-

Posts

2,698 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by HIPEXEC

-

Still putting the two anchors together. Good old Constructo's lack of instructions gave me a small fit. The wooden cross piece on the anchors come in two halves. I dry fit them before gluing and they matched perfectly. I applied 10 second CA and put them together only to find out they weren't symmetrical and one of the cross pieces was glued showing a large seam! 10 second CA doesn't forgive that, so I had to file and sand the errant anchor to match its cousin. Now I'm touching up the paint and will re-stain the wooden cross pieces. Then I'll fit chains and blocks and lines.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Bob, I have tried your tape idea before...and it seemed to work. I'm still holding off until I feel brave enough to drill that hull. I worked very, very hard to plank it as perfect as I could since I didn't want to fill and paint the hull. I definitely will use progressively larger drills.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks Bill. I'm looking for small fittings for the rudder chain where it enters the hull since I've just tacked the two ends for now. I had to create the rudder fitting from a left over hinge.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

While I'm getting up the courage to drill into my hard-earned hull....I installed the rudder chain. Constructo misses the boat and only shows the chain as a safety chain. My research tells me it's that as well as emergency steering in case the topside steering is disabled. The chains run through the hull into the gun deck.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I'm building a Constructo USS Constitution for the very same reason....the natural wood and to make me improve my woodworking skills and not rely on wood filler.

- 708 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

You have great sawing skills! Your gunports are fabulous.

- 708 replies

-

- victory

- constructo

-

(and 1 more)

Tagged with:

-

Thanks Bill. I'm still holding off so I can get up the courage to drill. I'm not painting the hull, so I'll go very, very slow!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I'm not going to enjoy drilling into my hull!

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

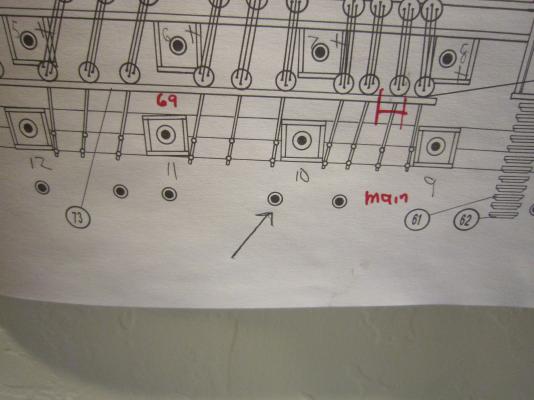

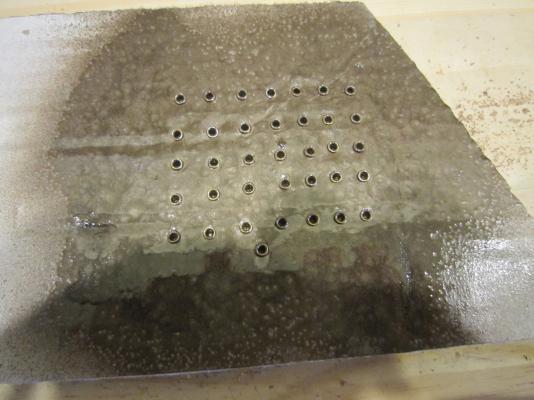

I "bronzed" the air ports since they were bright brass and I didn't want them gleaming on the hull under the gunports. I found out from Jeff and also did research that they are vents to the berthing deck that can be blocked with a wood block in rough seas.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

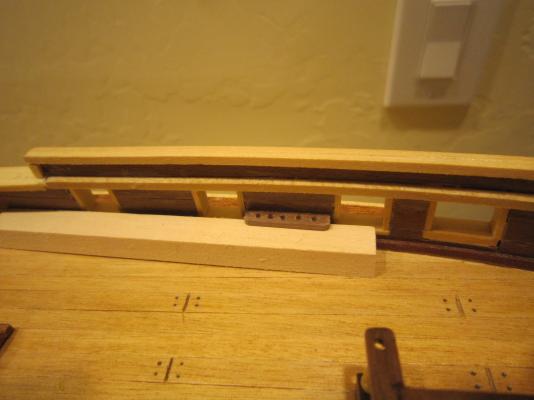

Pin rails are done! They shouldn't break loose unless I hit them with a hammer. The jig made alignment easy. Now I'll clean them up and varnish them.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Sometimes you just have to double up. Nice job.

-

Pin rails are progressing slow but sure. The pins drove me crazy, so I'm using the tiniest pins imaginable, but I drilled micro holes where the rails go the give the CA glue a place to bite.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Thanks David. That would be for both holes....the rail and the gunwale. It split when I pushed the rail into the plank even though I had pre drilled the plank. I'll have to make the receiving hole bigger since the pin went into the rail with no damage. I'll practice some more until I get a good formula.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Pinning rails is easier said than done. I did a practice pin and the rail split longitudinally. The pin is .5mm and the wood 1.65mm with swiss cheese holes. Any ideas?

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

I've only installed one, so I'll pin the rest. Thank you Dave, Augie & Harvey.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Installing gun ports

HIPEXEC replied to richardpepi's topic in Building, Framing, Planking and plating a ships hull and deck

I built my ports by cutting the planks as I installed them. I got very square cuts and all the right size. ...And I only had to plank once. It took carefull planning, but I'm not a good hole cutter. -

Moving on. I installed the first pinrail. I cut it to size and drilled the holes, but when I went to glue it on.....I couldn't do it. It would be crooked or at the wrong elevation, etc. After pondering it for a while, I got the bright idea to make a removable support that would allow me to keep the rail parallel and straight and at the same height all the way around. It think it's going to work.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Maybe your right. Now that I have practice, I should change it. As usual, no instructions from Constructo, so I just guessed.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

Here's the lashed long boat. Me running this line through tiny eyelets and tying it off are shades of rigging to come....I'm really all thumbs. It's difficult.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

-

The preceding painting is what I used to copy the colors of the long boat, the size and the number of oars.

- 1,756 replies

-

- constitution

- constructo

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.