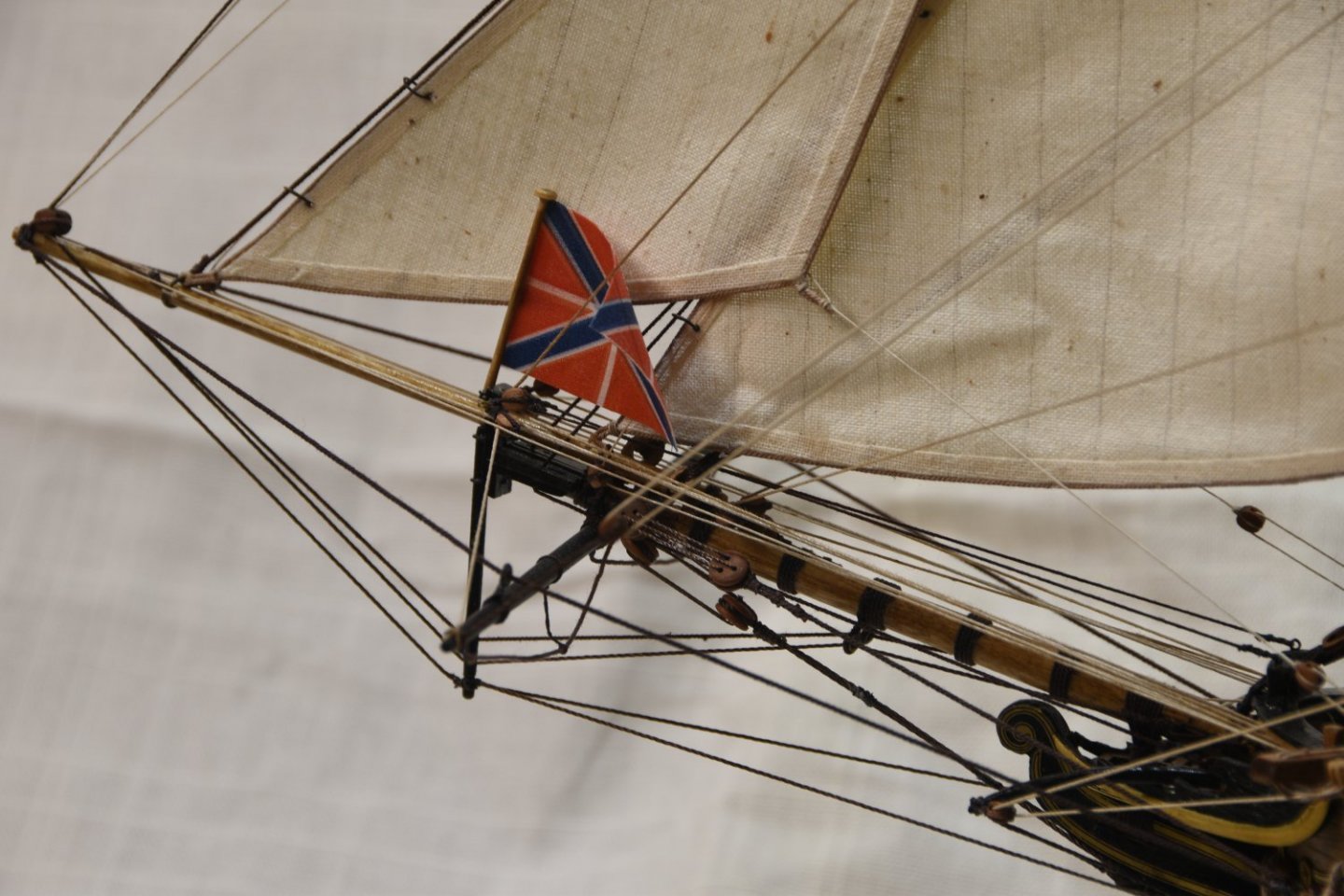

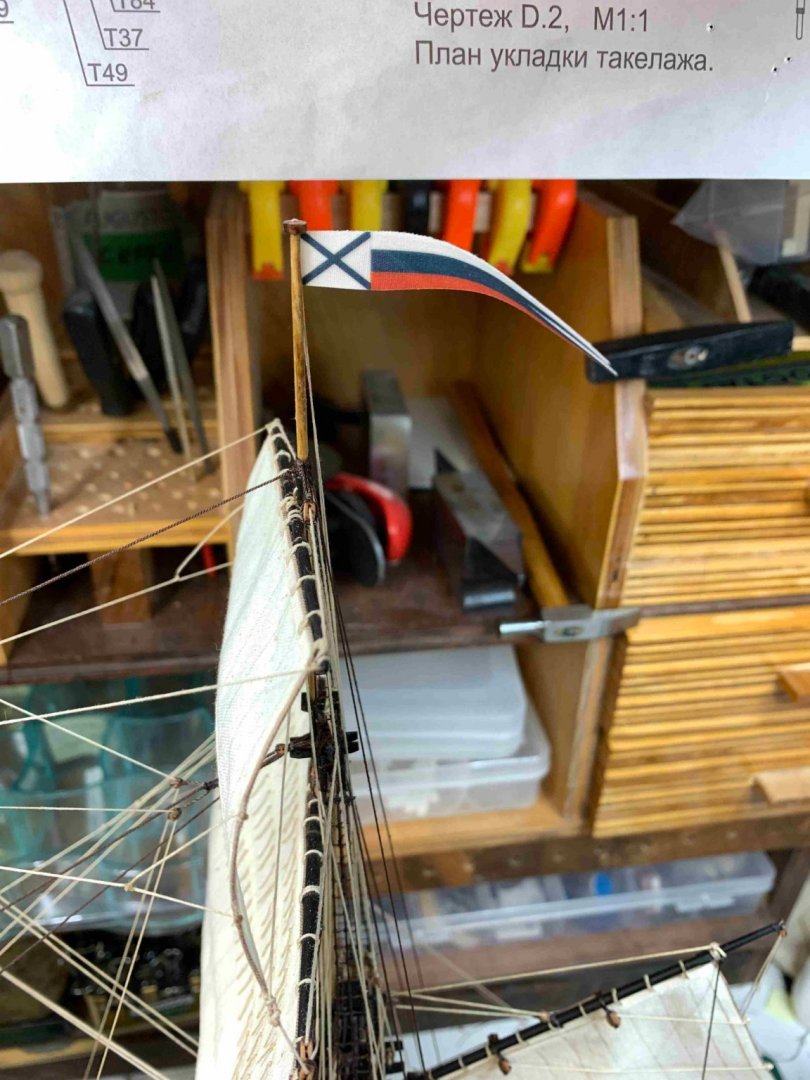

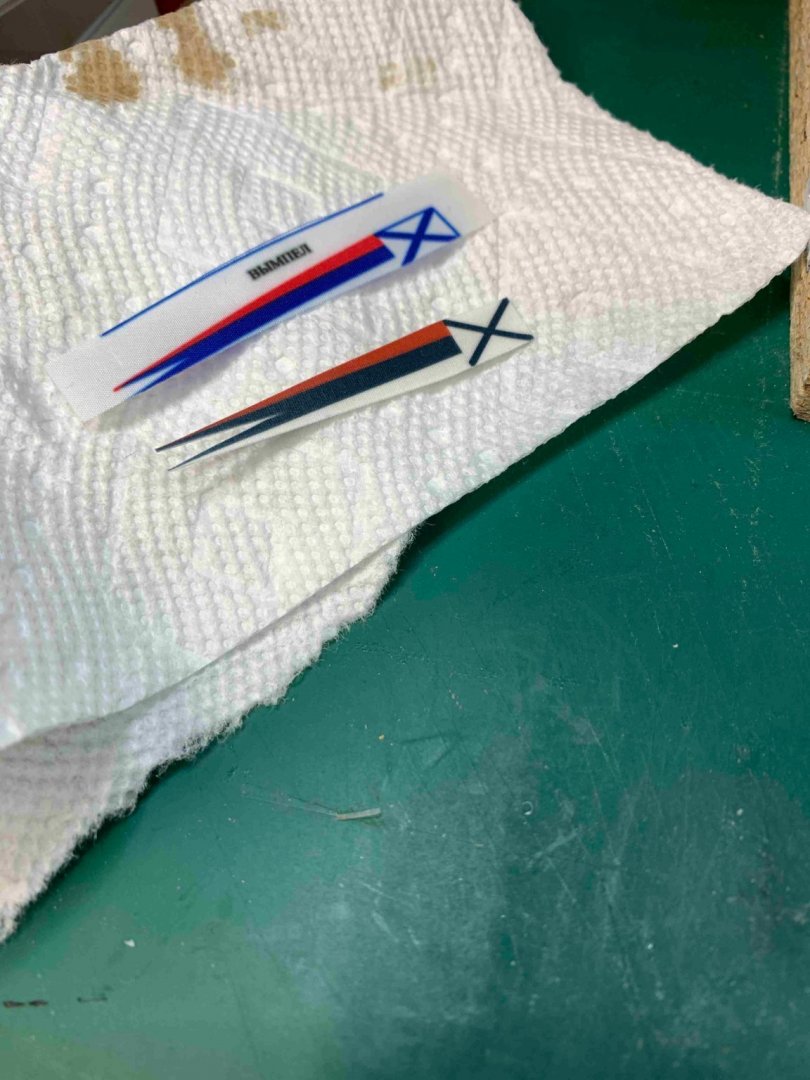

Ship flags are next. I decided to make my own flags even dough kit provided flags are good. This was just a test for making technology... I used software to make the flag, printed on the transfer paper and used iron to transfer picture to the material. It took me few attempts to find out correct material, correct layout and temperature as well as the way to line up both ends of the flag. For this task, i actually sandwich the material between two printouts, and with just one iron pass the pictures will transfer on both sides of the material. I have tried several different material thickness as well as a paper and ended up with white shirt cotton. After all flags are made, i started mounting them.. The flag is glued to the line... The line is positioned on flag poll... And the rope was tighten to the poll as well... The whole assembly was glued to the ship.. Second flag is proudly up... This one was slightly twisted around small brush... Here is comparison between kit provided and home-made... The flag was also glued to the line and mounted on the ship...On the way up.. And the last one, same process, this time without the line.. As always, the mighty greek warrior arrived to check the progress. He usually comes at the end of the work, waiting to take control of the ship, suggesting that THAT IT IS... I can call it a finished project. The next i will work on pedestal, acrylic cover and some final pictures... Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

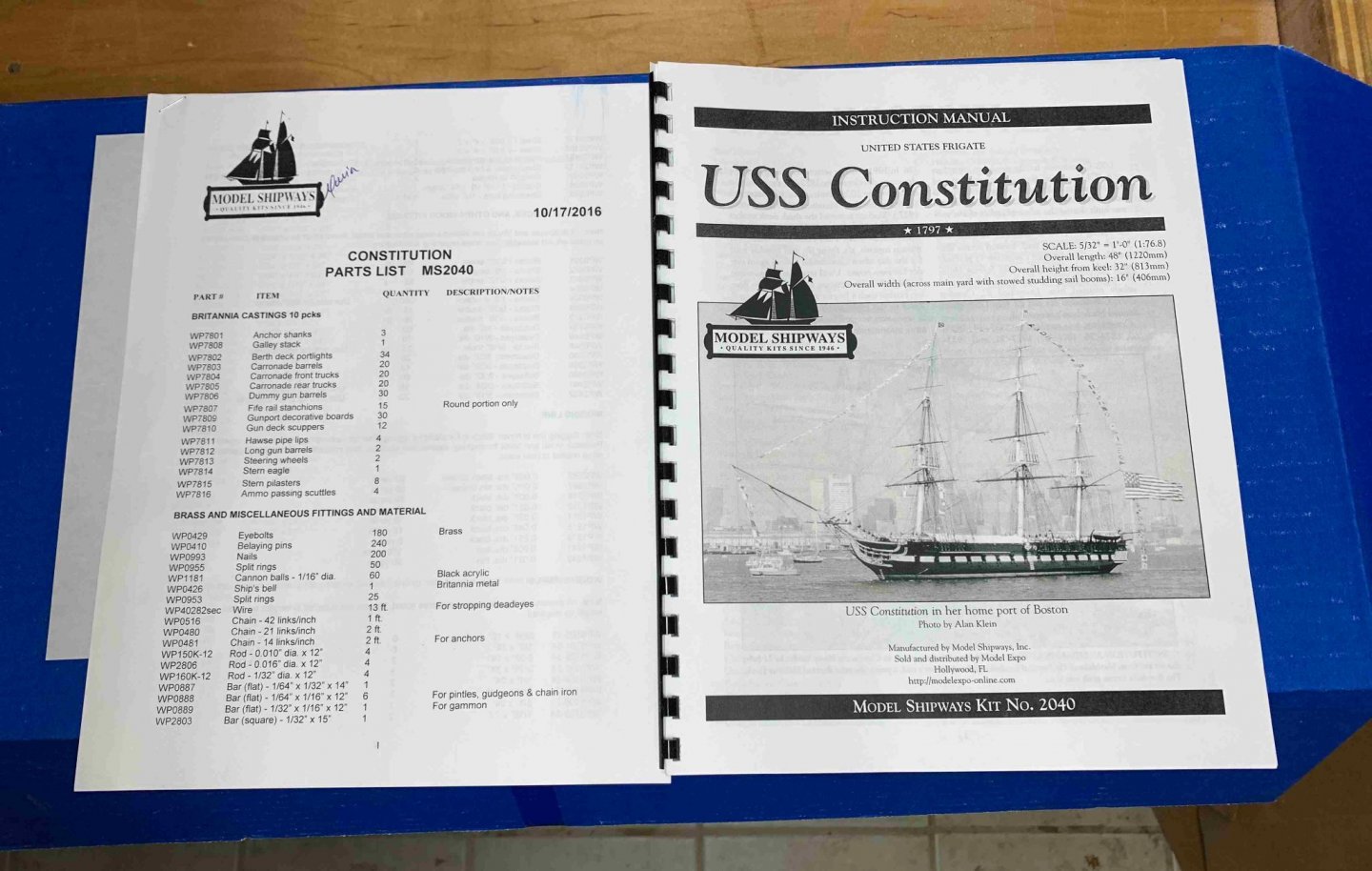

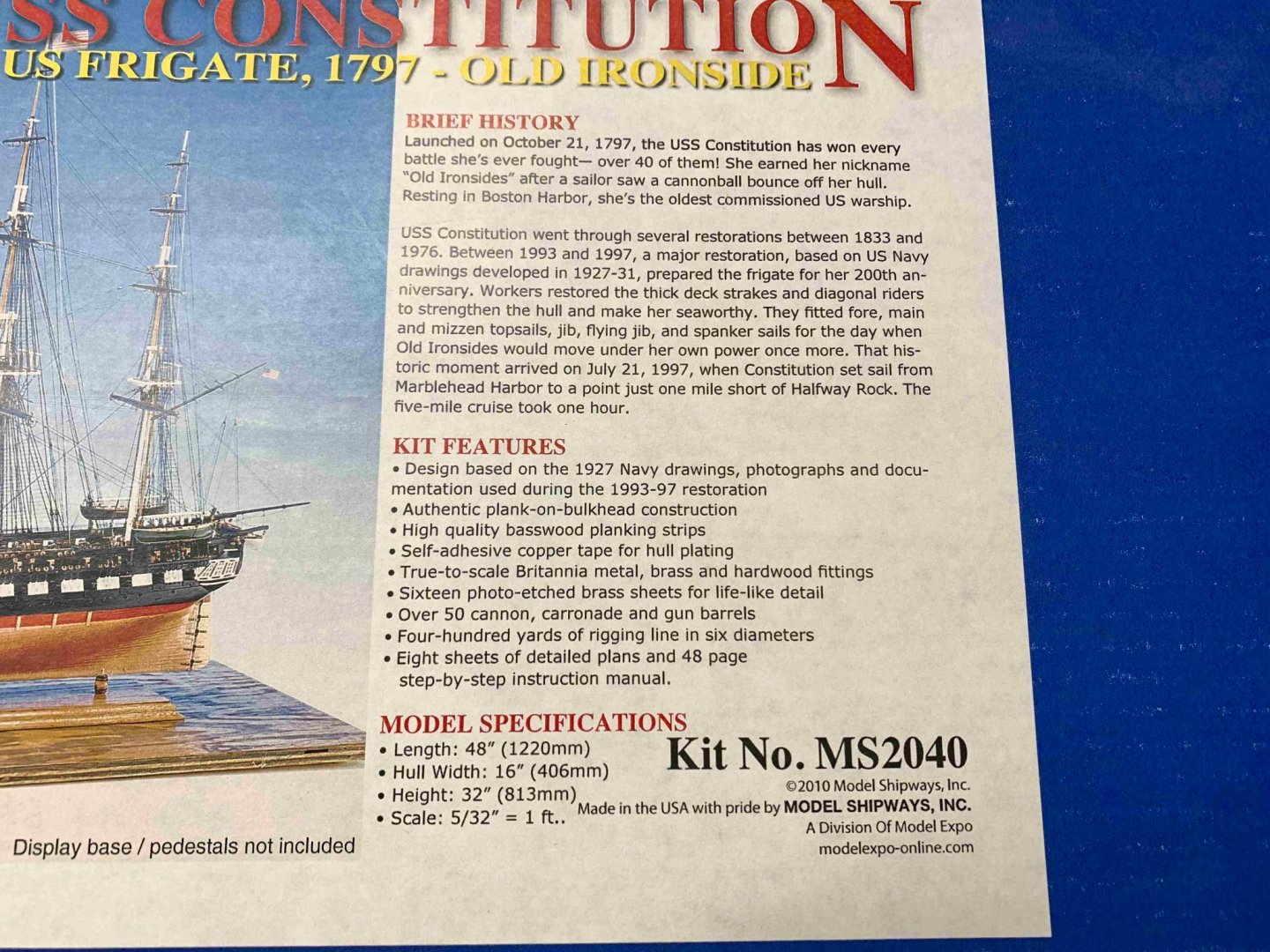

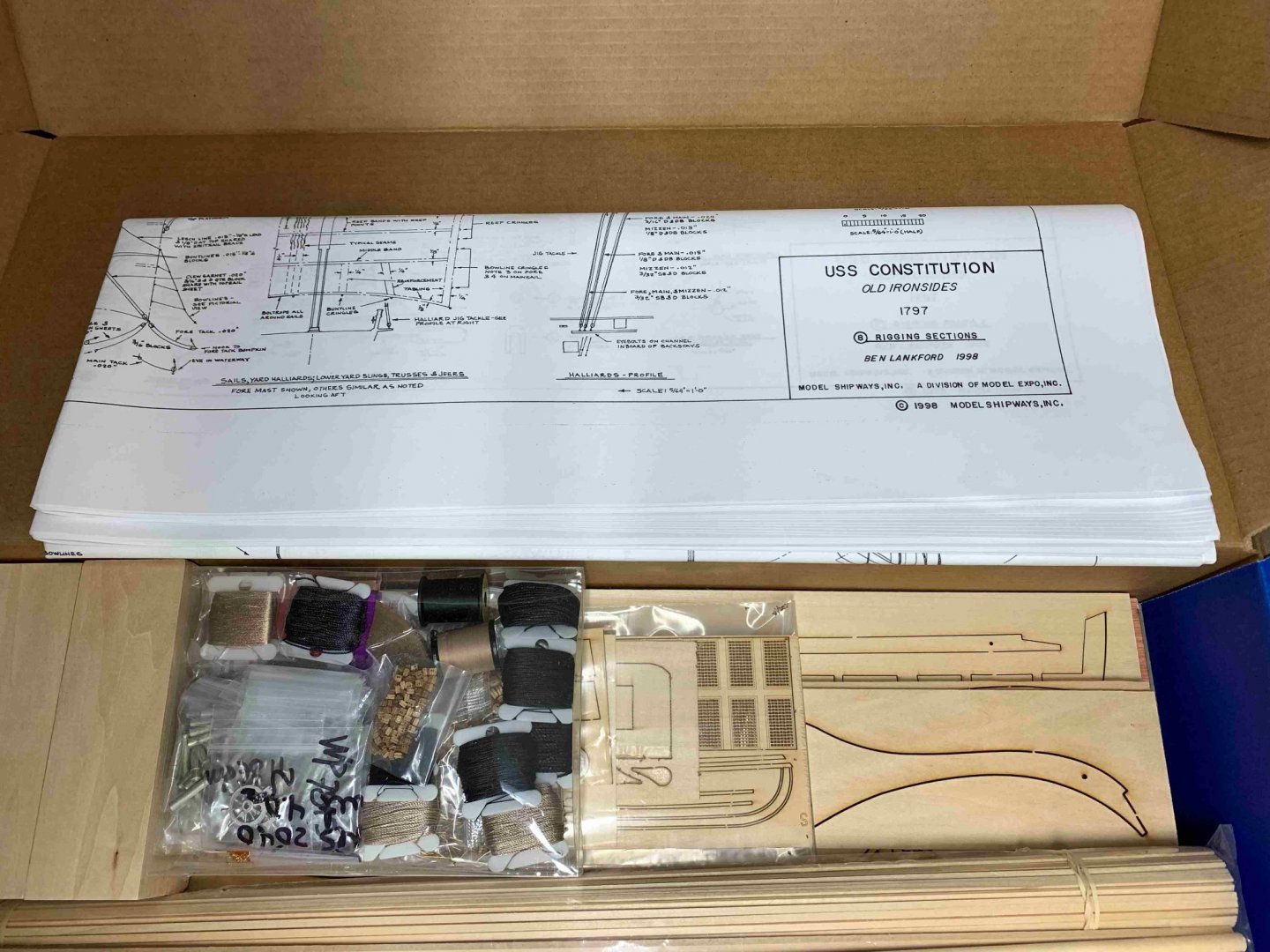

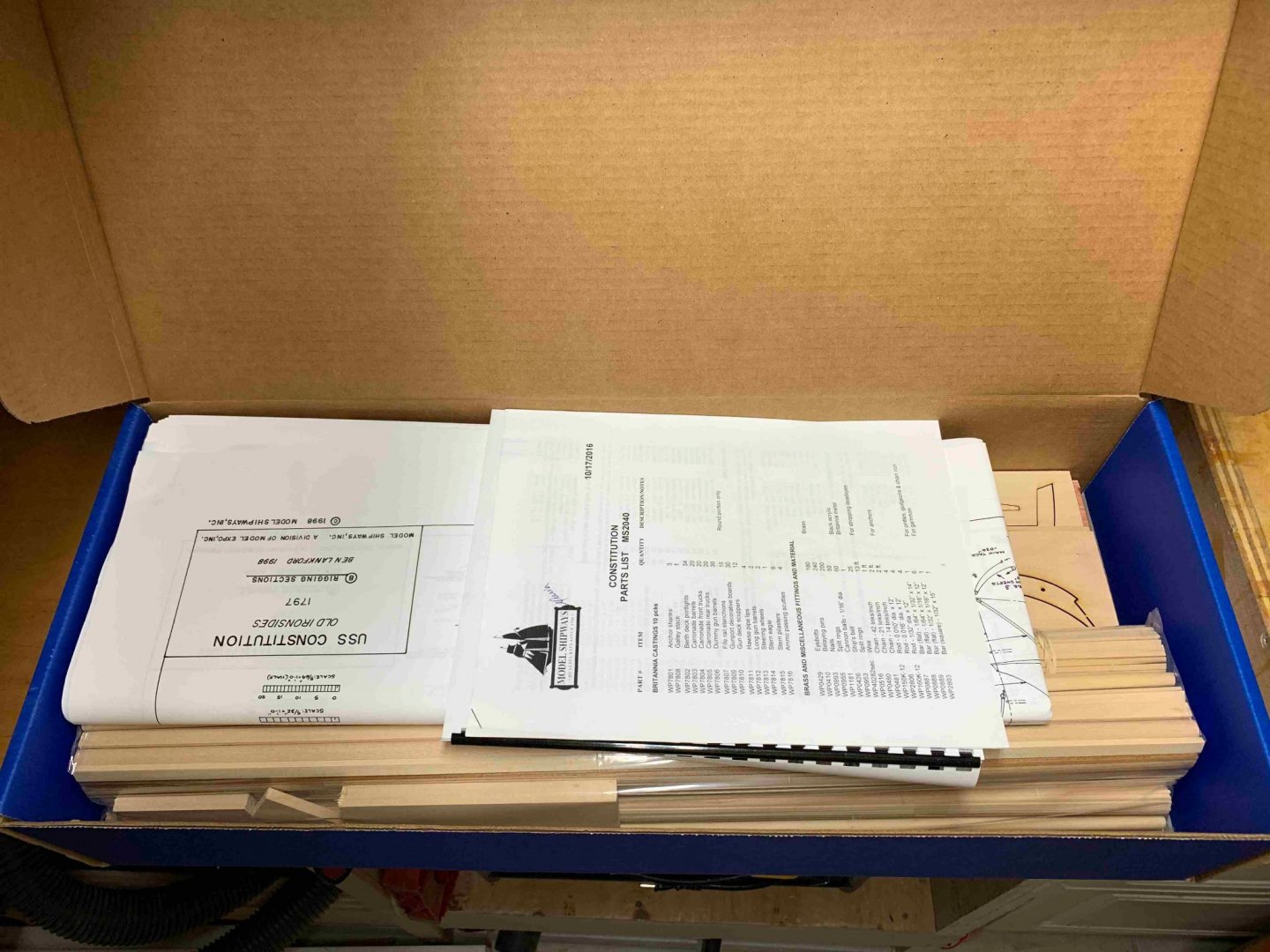

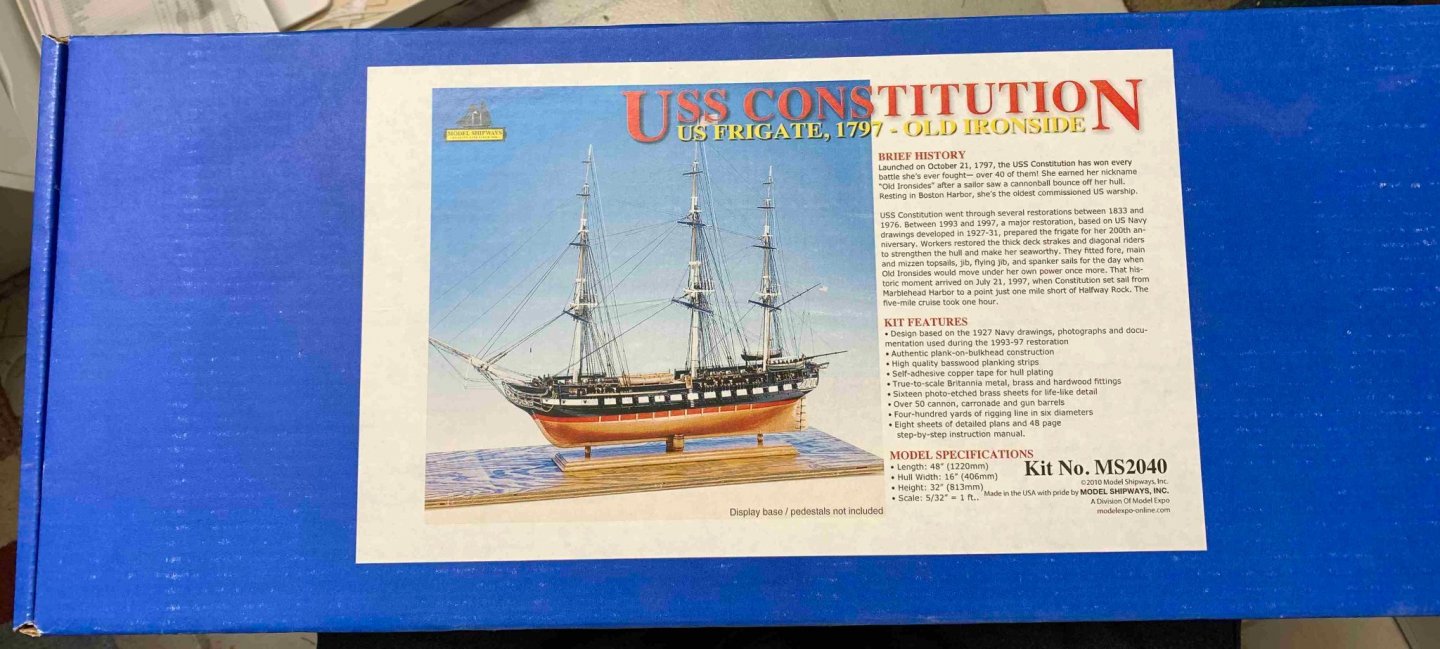

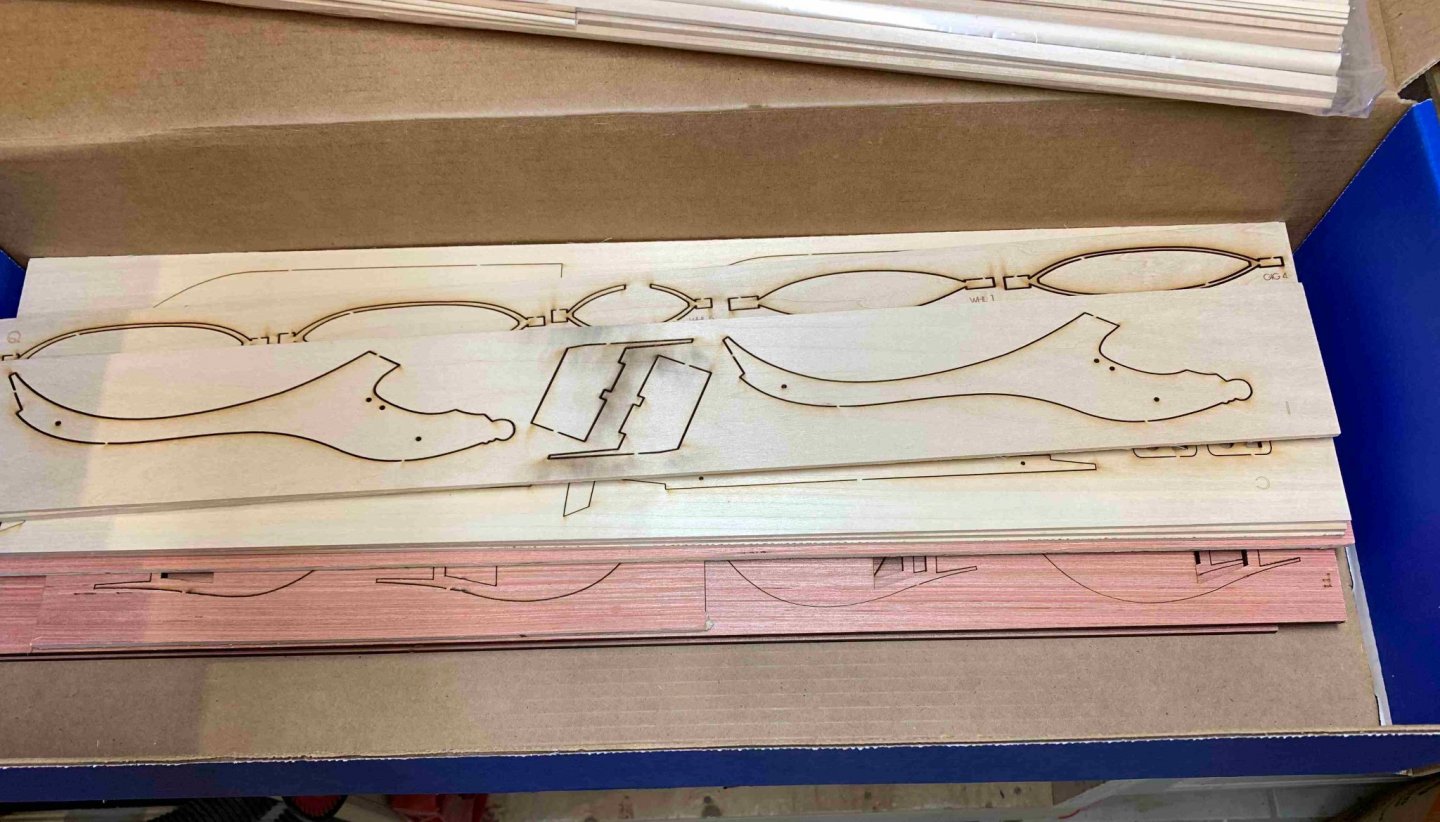

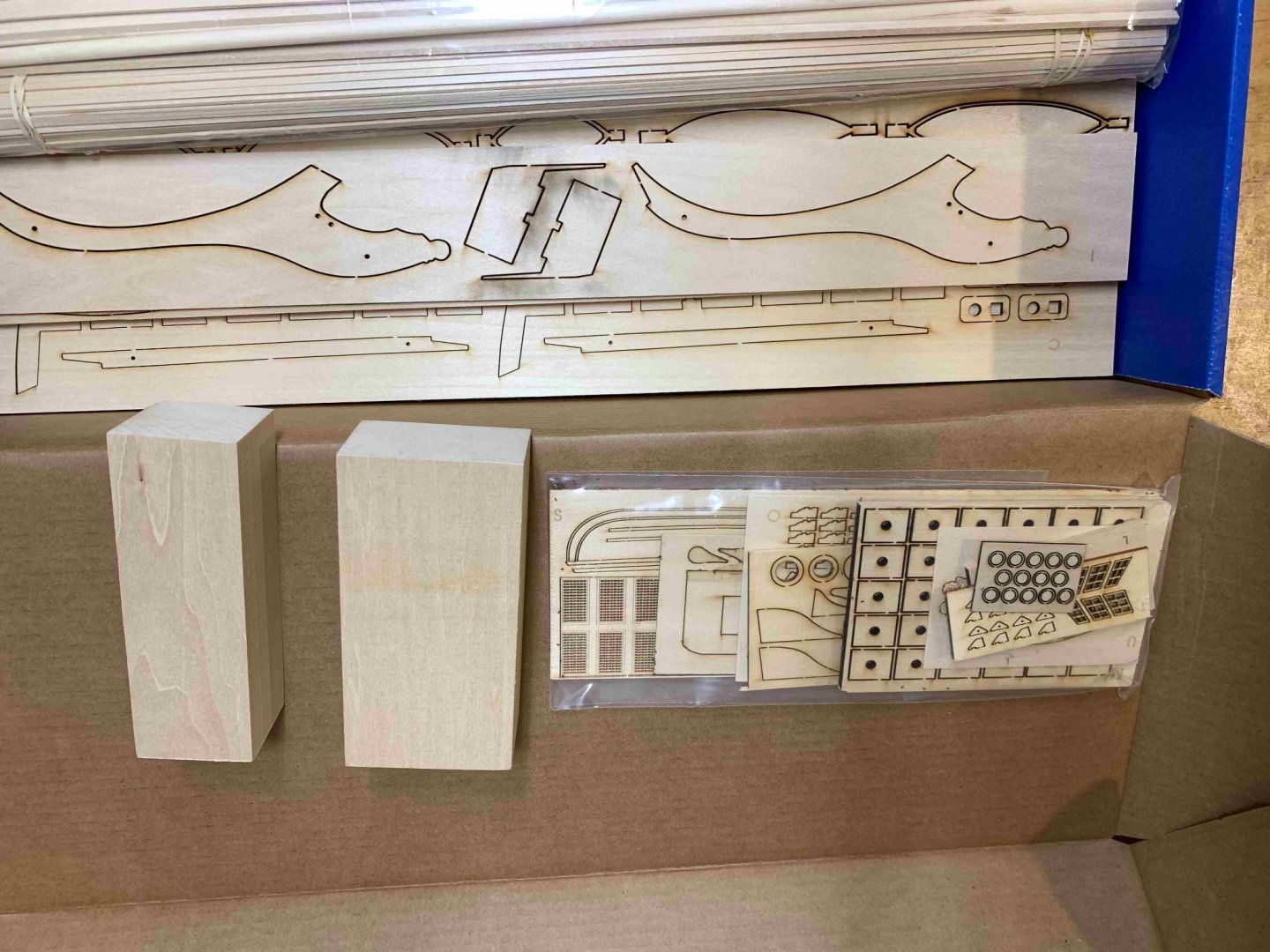

Right on time for a holiday season, i am selling M2040, USS Constitution model kit, a real treat for any ship model enthusiast.. The kit is brand new, purchased three years ago, opened only to take pictures. For last year holidays, i got the same kit from my family so ended up with two kits. One is for sale now, priced very good for a modeller to enjoy package opening on the Christmas day or New Year's day.. Kit description from the manufacturer's web site.. https://modelexpo-online.com/Model-Shipways-USS-CONSTITUTION-48-LONG-176-SCALE_p_1013.html ================================================== Model Shipways is proud to produce the best and most accurate USS Constitution available. Our kit is based on the 1927 Navy drawings, photographs and documentation used during the 1993-97 restoration. It is so complete and highly detailed that shipping weight is an incredible 12 pounds! Plank-on-bulkhead construction features laser cut wooden parts. High quality basswood planking strips cover the hull and we include self-adhesive copper tape for hull plating. True-to-scale Britannia metal, brass and hardwood fittings and 16 photo-etched brass sheets provide life-like detail. Over 50 cannon, carronade and gun Model Shipways Barrels duplicate original armament. Extra touches include laser cut gratings and engraved scrollwork. Four-hundred yards of rigging line in six diameters is also supplied. Model Shipways kit includes eight sheets of detailed plans and 48 page step-by-step instruction manual by Ben Lankford uncover the secrets of building a museum quality replica. (Display base and pedestals not included.) Launched on October 21, 1797, the USS Constitution has won every battle she's ever fought - over 40 of them! She earned her nickname Old Ironsides after a sailor saw a cannonball bounce off her hull. Resting in Boston Harbor, she's the oldest commissioned US warship. USS Constitution went through several restorations during her career. A major restoration between 1993 and 1997 prepared the frigate for her 200th anniversary. Workers restored the thick deck strakes and diagonal riders to strengthen the hull and make her seaworthy. They fitted fore, main and mizzen topsails, jib, flying jib, and spanker sails for the day when "Old Ironsides" would move under her own power once more. That historic moment arrived on July 21, 1997, when Constitution set sail from Marblehead Harbor to a point just one mile short of Halfway Rock. The five-mile cruise took one hour. Model Expo No. MS2040 Length 48" / Height 32" / Width 16" / Scale 5/32" = 1 ft. (1:76 Scale) Previous modelling experience helpful. ====================================================== The price for this kit is 580.00 Canadian dollars plus shipping and if you are close to Vancouver, British Columbia, we can arrange deliver as well. I am accepting PayPal payments. If you are interested, pls PM me and we can discuss it further. Happy modelling.

-

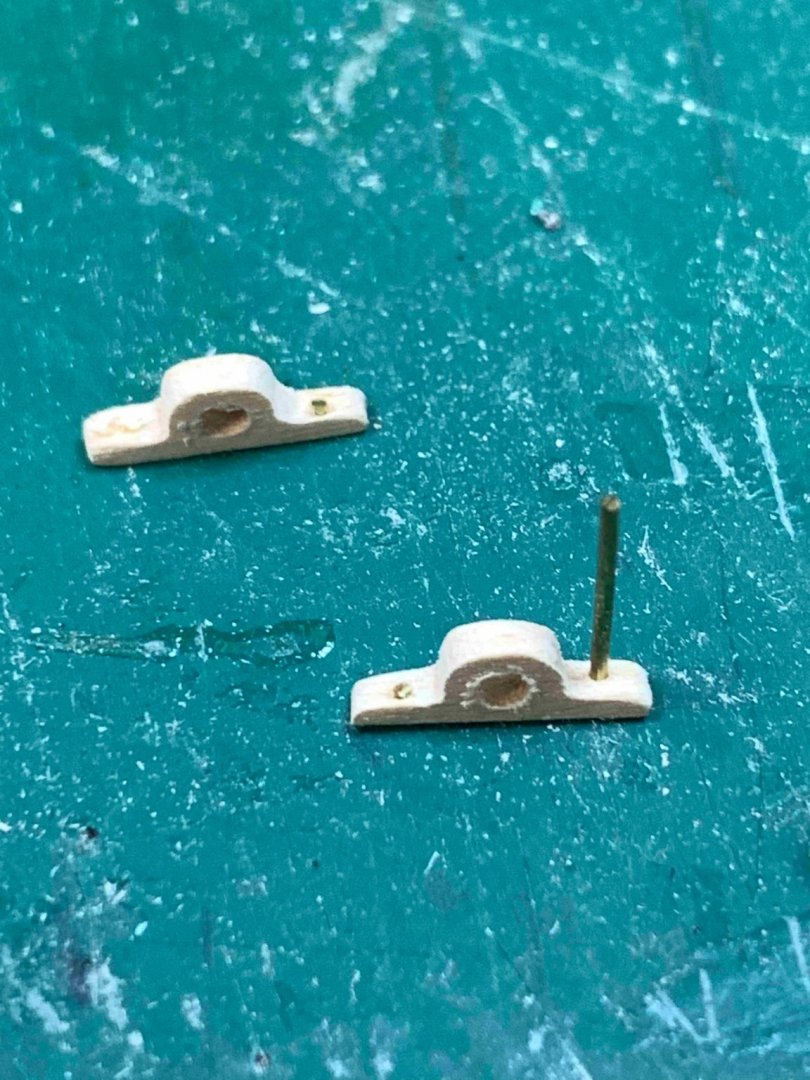

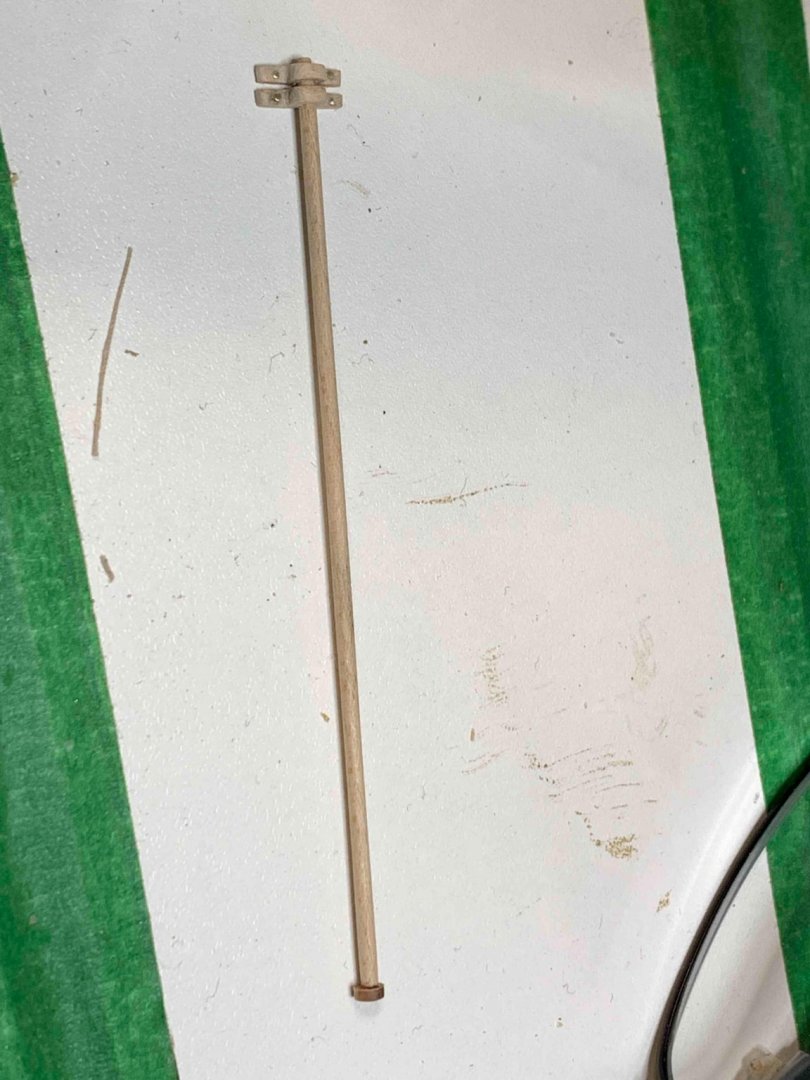

Worked on a stern flagpole; here is completed pole: And the process of sanding and shaping... Cut in half... Adding pins for details.. Now i am working on flags; even dough the kit provided flags are decent, i will try to make my own, just to test the process and will decide which set to use. Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

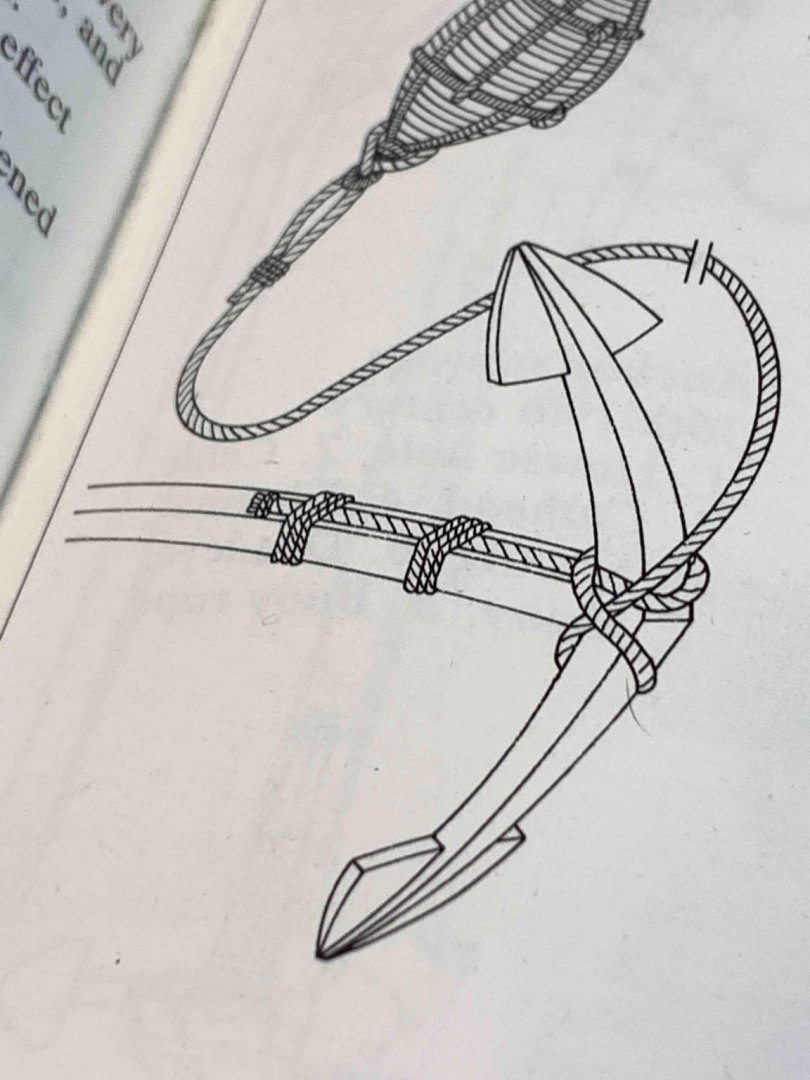

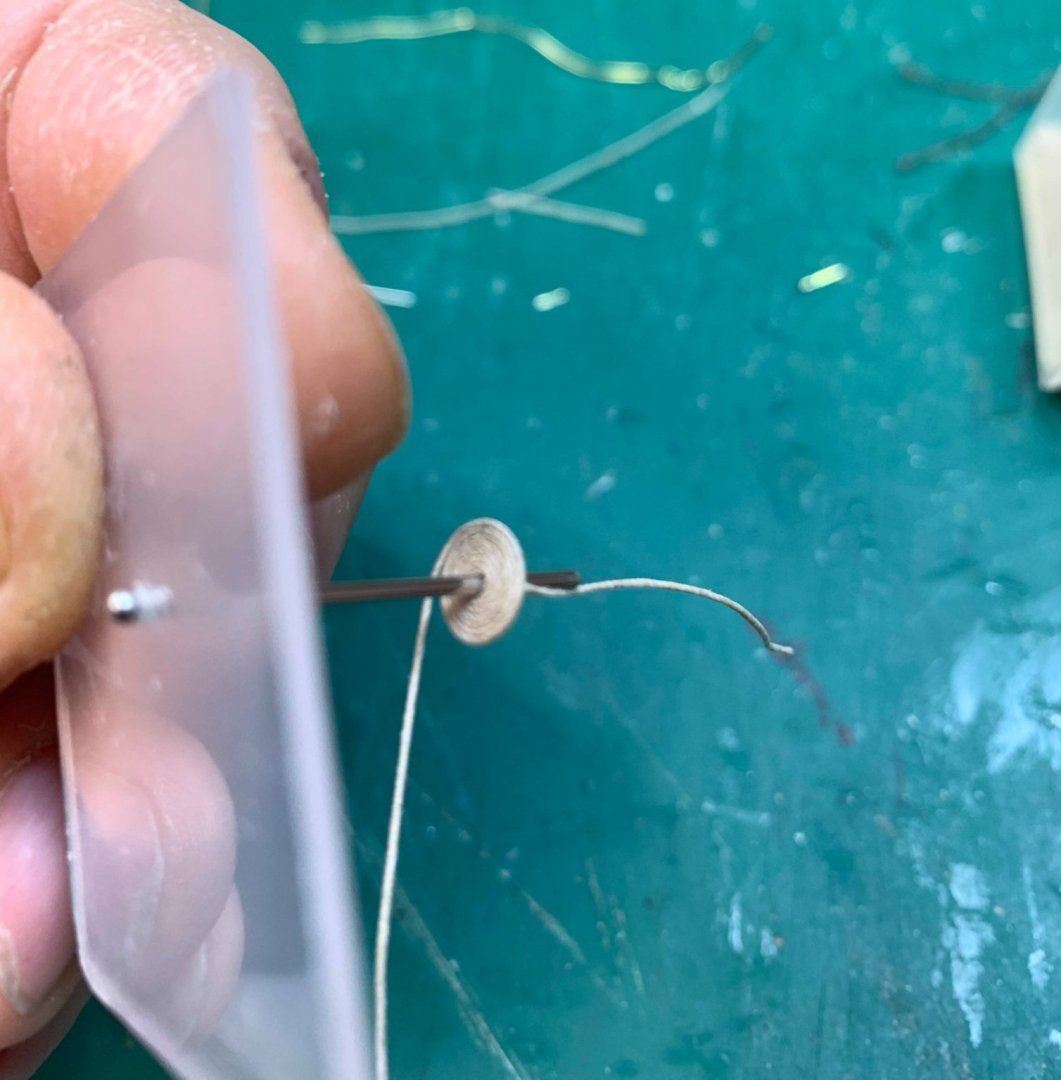

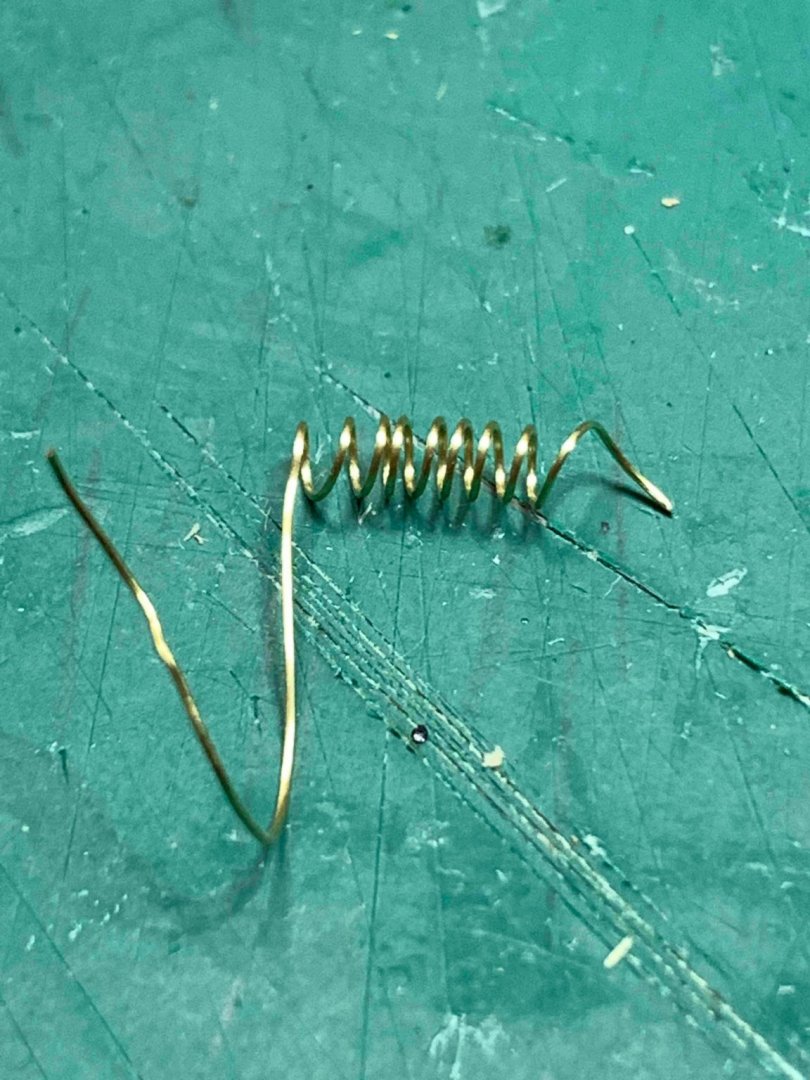

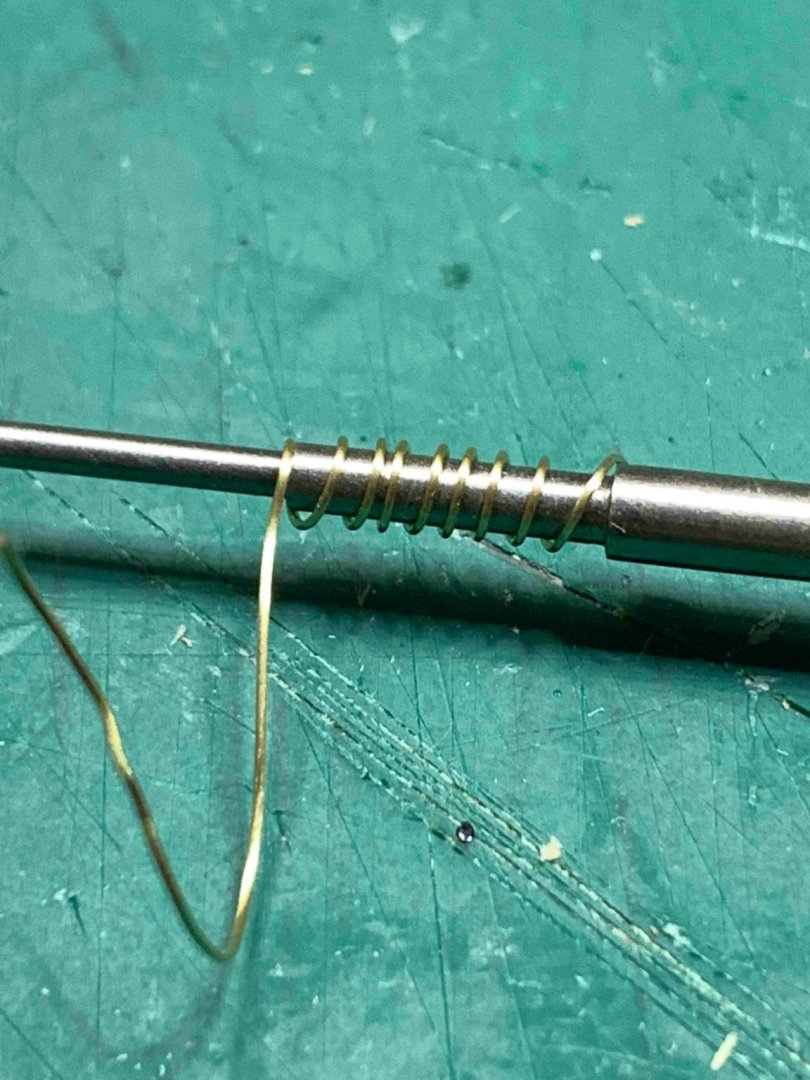

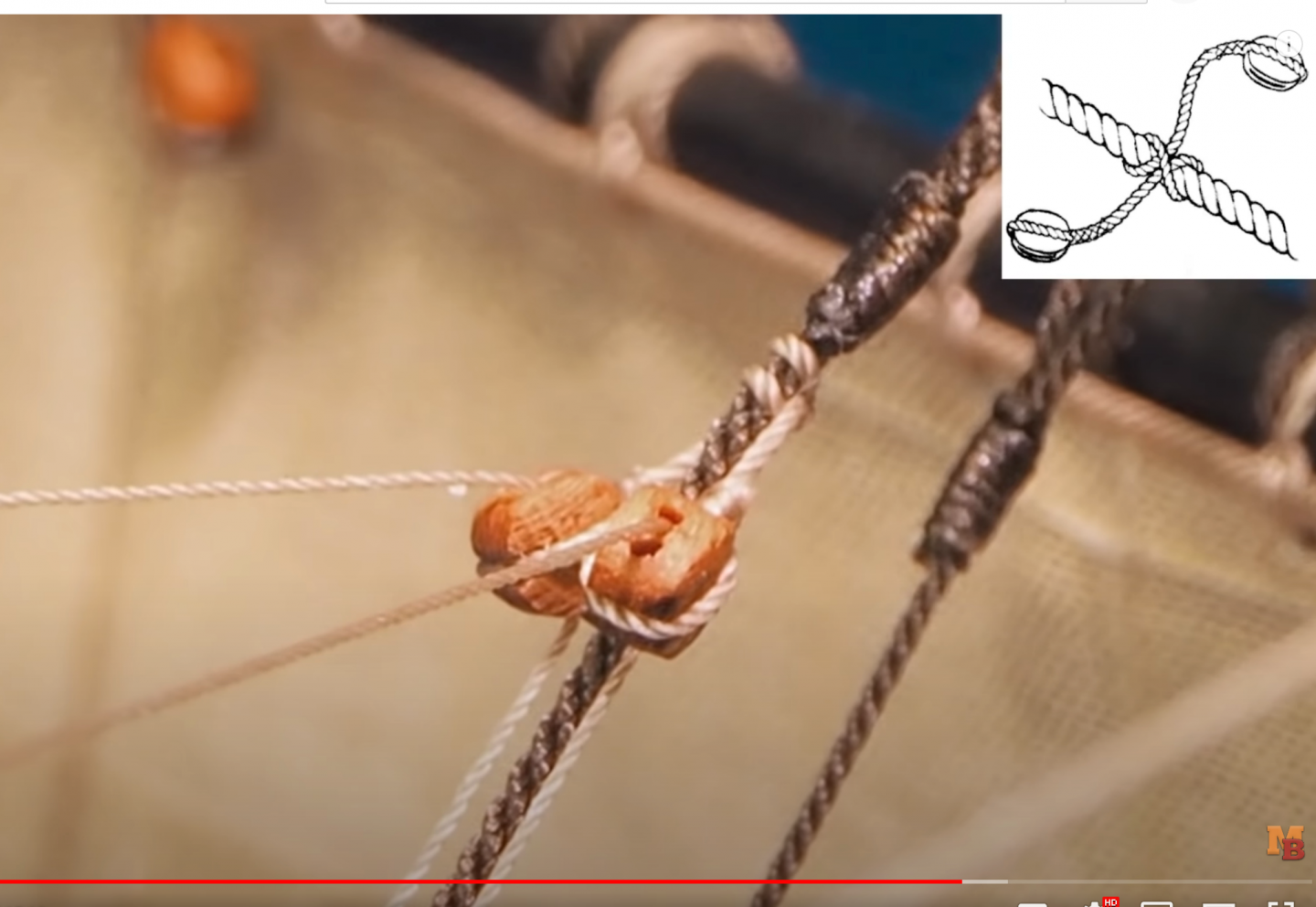

On anchors i will try to simulate this: Let start... the rope was fixed on the anchors with a glue that will be covered with seizing.. My way of making a coil rope on the spot... Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

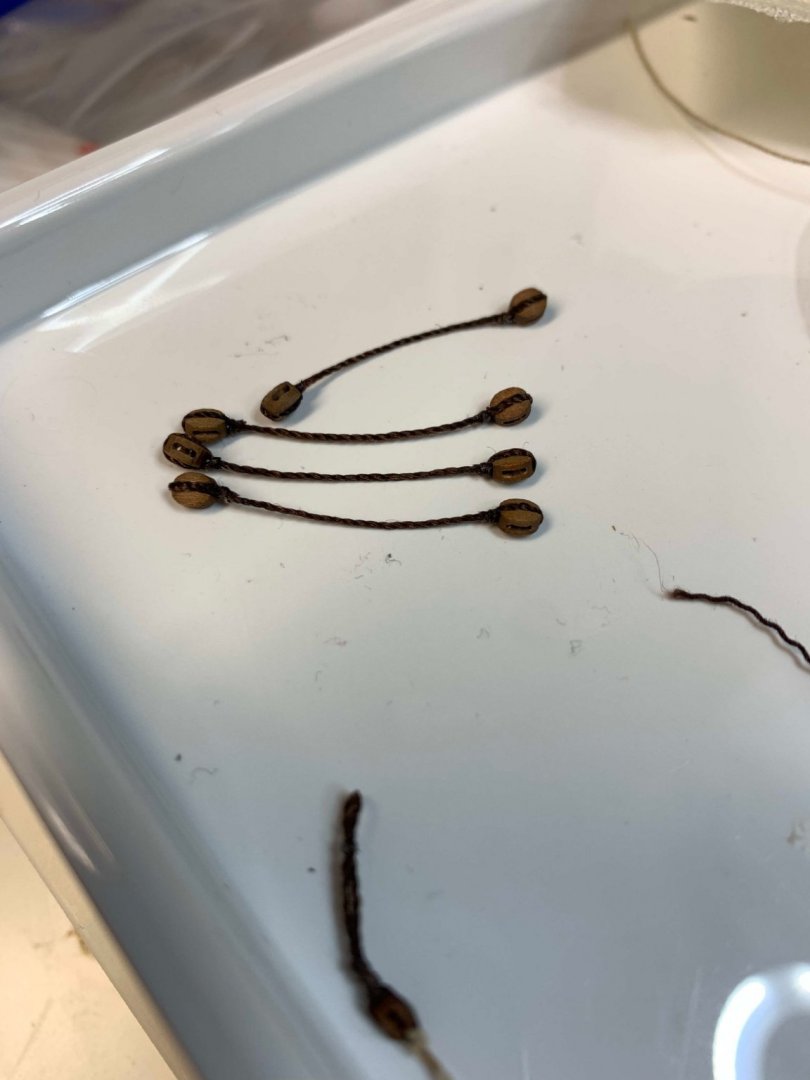

The anchors' buoys are next. First started with carving them... Last time in my Sultana build, i used sculpey to make buoys, this time tried a different approach. In below picture are two buoy prototypes, i carved without a lathe.. Then pilot holes are drilled and two hooks per buoy are made and inserted, not all the way thru to leave a bit room for seizing.. The buoys were painted in white. Then harness for each buoy are made, two per buoy. Three lines were knotted along another rigging line. Spacing between the lines was appr 6mm. Then the harness were wrapped around the rod, knotted and glued. The harness was wrapped around the buoy and glued with super glue. The second harness was attached as well. This part was a a bit tricky, since three lines of the second harness have to be run under the existing harness before being seized but with little help this was done OK. The seizing was done around the hook, on both ends of buoy. And completed. With this all work, the buoys were weathered a bit which ended up to be a nice detail.. Ready for anchors.. Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

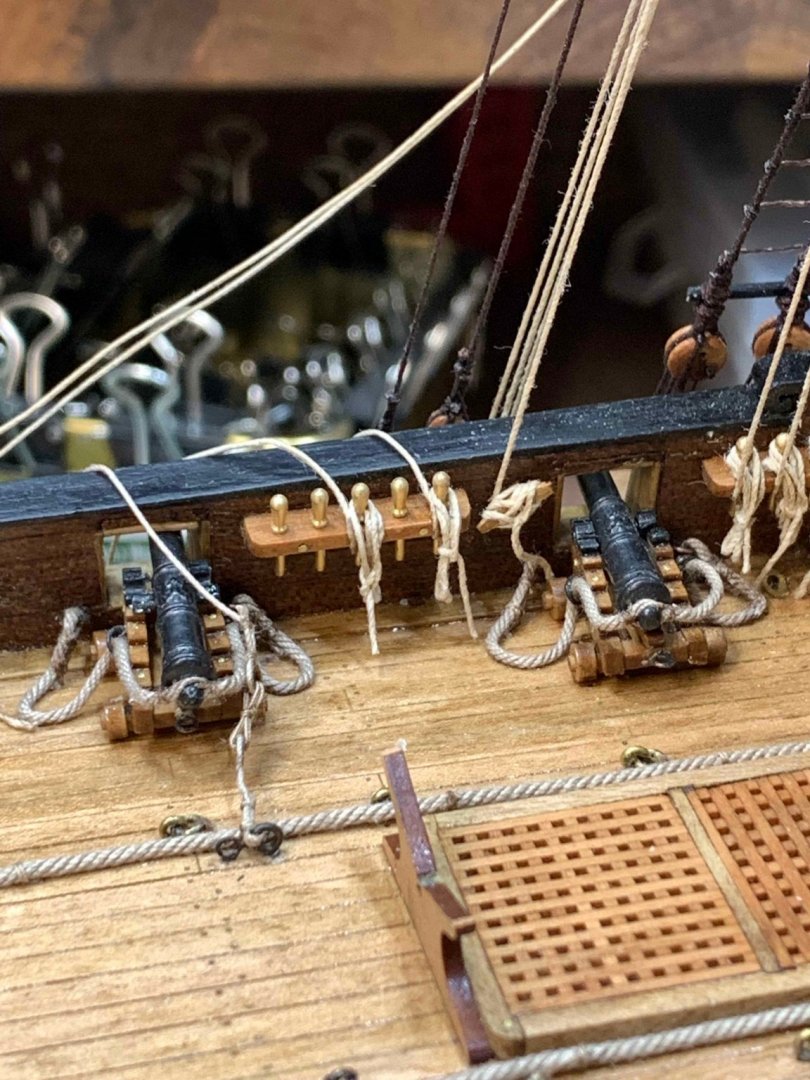

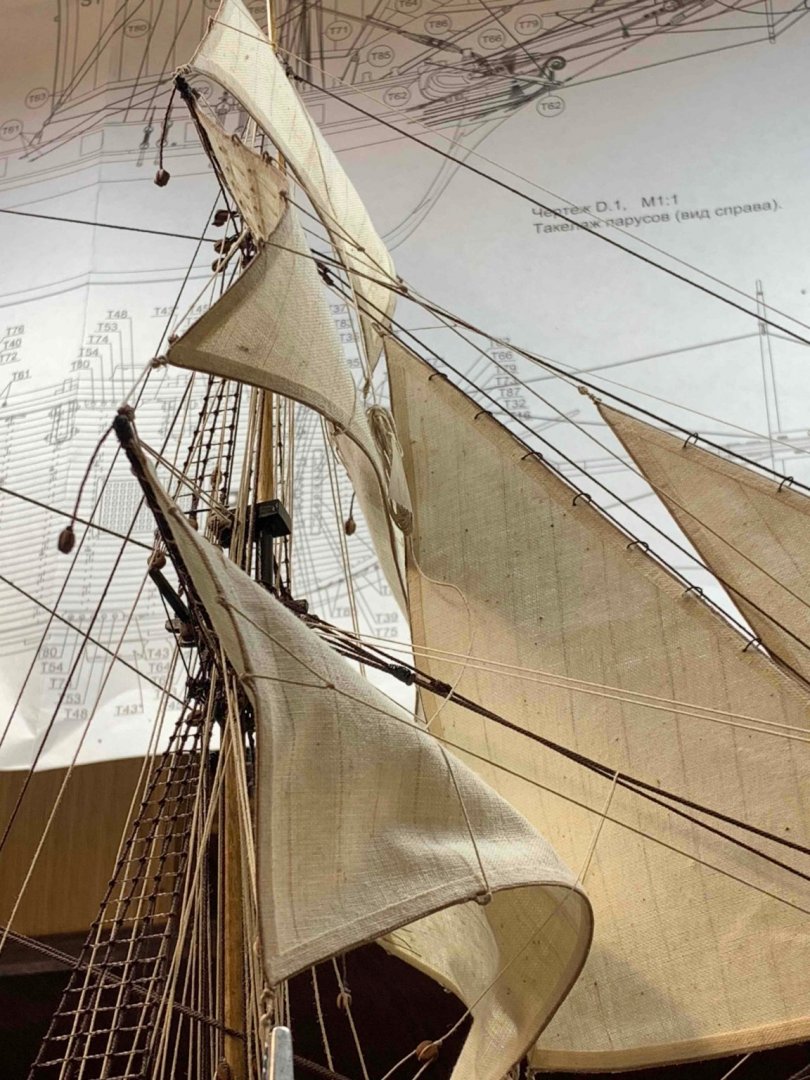

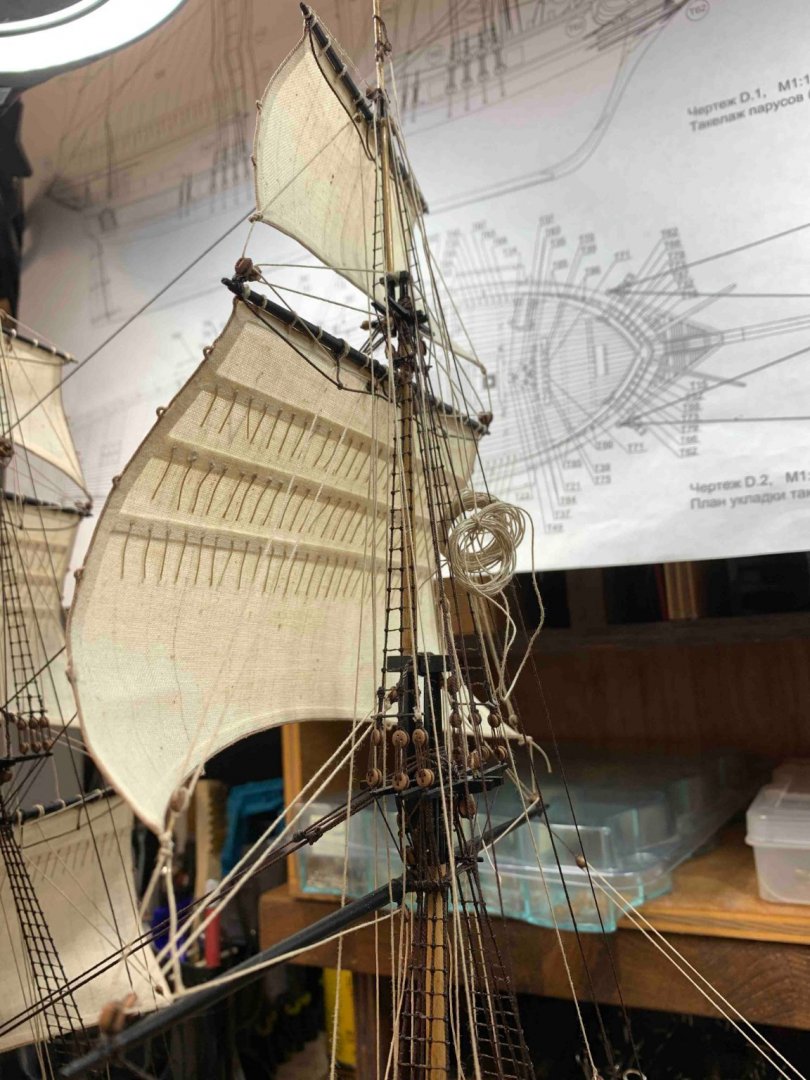

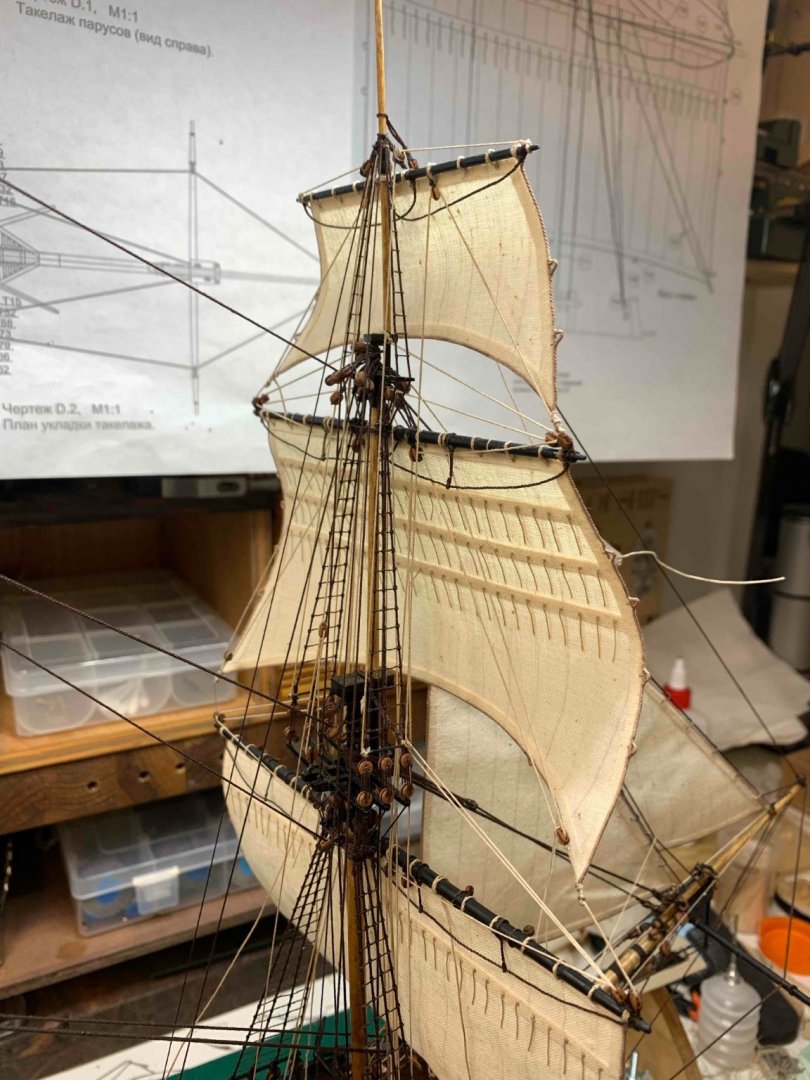

Wrapping it up slowly... Forgot to put blocks on both side of the yard and now it is time for a re-do... Continue with rigging... Getting busy... Happy modelling...

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

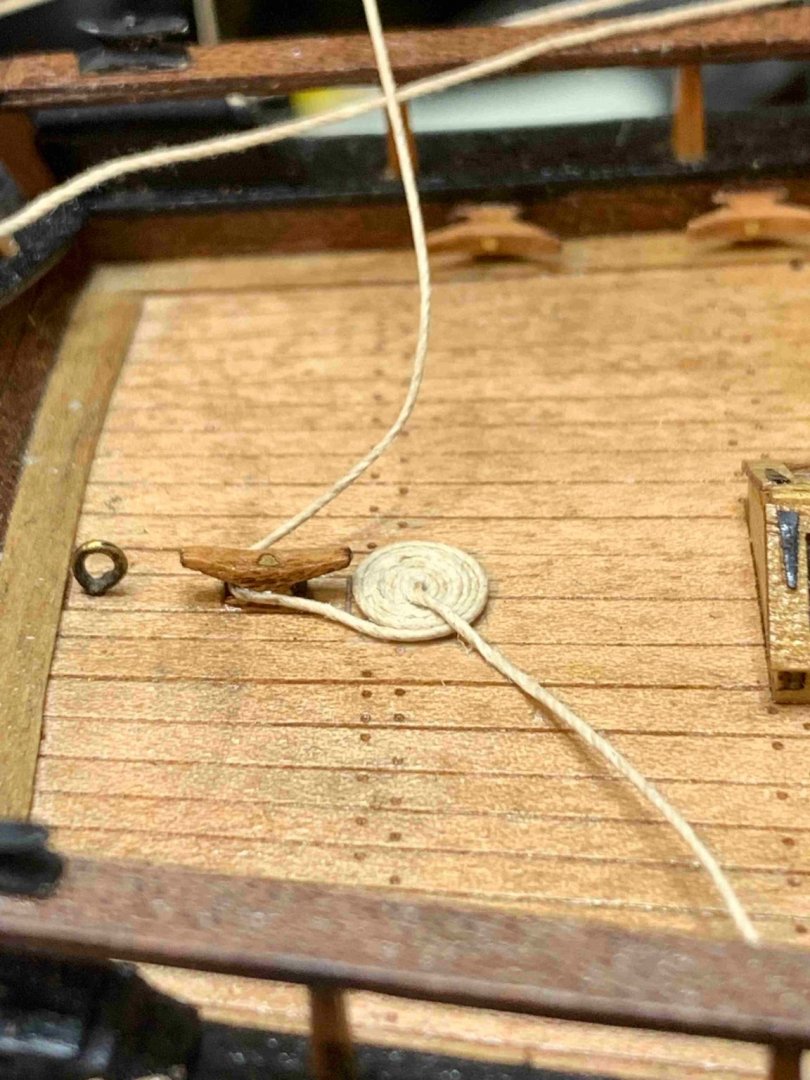

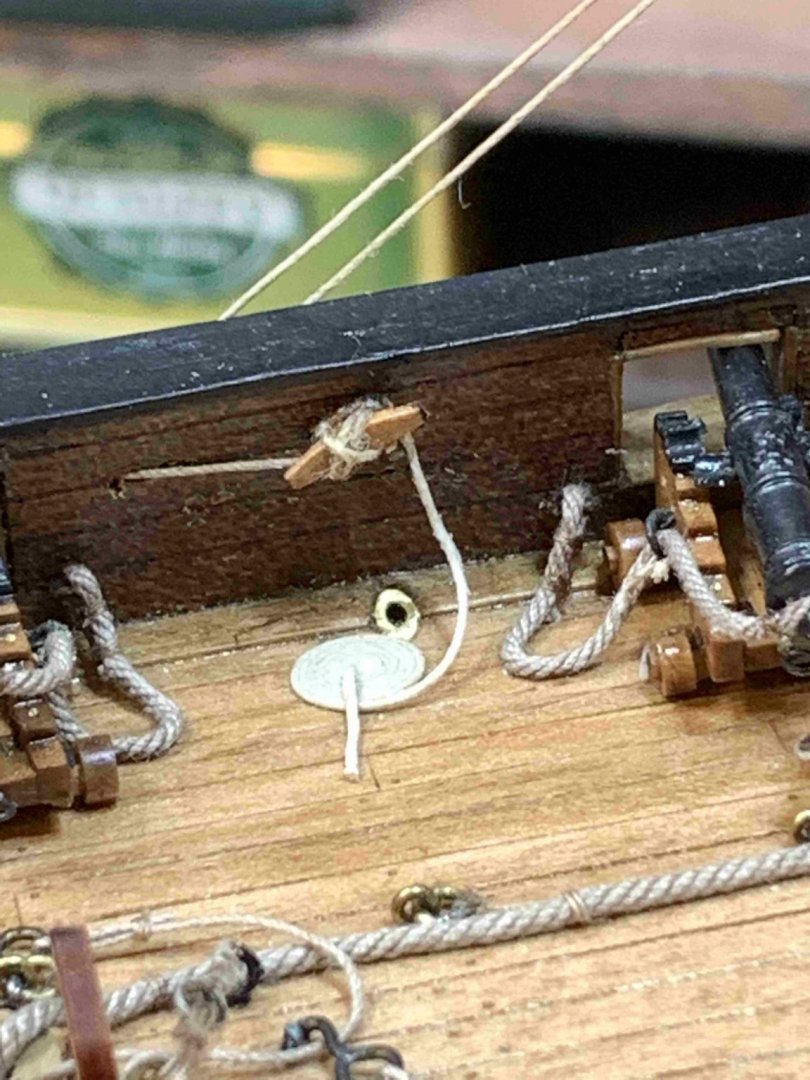

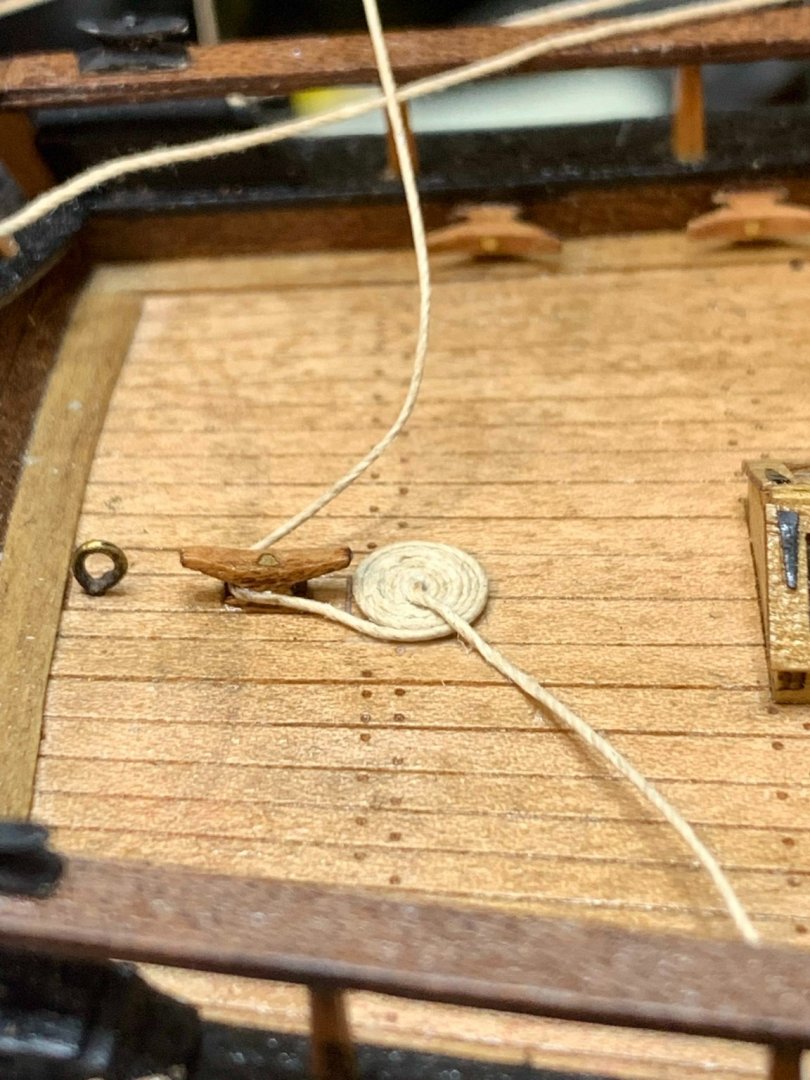

Continue with rope coils installation; mental note for a future builds: do this task when deck is free of other items.... The coil is fixed on the deck with a touch of white glue, non diluted. After drying, the excess rope is cut... Few more installed... Next one was particularly challenging because of its location... The reason more to do these ahead of time is no need to use CA glue which is discolouring the rope. Tried with PVA but was just not holding the place.. Then was working on guy rope... During my build process, i lost several blocks. Very likely i will be able to find them walking barefooted but i decided to order few sets online... and here they are, brand new, with attached hooks... And mounted, temporary... Happy modelling...

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

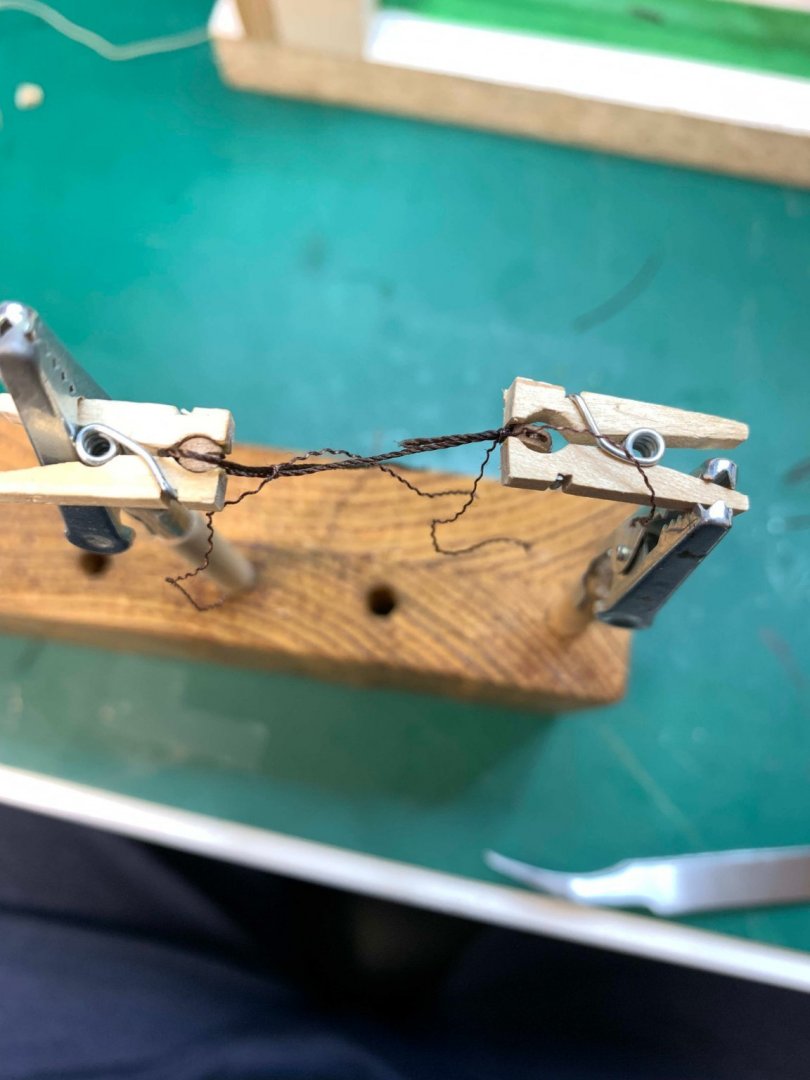

Deck coil time.... With a help of small jig, it is working like a charm... And installed on the ship.. I also added two cleats.... from aluminium, cleaned, drilled a hole for a wire and mounted on the ship... Will finish them later... Continue with blocks and rigging... Happy modelling...

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

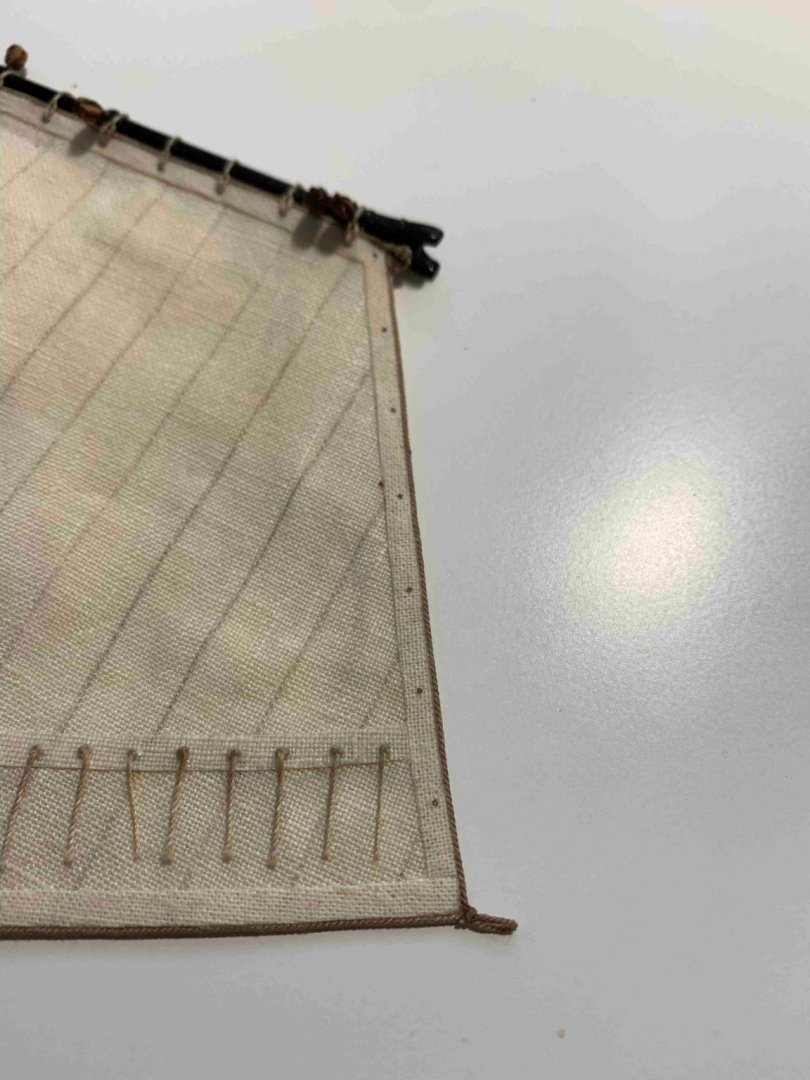

Continue work on parrel trucks for sail boom and gaff. Trucks are shipped coloured in red so i painted them in matt black and attached. I decided to attach spanker with a spiral lacing explained in Lennarth Petersson's "Rigging period ship models". Not quite sure if it is completely historically accurate but it appears to me as very interesting way.. So, it is.. First i made few hoops.. Blackened... Then the hole locations are marked on the spanker.. And hooks inserted.. First, the spanker was mounted.. Few blocks... Then the lacing after spanker is mounted.. And completed... Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

Continue with different bowlines rigging... if there is an interest in how a specific rigging line is running, i can snap more detailed pictures... For rigging line colour and size i was following the kit plan.... all lines are dragged thru a beeswax to lower the fuzziness on them but zoomed pictures are as bad as they are good... From sailor's perspective.. Happy modelling...

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

I have tried a slightly different approach now... wanted to try starting the work from the pin, first tightening the rope around the pin and work towards the yards.. this will give me a bit more workspace and it might ended up better and more realistic.. So lets see... The rope was ran thru... .. the knot was tight around the pin... .. a bit of a CA was dropped to make sure the knot will stay in place.. Then the coil was attached, again with a help of a CA... The rope looks a bit fuzzy on zoomed picture but it was dragged thru a beeswax and from the naked eye it does look OK. So far it does look more realistic this way.. and easier to install... Then, the rope was running thru a block and attached to the sprit-sail yard.. Hmm, it does not look that bad after all... Will try few more times.. Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

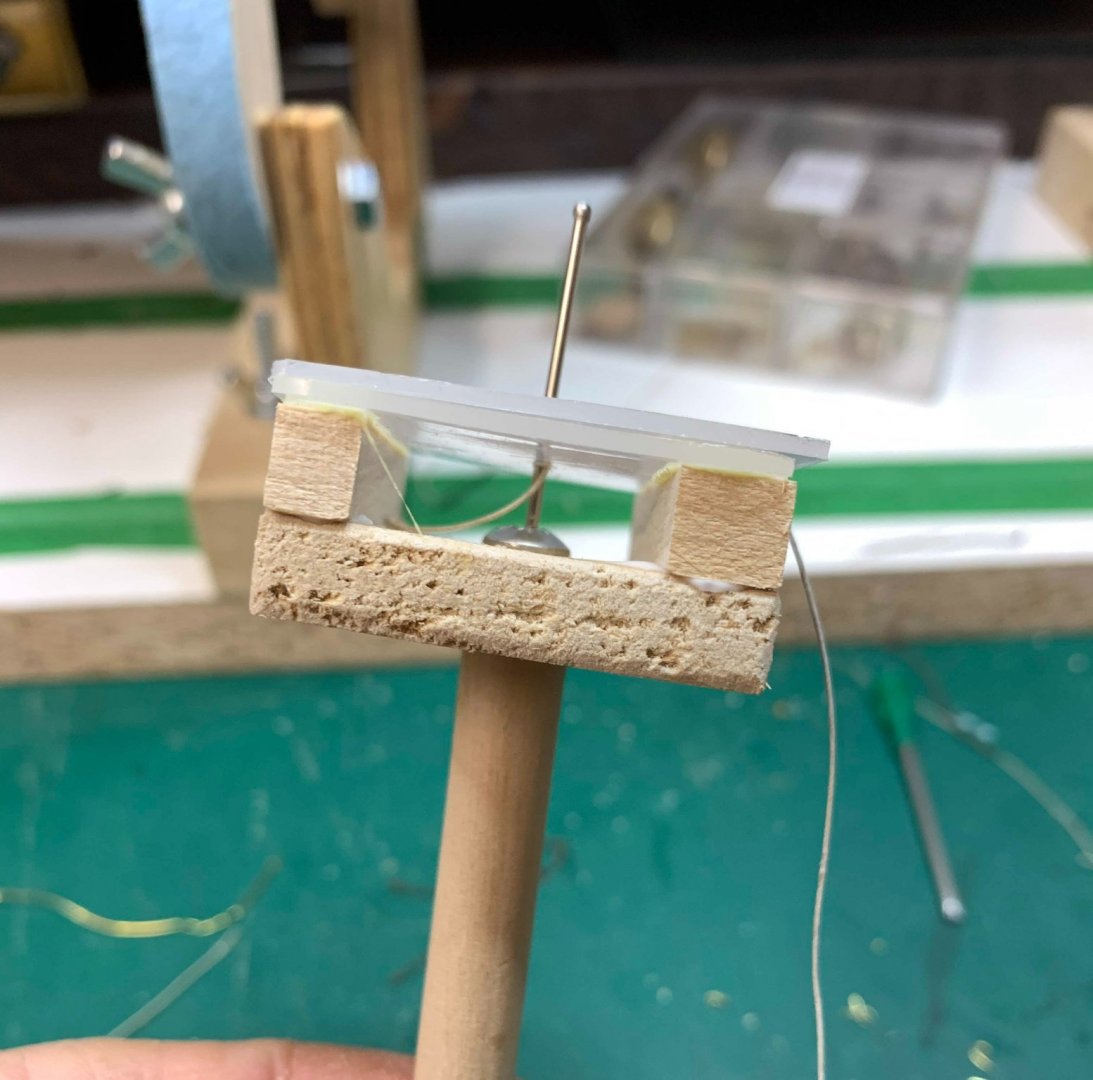

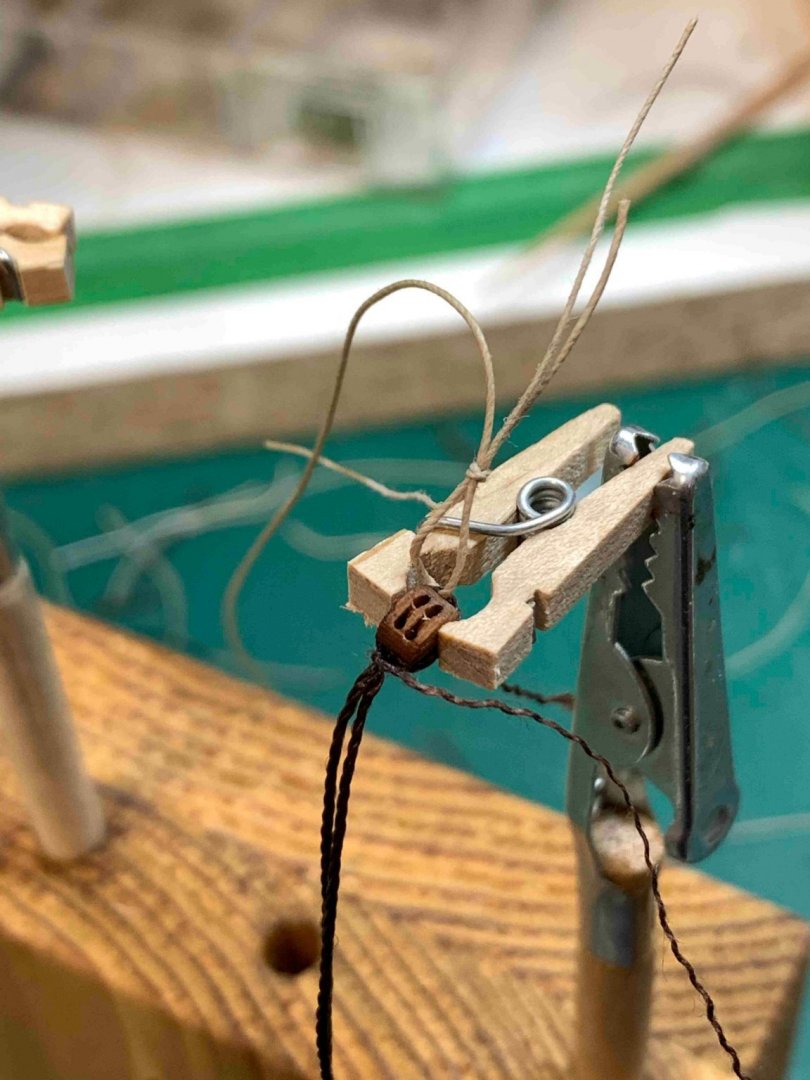

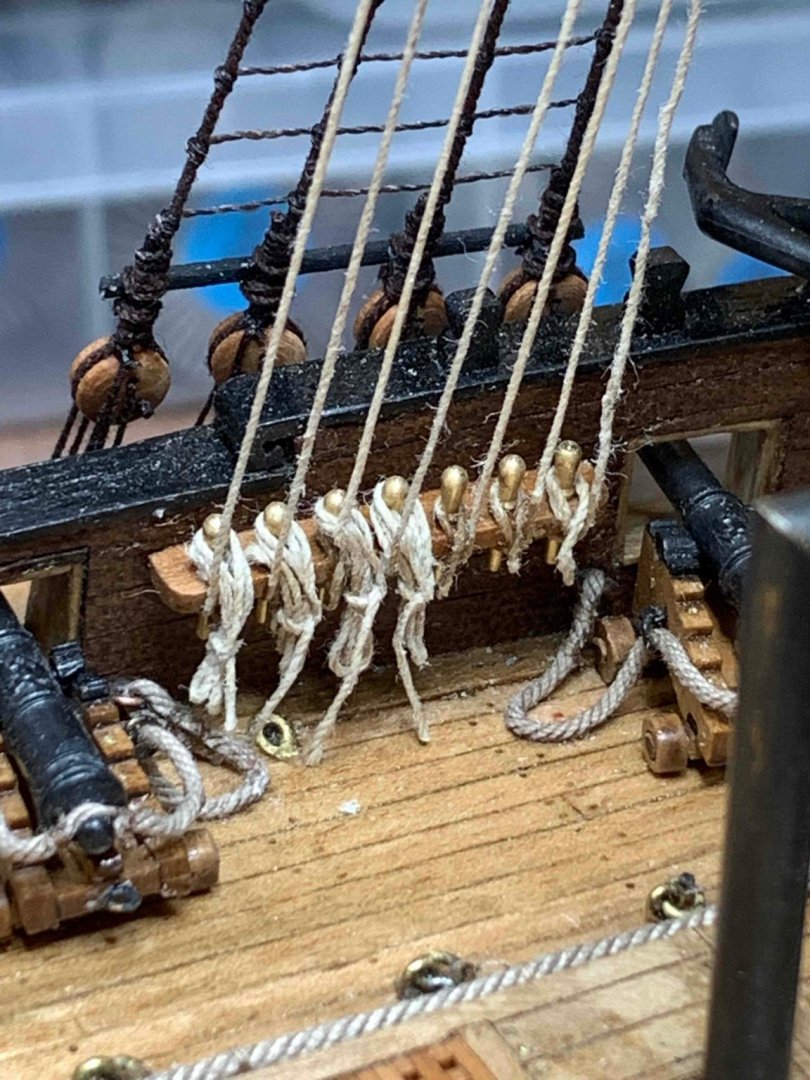

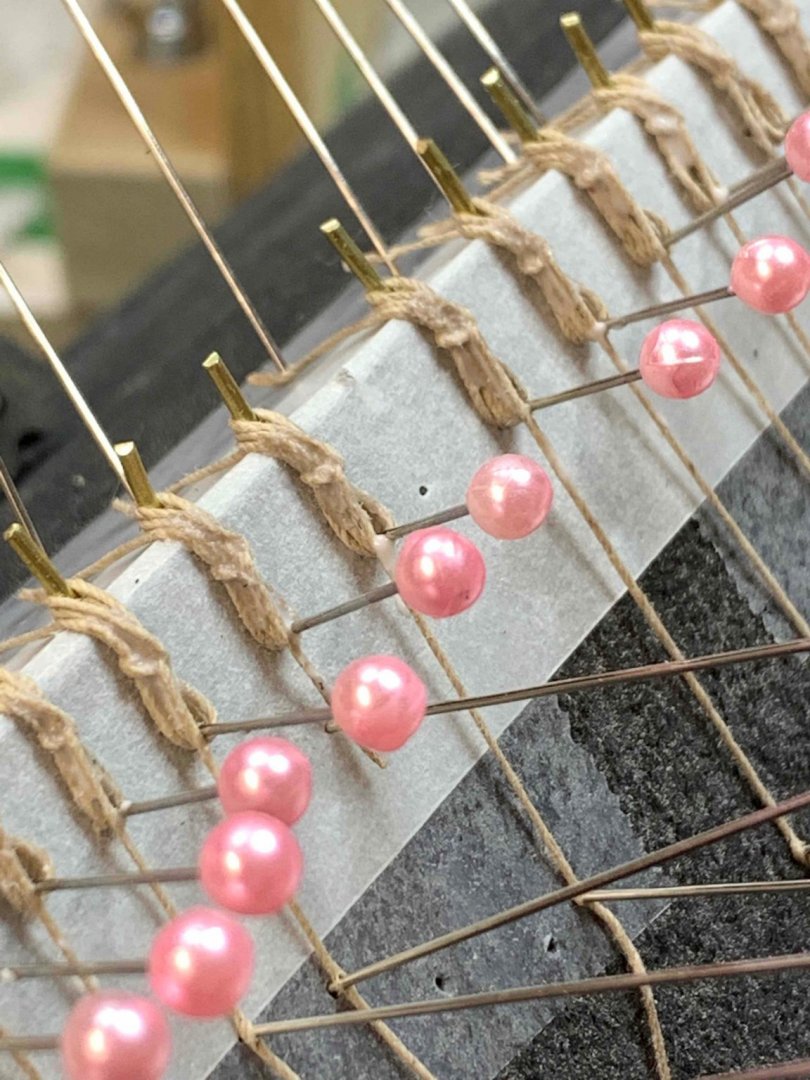

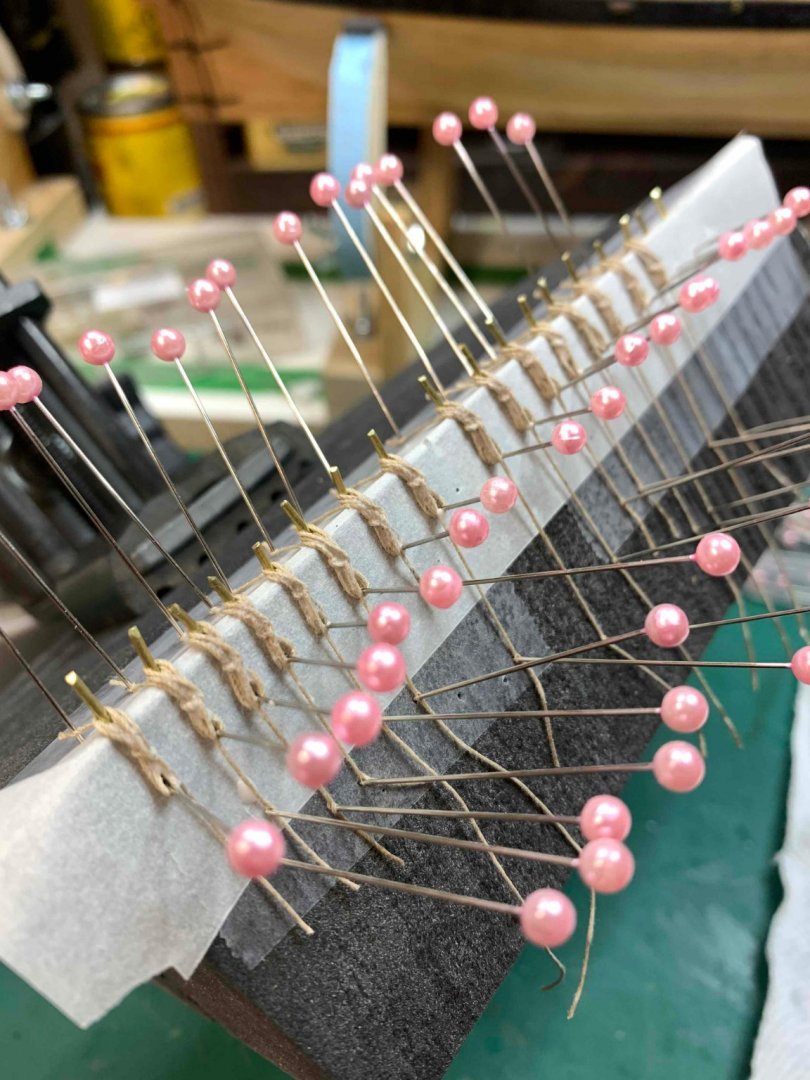

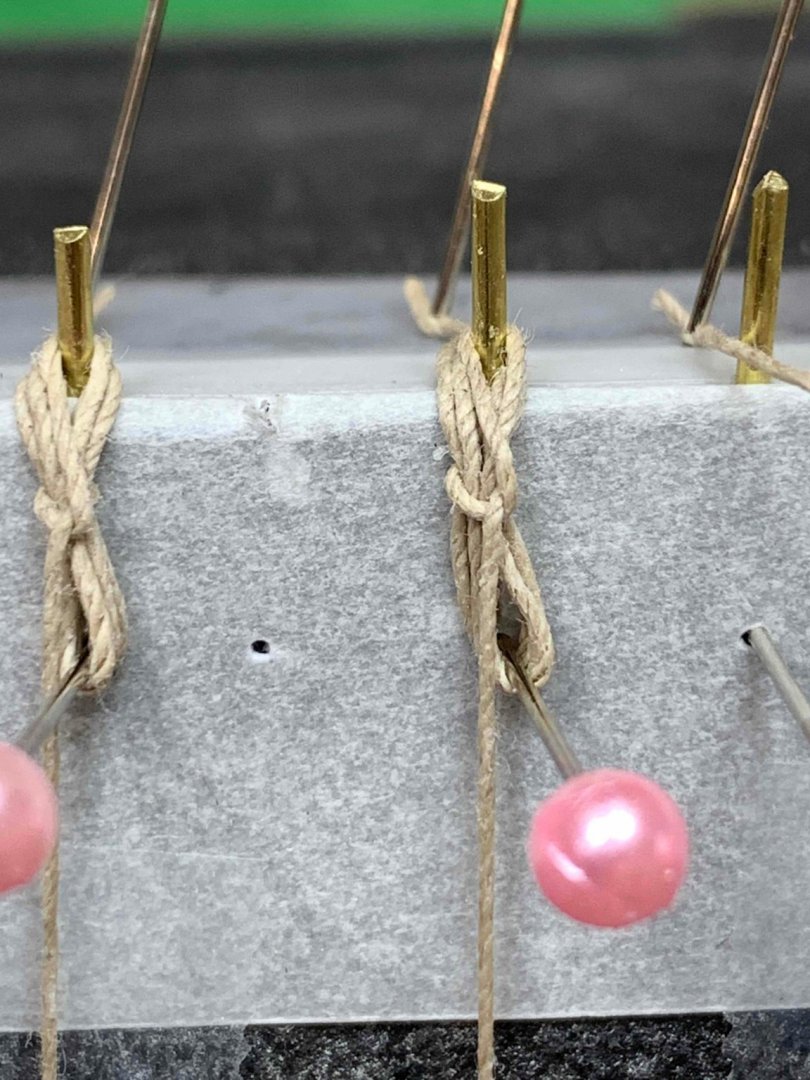

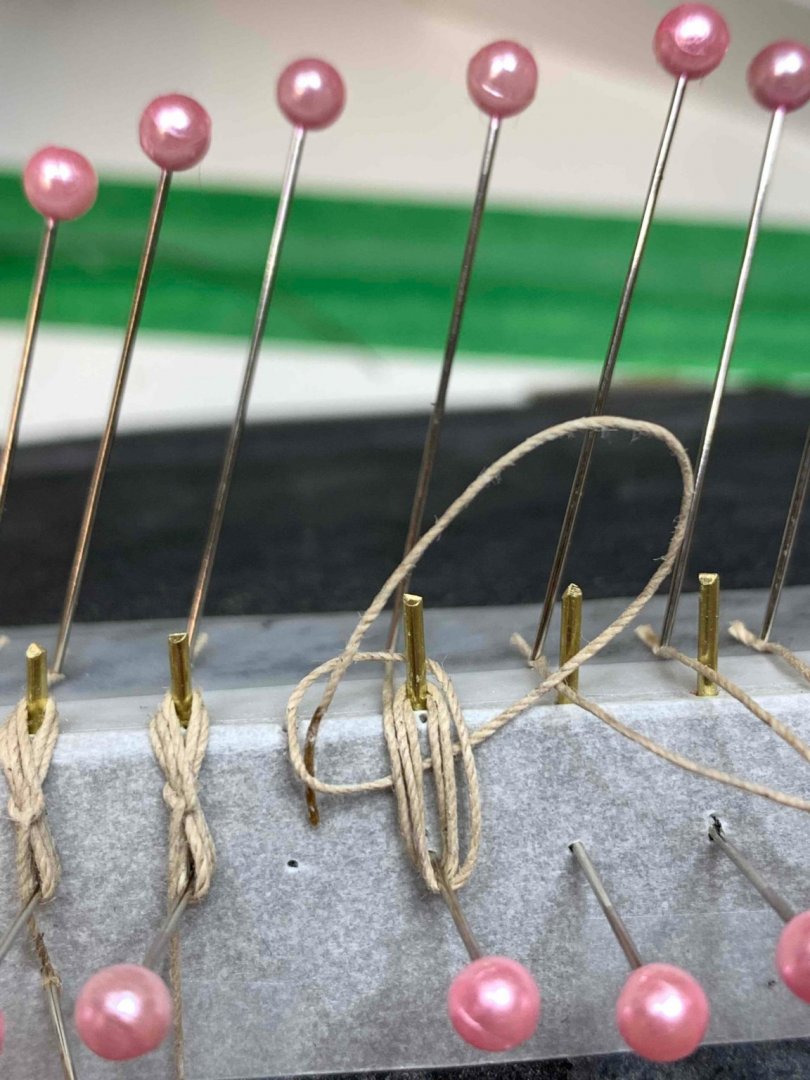

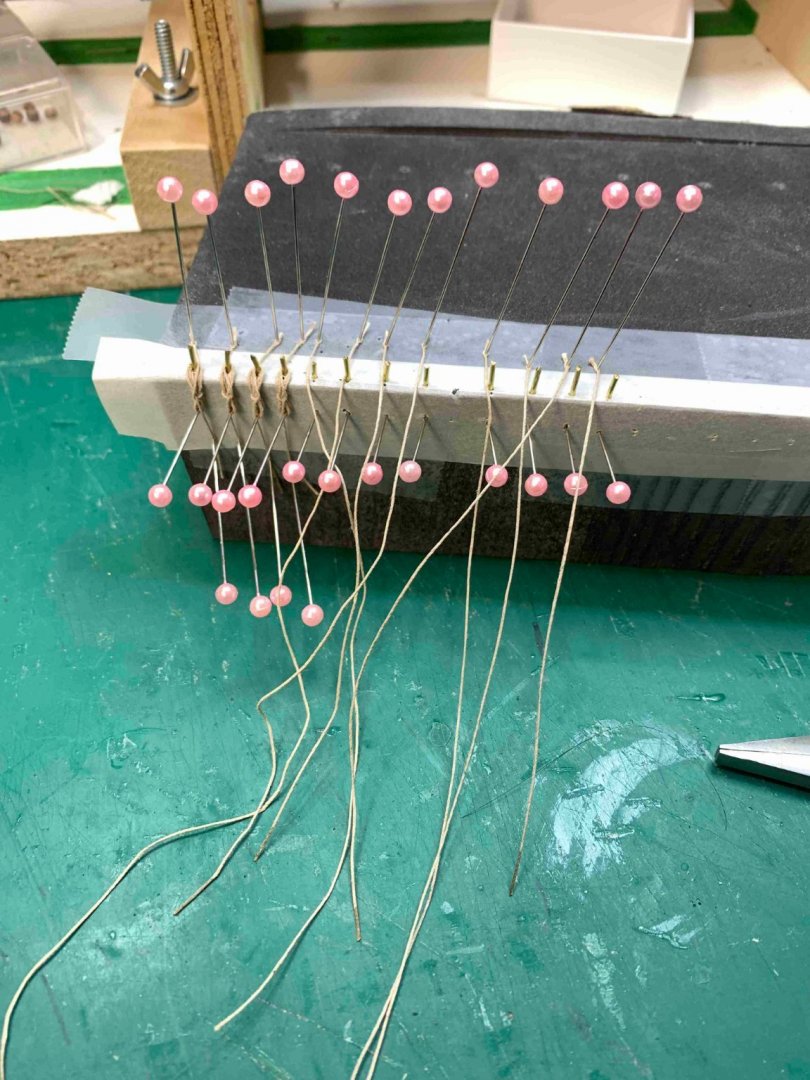

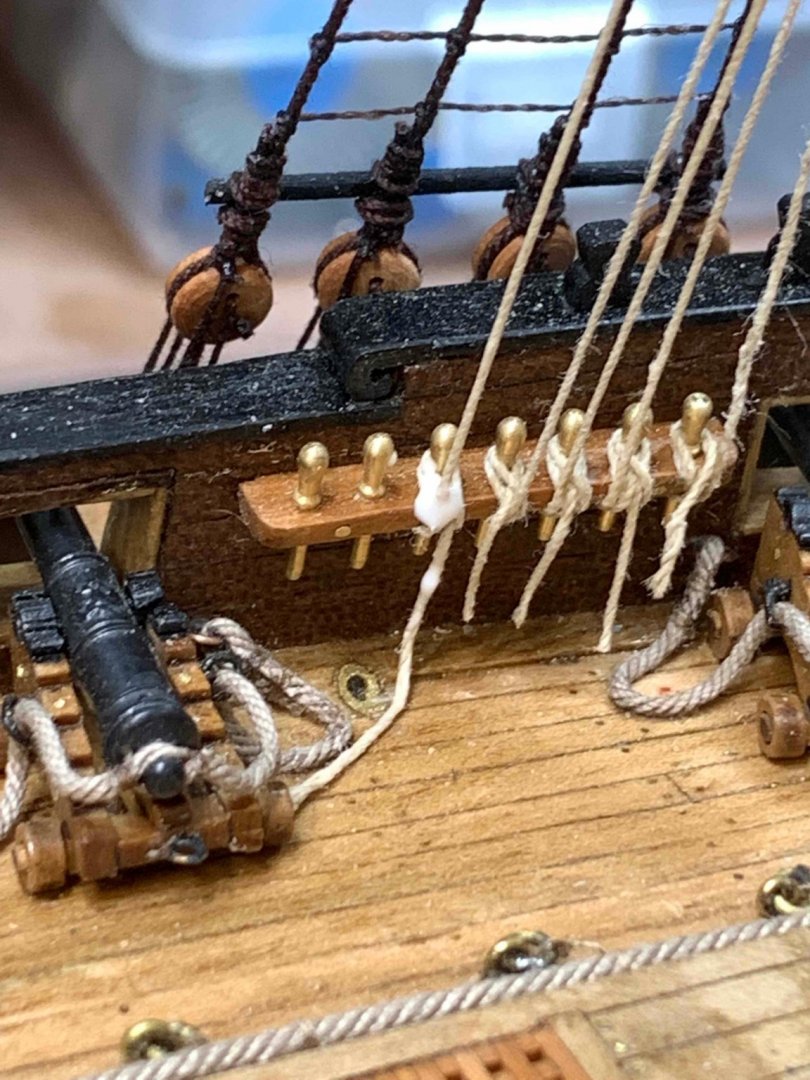

Did not quite like the way how all rope tail end ended up around belaying pins.. It is working just fine but the end results were not quite there so i decided to add a line coils... A bit of a different approach was also involved since i already cut all ropes to a length, so for me to lay the tail ends as they supposed to be, properly, coiled around the pins, was out of the question... First i a line coils factory... the flora craft foam was used as a foundation because of its sharp edges, and well, spongy structure, not hard to push all those small pins... The baking paper was used to prevent glue from sticking on the foam. To create a line coil diameter as close to the original pins diameter, i cut a 2mm wire into 1cm long "pins" and push into the foam.. The distance from the edge was measured from the pin location on the ship and hanging part was also measured to provide a nice look at the end... And started to run lines around it... A drop of white glue was put in each line coil to keep the shape and they were left to dry overnight.. End the results were OK.. A drop of diluted white glue was also applied on the final product.. There are definitely other ways of doing this exercise and the best way will be to do the line coils on the ship directly, but this scale is fairly small for my fingers... Maybe next time.. Happy modelling..

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

Making few blocks with a hook... first, wrapped a wire around the block, added a rope on the opposite end off the hook, twist the wire and make a hook. Then, siezing the rope and freeze it with a glue. The whole block was dropped in blackening solution. With seizing the rope and freeze it first, the blackening solution will no "blackened" the rope, because the glue will prevent solution going into the rope. It is not a bid deal if seizing is done after blackening, just rope has to be pulled a bit more so the blackened rope is removed... Rigging the sprit-sail yard is next. First, the block was rigged and attached to the yard.. ... the rope was pulled thru... Few more other ropes were attached... Getting crowded up here... ... and ended up on pin. I put a small amount of white glue to freeze the knot... when is dry, less visible than CA glue. Extra cord length will be cut off later.. Happy modelling...

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

-

- 275 replies

-

- phoenix

- master korabel

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.