-

Posts

74 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Auckland, NZ

-

Interests

Cars,computers, ships, naval history, games, books.

Recent Profile Visitors

-

popeye the sailor reacted to a post in a topic:

Licorne by mtaylor - (POF) - 3/16 - TERMINATED LOG

popeye the sailor reacted to a post in a topic:

Licorne by mtaylor - (POF) - 3/16 - TERMINATED LOG

-

modeller_masa reacted to a post in a topic:

Proxxon PD230 metal lathe and CNC kit short review

modeller_masa reacted to a post in a topic:

Proxxon PD230 metal lathe and CNC kit short review

-

Duanelaker reacted to a post in a topic:

Proxxon PD230 metal lathe and CNC kit short review

Duanelaker reacted to a post in a topic:

Proxxon PD230 metal lathe and CNC kit short review

-

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

-

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

-

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

-

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

-

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

billocrates reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

-

Have you ever read BRENTON'S NAVAL HISTORY? It has mention of this Blanche action among many other frigate actions.

-

Hi Mark It is a photo of part of a print I got from the Maritime Museum showing the Blanche in her last battle. You can find it here: http://prints.rmg.co.uk/index.cfm?event=catalogue.qsearch&searchstring=PY8041 They scanned their negative and printed it. Here is my photo of the print which I have hanging in my modelling room to remind me of what I should be doing ..... Cheers Rob

-

robbl reacted to a post in a topic:

Licorne (1755) by mtaylor - (POF) - 3/16 - French Frigate (Hahn) - Version 2.0 - TERMINATED

robbl reacted to a post in a topic:

Licorne (1755) by mtaylor - (POF) - 3/16 - French Frigate (Hahn) - Version 2.0 - TERMINATED

-

robbl reacted to a post in a topic:

La Salamandre by tadheus - 1:24

robbl reacted to a post in a topic:

La Salamandre by tadheus - 1:24

-

robbl reacted to a post in a topic:

Licorne (1755) by mtaylor - (POF) - 3/16 - French Frigate (Hahn) - Version 2.0 - TERMINATED

robbl reacted to a post in a topic:

Licorne (1755) by mtaylor - (POF) - 3/16 - French Frigate (Hahn) - Version 2.0 - TERMINATED

-

The kauri I have is not as nice as the totara to be honest. The totara that has been fence posts or something outside is a bit hard to put a nice edge on sometimes but has a nice dark colour, but the totara that used to be internal or furniture is lovely. That and the big block of totara I have are a nice reddy brown and cuts and shapes a treat. Matai is nice but the colour variation of the floorboards is apparent when used on the model. It works ok for the bulkheads though. I have some ancient kauri that was cut up from old church pews that I have yet to try out properly that might be good. I also have some rimu, and I like that to work with as well.

-

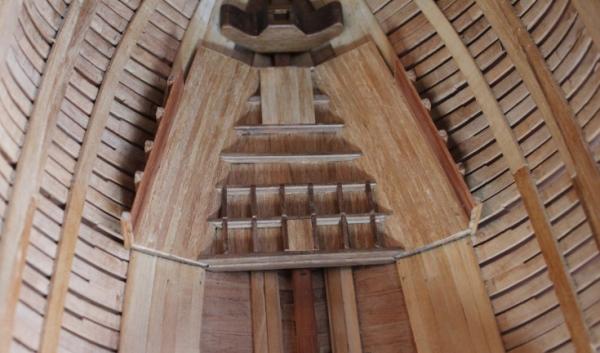

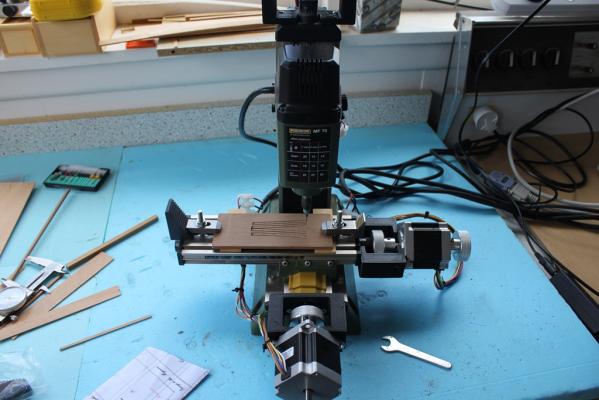

I am happy to see the end of 2014, as it was a year of health drama in the family and not a lot of building work at all, but there has been a little bit of progress in making the forward magazine and platform. I intended to build this in the same way as the aft magazine and platform, by building the both off the model to make it easier to work on them. I think it went ok, however I got seriously confused with my measuring and the platform was way too high at the bow, Some sanding of the platform and the clamps remedied that, and the magazine fits comfortably under it in place. Next for these will be completing and fitting out the magazine and adding the filling room, light boxes and structure that surrounds the foremast step before fixing the platform in place over it. I think I will have to fit the bitt pins in place as well. The first few pictures show the magazine being formed by first laying out the beams then the planking. It currently finishes where the light boxes will go and will later be extended forward. As I mentioned above, the platform was built mainly off the model. There are still a few ledges to be fitted, but it is mostly complete apart from planking and a couple of timbers forward. Finally, where would I be without my toys. Making the knees has been relatively easy since I fitted some CNC gear to the Proxxon mill

-

robbl reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

robbl reacted to a post in a topic:

HMS Blanche 1800 by robbl - 1/48 - POF - was HMS Euryalus 1803

-

Hi Jan You pose a very good question that I have spent some time pondering. I have, a couple of times, tried to get an idea of what figurehead to use but with no luck. It is something I intend to look at later and will probably need to research it correctly rather than try to google it. I have a couple of books on figureheads, but they haven't helped apart from being good reads. Are you going to rig yours? Cheers Rob

-

robbl reacted to a post in a topic:

HMS Atalanta by tlevine - FINISHED - 1775 - 1:48 scale - from TFFM plans

robbl reacted to a post in a topic:

HMS Atalanta by tlevine - FINISHED - 1775 - 1:48 scale - from TFFM plans

-

robbl reacted to a post in a topic:

HMS Pandora 1779 by Bruno Siljeg - 1/48 - Navy Board Style

robbl reacted to a post in a topic:

HMS Pandora 1779 by Bruno Siljeg - 1/48 - Navy Board Style

-

robbl reacted to a post in a topic:

HMS Pandora 1779 by Bruno Siljeg - 1/48 - Navy Board Style

robbl reacted to a post in a topic:

HMS Pandora 1779 by Bruno Siljeg - 1/48 - Navy Board Style

-

robbl reacted to a post in a topic:

Licorne (1755) by mtaylor - (POF) - 3/16 - French Frigate (Hahn) - Version 2.0 - TERMINATED

robbl reacted to a post in a topic:

Licorne (1755) by mtaylor - (POF) - 3/16 - French Frigate (Hahn) - Version 2.0 - TERMINATED

-

robbl reacted to a post in a topic:

HMS Atalanta by tlevine - FINISHED - 1775 - 1:48 scale - from TFFM plans

robbl reacted to a post in a topic:

HMS Atalanta by tlevine - FINISHED - 1775 - 1:48 scale - from TFFM plans

-

Here's pics... and for those who wanted it.. a picture of (naturally) the sawdust from cutting the pieces. Ahhhhhh, there's nothing like the smell of sawdust in the morning ....

-

Hi all Being distracted by new toys, followed by work, I haven't done much that was photo worthy, so I thought I would post a couple of "proof of life" shots having just finished the orlop deck framing. In the background of the photos you can see the aft magazine with roof and hoods on. Some scratches still need to be smoothed out on this, and the flash makes it look worse than it really looks. There are bulkheads still to go in either side of the aft magazine, and the platforms will be planked, but until I start work on the forward magazine and platform I won't decide how much to plank. At this juncture I would say I am not a fan of carlings and ledges .... only the fore platform, two full decks, quarter deck and forecastle to do, then no more of them - yay! Cheers Rob

-

I suspect "kindling" would be frowned upon below decks of a wooden ship ....

- 1,449 replies

-

When you start putting frames/keel etc into that, how do you stop it sticking to the mold while gluing the joints? I thinking treating the mold with oil might do it? or is that what the furniture polish will do? I only ask because my construction technique involves glue getting all over the place..... Cheers Rob

-

Proxxon PD230 metal lathe and CNC kit short review

robbl replied to robbl's topic in Modeling tools and Workshop Equipment

Ah ha! Thank you David, that helps a lot. Cheers Rob -

Proxxon PD230 metal lathe and CNC kit short review

robbl replied to robbl's topic in Modeling tools and Workshop Equipment

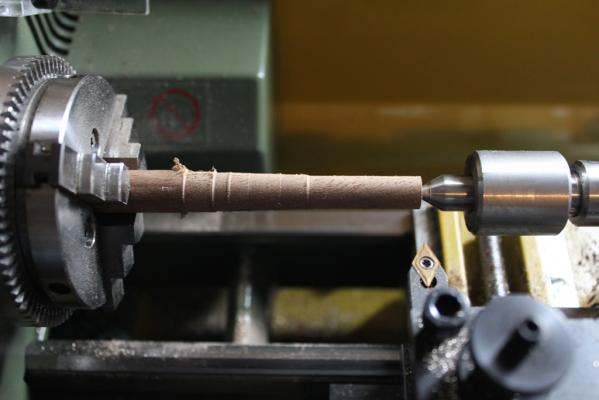

And this year's "Cannon Award" goes to ...... Getting better but a couple of fixes to make yet. Finish was ruined because, as I found out, turning the thin area behind the breech causes the rest of the barrel between that and the tail stock to move slightly .... tarnation! I will have to make that step happen after the fine finishing turn of the barrel. To give an idea of accuracy, I had the lathe turn a length of brass down to 0.2mm. The rod connecting the barrel to the pedestal in the attached picture is .9mm Cheers Rob -

Proxxon PD230 metal lathe and CNC kit short review

robbl replied to robbl's topic in Modeling tools and Workshop Equipment

Hi Brian, sorry should have added the specs. Centre distance: 230mm Editing the first post to add tech specs and a couple of photos of wood turning. Cheers Rob -

Having cleared the cupboards of some my old unmade plastic models and generated some spare cash, I finally splashed out and got a metal lathe, so I thought I might make a couple of notes about it. I am a lathe novice, so if I get terminology wrong, I apologise. My requirements included: Light weight so it can be stored in a cupboard or moved outside for use Able to turn 45 mm diametre (I hope to make a 1/24 scale cannon and a carronade) Able to use a variety of tools Able to take a CNC kit to repeat jobs accurately and to cope with tapers and curvey bits Locally in NZ, the Sieg machines and a lot of clones are available. They are cheap but quite heavy at between 35 and 55kg for the small ones. So in the end I chose a Proxxon PD230 which weighs in at 10kg with its clothes off, can turn up to 56mm, can use small lathe tools (up to 8x10mm tools) and has various CNC kits available on the market. Technical specifications: centre distance: 230mm swing: 52mm height over cross slide: 28mm cross-slide travel: 60mm top slide travel: 45mm steel toolholder: accepts 8mm x 8mm cutters spindle bore: 10.5mm thread cutting capability: 0.5mm, 0.645mm, 0.7mm, 0.75mm, 0.8mm, 1.0mm, 1.25mm, 1.5mm spindle speeds with reduction: 3,000rpm, 900rpm, 300rpm automatic feed resolution: 0.05mm/rev or 1.0mm/rev tailstock spindle: MK1 bore (short) tailstock travel: 30mm internal chucking capacity: 2mm - 35mm external chucking capacity: 24mm - 68mm handwheel resolution: 1 revolution = 1mm feed (40 divisions) mass: 10kg dimensions: 530mm x 250mm x 150mm The lathe came with 3 jaw chuck and live centre and a few bits and bobs for threading and gear cutting, which I do not plan on using. In addition, I got (over the following couple of weeks) splash guard/tray Quick tool change post plus extra tool holders Proxxon's HSS tool set (5 tools) Fixed steady Boring tool set Tail stock drill Tool holder for rotary tools (Dremel etc) Set of 7 indexed tungsten carbide tipped tools (on special from sieg shop here) The 8mm high x 10mm wide tools fit in the tool holders made for the quick change tool post. Out of the box, the PD230 is almost ready to fire up after a quick check on the various fittings. It runs surprisingly quietly, and is very compact (in fact the lathe could sit inside my HMS Blanche). I got some Acetal (Derlin) rod for practising on and created a bit of a mess which pleased me no end. With the tools all adjusted for height and distance from the centreline, it is very easy to swap tools around in the middle of a job. I got used to facing and general turning (the lathe has an automatic feed if required) but the one task I am struggling with is parting and deep grooves. At the moment I am avoiding both tasks by using a saw. The CNC kit came from Ideegeniali.it, and it arrived shortly after the lathe did. They claim it only takes 5 minutes to assemble, but it took me about 10 minutes ... but who's quibbling. Wiring it up wasn't difficult either, and then it was time to consider the control software. I chose Mach3, which requires a PC with an printer port. That took a bit of finding, but after a bit I had everything hooked up and ready to go. Ideegenialli supply configuration files for Mach3, so apart from a couple of minor tweaks the computer soon had control over the lathe, with the ability to make moves in the X and Z axis rapidly or jog tiny distances. With the kit in place, I can still manually work the lathe, although I need to remount the original hand wheels onto the stepper motors to make that easier. I already have a CAD/CAM program, so the next step was to create something. I worked up a drawing of a carronade and a cannon from Wayne Kempson's plans in Allan Yedlinski and his book Euryalus V2 and started testing. The testing taught me a few things about tool selection and pathing, as well as how to cope with the complex shapes, such as the breeches of the cannons and carronades. Under CNC control, the carronade can be turned in one job (several passes) with a single tool, while I am turning the cannon first from the barrel back with one tool, then flipping it in the chuck and turning the breech end using two tools (here the quick change post comes into play). I still do facing, drilling and parting off manually. The jobs are not perfect yet, as I have a couple of issues to work out: When I flip the cannon to turn the breech end, the chuck marks the barrel. I am contemplating leaving a V groove oversized in the barrel to slot the chuck into the barrel, then manually turning that out at the end of the job. The finish is not as good as I would like, which I think is a result of tool choice. When turning from the left or right, it is really nice, but the 55 degree straight tip is leaving grooves. Multiple finishing passes clean these up, but a better tip might be a plan. Parting ... if I can't do something manually, then there is no way I'm going to do it under CNC control. I think I have the height correct (on or slightly higher than centre) and am feeding slowly, but it just doesn't work well for me. This may be due to the plastic bending away from the tip, then trapping the tool as it flexes - brass may be better. Or I am parting to far away from the chuck, or with the part still under pressure from the tail stock it is trapping the tip. Conclusions: Pros: The lathe is more expensive than others, but meets my requirements for space and capabilities. Accuracy of the lathe is impressive, but I can't compare to other brands. The CNC kit works well and lets me do things I think I would struggle with (complex curves and repeat jobs) Both the lathe and the CNC kit worked straight out of the box. I spent (and still spend) a lot of time looking for hints and tips on turning - that is time well spent. Con: The operator is a bit inexperienced and could do with a bit of learning. Overall, a nice machine to have and I am glad I finally took the plunge. Cheers Rob PS: some wood turned - old walnut dowel from an old damaged kit.

-

The CNC mounting parts and controller were a kit from Italy, and took about 10 minutes to set up. Motors, power etc can be sourced locally.

-

Hey Daniel, there's no such thing as a bad question. If people didn't ask "why is that like it is" I wouldn't go back and correct the deliberate errors I make to test peoples' observational skills....... Nils, every time I look at the forum I see new things to try and parts to make - the work done here is inspirational to say the least, for example your Pamir. As for me, no progress this week. Not even a little bit. I have a good reason though. The Admiral wanted some special knitting needles made to knit rugs with, so it was plain to the simple deckhand that a tool was required for the task....... Obviously a CNC kit would be beneficial to optimise said deckhand's time in the yard......(What can I say, I work in IT, lived with computers since 1976 and remain fascinated by geek stuff, love toys of all types and this thing is just immense fun.) Haven't started on the needles yet, but have done some test subjects just to be sure I get them right .... Here we see examples of a "pointy" end that didn't meet specifications for wool handling. And apparently they were too short .... sigh, I shall just have to try more "tests" and , ok, I admit the whole needle idea came up after the lathe arrived.... This is the third attempt on both the carronade and cannon (we don't like to talk of the 2nd attempt at both - hair raising would be an appropriate comment, if I had any). I am practising using Acetal (Derlin) plastic rod which I believe is hard to glue bits to, so brass will be the final material - I just have to get brave enough to see the metal fly and then relearn soldering - fortunately there is a very good thread on soldering on the forum. However it is back to the "real" work this weekend, I promise. Oh, and the needles.....mustn't forget the needles.......

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.