-

Posts

140 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SimonV

-

AON, Elia and shihawk ,Thank you very much for your kind words and others for likes . Yes, time becomes even more precious now. Some of it will be definitely devoted for shipbuilding. Cheers,

-

Finally I could write, Bluenose is finished . Life boats were last piece in puzzle. I replace kits plywood with pearwood, and definitely looks better. The reason for slow progress is on the last photo . I will post photos of finished model in a few days.

-

hmmm, I have already opened the box and now I am planning ahead, because there will be quite bashing. Will finish Bluenose first, I promise . Dbot, welcome to my log, glad you like it. Thank you

-

Thanks gerty and Elia . I hope that end is near because I am already looking to the boxes in My stash .

-

Good progress and great work. New windows definitely looks more authentic than PE parts.

-

Ratlines finished . Kit instructions suggest to use rope for attaching anchors. Instead of rope I used chain. For blackening I used Blacken-it solution and slightly oiled it before installation to hide patina look. Still few bits to go, currently working on display case.

-

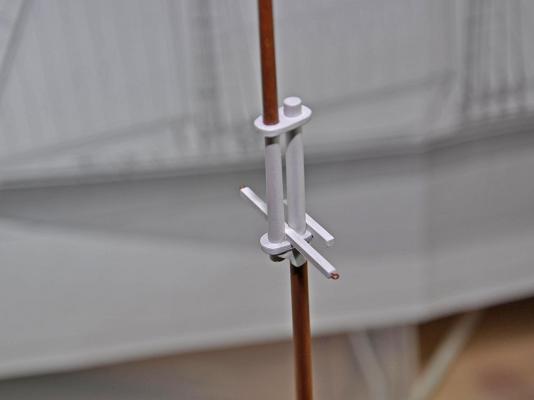

I rigged all the Shrouds to the Deadeyes. To hold the Deadeyes in place while seizing the shrouds, two wire hooks were used as seen on picture. Currently working on Ratlines. I tried working with 0,1mm rigging line but found it is too big for my taste, so I used thin black sewing thread impregnated with beeswax.

-

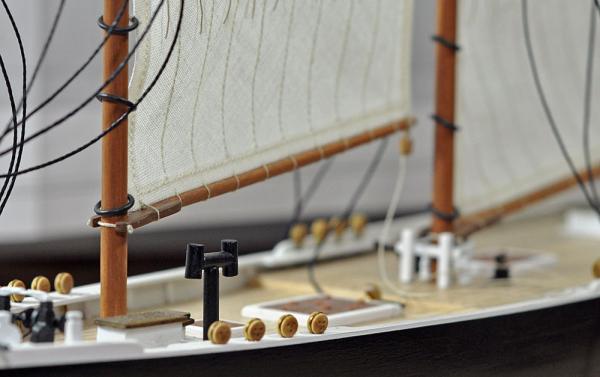

Finally, all sails are on the model. Now it looks more like a real Bluenose . All the running rigging is also complete. Belaying pins are made from bamboo toothpicks to add a bit Of realism (kit instructions suggest only tying lines directly on holes). Some belaying points from instructions were little odd, so I change them to look more realistic. I now have to add rope coils, lash the Deadeyes to the standing rigging ,tie the ratlines,... Still a bit Of building yet

-

What a beautiful ship Max. I really enjoy following your build log and will definitely follow Endeavour build. I also like your photography, very well done

- 153 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

After completing all sails ( Fore sail was not the "lucky" one, I need to repeat process 5 times to get good result, but now I can sew them with closed eyes , ha ) it is now time to put them on model and start the rigging process. I began lashing Main and Fore sails to booms and gaffs with running stitch using 0,1mm line. For rigging the kit thread is useless because it is to thick and stiff, so I replace that with 0.1 , 0.25, 0.5 and 0.75mm thread from Jotika.

-

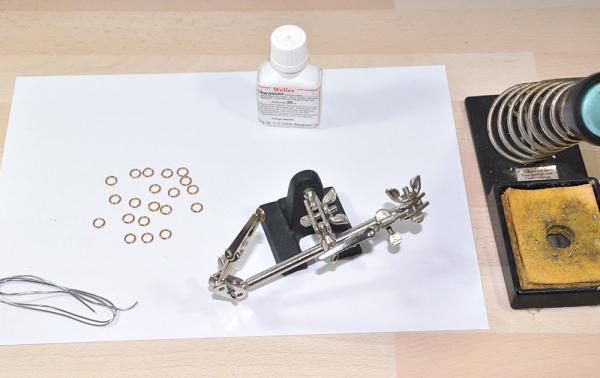

My "recipe" is as follows: 1) I dont know translation but I use "triklorethilen" cleaning solution for grease removal. It is usualy used in electronic cleaning - 20 min in 100% Solution 2) Muriatic acid for surface etching - 20 min in 100% Solution 3) Thorough rinsing with water 4) Blackening, 80% Blacken-it Solution, 20% distilled water - 5-10min. 5) Thorough rinsing with water 6) Buff with soft cloth After buffing I noticed some spots where solution didn't "grab" well. If that was on canons or carronades I will repeat the process. I found this article very useful: http://www.modelboatyard.com/blackening.html

-

Holiday update . 7 from 8 sails are now finally finished . Last one will be done after installing fore and main mast. I learned a lot and next model will certainly have sails on. Today I finished attachment rings for fore and main sail. I used 1mm brass wire and made spring from which I cut out rings . Ends were soldered together. Because I didn't like brass color I decide do blacken them with Blacken-it solution. First I put them on cleaning solution for grease removal, then Muriatic acid for surface etching and finally blackening bath. To achieve final look I buff them with soft cloth.

-

You are doing a beautiful job Max, I am looking forward to following the rest of your build.

- 153 replies

-

- royal caroline

- panart

-

(and 1 more)

Tagged with:

-

Thanks Hamilton and shihawk. At first I was very skeptical of how it will go sewing sails, but the fear proved to be superfluous. It is a lot of fun and I enjoy every minute .

-

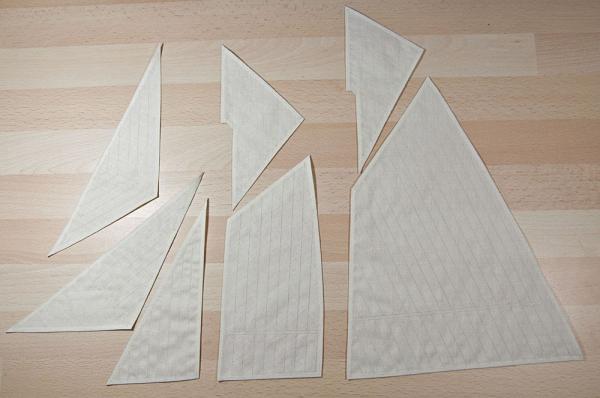

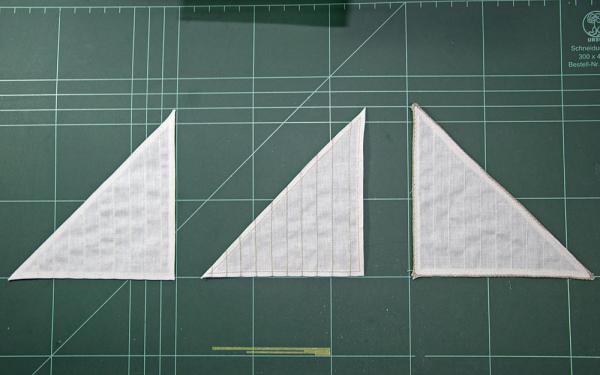

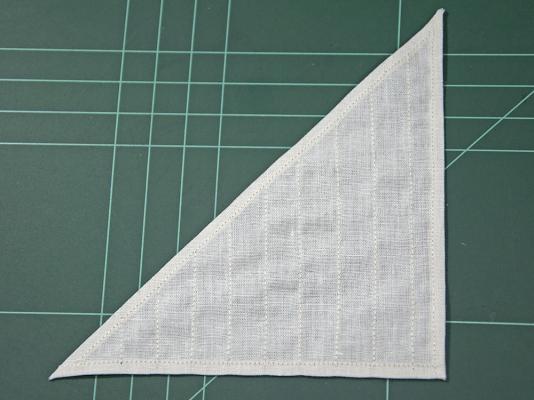

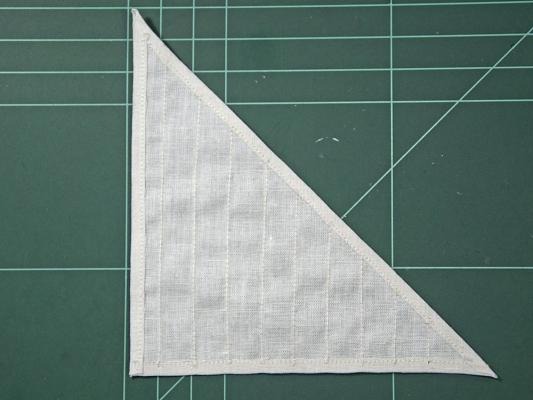

Amati did include sail cloth into the kit, but there is only enough material for one attempt, no mistake is allowed. After some research in shops I found material very similar to Amati sail cloth and bought it enough for a few models I borrowed Admiral's sewing machine and start to learn, from knowing what all those knobs are for to sewing first lines. After several days I managed to make three small samples, testing different colors and technics. The most difficult was that with sewn rope on outer edges,but is a bit out of scale. Maybe I will use it on future bigger models. I decide for first version (left - 2nd picture) with lighter thread. Than I made first real sail which came out fairly good, but I am not satisfied because it wrinkles too much. I think that tread tension is a bit too high. Practice, practice,...

-

Paper templates are finished. I am still waiting for sail cloth, than will post my sewing progress .

-

Bob, thanks for tip. Actually I am planning to fully complete sails off the model, incl. attaching Mast hoops on sails. During construction I already finished display base. I think now is time to permanently mount model on it. Because I didn't install nothing into the keel for mounting model I came up with next idea. I place M3 thread rood into the keel (keel thickness is 3,5mm). After that I made M3 thread into M4 bolt. So I can disassemble model of the base if it is needed.

-

Thank you Hamilton and others. I really appreciate all your comments, or if you just stop by at my build. They give me "extra energy" for work .

-

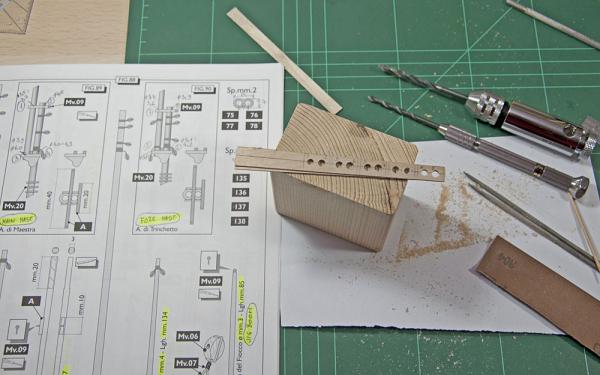

Main mast and fore mast assembly completed. I can still remove Fore (main) mast from fore (main) topmast like seen on 2nd picture. Next task- sewing sails

-

The parts for jaws were also poor quality, so I made new one from 2mm plywood. Next task was panting masts, gaffs and booms. I like natural "wallnut" wood finish and I tried several stains and paints . Best result was achieved with highly diluted wallnut brown paint. 2 very thin coats were needed. After that all blocks were tied on Bowsprit, masts, booms, and gaffs.

-

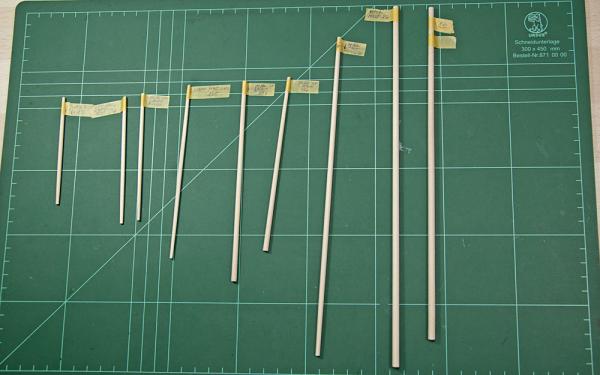

Elia thank you for nice comment All masts are now tapered. The parts for mast caps were very poor quality and holes for masts were far too big for tight fit. I made my own from 2mm plywood. Every part is specific to the location they go. Nothing is not glued yet.

-

Thank you bigcreekdad, Doug James and hamilton. I just received Proxxon wood lathe. It is worth every cent . It is so much easier and controlled to bevel masts, than hand drill which I used for Bowsprit.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.