-

Posts

1,005 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Der Alte Rentner

-

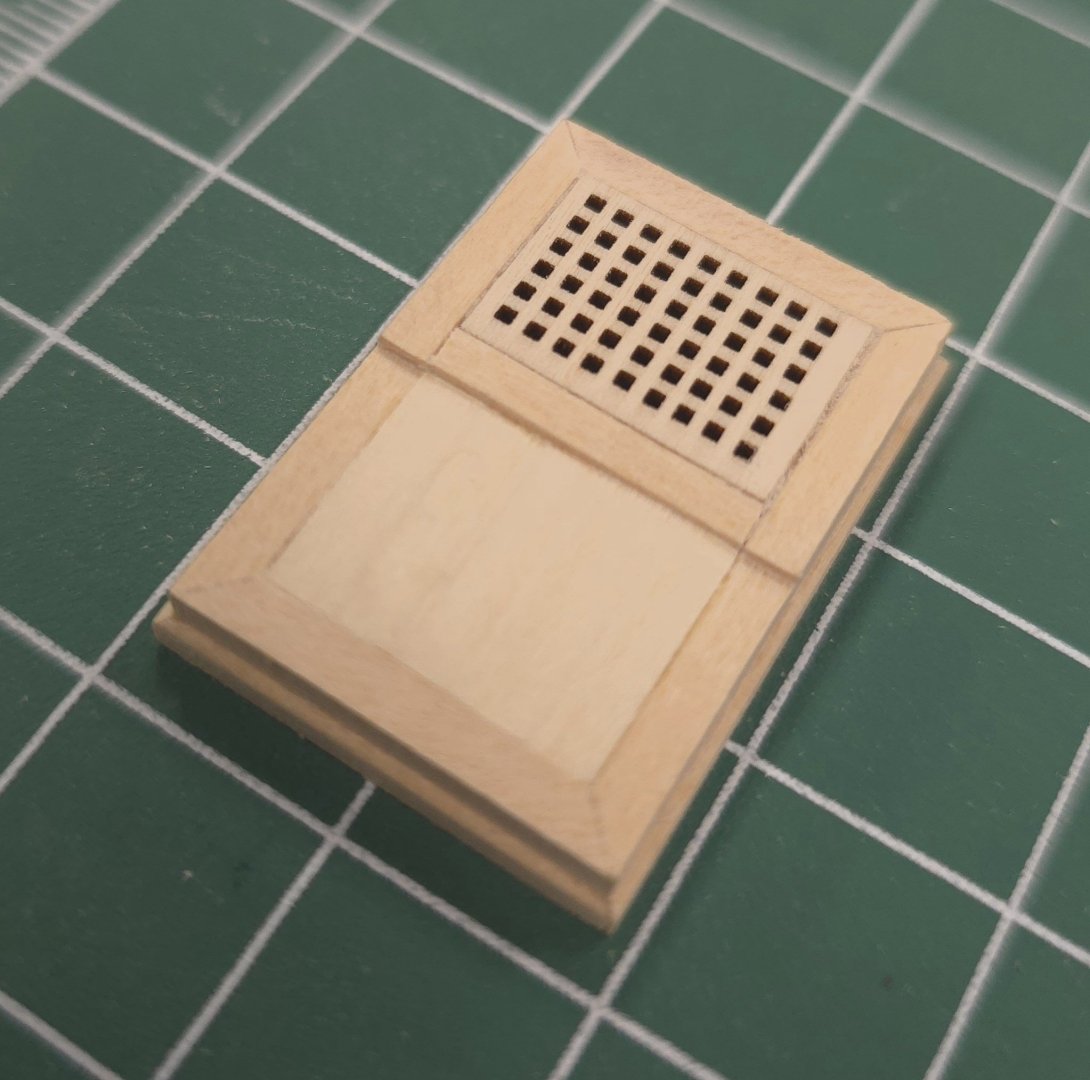

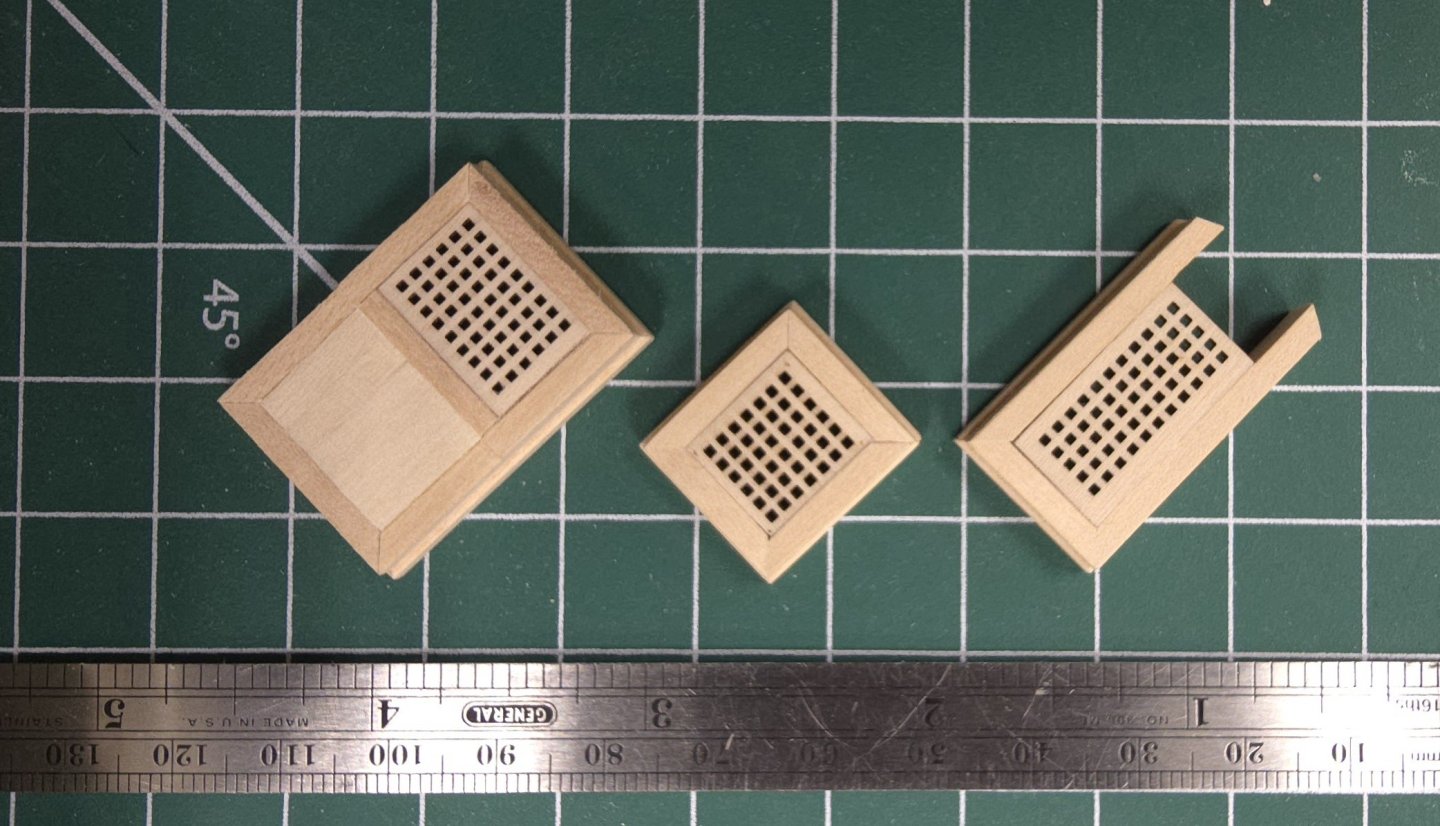

Funny you should ask, Geoff. I didn't spend much time at the shipyard yesterday, but I did manage to mask the small error of sanding away the detail on those laser-cut hatches. Very light application of pecan gel stain. Not much else to say. Here's the evidence. and today, Wednesday June 5, after delays to to shipyard A/C going down, I finished the last of the hatch coamings. That last one was a royal PITA. The joinery came undone twice (super glue isn't that "super" on miter joint?) But it's done. Mast tenons and planking up next..

-

What I like about the Gorilla Glue product is the squeeze button on top (or two on the sides of the non-gel version). Let me know how squeezing these little tubes works for you - even with those syringe style tips attached. I get quite a bit of mileage out of one container. I believe I've only purchased three in a year, and I just started the 3rd one.

-

Especially when it came to masking over the eyebrow.. How you got such a fine straight line over the eyebrow is amazing - in and of itself. Part of the reason I don't want to paint Connie, is that I don't think I can manage a paintbrush well enough to do a decent job - not just the straight lines, but on the intricate work on the scroll work. Your build is looking good, looking forward to your coming back to it. No rush though, wait for me to catch up 😁

-

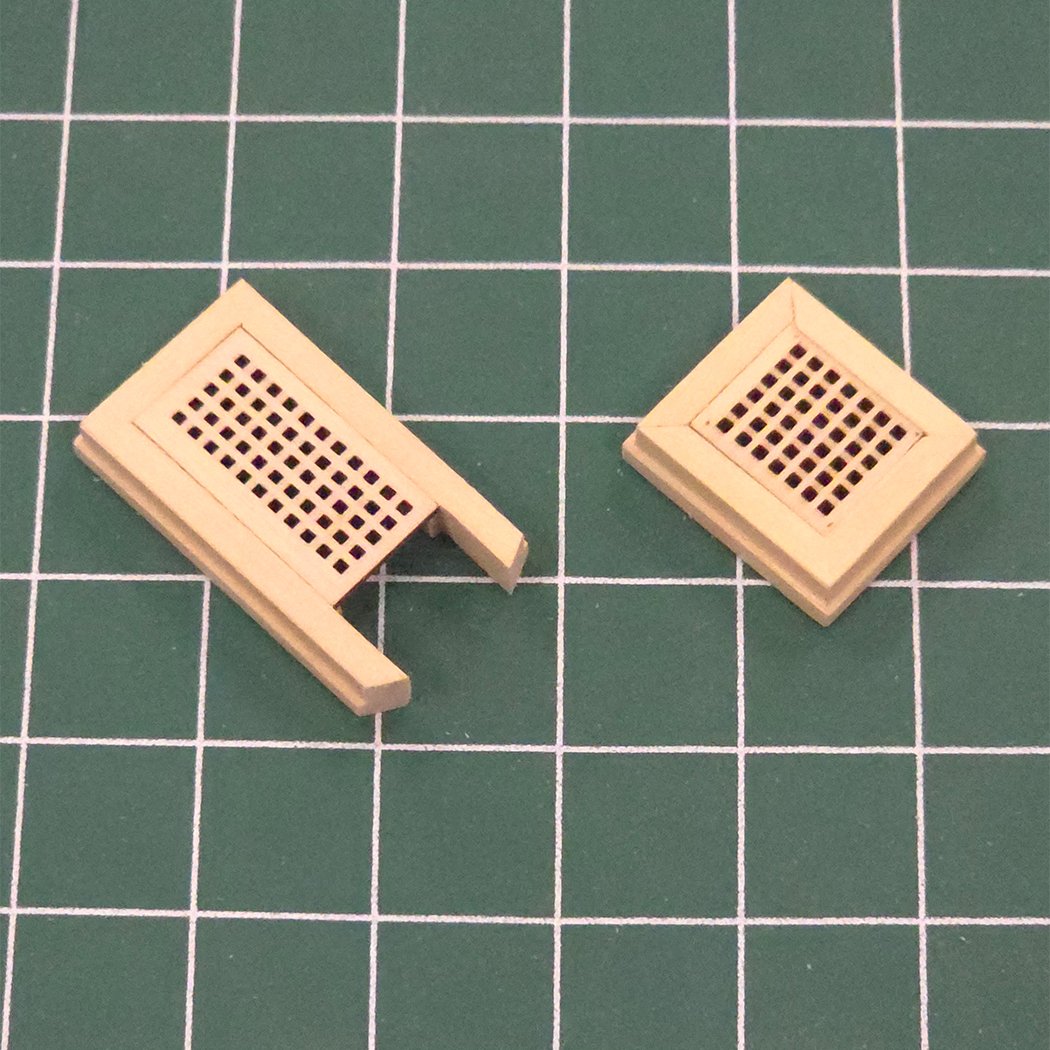

Thanks Geoff. I went to the shipyard this morning intending to start the main hatch. After a quick peek at the practicum, I was ready, willing and able to take the easy route by not cutting up the pre-fab laser cut grate provided in the kit. When I took a closer look at that large grate and how it would look in the coamings, I realized I probably should not have sanded the other grates smooth. Furthermore, I it dawned on me that these grates had a top and bottom side. Now that I know which side is up, I'll have to make sure I retain the detail in grate for the main hatch, which could be lost if I over sand. Live and learn.. By the way, how goes the rigging? and lastly, I checked out your Armed Virginia Sloop in the Gallery. Very nice!

-

Doing some research at the site to see how folks are dealing with hatch coamings, which I wish I'd done a little bit sooner. Seems as thought I should NOT have sanded the top side of the grates. But I digress. Too late for me, but I wish I'd thought about cutting the waterway to fit the cathead instead of the other way around. I haven't looked at your build in a while, but as I get further along in my build, that will change.

-

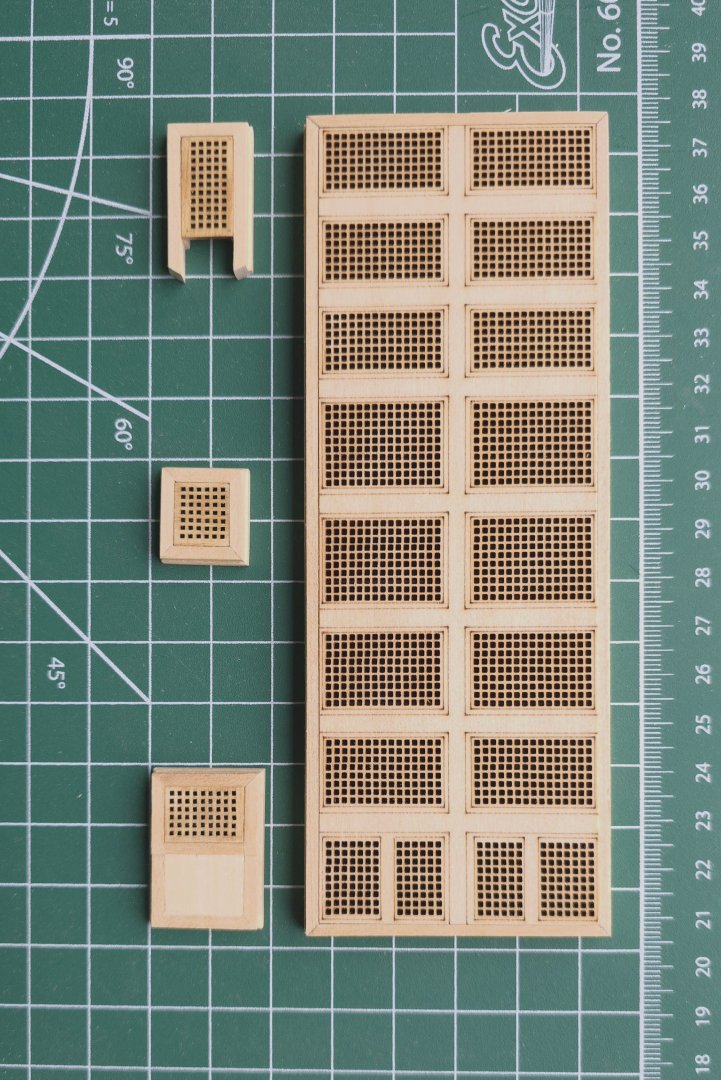

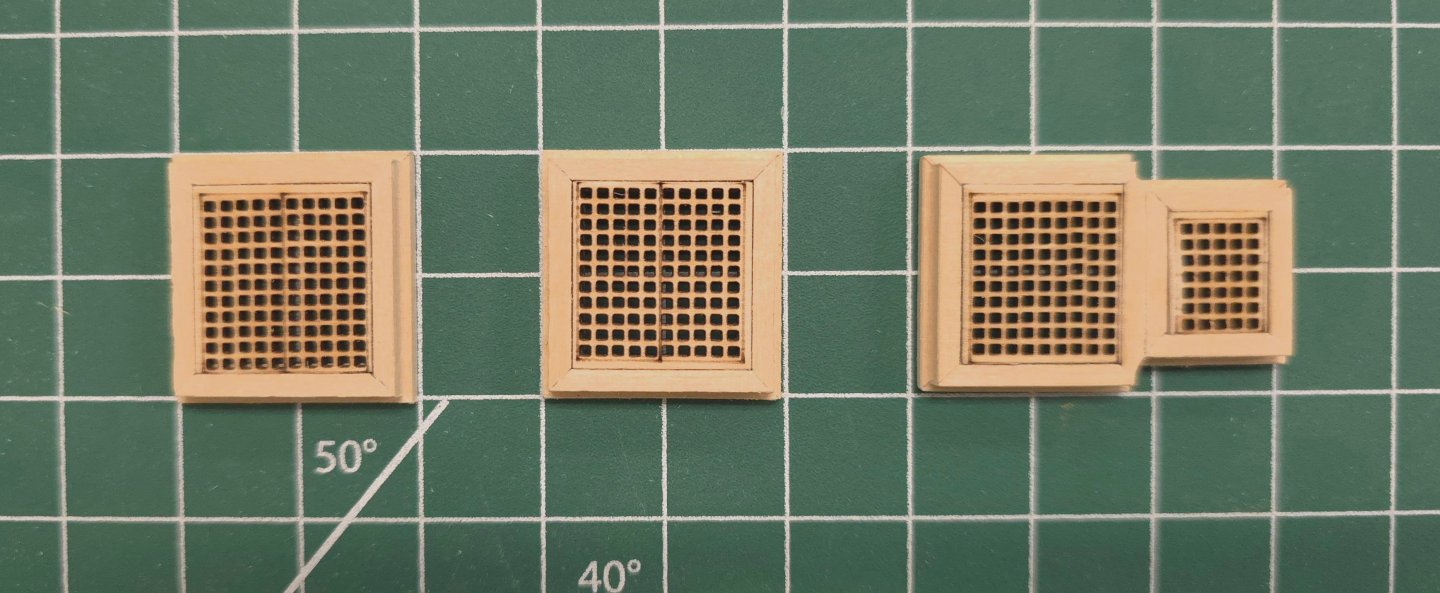

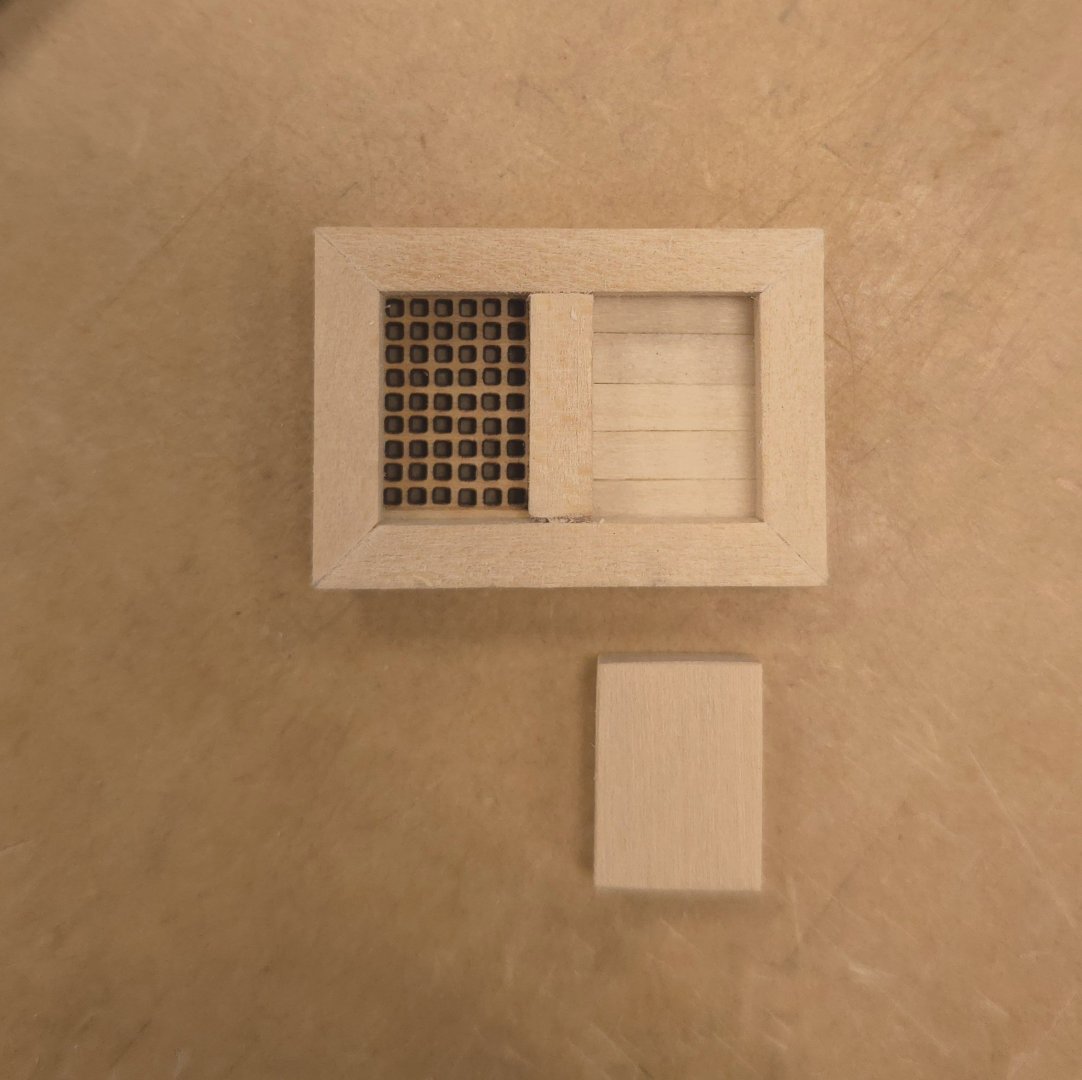

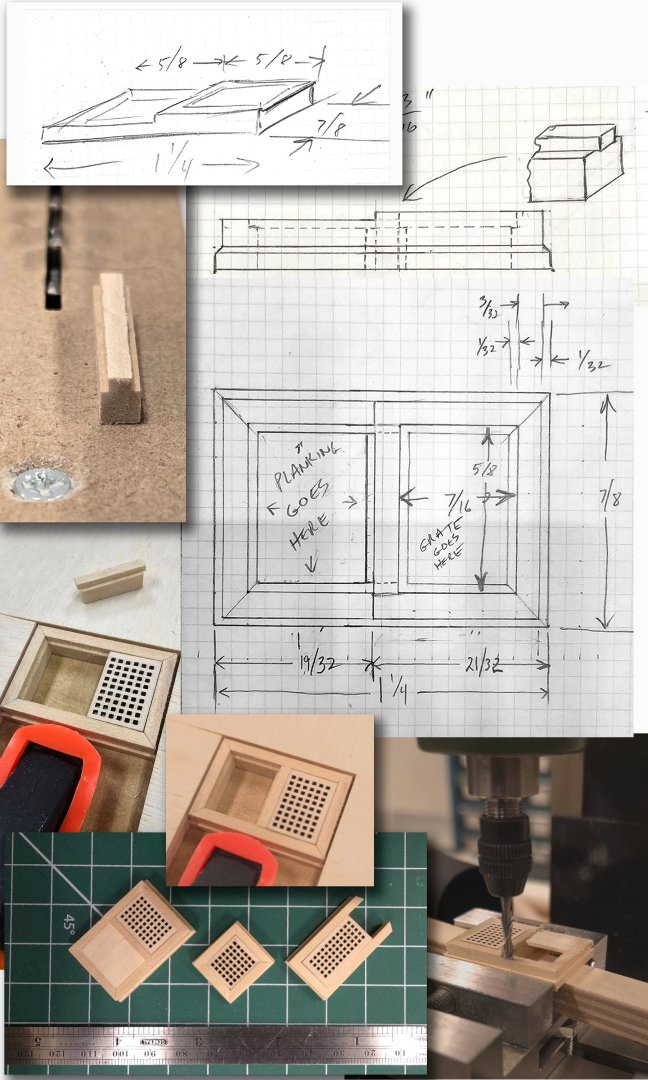

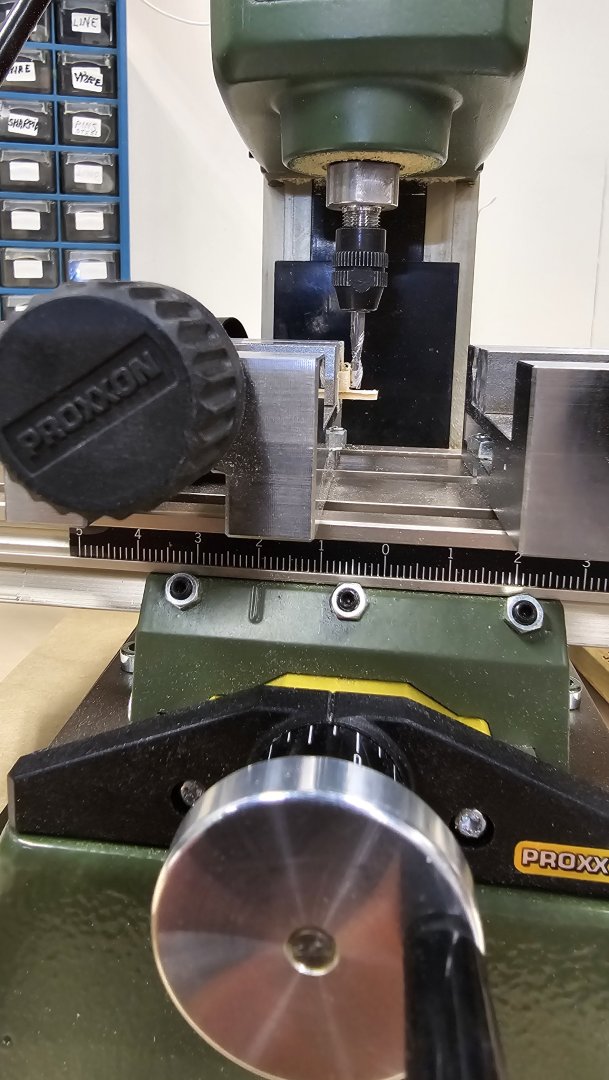

After a week's downtime, due in part to a pit bull attack, and exacerbated by a power failure that took my shipyard off line, I returned to work this morning and knocked off the galley stack hatch. (Chapter 4.3.4, if you're following along with the Hunt practicum.) As with the previous hatches, I found it easier to work with mitered corners than the lap joinery Hunt used. I realized after I was finished that I didn't need to produce another coaming piece. I could simply have used the same material I used to make the basic box, and filled the space under the planks on the stack side of the coaming with a slightly smaller filler block. Oh well.. I like the idea of the filler block because it made easy work of planking the stack end of the hatch. I just applied glue to five sides of the block and shoved it into the opening from the bottom. My router table was still setup from fabricating the strips I made for the two forward hatch coaming, so it took less than a minute to make the blank for the center piece. For that 1/32" overlap, I used the Proxxon mill to cut out the notch. Once the stack hatch coaming was assembled, I reduced the height of the stack side of the coaming by milling away 1/32". I little trimming here, a little sanding there, and viola, galley stack hatch done. Cutting the notch. Gally Stack Hatch Coaming from the bottom. Note the filler block below the coaming. I realized afterwards that I used 5 planks (3.2mm each) instead of the 7 Hunt used. Not worth it to me to correct that error.

-

whatever floats your boat.. Great fit! As I approach that part of the build where I need to fabricate and (dry) fit the mast, I may be coming around to your line of thinking when it comes to the tenons at the bottoms. I experimented with carving a tenon one end of a dowel and was not thrilled with the result. Even if the tenon is flush-mounted and reinforced with a nail after I test the fit, the method your brain preferred may indeed be the better option.

-

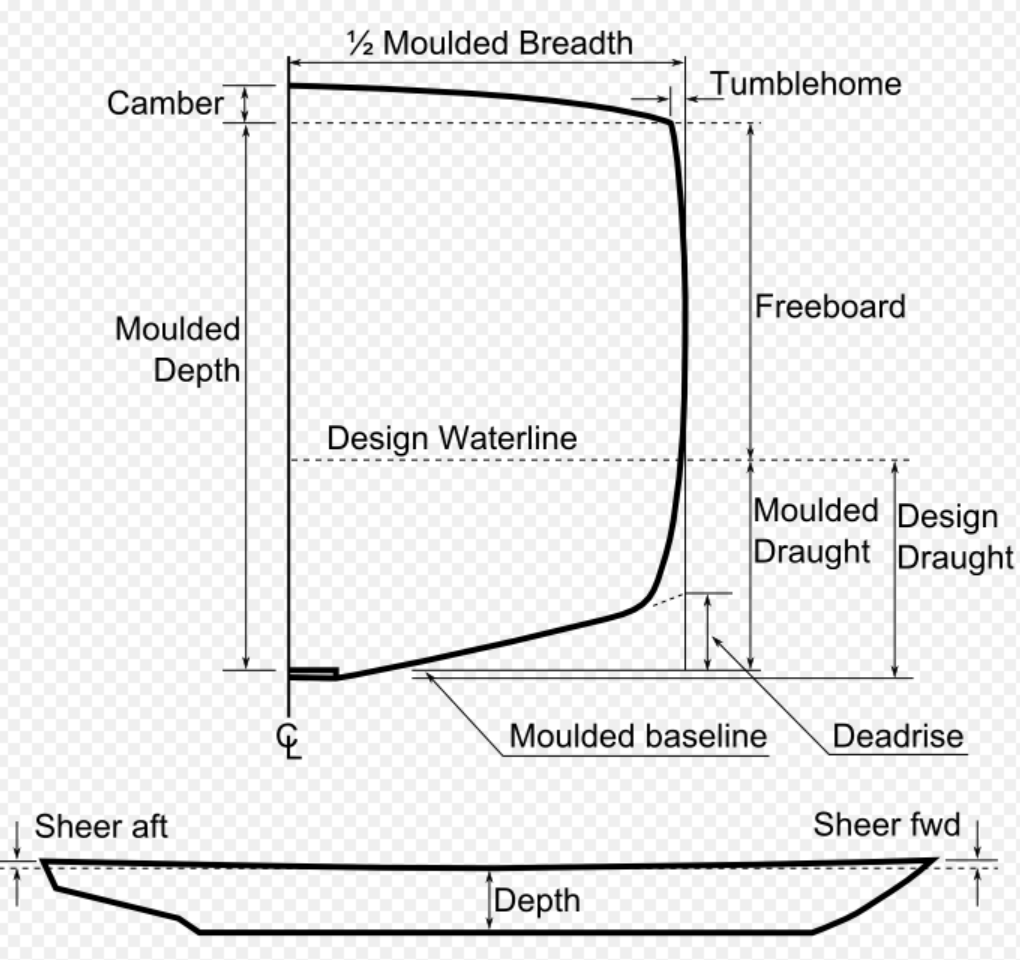

I am struggling to find the right word to describe the asymmetry between the port side and starboard side curves for the deck on the bulkheads. Camber? I had to shim up a couple of bulkheads so that there wouldn't be peaks or valleys when it came time to plank the deck. Checking the photo from above in post 170, I can see that the worst offenders were bulkheads D and P. Those needed to be to shimmed up on the port side of both. For bulkheads A and C, It seems that I trimmed the Starboard sides. I believe I laid planks on top of the bulkheads to find the high and low spots and/or asymmetry before trimming or adding to these four bulkheads. Hope that helps.

-

USS Constitution by mtbediz - 1:76

Der Alte Rentner replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Thank you my friend. I have very useful machines, they make my job easier. Even with machines, I can't produce as quickly as you. If doesn't help that my shipyard has been without power for nearly a week.. As always, your workmanship and productivity impress. -

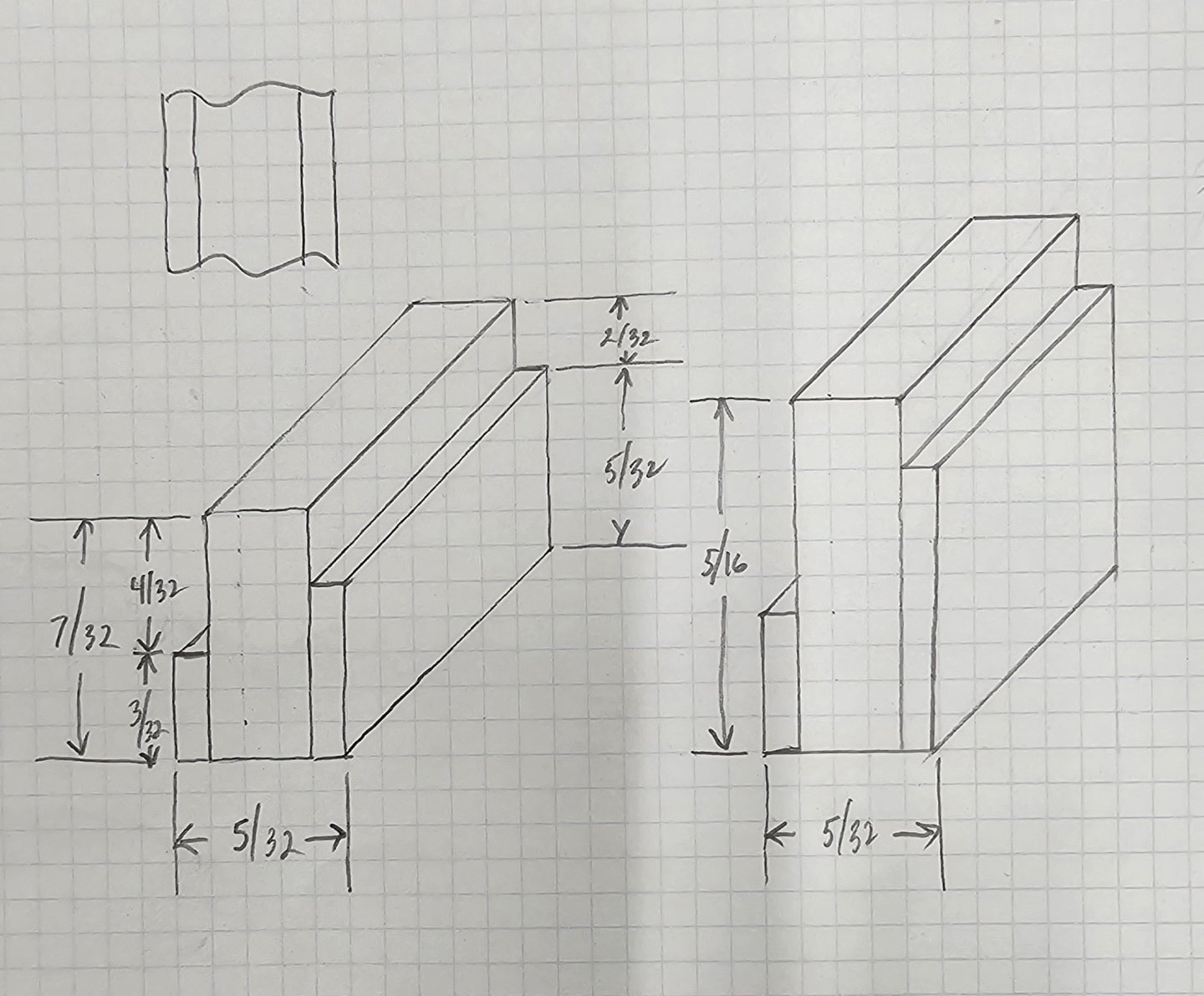

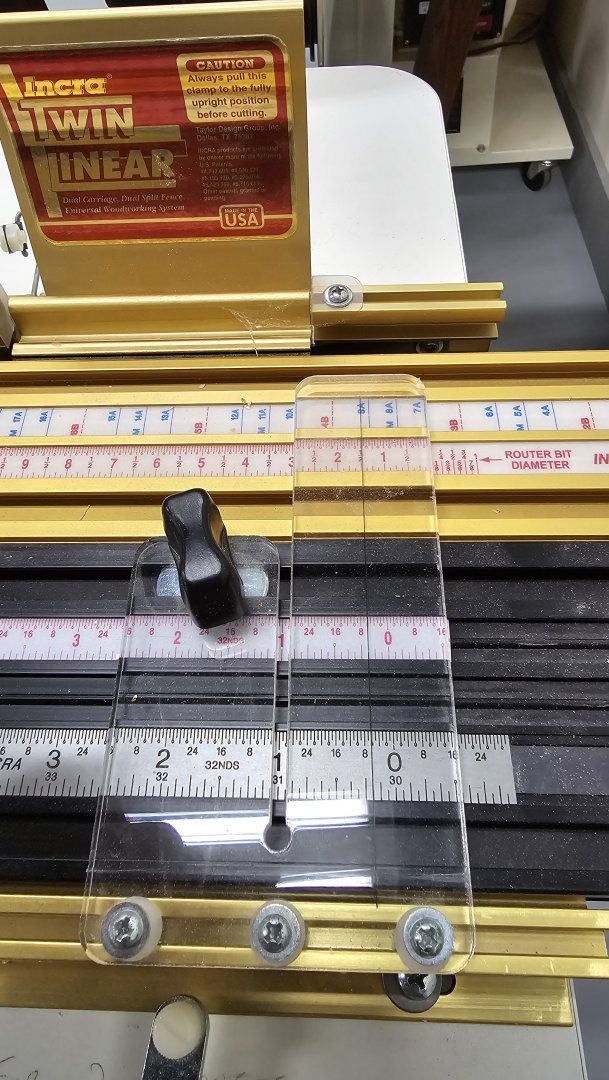

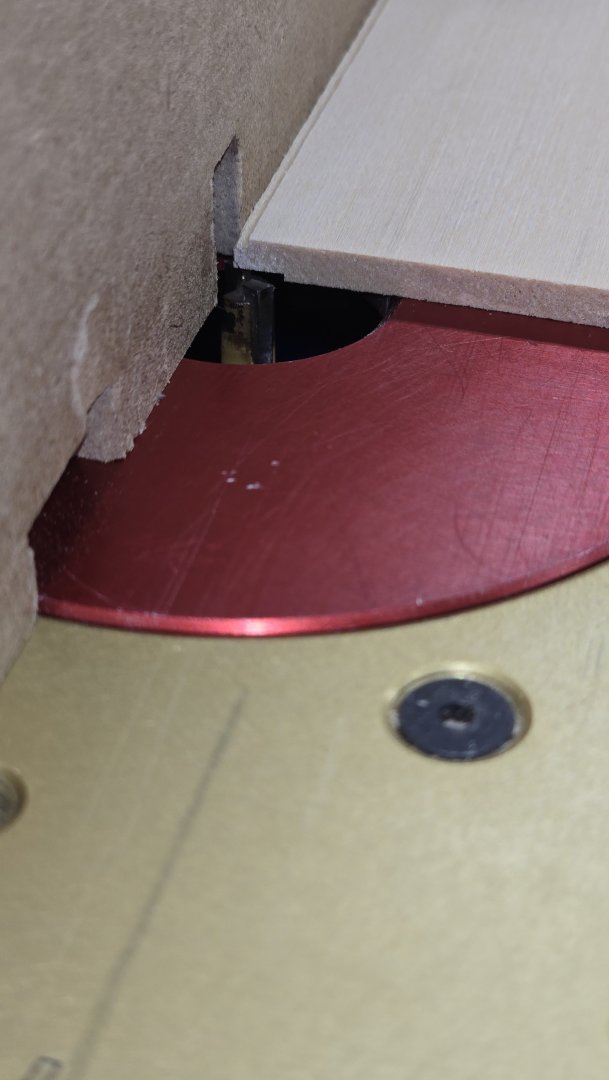

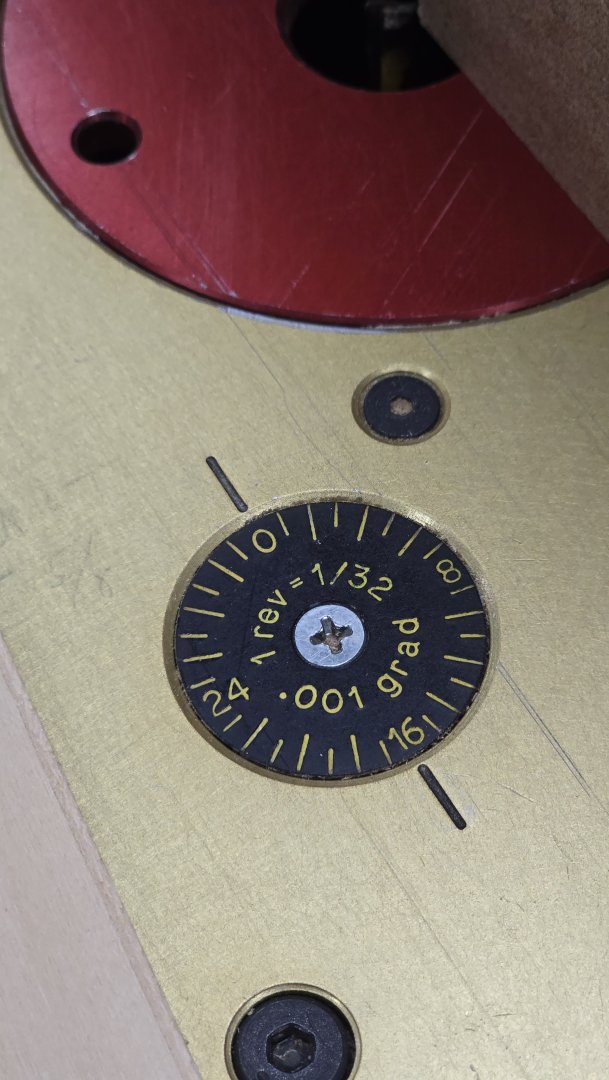

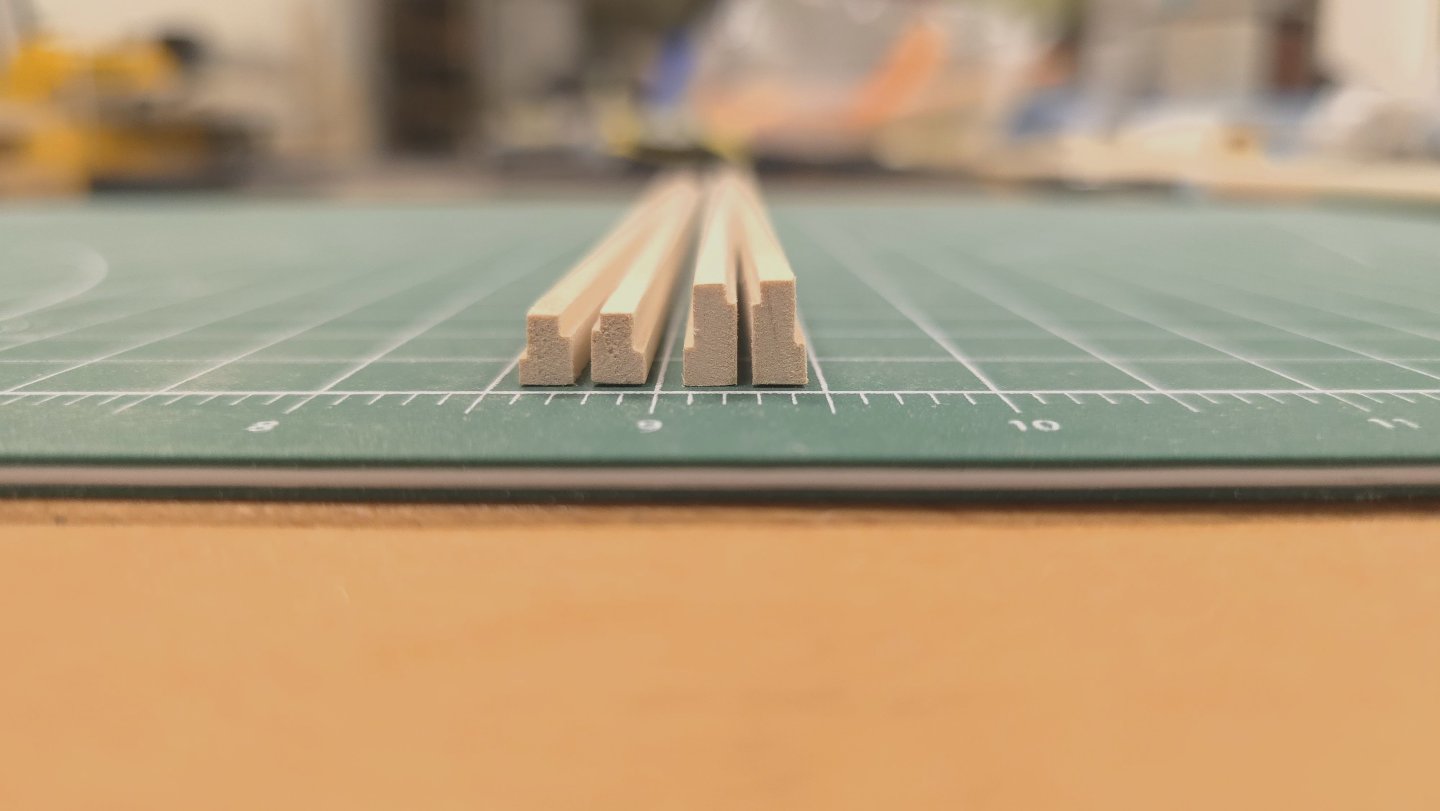

(Quoting myself..) I decided not to wait on the zero clearance rings for my router table. As it turns out, they weren't needed. Milling the hatch coamings was relatively easy using existing machinery - Delta Thickness sander, Wood Pecker router table, and Proxxon mini table saw. 1. I had some scrap 1/4" basswood sheet and used my thickness drum sander to work that down to 5/32". 2. Set up my router table with a bit height of 1/32". Used my Incra fence to dial in the distances for the rabbets. Easily done with this tool! Once zeroed out to the sacrificial fence, I could set the fence to 1/16", 1/8" and 3/16" rabbet depths. 3. Cut rabbets on both sides of the board. It was easier to do this with the board wide, as opposed to dimensioning the boards first, then cutting the rabbets. 4. Marked the heights on the boards (old school method - ruler and pencil) and 5. Cut to the line on the Proxxon table saw - the least easy tool to set up. Because I couldn't get the precision I desired across multiple cuts, I 6. Revisited the thickness drum sander to nail the coaming heights. As narrow as these coamings are, they nevertheless stayed vertical on their way through the drum sander. (sorry, no pictures of that machine here.) NOTE: I removed material from the bottom of the strips, so as not to mess with the depths of the rabbets. 7. Fabricated two hatch coamings - the one forward of the foremast, and the one that abuts the bowsprit. Note: I found the business of making lap joints tedious and opted for miter joints instead. Power tools were of no particular help in their construction, except the belt sander did make shaping the forward part of the bowsprit coaming easier to trim and shape. Hobby miter box and saw were the tools du jour. (I didn't bother marking all the dimension on this sketch. The grid represent 1/32" squares. The dimensions (after double checking) came from Bob Hunt's practicum. Chapter 4. Rather than start another entry for these two hatch coamings, I added the photo to this post.

-

USS Constitution by mtbediz - 1:76

Der Alte Rentner replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

I am so sorry that my innocent comment initiated such consternation. I only mentioned the scale issue as an aside. My apologies to you good sir. -

USS Constitution by mtbediz - 1:76

Der Alte Rentner replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hi there Mustafa. While perusing your earliest posts (I wanted to see what scale you were using to construct your Constitution), I saw that in a reply to me in your post #3, you added the photos you used in post #340 above in your reply to Greg about how you built your ladders. Just an FYI. (I don't know why, and this is why I checked your scale in post #1, but your photos make your Conny seem much larger than mine). -

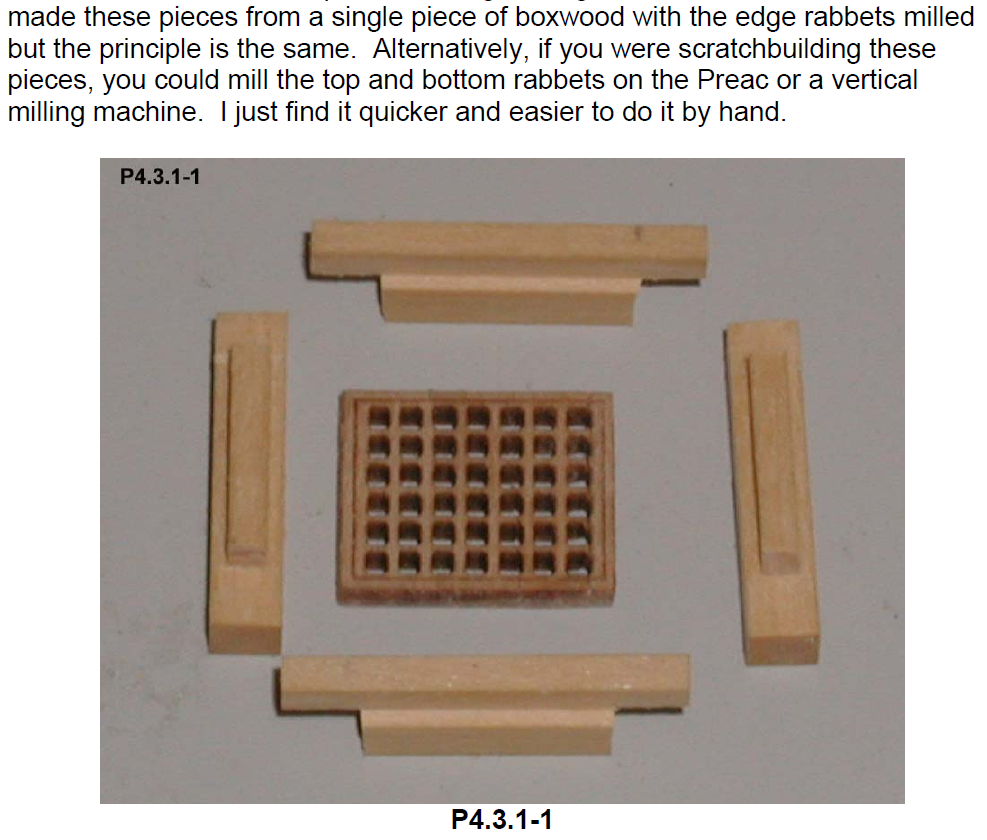

Just venting today.. While I ponder finishing options, I began working on the spar deck and hatch coamings. Thankfully, I double checked everything in the practicum before committing too much material and time to this phase of the build. 1. Hunt's instructions are to cut the foremast from 7/16" dowel and to make the opening in its mast partner to fit that diameter stock. The plans call for 3/8" inch, and the laser cut mast boot is likewise sized for a 3/8" foremast. 2. Hunt's instructions provide distances from the center line for the hatch coaming framework. There were several discrepancies there, as compared to the plans - most notably the dimension for the framework between bulkheads D and E. (my take? Trust, but verify.) 3. Adding another Practicum observation (May 20) for the benefit of anyone following Hunt's directions for constructing hatch comings. On pages 19 and 20 in Chapter 4, Mr. Hunt provides detailed instructions for fabricating the material needed for the coamings. Likewise on page 40 for the main hatch. He glues up three pieces of stock for each coaming. To boot, for the shorter coamings, because the kit didn't come with 3/32"x7/32" stock, he trims a piece of 3/32"x1/2" stock for the center piece. All well and good. But on page 26, where he shows the parts of the coaming in photo (P4.3.1-1), he says he I think I'll go the milling route myself. (I sure hope the zero clearance ring for my router table arrives soon. That will allow me to easily mill the material myself.) 4. Once again, the materials provided with the Model Shipways kit disappoint. All the dowels for the masts (5/6", 3/8" and 7/16") are misshapen - the 3/8" piece is completely warped. Were I to go ahead with the 7/16" dowel for the foremast, there wasn't enough material provided to then be able to construct the main mast. The dowels are all different colors ranging from near white to mahogany. Also, there wasn't enough 3/32" x 1/4" stock to complete the hatch coaming framework. Last but not least, the material for the deck planking is off by as much as a 64" inch in width and thickness. Having spent much time reviewing Cookster's 2013 build log for the spar deck and coamings (wow!), I've decided not to mess around with cruddy materials going forward. Even if I paint every thing later, I'm going to give myself better options by ordering replacement material from Modeler's Sawmill. (and before you ask, no, I'm not going to waste my time contacting Model Expo, where I bought the kit. I'm still waiting on the replacement material for the hull planking they said they were sending on December 1 of 2023. (Ticket #22286: replacement stock for USS Constitution kit)) Not sure where I'll invest my energy while I await material delivery. Maybe start the side galleries? Or take advantage of the nice weather?

-

I'll add my voice to those concerned about your health and well being. Loved your build log on the Model Shipways Constitution, and was sorry to see you stopped posting - hmmm, that was about the time you started this build.. Your workmanship and attention to detail are outstanding. Hope to hear from you soon'. Best Peter

-

Wes, I found your build log yesterday while researching planking of the spar deck. You haven't posted since November of 2014, so may have given up on your build. I hope not. If you're still occasionally checking in, I hope you're okay, and that you get back to the shipyard and this log sometime soon. All the best Peter

-

I've been following your Isabella build, and wondered why there haven't been recent updates there. No I know why. Boy do you like to keep a lot of balls in the air in your juggling. The planking here looks great. As you know, I debate (almost endlessly) with myself on the matter of painting vs showing off the workmanship. I'm still wrestling with that, but see you've made your decision. Looking forward to seeing the end result. Keep up the good work, and looking forward to your return to Conny (after you finish this and Isabella?)

-

USS Constitution by mtbediz - 1:76

Der Alte Rentner replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Hi there Mustafa, Did you stain the hornwood you used for the decking? Or is that just the way it looks with a coat of poly? Thanks, Peter -

For those of you who want a black hull, of all the things I've tried, Old Masters Carbon Black Gel Stain netted the absolute best result. Two light applications with a foam brush, solid black, no warping of the wood, and I know from experience, once it's cured, it will take a coat of clear polyacrylic. I will experiment further, to see if this can be applied over polyacrylic as well. Hello! In my digging through older build logs here, I found one by Cookster, who seems to be as finicky about workmanship and finish as I am. In his build log, on page 3 post 76, he discussed the merits of aniline dye. (This link takes you to page three of his build log). He seems not to have finished the project, but I will be consulting the build intently as I work through the planking of the spar deck.

-

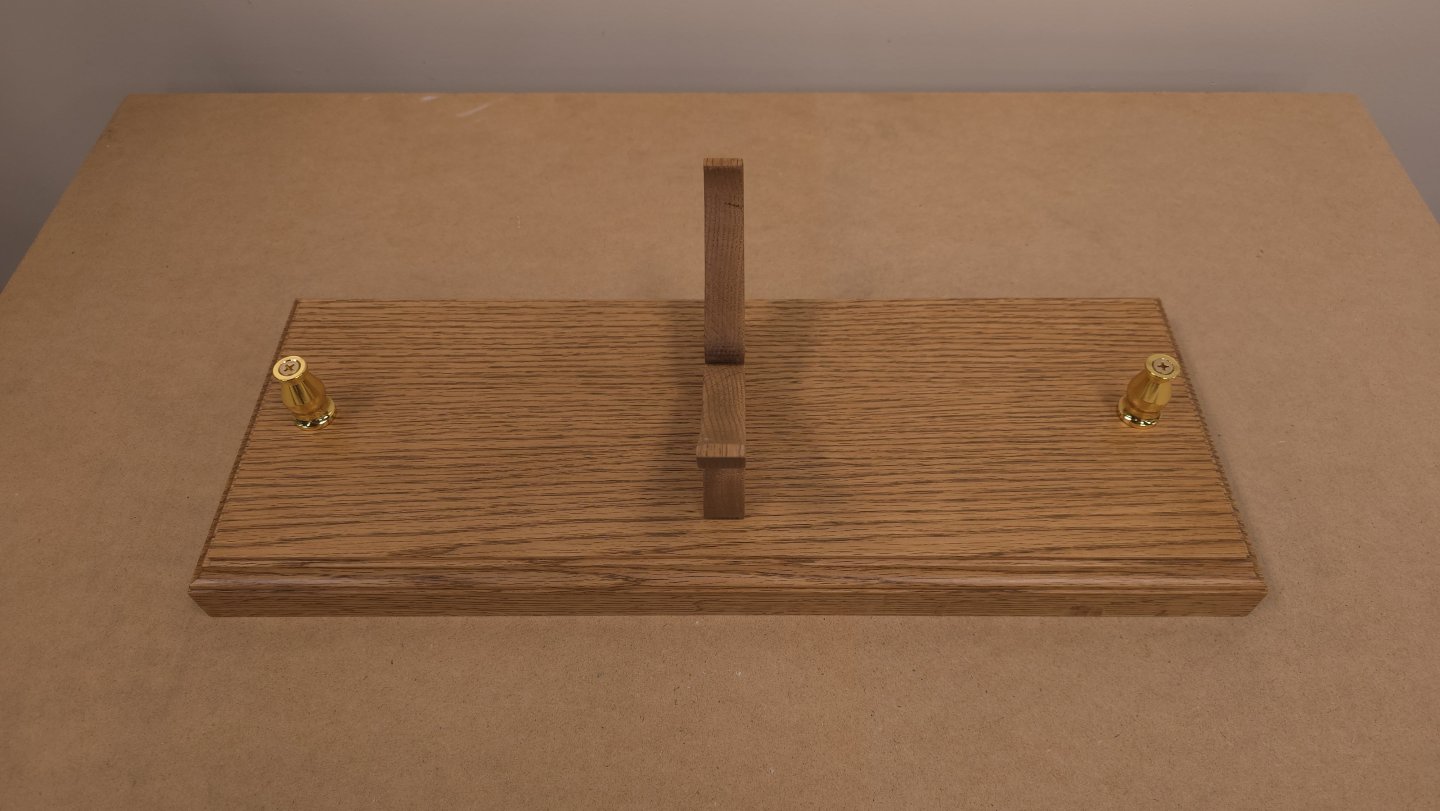

Chapter 3 ends with Mr. Hunt building a base with materials he had on hand. This is my own design, based on some photos of model ship bases I saw on the internet. The brass pedestals required counter sinking to allow the brass flat head screw to lie flush. I got the shape for the cradle from the plans for Buckhead J, which seemed to be the right place in the hull for the support. Some tweaking with drum sander required for good fit.

-

Yes, yes I have. However, as long as it took to get the first round of planking done, I'm not really thrilled about the prospect of repeating the process. My thoughts this morning are to try the stain first. If I like the way it looks, great. If not, covering the hull with the planking material provided in the Constructo kit may be preferable to painting.. P.S. your signature phrase, “Indecision may or may not be my problem.” ― Jimmy Buffett Made me LOL!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.