-

Posts

136 -

Joined

-

Last visited

About Daliab

- Birthday 07/21/1949

Profile Information

-

Gender

Male

-

Location

Bellevue, Nebraska USA

-

Interests

woodworking, computers, now model boat building

Recent Profile Visitors

-

ccoyle reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

ccoyle reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

GrandpaPhil reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Ian_Grant reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Ian_Grant reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

GrandpaPhil reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Landlubber Mike reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Landlubber Mike reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Landlubber Mike reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Landlubber Mike reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Holy Cow! Spent $250 for the oak lumber to build a similar display case built 2 years ago (pictured). Checked on the price of double pane glass for the display case.... $360. Total $610. The case will almost cost more that what I paid for the Mantua/Panart 738 kit. Crazy.

-

GrandpaPhil reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

GrandpaPhil reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Made a new display stand for the Victory today from Olha Batchvarov's Youtube video. Although the original design was for a smaller model, it also worked with a 57" long model with very little modification. Next I have to build a new display case similar to the one the Smuggler is housed in.

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Daliab reacted to a post in a topic:

Missing kit parts - what's a person to do?

Daliab reacted to a post in a topic:

Missing kit parts - what's a person to do?

-

Over the last year and a half, I keep reading about missing parts in kits from members of this forum. I to have been short changed in parts and have emailed the manufactor's sponsored UK store where I originally purchased the kit only to hear crickets in return. As everyone can agree these kits aren't cheap, not counting shipping. Why, as a forum, we don't publish a listing of kit manufactures with their contact info that we as individuals can use to get the missing parts replaced. Hobby store only sell the products thus the reason for the unanswered emails. Going to the manufacturers goes to the source where the problem can be fixed. This forum, with all its members, can make or break a manufactor's kit based on the quality and workmanship of their kit. When parts are missing, I don't care how good the quality/workmanship is, it's a ding against their product and doubly frustrating when you don't hear back from them when you reach out to them for replacement parts. I'm sure manufactures zero in on sites like this to see what they say about their products. I've seen new, upcoming, kit manufactures be very responsive to individuals on this site but this not the norm..... but we're buying from these new upcoming manufactures. Manufactures want you to buy their products and not pirated kits that are cheaper. What say you? Is it possible to publish contact info of kit manufacturers?

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

gieb8688 reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

gieb8688 reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

gieb8688 reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

gieb8688 reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

gieb8688 reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

gieb8688 reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

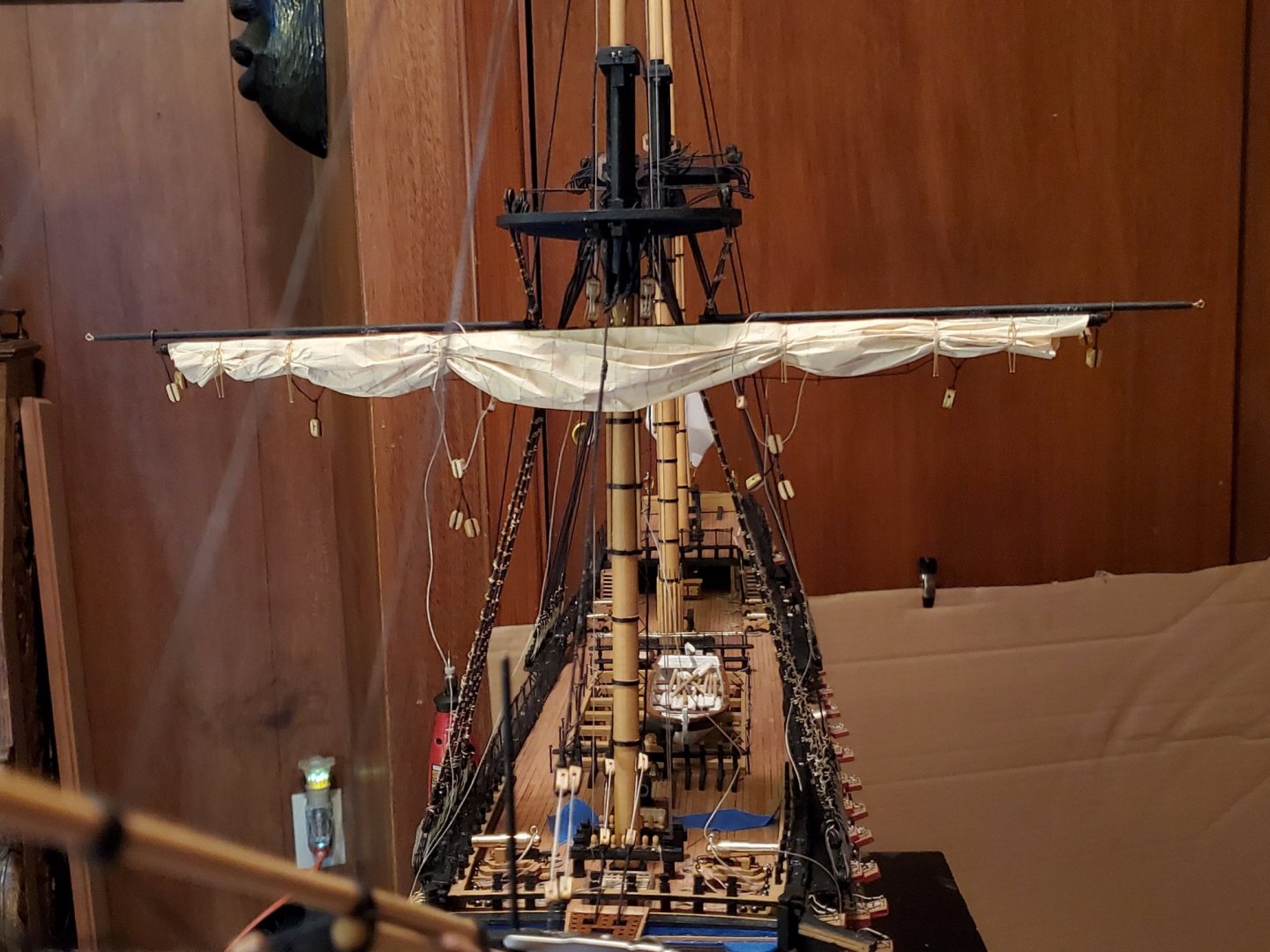

Completed the main mast this evening with exception of some of the lines temporarily omitted so as not to interfere with the detail work on the mizzen mast tomorrow. I'll add those lines when yards, sails, and lines are added.

-

David56... Glad to hear things are on more of a positive path for you and your family. As for your new build log, I'll be on the lookout for it. After building Mantua's Victory, I too would have been tempted to build the Caldercraft version of the Victory after your Mantua version was destroyed by a house fire. I was more motivated by price and didn't realize at the time the kit had changed as much at it has, in particular to the the stern cabins. I think the Caldercraft version looks better from the builds I have seen. I think you might be happier with the new choice if you didn't mind paying a higher price. I'll be watching with great interest. Thank you for your past help and advice on my build. It help a lot! Stay healthy and safe and prayers to you and your family.

-

Moving right along with furling sails and adding the rigging on just the bowsprit and foremast. Moving to the mainmast tomorrow.

-

Taking a break on installing ratlines and moved to adding furled sails using silkspan. I like the looser look on the furled sails and to me it may not be correct, but has a better presentation of the model's sails.

-

While waiting for missing parts to arrive from model ship venders, I managed to build/mount all three masts. Warning: For those who may order a Mantua/Panart HMS Victory 738 kit, I was missing 70 each 7mm single blocks, 11 each 7mm double blocks, the wrong size belaying pins. Pins were to short to extend below the belaying rack holders to tie ropes on each one. Some may say you should have done an inventory of pieces supplied. Problem the kit they currently sell today is the same kit sold years ago and the instructions show pictures of stuff they don't even cover. All of the accessories were packaged in a hard plastic units that were mounted on a cardboard panel. You can't loose any pieces unless you open everything and loose track of the parts. Unfortunately, you don't know what your missing until you get to that part of the build when those parts are needed. I've emailed the Mantua vender in the UK where I purchased the kit from and still haven't heard back from them... don't expect to either. The issue is with the worldwide pandemic, lots of modelers are spending time on their models. I've noticed that a lot of suppliers are out of models and accessories parts with no date when they expect to be resupplied. I do have to say that the Mantua/Panart HMS Victory 738 has been a fun build, just a little irritated that parts were missing.

-

Getting better making sliksapn sails. Many will say that the furled sails are too loose. You're right but, I wanted to expose more of the sails in a furled position than a sail rolled up in a tight mass. To this novice, I think it looks better for the overall presentation of the model.

-

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

Daliab reacted to a post in a topic:

HMS Victory by Daliab - FINISHED - Mantua/Panart

-

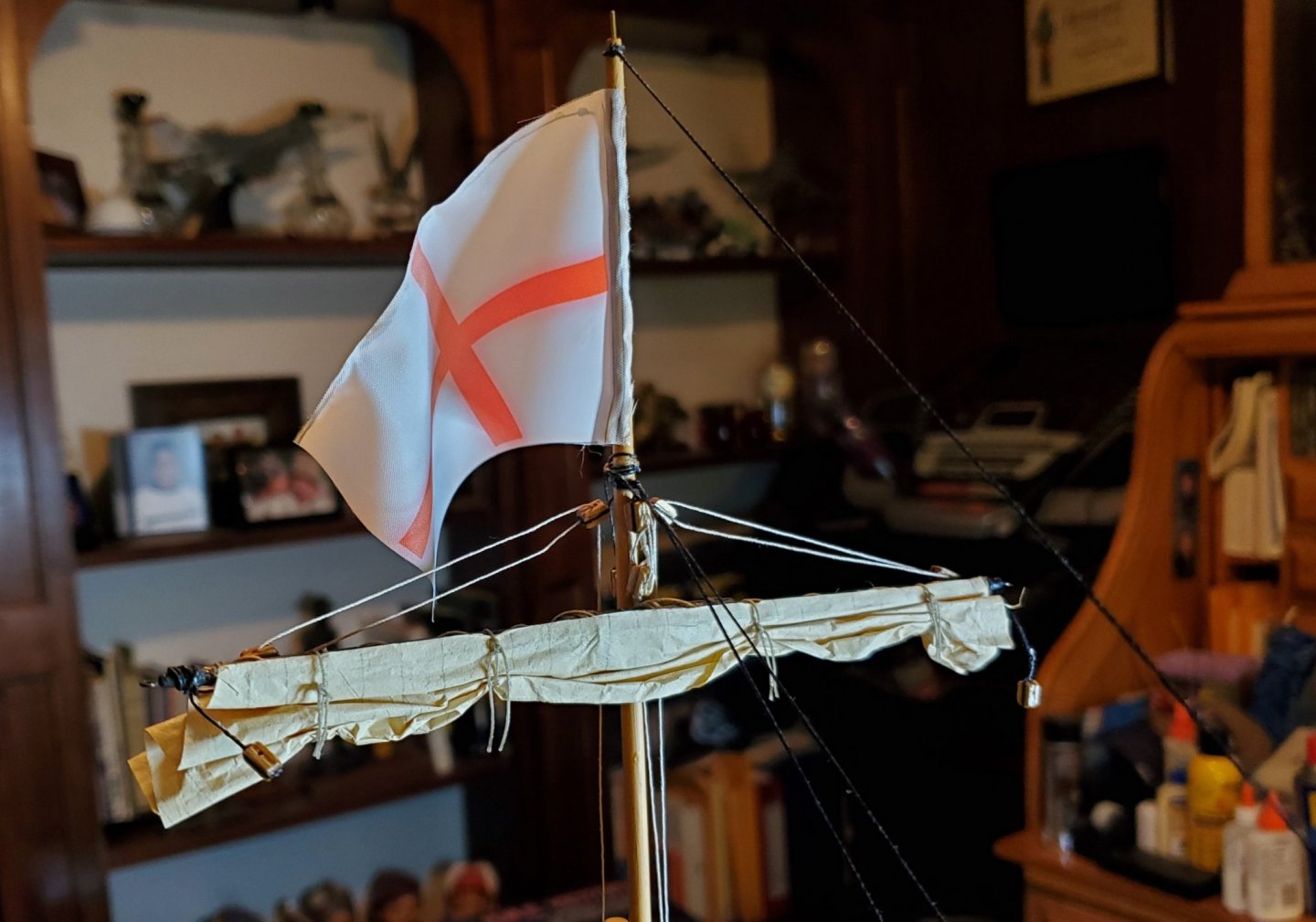

Took Tom Lauria's advice and used silkspan for the sails instead of the lightest weight muslin the local fabric store carried. I think this one looks less bulky and when wet, it was much easier to fold and tie to the yard. I believe I will use silkspan on all of my furled sails.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.