-

Posts

187 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ajromano

-

-

Thanks all for feedback!

-

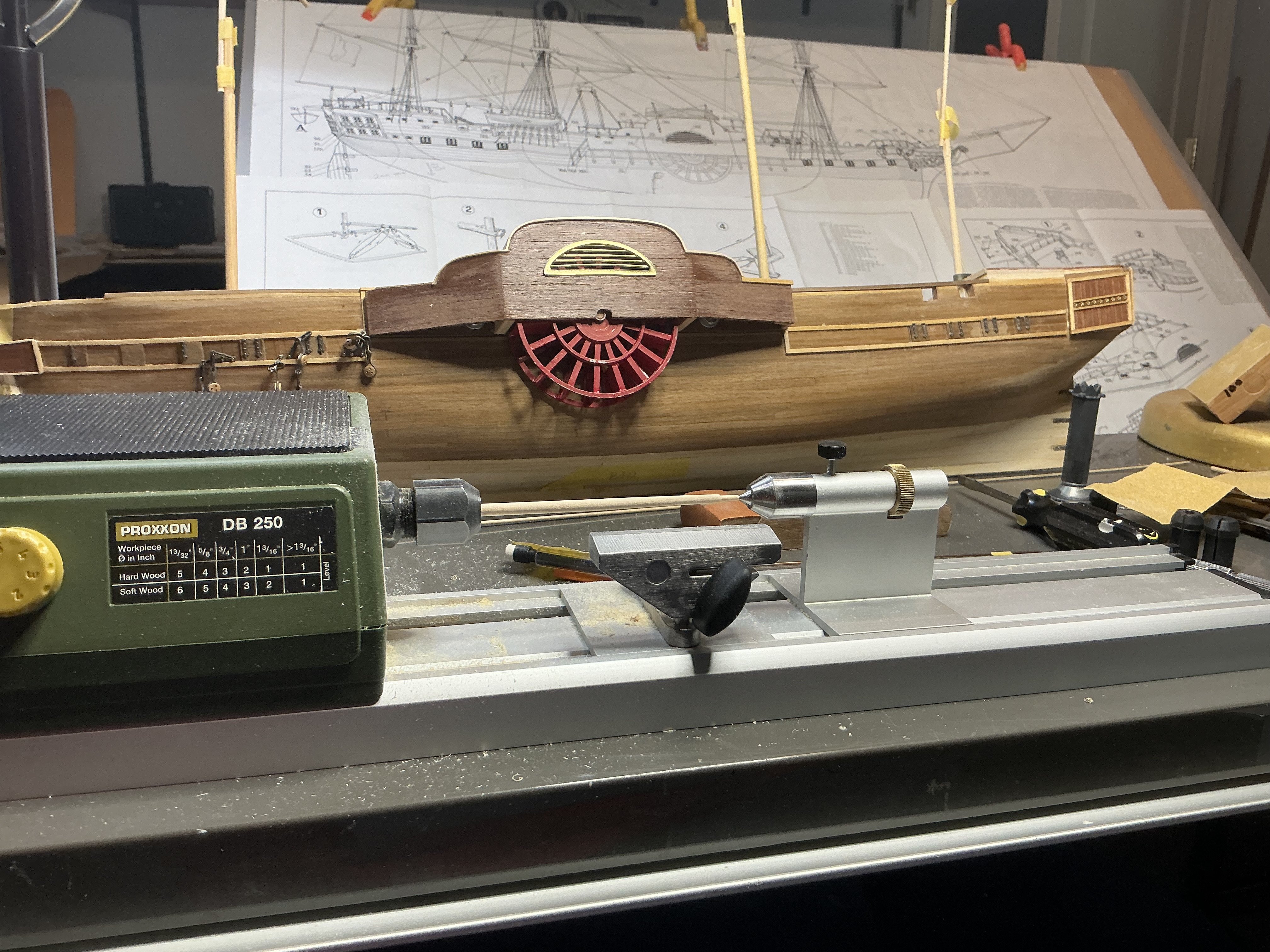

This is basically a training kit. If I wanted truly accurate I would scratch build or get more accurate kit. (Assuming there is such a thing) This kit was on sale and had additional discount applied. Wood ships and boats are such fun to build! Very challenging. Never rigged anything before, I have built several small boats and have current build of brig going. Model Shipways seems to actually be a tad better, especially if one paints ship.

-

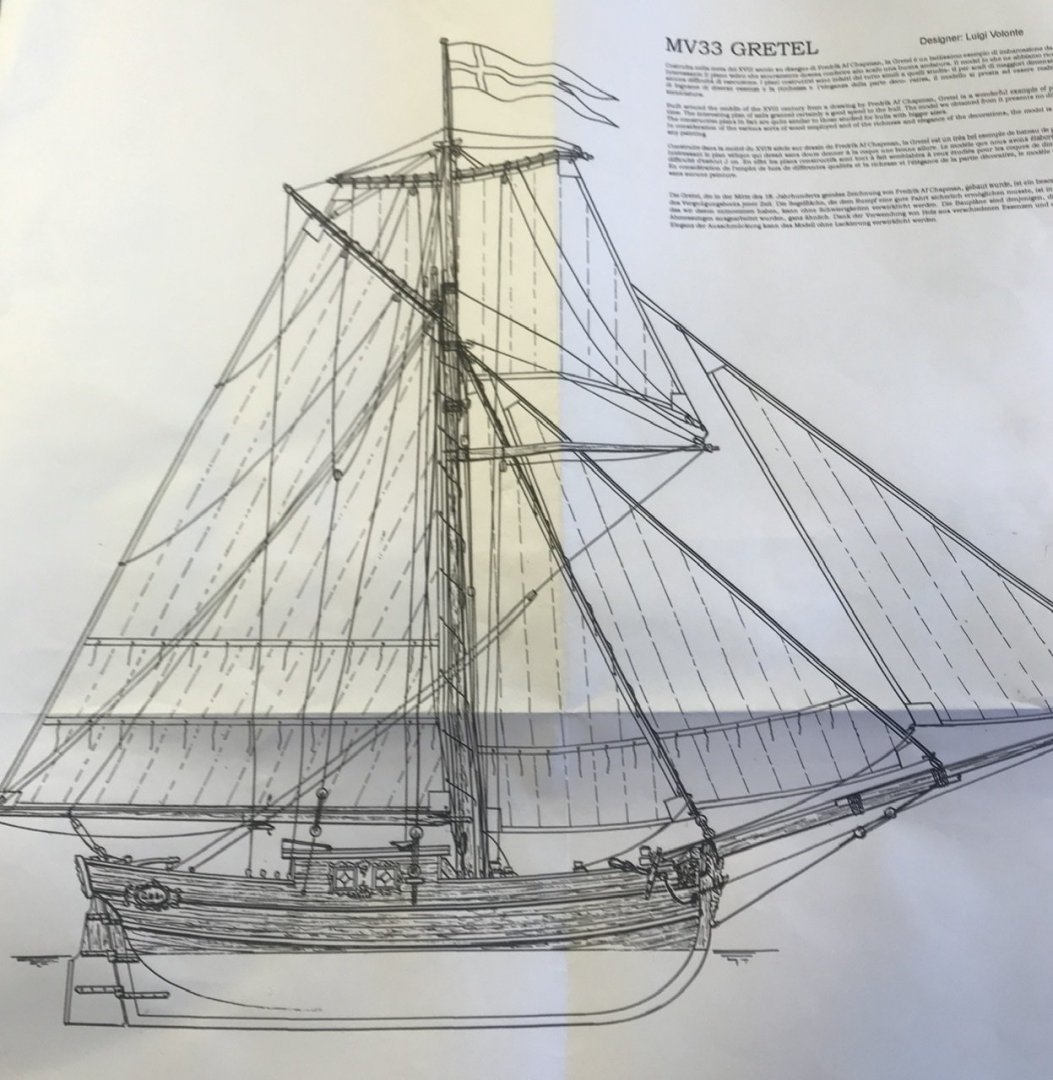

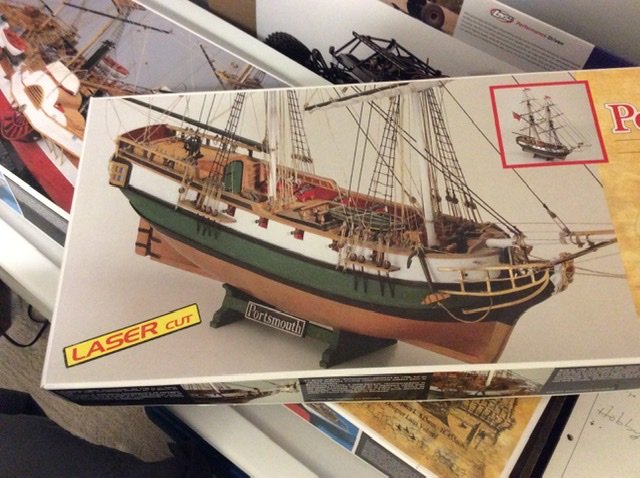

This looks pretty much like the kit.

-

This is actually a nice looking little boat, I have been almost fanatical about quality. Still missed a bit on planking, but it looks fine! Only I will notice flaws.

-

Thanks. I assumed it was totally inaccurate. Small boat! Real boats use I-bolts?

-

On the hull?

-

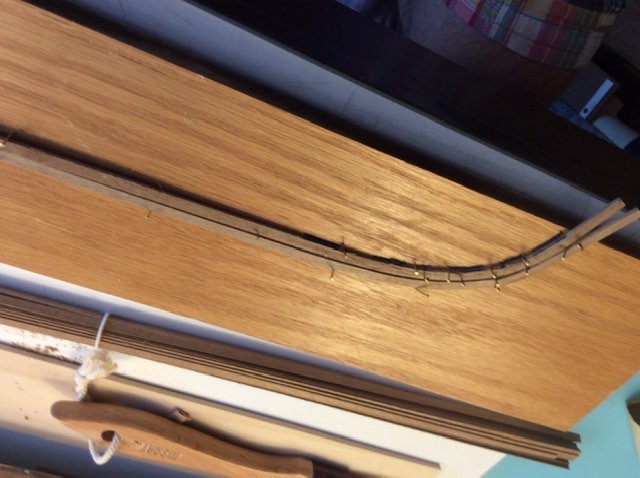

Seems to be close to what is called a naval sloop or Bermuda Sloop. I am getting way this would work in real life. Blocks attached to little brass “I bolts” seems wrong! This is worse than model trains!

-

-

-

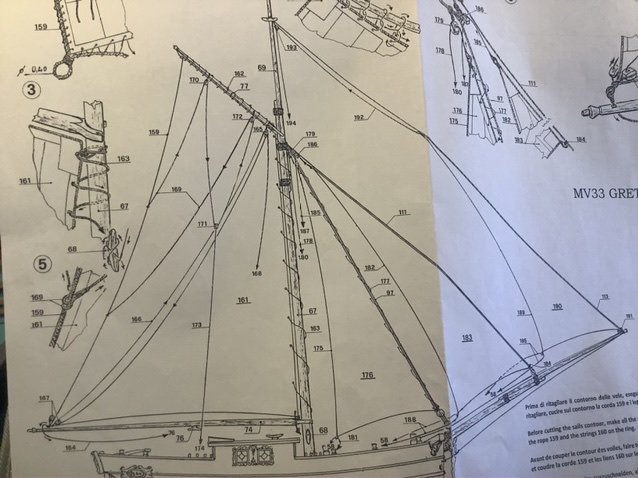

I think it is just a inaccurate kit. I will post more details later. Thanks, I reached same conclusion or question. How to reach upper mast to secure sail. Also I do not know all the proper terms! More reading in order 😉

-

Is this close to how a real boat would be rigged? Looks like mainsail would be furled to mast......?.??

-

Byrne's Table Saw additions/add ons

ajromano replied to blackjack40's topic in Modeling tools and Workshop Equipment

LOL! Discussion over before it started! With wife about cost of shoes. -

Byrne's Table Saw additions/add ons

ajromano replied to blackjack40's topic in Modeling tools and Workshop Equipment

Impressive! I am close to ordering one! -

Brig Eagle 1814 by ChadB

ajromano replied to ChadB's topic in - Build logs for subjects built 1801 - 1850

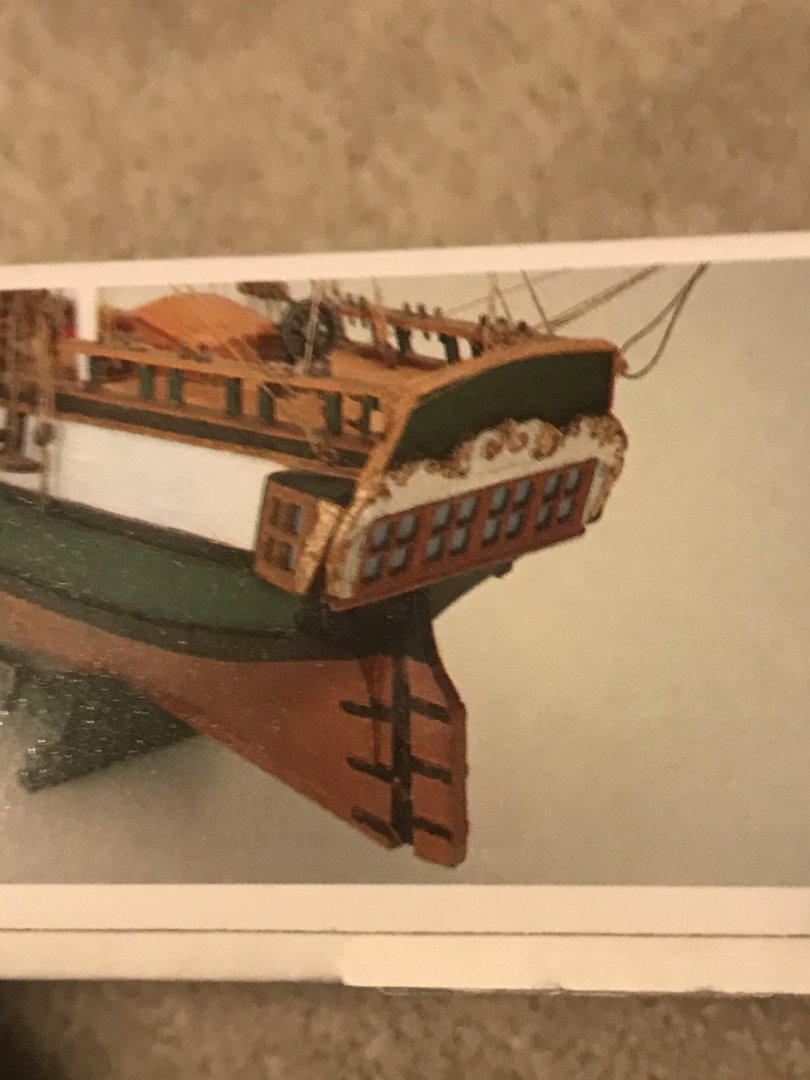

Fantastic build! Picture perfect quality, masterful!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.