-

Posts

74 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Hartfield,Va

-

Interests

Military Aviation, metal detecting, model building, boating, fishing, crabbing, photography, shooting.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Jeffsmuggler reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

Jeffsmuggler reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

Jeffsmuggler reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

Jeffsmuggler reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

schooner reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

schooner reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

JacquesCousteau reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

JacquesCousteau reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

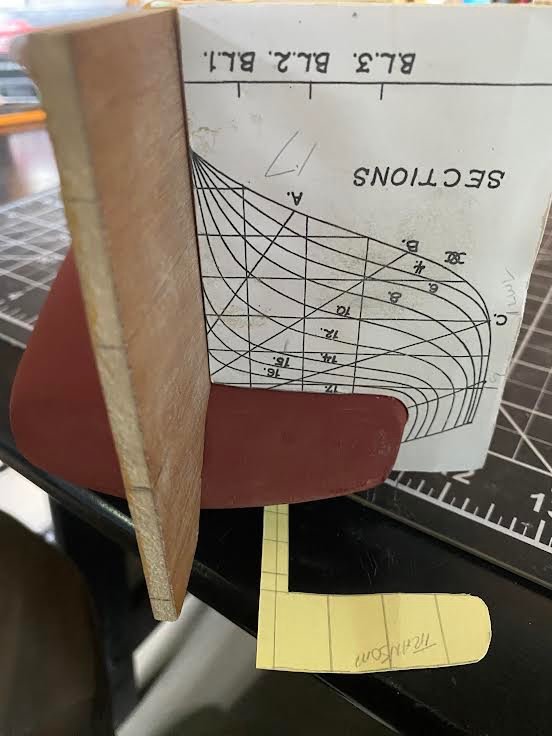

Today I revisited Smuggler and began carving the bulworks . It seems Smuggler lost some weight amidships, as it is 1/8 narrower on each side than the print. A bit sleeker than the real ship, I think it will be difficult to notice. I have that small 1/32 deep half round detail that runs the fore and aft length length planned out using 1/32 safety wire which I will stretch fore and aft at the correct location and press it in, to create the detail... somehow. Book says folks usually just paint to simulate it. I’m still stumped as to how much to trim that mass of wood at the stern. Any help would be appreciated, as the instructions are a bit lacking in this area. I will just leave it full for now.

-

jcurtis55 reacted to a post in a topic:

Chesapeake Bay Bugeye by East Ender - Wye River Models - 1/4 scale

jcurtis55 reacted to a post in a topic:

Chesapeake Bay Bugeye by East Ender - Wye River Models - 1/4 scale

-

Zocane reacted to a post in a topic:

Best paint for wooden ship models

Zocane reacted to a post in a topic:

Best paint for wooden ship models

-

East Ender reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

East Ender reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

ccoyle reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

ccoyle reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

JacquesCousteau reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

JacquesCousteau reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

Hi everyone. Yes, it's been quite a while since I've been on the site, I was on earlier and received an email wondering if it was me. Life just got in the way Anyway, I was at the table getting reacquainted with Smuggler today, trying to get motivated. Seems I'm still a bit stumped with the transom and how much to trim back the solid hull. One step at a time. Tim

-

Old Collingwood reacted to a post in a topic:

Best paint for wooden ship models

Old Collingwood reacted to a post in a topic:

Best paint for wooden ship models

-

Old Collingwood reacted to a post in a topic:

Best paint for wooden ship models

Old Collingwood reacted to a post in a topic:

Best paint for wooden ship models

-

East Ender reacted to a post in a topic:

Chesapeake Bay Bugeye by East Ender - Wye River Models - 1/4 scale

East Ender reacted to a post in a topic:

Chesapeake Bay Bugeye by East Ender - Wye River Models - 1/4 scale

-

East Ender reacted to a post in a topic:

New from Minnesota-MS Constitution

East Ender reacted to a post in a topic:

New from Minnesota-MS Constitution

-

East Ender reacted to a post in a topic:

Is this an accurate way to mark the waterline? (Moved by moderator)

East Ender reacted to a post in a topic:

Is this an accurate way to mark the waterline? (Moved by moderator)

-

Sanded down the first few coasts of primer on the hull again, used a little red lead, made the repairs to the keel with Bondo where I accidentally overcut. Bondo is now my friend. I'll let the primer cure a day or so then I'll start on the bulwarks. I ordered a surface gauge to mark the waterline and and all of the other details on the side of the hull. I also located my old Grumman drill bushings which should help me be accurate with drilling holes for the masts, at least with the pilot holes. The rudder post/drilling looks like a critical set up.

-

East Ender reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

East Ender reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

East Ender reacted to a post in a topic:

Grumman F4F-4 Wildcat by ccoyle - FINISHED - WAK - 1/33 - CARD

East Ender reacted to a post in a topic:

Grumman F4F-4 Wildcat by ccoyle - FINISHED - WAK - 1/33 - CARD

-

East Ender reacted to a post in a topic:

Red Jacket by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - Scale 1/8" = 1' (1:96)

East Ender reacted to a post in a topic:

Red Jacket by MrBlueJacket - FINISHED - BlueJacket Shipcrafters - Scale 1/8" = 1' (1:96)

-

Roger, just watched a video on transom expansion. Now I get it. Skewed perspective and laying out a transom, inboard and outboard. Going out to the shop to study the print and give it a go. I doubt it but I'm wondering if Bluejacket has already accounted for this on Smuggler and the transom just needs cleaning up. Perhaps Mr.Bluejacket could weigh in? Thanks.

-

Thank your compliment and information Roger. I'm going to research Transom Expansion. I've looked into the miniature spoke shaves as well as the old Stanley 75 rabbet plane and the Stanley 100/1/2 model builders plane. Yes, I'm sure these spokeshaves would have made the job easier. They will help on my next solid hull, I will not start one until I have a set. This was my first solid hull. and I've learned a lot, especially of what not to do. I do need to improve on my layout skills.

-

East Ender reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

East Ender reacted to a post in a topic:

Smuggler by East Ender - BlueJacket Shipcrafters - 1/4" = 1 foot

-

East Ender started following Bob Cleek

-

East Ender reacted to a post in a topic:

Dark wood putty, rather than Tree Nails

East Ender reacted to a post in a topic:

Dark wood putty, rather than Tree Nails

-

East Ender reacted to a post in a topic:

Spray by MTC - FINISHED - BlueJacket Shipcrafters - 1:32 Scale

East Ender reacted to a post in a topic:

Spray by MTC - FINISHED - BlueJacket Shipcrafters - 1:32 Scale

-

I suppose you could call this a major milestone, at least for me. With encouragement from Nic at Bluejacket about the use of Bondo, and epoxy /glue adherence to it. I triple checked the hull today to ensure all the templates which fit snuggly. My only dilemma is how to you position the very last template, the transom. The transom is on an angle and I do not want to overshave the area. Also not sure how much wood to remove on the top deck at the transom, see photo. I masked off the keel rabbet and primed the hull lightly with Dublicolor red oxide automotive primer and will lightly sand tomorrow and apply some with red lead where needed. Some of the grain was a bit narly in spots. I still need to repair some over cuts on the keel rabbit caused by my hamfisted use of the Dremel tool. I'll use a bit of bondo to reform that area. I've put the Dremel tool away for now as it cuts so fast and gets me in trouble. My second dilemma or perhaps this is normal for a solid hull model, and that is I need to shave the deck down as the bulwarks are not high enough when checked against the print. Why this is, I'm not sure. a I need to cut down at least .100. Here are a few photos of todays progress, and thanks again Nick for your support!

-

I don't think any two wooden boats are the same anyway. Here along the Chesapeake Bay, Deadrises were commonly built by "Rack of Eye", no plans, just experience. If you have time, look up Billy Moore: Chesapeake Boat Builder 1981 on YouTube. He builds a Deadrise using only his years of skill and "eye" at the the Mariners Museum in Newport News,Va. I'm sure your model will be stunning when done, it's still a piece of art.

-

Thank you Jaager and Bob. I now want to run out to the shop and grab one of my planes and try my hand at this. All those wasted "curlies" over my life. This is a very interesting concept! I used to collect planes, and even have some of my Great Grandfathers tools as he was a Danish cabinet maker in Denmark and later in Quincey, Massachusetts. I have my grandfathers drawing tools as he was Art Director at Grumman Aerospace in Bethpage NY for years. I worked there for years myself in flight test and the prototype/production departments where prints were out on the bench every day. I'm struggling with them after two brain strokes and multiple myeloma cancer, which is in remission. Memory is a funny thing, all you need is a spark, and memory returns. So it is now working on Smuggler, It's a good exercise for the brain matter. My grandfather left me all of his drawing and drafting tools, lots of templates, french curves, triangles ect and I am presently using them on his drafting table along with mine he bought me back in 1970. I keep telling my grandson that he needs to learn a trade, something that will be useful for him, if not now but perhaps in the future as something to fall back on. If only he'd put down the X Box and learn one. We did send him to sailing school while he was visiting one summer and he did well. I will introduce him to my Bluejacket prints and explain to him some basics. I'm a tool junkie and will quiz him on certain tools and hopefully he'll remember. Back to the subject and sorry for the ramble on. I do have some cherry stock from our cabinet installation, along with lots of pine, 300 old re-claimed heart pine our floors are made of. Probably some oak and mahogany trim pieces out there in the garage as well. So I'm going to try the plane shaving method and practice on flat and curved surfaces and see how I do. I'll use PVA as they will be so thin, PVA will let me slide them around a bit if needed. The biggest challenge on this solid hull was finding a good centerline, both keel and deck. I measured and measured, used my dividers, calipers ect trying and get an average centerline on the deck then went around to the bottom stretching fishing 10 lb test monofiliment fishing line down and along the keel. I then centered the keel and went back and forth between the keel and deck until the met reasonably well .This took many attempts to get it as accurate as I could, but "I think" I got it right. My blank hull was thicker on one side than the other, the deck was off from side to side, the bulwarks were ..350 - 450 on the starboard side and .150-.200 on the port side. Cattiwampus? There's mention of cutting off the bulwarks and building them back up with wood strips. I'm going to try it the way the instructions say first,. Why? Because it's harder and a challenge. We shall see! Once I got the centerline, I worked the templates and have the bulwarks where they need to be. Before I did all this, I did ensure what I think was a squared and flat keel using the template. "Blueprints rule" so I made it work all around. I was concerned I was cutting too much. But, as mentioned, fixing a solid hull is easier than plank of frame. Solid hulls, I think I want to try another solid hull. Maybe 5 years from now.

-

Such an interesting topic on solid hull building. Bob Cleek hit the nail on the head with the lack of manual skills taught in todays schools. I asked my grandson about his courses in high school and asked him if he has ever had a shop class or mechanical drawing class and he said "what is that"? It's disturbing to me to hear that. As a new modeler, I chose my second build, Bluejackets Smuggler, which is a solid hull kit. Every step of the way has been a challenge, from becoming reacquainted with blueprints, to using old drafting skills with old tools learned 50 years ago in high school, to which tools work the best for shaping. Measuring and laying out stations, finding the centerline, becoming frustrated with mistakes but learning from those mistakes. Slowly figuring things out. This to me is the beauty of creating something. I may want to plank the deck on Smuggler, just to learn another skill. We'll see. I'm learning something new every day from everyone here. At my pace, I should be done with Smuggler in about 5 years...

-

So after two months of searching, I found, by chance, my Dremel MM35 Mutli tool tucked away in that "safe" place that I had put it. In my opinion,this is the tool to have for solid hulls. Perfect weight and balance, at least for me, it can be held with two hands to be very precise. Shaping the hull is now a breeze compared to rasps, sandpaper and the old regular dremel with drum sander. Using 60 grit, it cuts aggressively, but you can control that with light pressure. I originally purchased it to cut the grout in our marble shower, and it performed flawlessly, and it also came with the sanding attachment and various pads. So any other newbies out there like me attempting a solid hull model should consider one. Almost completed the port side today on Smuggler. You can see the station 8- 10 repair with Durhams, where I found my template mistake, which in turn prompted me to stiffen the templates with craft sticks. This proved to work extremely well and accurate. Durhams is very strong and is extremely hard. Using Bondo if needed here on out with a glaze after priming on low spots.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.