-

Posts

1,159 -

Joined

-

Last visited

About Some Idea

- Birthday 08/10/1967

Profile Information

-

Gender

Male

-

Location

Dudley Black Country England

Recent Profile Visitors

-

Some Idea reacted to a post in a topic:

Ring Bolts

Some Idea reacted to a post in a topic:

Ring Bolts

-

KARAVOKIRIS reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

KARAVOKIRIS reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

KARAVOKIRIS reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

KARAVOKIRIS reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

KARAVOKIRIS reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

KARAVOKIRIS reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

serikoff reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

serikoff reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

serikoff reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

serikoff reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

serikoff reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

serikoff reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

yvesvidal reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

yvesvidal reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

Keith Black reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

Keith Black reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

Hi Paul if you anneal the rings again before cutting they cut very easily with a saw. I’ve found that very sharp and small snips are far easier and do a similar job Mark

-

yvesvidal reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

yvesvidal reacted to a post in a topic:

Le Rochefort by Some Idea - 1/24th Scale - First POF Build

-

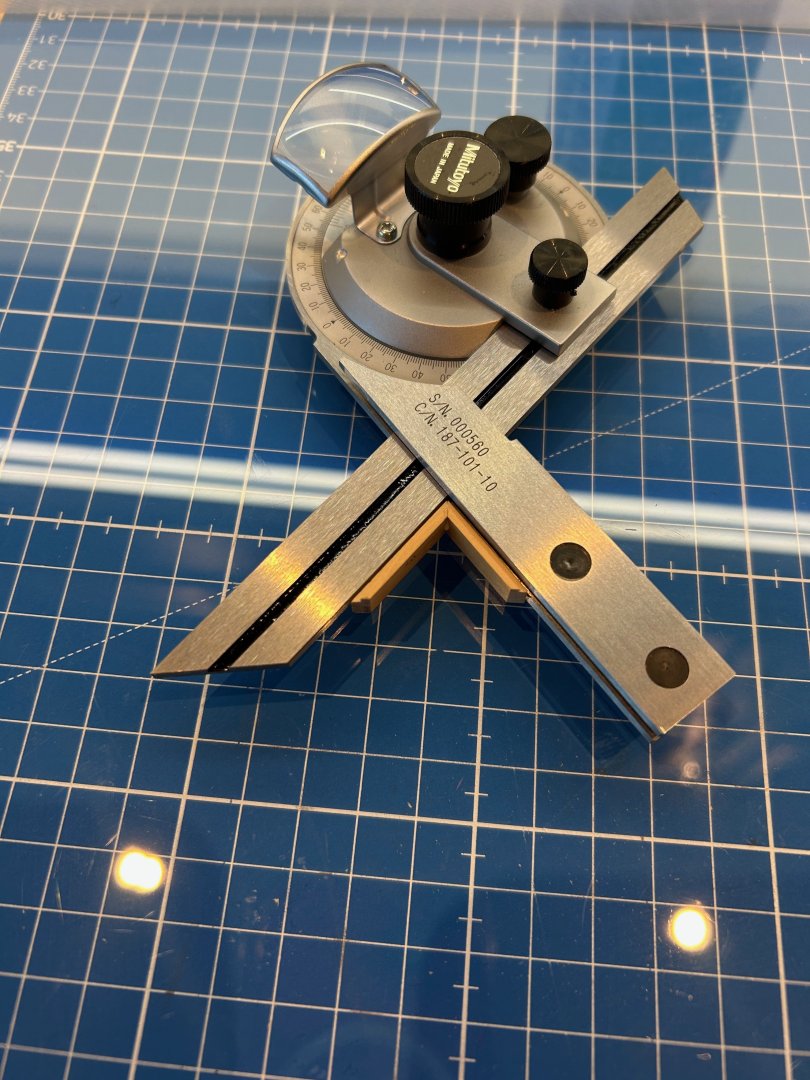

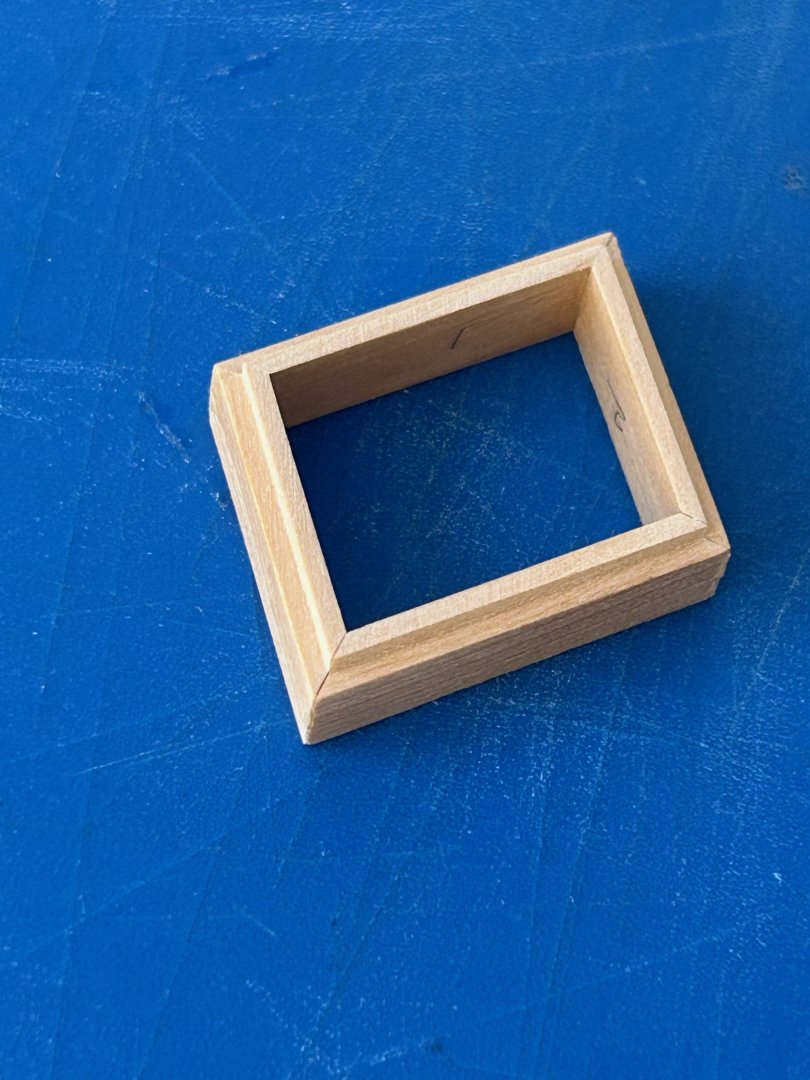

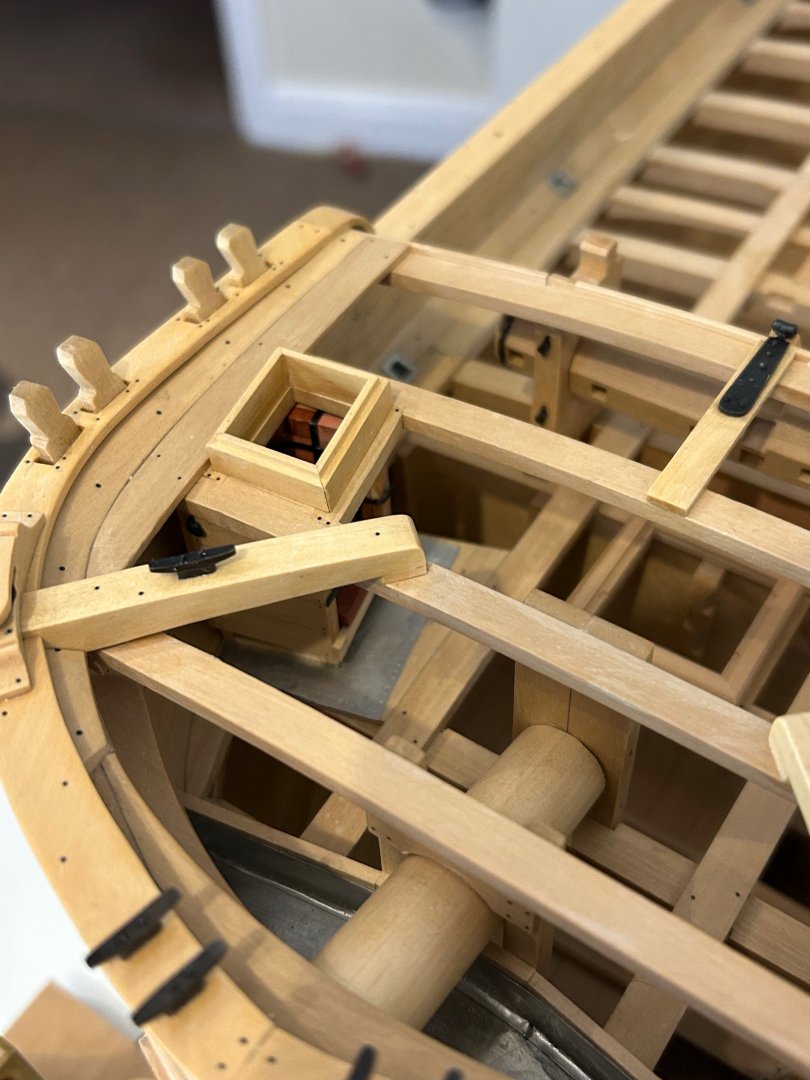

Thanks Andreas I'm following your fantastic build too. Only a little update this week. I completely forgot to make the supporting knees for the catheads; I only realised this when I was taking stock of the drawings and where I was now. They are so simple to make I think it took less than 20 minutes for both of them. However the fitting was a good couple of hours as like the catheads the knees are cut into the moulded and rail and partly the planking too. I just took my time but I think they finish the catheads off really nicely. Next I made the frame of the offset hatch just above the stove. This is a different construction to the other frames on the ship which I guess is this way due to it being higher up on the ship. I really wanted to get angles right on this frame as it's one of the first things you see when you look at the forecastle deck. I'm not going to make the cover for it as I like the open look so that you can see the stove below. Now apart from a few ring bolts I think thats the forecastle deck finished. My next task is definitely the pin rail Cheers Mark

-

If you want a nice polished finish close grained hard wood is probably the best for this. Personally if I want a really polished finish I work my way down the sand paper grades to 400 and then finish with a grey scotch pad. It's the scotch pad that gives the polished finish but is not a good surface to glue onto. If you want a mega polished finish Foredom sell pink coloured sanding discs which are 1600 grit. They really make wood shine but can only do small areas

-

L'Amarante by marsalv - 1:36 - POF

Some Idea replied to marsalv's topic in - Build logs for subjects built 1501 - 1750

Precise woodwork and lovely brass work; what's not to like! here It will be nice to see the stove sat on the area you have prepared too. -

Some more work done and this time it's the windlass pawl which is a very simple mechanism on this ship. Firstly I made the hinge out of brass but I forgot to take any photos of the actual process. It was quite simple really as all I did was to silver solder some 2mm tube onto some 1mm plate and then put it in the milling machine. The only issue I could foresee was that the holding point in the vice was very small so only light cuts could be taken. I also had the machine running at 10k rpm which lessoned the vibration during cutting. Why is it I always drill one hole out of line? I wouldn't mind but I centre punched it too........ The pawl has a wooden piece that it is recessed into - its this wooden part which locks into the windlass. Finally the completed installation and I'm glad to say that it did fit into the windlass My next job will be the hatch surround on the forecastle deck and then the pin rail. Thanks for all of the comments, likes and help Mark

-

What lovely carpentry and all by hand too - you certainly have skills with hand tools.

- 32 replies

-

- NRG Capstan

- NRG

-

(and 1 more)

Tagged with:

-

Gregory and druxey - thanks both for the information. Your ideas should definitely improve my efforts so I'll give them a go.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.