-

Posts

187 -

Joined

Content Type

Profiles

Forums

Gallery

Events

Everything posted by ajromano

-

I have plenty of skill, it is experience with ships I lack. The sample wood is much bigger than planking on actual ship. I am planning on using some kind of jig and mini drill press if I do fake nails on entire ship. I think however with this Bass wood, painting is going to be way to go. Adds protection a hard shell layer.

-

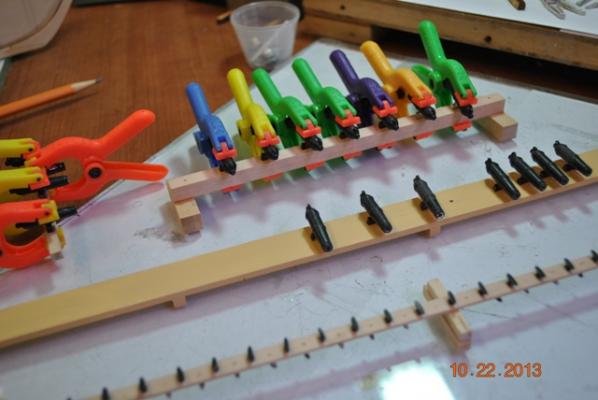

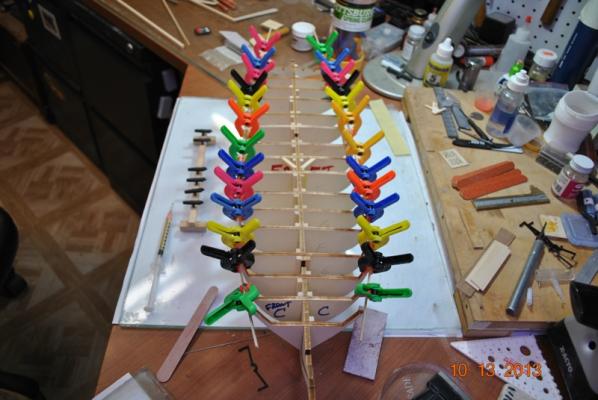

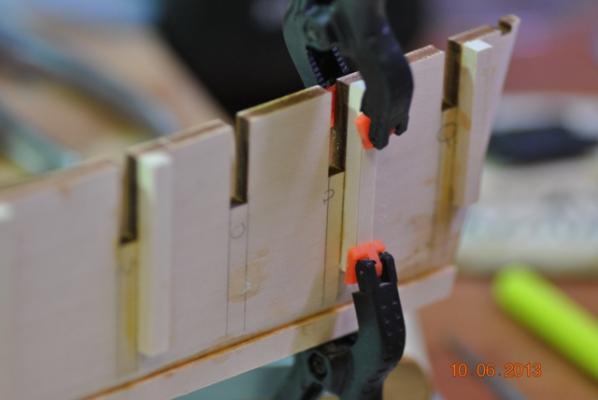

After reading Bob's build I decided to try a little washing test. One sample has CA on surface other does not. The sample with fake nail holes also has faked joint. I used MS latex paint and tap water. I think the proper way to do washes on wood is to seal with sanding sealer, sand then use solvent based paint thinned 10:1 or so or use ink thinned. Washing will show all glue spots, I am now thinking washing over painted deck vs raw wood maybe better. Bass is really not a stain grade wood, too much like sponge. The sample without nails has slight beveled edge to expand joint, I did a pass or two with 400 grit on block. More clamp mania!

-

I made a sanding block for inside curve. This is a piece of a changable sign from an office building, I sanded off holder part and CA glued 400 grit. The 4 steel blocks are from Modrl Expo, work very good holding bulkheads. They were on sale for next to nothing, 3 bucks vs 17. A little side project, again on sale. Model Expo has great sales on Sunday, Monday abd Tuesday. I check often and think there is a pattern for really good sales. /////my guess is they try to keep x dollars of sales daily.

-

20 clamps for 5 bucks, I bought 2! I thoughy there was a bit of silly humor in the clamp mania! The work area is not bad at all, good light and TV! I do have too many items in there and rest of house 25 years of toys! I am finding this a pretty easy build the first bulkhead was the real work. I ordered a Jim Baryn's sander, my old dremmel moves around too much, it was my Dad's and must be 40 years old.

-

Be glad you have a boss!! Mine quit, I spent too much time and money on toys! (And she lost her mind in 2006!) LOL Great little boat! I built 3 Midwest kits as training. I want to do more from plans, when I get my Jim tools!

- 109 replies

-

- zeeschouw

- billing boats

-

(and 1 more)

Tagged with:

-

CA is a bugger to work with. I use it only if nothing else does job. There are tips from Tower and a set spray that help. Every time I use it I swear never again. Epoxy is actually much more user friendly, the longer the cure time the better the bond, it can be thinned to use as paint as well. Ebony seems like a real bugger to work with, being a nut I will have to try it!

-

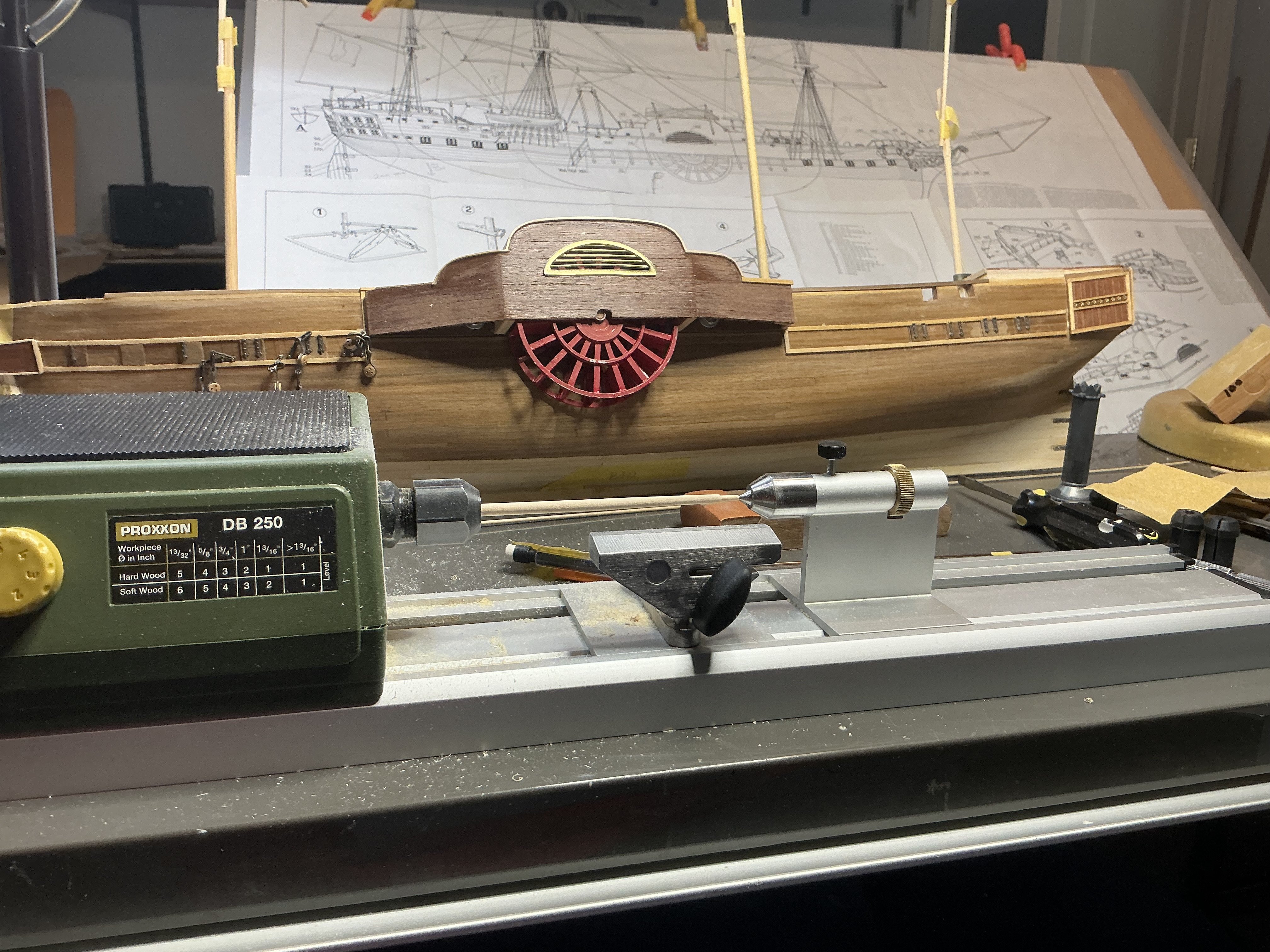

Tower (great planes) also has great sanding bars. I make custom shapes out of scrap hardwood, square, rounds, whatever shape needed with 100 to 400 grit thin CA works great. I guess I joined the club this week. I started building Coral Greyhound, but after reading about how bad the plans and bulkheads are I ordered a book to get good drawings and put it back in the box. Started to work on Niagara, much better kit.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.