-

Posts

140 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by SimonV

-

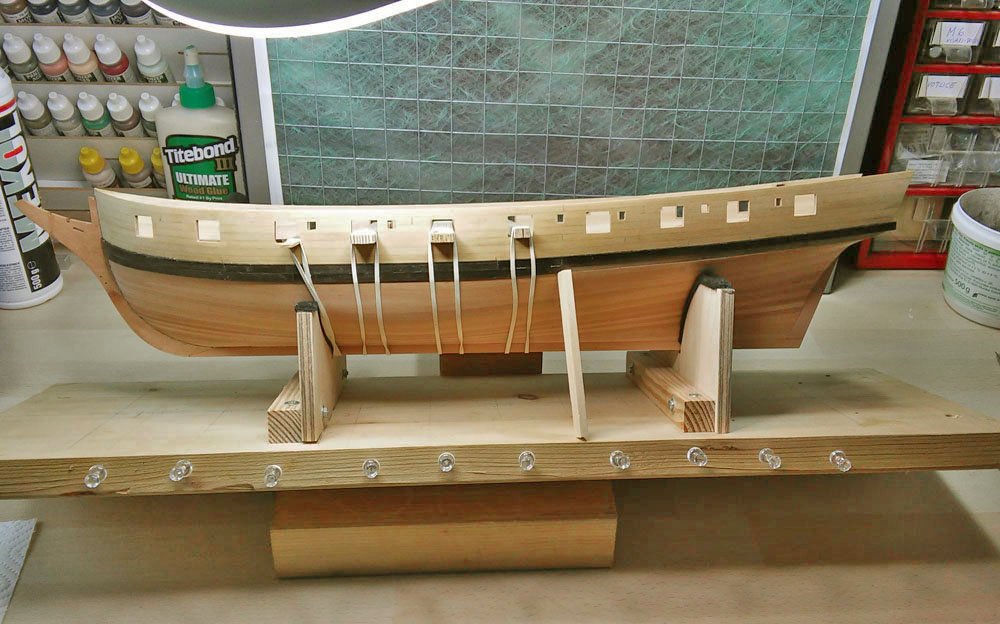

Slow but steady progress on planking. At first, I was in doubt and fear about how to carry out this process, but I must say that I enjoy it very much .

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Thank you captain_hook . Regarding transferring print to plywood. Mirror image of Plan was printed with laser printer on regular paper. Paper is then placed on plywood sheet (print side facing downwards). For transfer I use acetone and soft cloth, carefully rub around the entire surface. I found it is best to use fresh print and generous amount of acetone (ventilation is desirable due to poisonous vapors). I hope this helps. If you have additional questions, please feel free to ask.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Thank you Jason , and others for likes. Very appreciate it . Regarding planking. Each plank is made individually to achieve difference in tone and grain direction. Due to this I prepared short sheets of castello boxwood instead of one single long piece. It is time consuming work but I think it is worth it.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

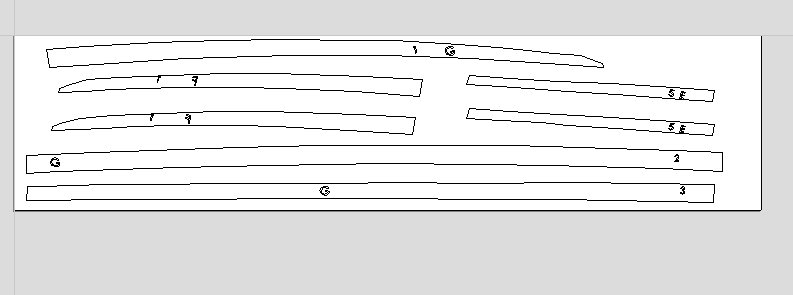

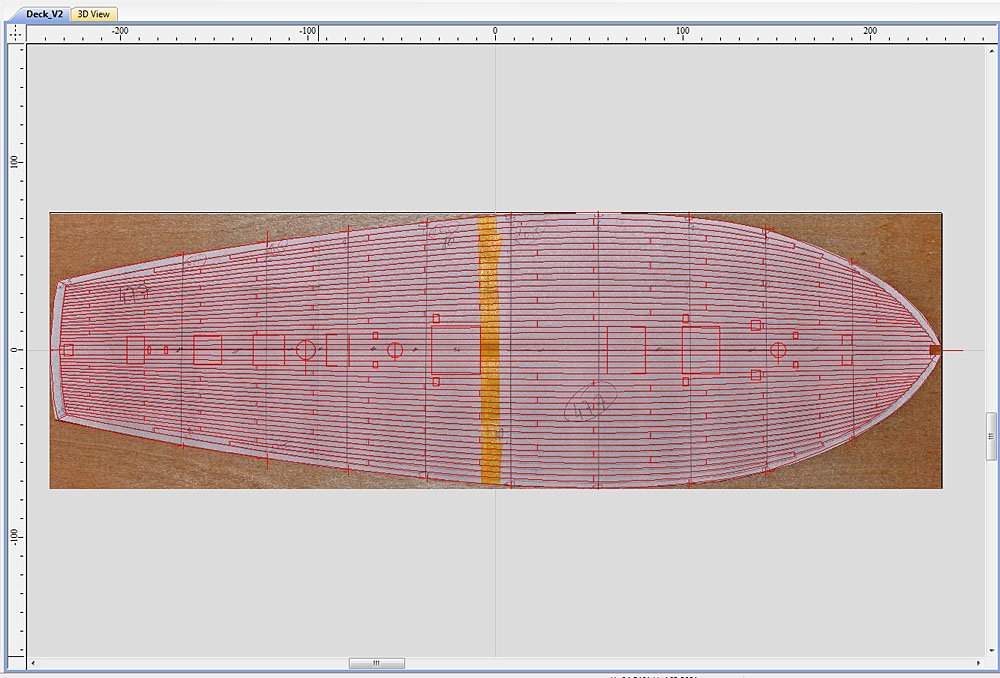

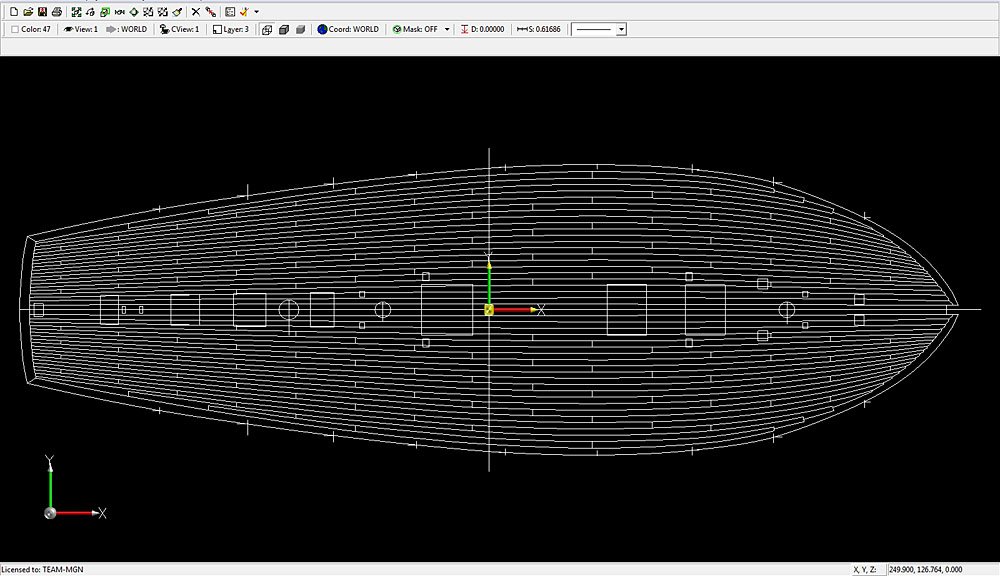

I draw all deck planking in CAD form. After several changes to achieve best fit to hull shape, 1:1 scale drawing was transferred to 0,6mm plywood. This is base for final planking.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

I started working on the deck. Contrary to my initial planning (simplified straight planking pattern), I will stick to original plans.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Finished rudder section . There is a color difference because Hull is not oiled yet. I also added Fish plate.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Manufacturing nails/rivets for rudder hinges. Base material is 0,3mm diameter copper wire and could not achieve to produce head bigger than 0,4mm, which is dimension of holes on hinges (learned for next time to use same dia. holes as material or max. 0,05mm bigger). I tried with knurling tool and cutting with kitchen knife as some Russian modelers do, all without success. Finally I came to idea shown on pictures below. It is slow process, but manage to produce usable nails.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Thank you Jason for such kind words. I put a lot of effort in this build and take the time to make things as good as I can. I am using CNC as my "second hand" for creating things which would be very hard to achieve due to my physical disability/illness.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

I have started to work on rudder. Hinges are made from 0.3mm brass sheet, 0.9/0.7mm Albion Alloys tube and 0.6mm wire.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Thank you Katsumoto for kind words and others for likes. I choose different path with this model (considering my 1st post in this build), which will be 99% scratchbuild. Your comments & likes mean a lot to me.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Work continues on stern decoration. CNC machining could be very frustrating. I have great difficulties with machining, due to unexpected movement of tool into the part (-Z axis). Full inspection of machine was needed incl. mechanical and electrical parts. Also programming was changed and I finally (after two weeks of work and several destroyed parts/ tools) managed to get undamaged part. Windows were also made from 0,3mm transparent plastic sheet.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Hello, due to space limitations I am selling Caldercraft HM Cutter Sherbourne in 1:64 scale. I bougt this kit new as 1st model and only started on hull assembly (please see attached images). Everything elese is as new. Model was stored in dry room and is not deformed in any way. Price: 50 EUR or best offer + shipping costs I am from Slovenia (EU) but could ship worldwide. Please provide me location to calculate shipping costs. Payment: Paypal or Bank transfer Please contact me on PM if you need more information. Thank you. Best regards, Simon

-

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Hello everyone, it has been long since the last update. I make some progress on Mercury, but my build speed is very very slow due to disability caused by illness. I managed to finish wales and started with stern. I really like to work with ebony wood, but is very difficult to process.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Hello James, work on brig Mercury is currently on hold, due to severe health problems. I hope I will come back soon.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Hi Mike, because Euromodel LR is also in my stash (for sale) I was gathering information about ship kit and possible build logs. I found one on Russian site and can be very useful. LINK: https://www.shipmodeling.ru/phpbb/viewtopic.php?f=35&t=5116 . You are doing good progress and I like your attention to details.

-

Pandora by marsalv - FINISHED - 1:52

SimonV replied to marsalv's topic in - Build logs for subjects built 1751 - 1800

WOW! Incredible work !!! -

Mike, John - Thank you for comments, and others for likes . My goal is to "paint with wood" - using pearwood, boxwood and Ebony. Plan "A" was to use black stained pear as simulated ebony (wales & other black parts). Now I proceed to plan "B" - to actually use Ebony. After several tests with different dyes, stains, etc. nothing really "catch" the look of real Ebony. Currently I am working on wales from Ebony - still experimenting on scrap wood, but results are good .

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Hi Mike. Thanks for tips of using finishes on boxwood. I also noticed that it absorb oils and stains different than pear wood. Before applying final finish on model test will be made on scrap parts/wood. I look at your Trajta log... beautiful work . Regarding production time of stern decoration. Final version took approx. 2 hours of machining time.

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

-

Hi Mike. Decor is made from boxwood and it will stay in natural colors. I will use oil finish and some kind of dark "wash" to highlight details. My goal for whole model is to "paint with wood". Thank you Lou. I am glad you like it . Will post progress...

- 120 replies

-

- mercury

- victory models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.