rtropp

NRG Member-

Posts

936 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by rtropp

-

I have noticed that many model makers do not think highly if solid hull models, many of which seem to be fairly detailed builds. I have also seen that many POB/f makers will fill the space between bulkheads which seems to, in effect, make a solid hull. As arthritis takes a stronger hold on my hands, I have become curious to hear the opinions of more knowledgeable builders. thanks richard.

-

I have used a product called "Model Lite - a lightweight filler." It is by Deluxe Materials. I can't remember where I got it, probably either Hobbylinc or Amazon. At first, I thought it was too light, i.e., weightless. When wet it was very easy to shape and when it dried it was solid, extremely smooth and easy to sand. It worked well to fill gaps in single planking. It was also good in other areas where there were some gaps, such as a deck cabin. It took airbrushing well, but I did not try staining. Richard

-

Thanks all, I guess as I run across wood that looks like it would work I should at least give it a try. It seems to contain "luck of the draw" elements. I found I can't always tell how accurate the pictures depict color and grain. I shall stick with some of the dealers that are mentioned on the site. Richard

-

So, I did some testing and allanyed was spot on. The glue was very helpful when I need to fix an already mounted piece. Sometimes when mounting a difficult part I don't want to have to remove it to add glue. But drying takes forever and it does leak to unintended places. But, for pre-mounted parts it is a real help, just need to wait a while before sanding it back. Richard

-

I will need to check on the drying issue. I had not noticed it at first but have not tried sanding. I was checking on diluting a titebond or others like it on this on MSW but seemed to get less than positive responses. That do not seem to have the wicking quality which is what first attracted me to CA thin and then to Super Phatic. Thanks for the tips. Richard

-

I experimented with Super Phatic glue, and it seems to work. I used it after adding a wet plank to a number of bulkheads over a very irregular shaped stern. Lots of bending. First the plank was molded to shape by soaking and then added to a number of stern bulkheads with clamps, rubber bands and some nails to form the appropriate shape. Then I added the Super Phatic after the plank dried all the while leaving it on the bulkheads the whole time. I utilized the glue's wicking qualities along the joined plank edges and again at each bulkhead. It seems to have worked pretty well and was a lot quicker and easier to add the glue without removing and replacing the plank. I am wondering what, if any, are the downsides of using Super 'Phatic that I should consider. Thanks. Richard

-

Thank you all for your responses. They were very helpful. It does not appear that anyone has tried an electronic Nailer vs push Nailer. I'm guessing there is a darn good reason. So I will continue to use rubber bands and modified bulldog clips. Richard by the way, in answer to your question this is a single planking that will be painted.

-

I am not having a great deal of success with push pins (arthritis). Any thoughts on using an electric or battery powered pin nailer? I would use it for planking or other similar, temporary tacking rather than one of the push hammers such as that on micromark. If yes is anyone able to recommend one? Thanks, Richard

-

Ed, I had not thought of trying that. I will give it a try on my current mill. Michael, do you have to use the sherline milling vise or can another be used? Thanks, Richard

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I tried this a while ago with my current micro mill. (In fact I think i still have it somewhere.) One problem for me was that I did not see a way to create a stop point for the drilling. So, both accuracy and repeatability became a problem. Also, using the drilling attachment was not as comfortable, accurate as using a standard lever. Probably just habit and preference but I found myself using my Proxxon whenever I had to drill multiple holes. Thanks for the advice. Richard

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

I use a mill for drilling also. (Space is at a premium in my shop.) My difficulty with Sherline is that working the drill requires turning a wheel, a very finely tuned wheel, rather than pulling a lever as in a drill press. After a few holes, I find the wheel awkward, a pain for most drilling tasks. It takes a lot of turning. Sherline does have this jiggly attachment that lets you lower the drill bit but it seems a bit kludgy and still a pain for repetitive hole drilling. Richard

- 3,618 replies

-

- young america

- clipper

-

(and 1 more)

Tagged with:

-

Looking for info on scroll saws.

rtropp replied to Moab's topic in Modeling tools and Workshop Equipment

GRSX, wondered how often you use the tilt table? -

Non-glossy CA??

rtropp replied to rtropp's topic in Building, Framing, Planking and plating a ships hull and deck

Thanks for the help. I will test a few finishes to see which works best for me. On another note, I thought I once read about a pva that works like thin CA. You can set up the pieces then at the seam the pva will "seep" into the crack. Anyone herd of this? Richard -

Copper Tape vs Plates

rtropp replied to Keithbrad80's topic in Building, Framing, Planking and plating a ships hull and deck

The links above will help tremendously, especially the jig for stamping the plates. One lesson I learned the hard way is that any finger prints, grease, dirt, etc. will cause sticking problems with copper tape, if not right away then eventually. I carefully washed my hands every time I returned to the coppering process. At times I actually wore white collectors type gloves, but the cotton ones can get fuzz on the plates so I used the nylon. Richard. -

Clarification of wolding for the Victory Cross Section

rtropp replied to rtropp's topic in Masting, rigging and sails

Allan, I appreciate the help. I have obtained a copy of Lee's book and it is going to be very helpful as I try to work my way through masts and rigging. Thanks, Richard -

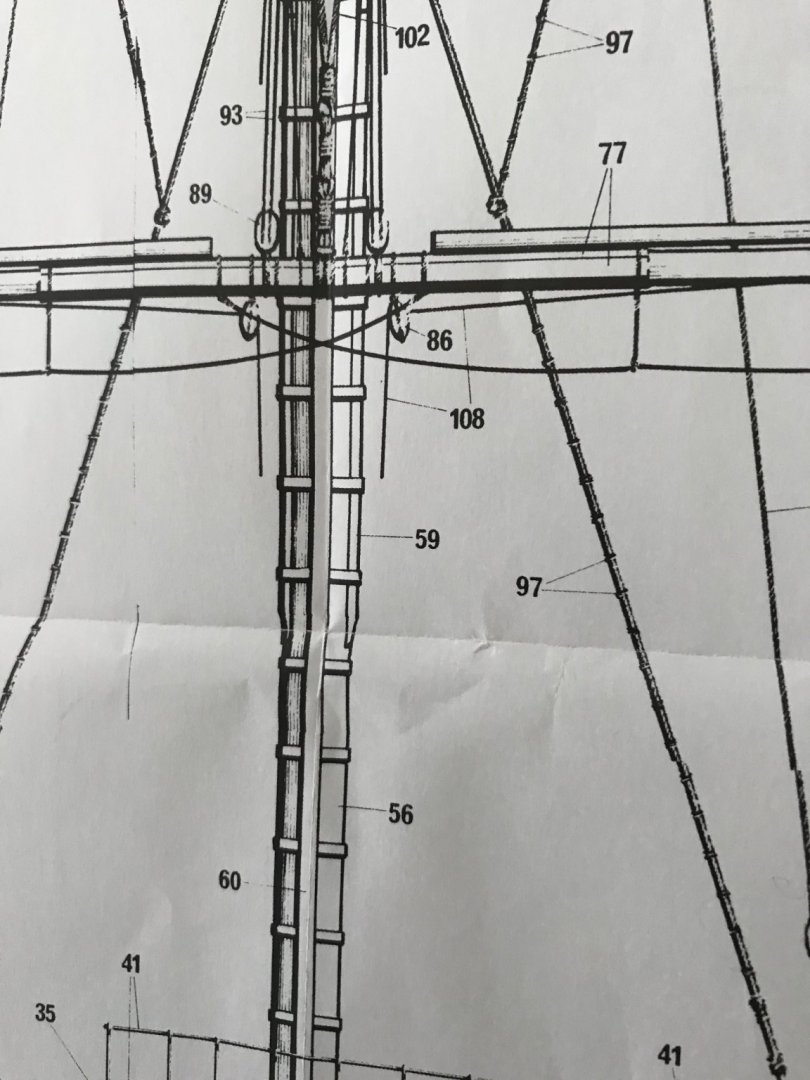

I am about to add the wolding (cross bands with no number in the plans??) to the mainmast of the Corel Victory cross section. The mast has what they refer to as "mast finishing. These are a pair of long, vertical strips and a pair of short vertical strips. It appears that the wolding goes under the long pair (part 60) and over the short pair (part 59). Am I reading this correctly? Thanks, Richard

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.