-

Posts

1,933 -

Joined

-

Last visited

-

tlevine reacted to a post in a topic:

French 64 Gun Ship 1729 by Jeronimo

tlevine reacted to a post in a topic:

French 64 Gun Ship 1729 by Jeronimo

-

tlevine reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

tlevine reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

tlevine reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

tlevine reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

tlevine reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

tlevine reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

CraigVT reacted to a post in a topic:

Planking Tutorials PDFs

CraigVT reacted to a post in a topic:

Planking Tutorials PDFs

-

tlevine reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

tlevine reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

ferretmary1 reacted to a post in a topic:

Are you an NRG Member???

ferretmary1 reacted to a post in a topic:

Are you an NRG Member???

-

tlevine reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

tlevine reacted to a post in a topic:

Beavers Prize 1777 by Mike Y - 1:48 - POF - Hahn style

-

tlevine reacted to a post in a topic:

HM Sloop Echo 1781 by VTHokiEE - 1:48 - Cross-Section

tlevine reacted to a post in a topic:

HM Sloop Echo 1781 by VTHokiEE - 1:48 - Cross-Section

-

tlevine reacted to a post in a topic:

HM Sloop Echo 1781 by VTHokiEE - 1:48 - Cross-Section

tlevine reacted to a post in a topic:

HM Sloop Echo 1781 by VTHokiEE - 1:48 - Cross-Section

-

tlevine reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

tlevine reacted to a post in a topic:

HMS Tiger 1747 by Siggi52 - 1:48 - 60 gun ship from NMM plans

-

tlevine reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

tlevine reacted to a post in a topic:

Sloop Speedwell 1752 by Chuck - Ketch Rigged Sloop - POF - prototype build

-

James G reacted to a post in a topic:

NRG Rigging Project by tlevine

James G reacted to a post in a topic:

NRG Rigging Project by tlevine

-

James G reacted to a post in a topic:

NRG Rigging Project by tlevine

James G reacted to a post in a topic:

NRG Rigging Project by tlevine

-

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine

-

Freebird reacted to a post in a topic:

NRG Rigging Project by tlevine

Freebird reacted to a post in a topic:

NRG Rigging Project by tlevine

-

Mr Whippy reacted to a post in a topic:

18th-Century Merchantman Half-Hull Planking Project by mtaylor - NRG

Mr Whippy reacted to a post in a topic:

18th-Century Merchantman Half-Hull Planking Project by mtaylor - NRG

-

Mr Whippy reacted to a post in a topic:

NRG Rigging Project by tlevine

Mr Whippy reacted to a post in a topic:

NRG Rigging Project by tlevine

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

Thanks, Tom. Sorry for the delayed response but I was on the road and without internet access.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

At this point videos are not planned. There is more detail in the monograph and, if you purchase the kit, I would be available for questions. The Guild hopes to have it available in 4-6 weeks.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

HMS EURYALUS by Matiz - FINISHED - scale 1:56

tlevine replied to matiz's topic in - Build logs for subjects built 1801 - 1850

Congratulations on finishing this masterpiece. Looking forward to your next project. -

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

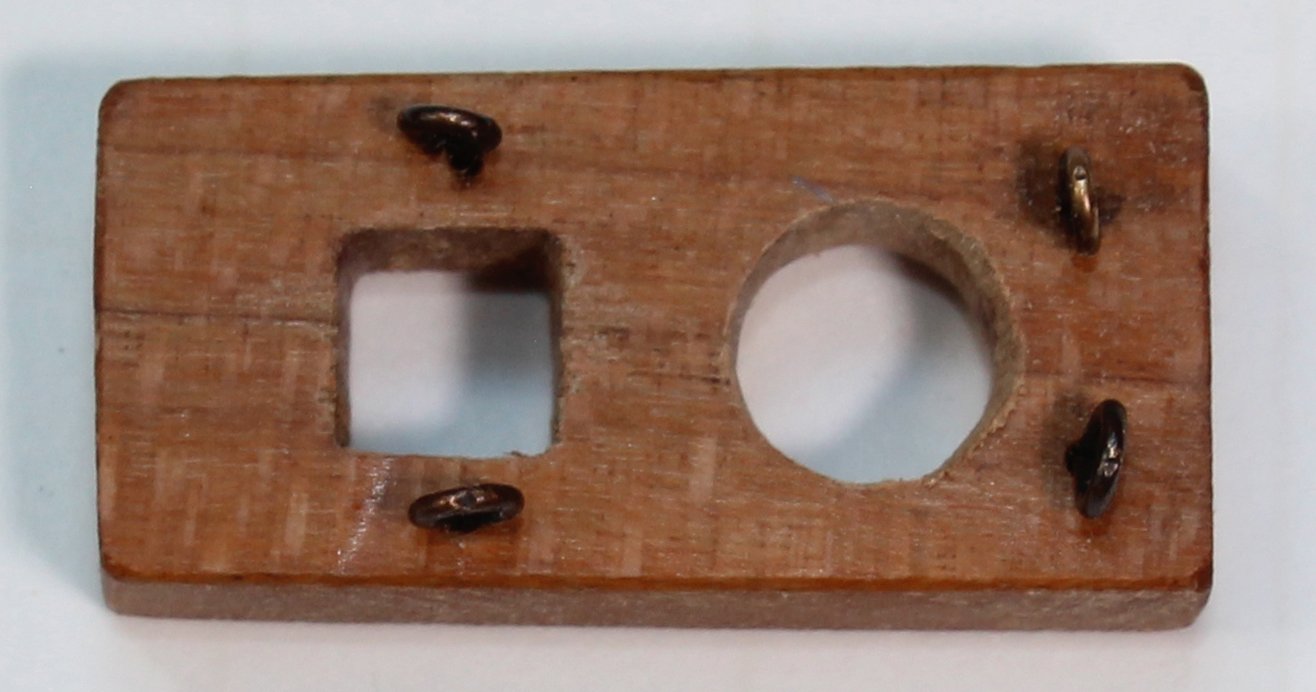

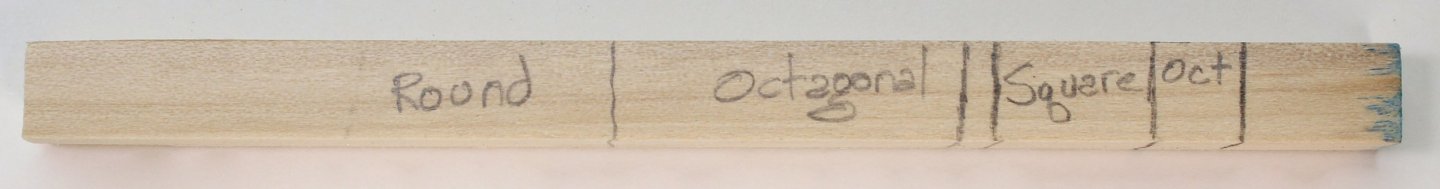

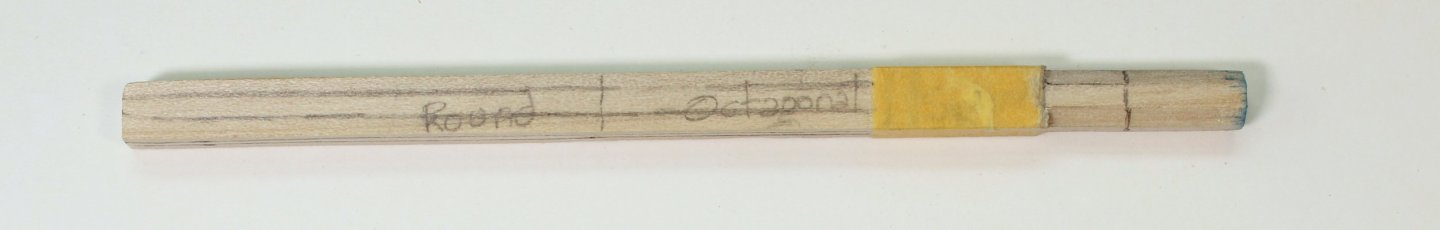

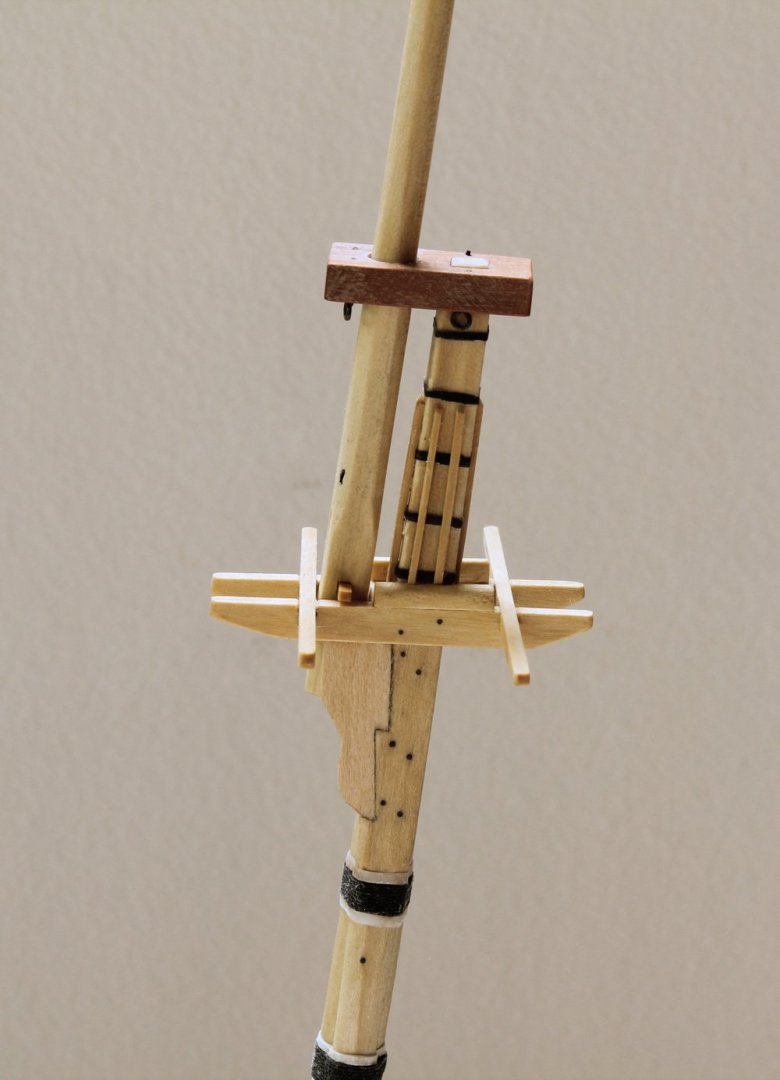

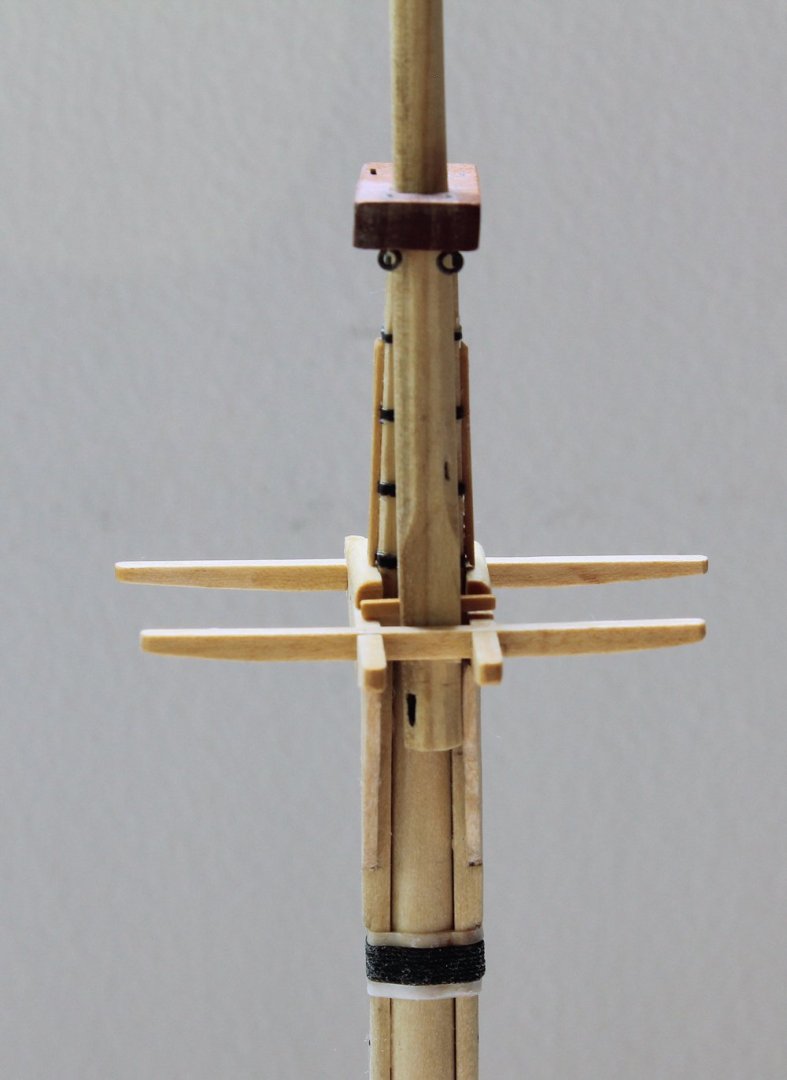

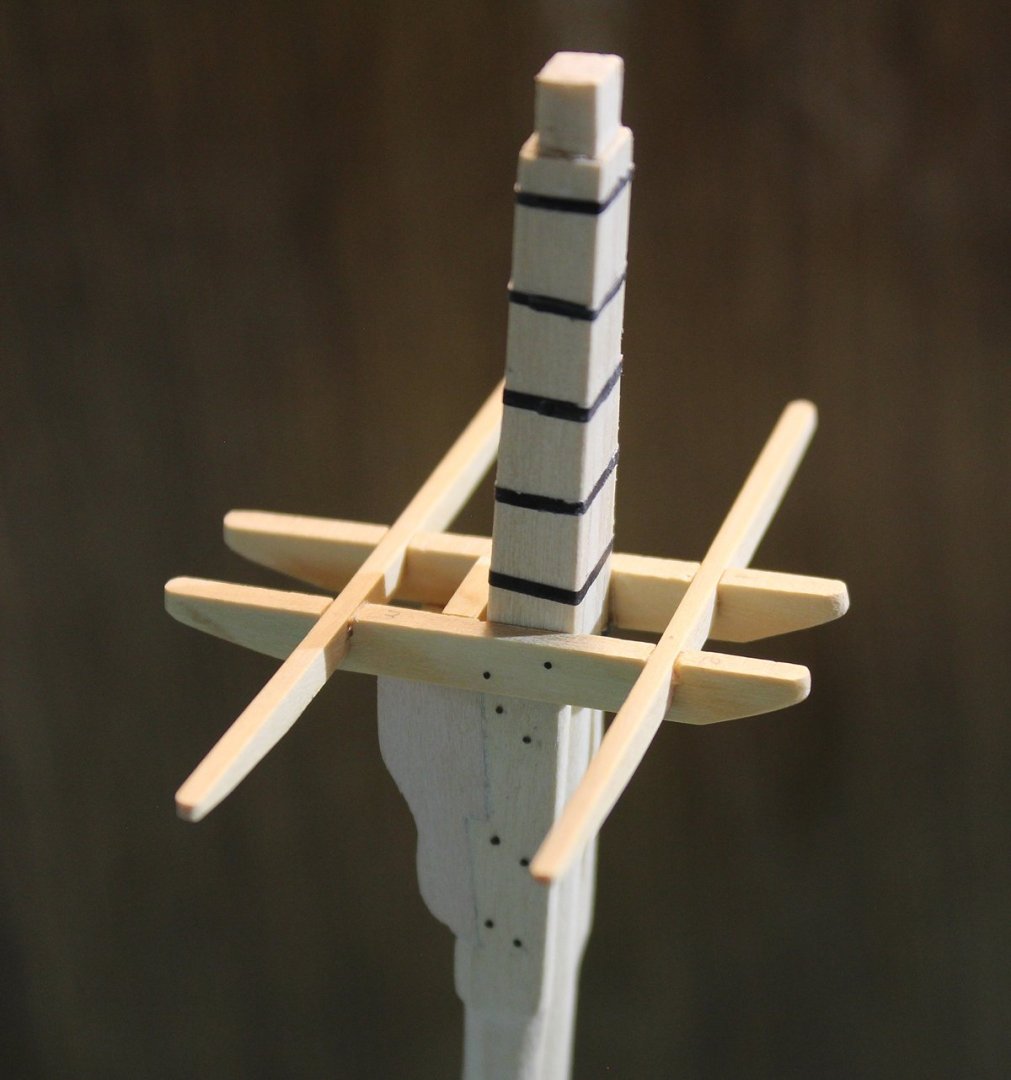

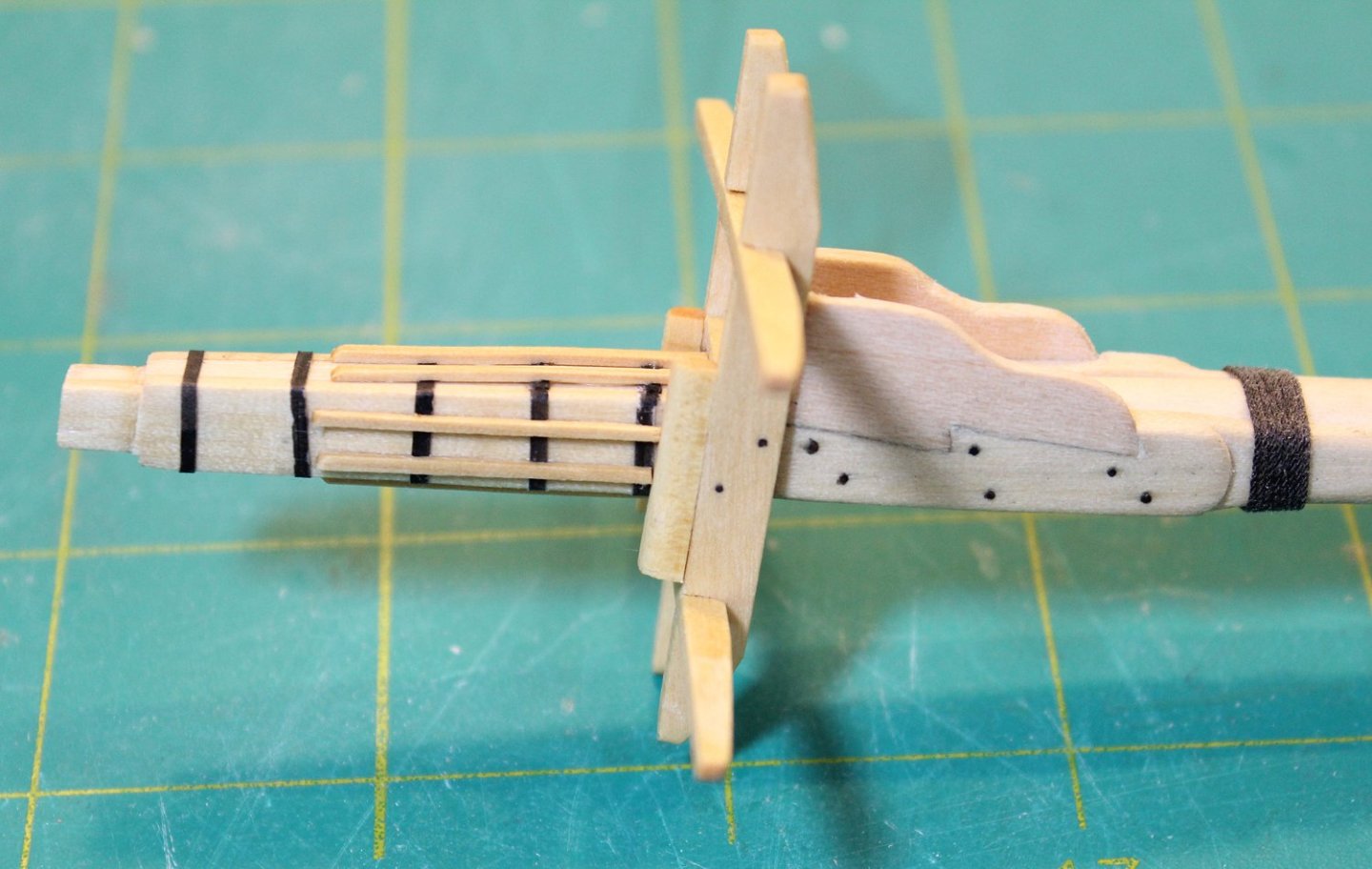

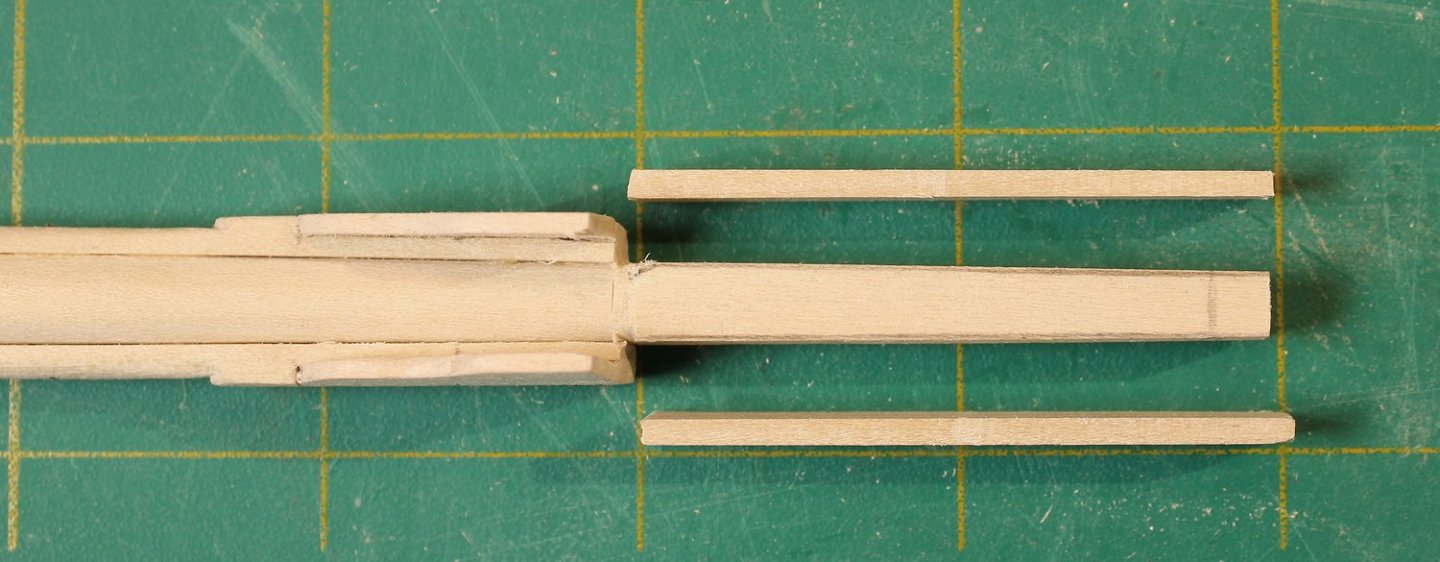

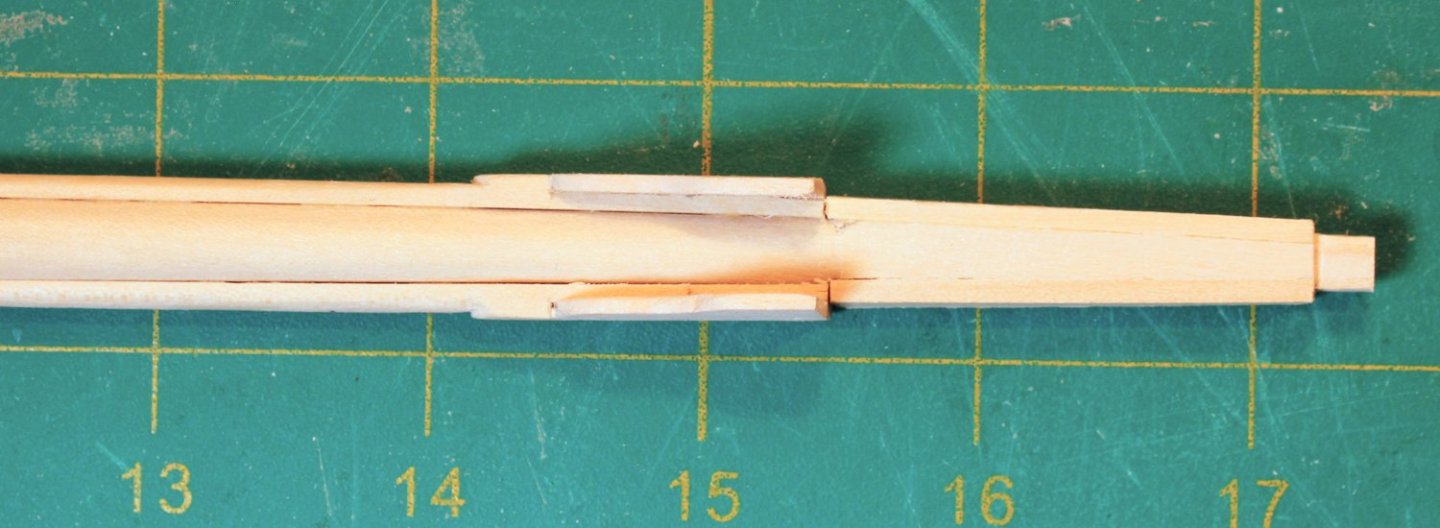

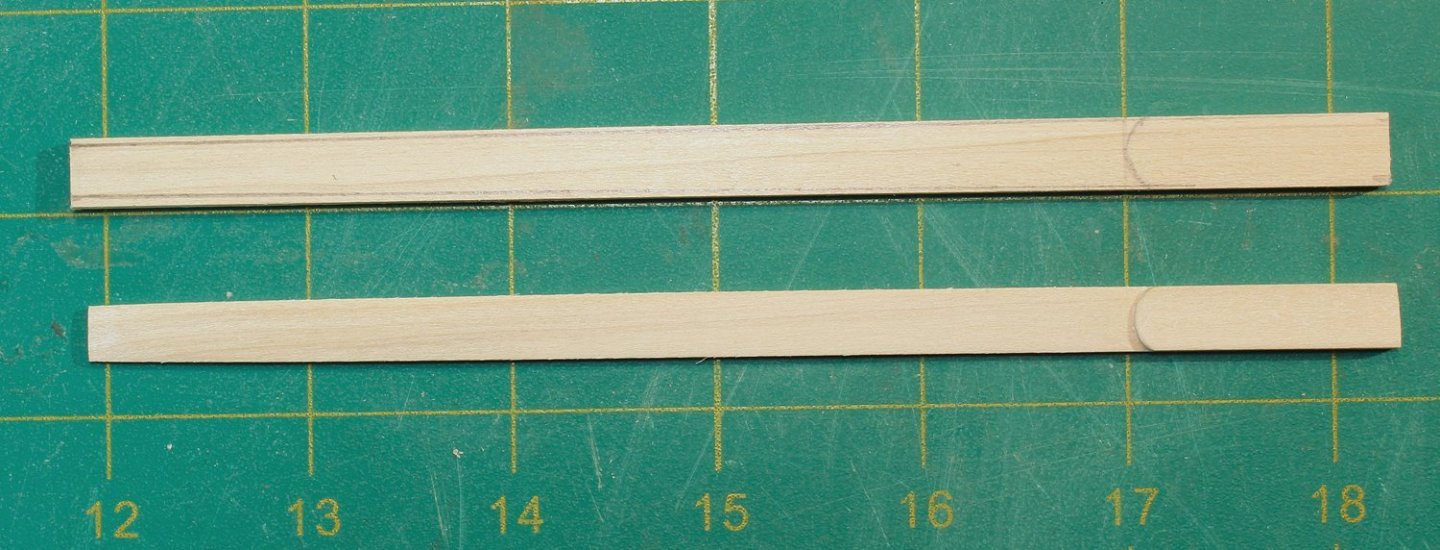

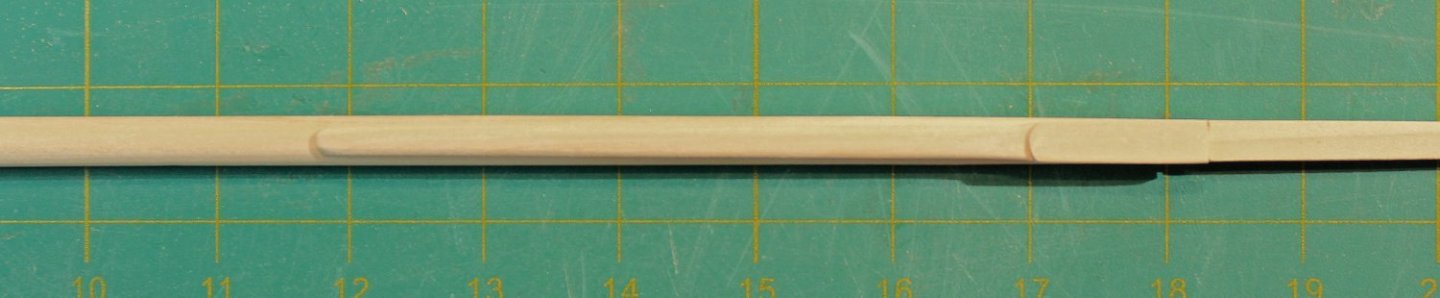

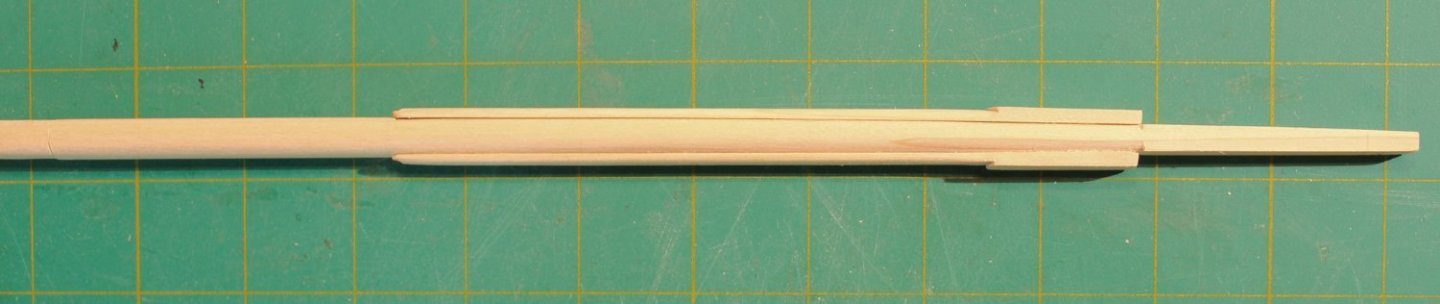

The mast cap has two openings: a round one for the topmast and a square one for the lower mast head. There are four eyebolts that extend all the way through the mast cap. I raided my scrap box for a contrasting color piece of wood. Both openings were made with a regular drill. The square opening was then shaped with a chisel and the round one was enlarged with sandpaper wrapped around a dowel. It will not be installed until much later. Although it also will not be installed for a while, I made the topmast next. The dimensions of the topmast are determined by the diameter of the lower mast. The lower end of topmast is 7/10 the diameter of the mast and the upper end is 11/20. This will be a stub topmast as the actual length of this mast would be 8” on the model. Its shape is more complicated than the lower mast. The lowest section (the block) is octagonal, the next section is (the heel) square, followed by another octagonal section. The upper part of the topmast is round, tapering as it goes to the head. There are three openings in the mast; the middle one is for the fid (the rectangular peg which prevents the mast from falling between the trestle trees) and the other two are for sheaves. The kit will contain a template for the topmast. Starting with a ¼” square dowel, I marked out the mast for the various transition points. Using the 7:10:7 ratio for determining the corners of the octagon, I drew the lines for those two sections. The mast taper begins at the end of the upper octagon. The blue line is the centerline and the red lines are the corners of the octagons. Just as was done for the main mast, I taped off the square section to protect it from errant chisel cuts. The pictures shows a completed topmast above a square dowel. There is extra wood on the top and bottom of the dowel for ease of handling. I used a saw to cut a shallow groove between the octagonal and square areas on the corners of the square section (circled area). This transition should stay sharp. The lower octagonal section was shaped with a sanding stick. The upper octagon and round area were both shaped as octagons, without any taper. Another piece of tape was used to protect the upper octagon and the upper part of the mast was rounded and tapered. After removing the tape, the transition between the octagonal and round sections and between the square and upper octagonal sections were smoothed. Making the holes for two sheaves and the fid was next. The upper and lower sheave openings are in the octagonal sections and are 90 degrees to each other and 45 degrees to the fid hole. The dimensions for the fid opening are one-third the mast diameter high and one-quarter the mast diameter wide, in this case 3” x 2.5”. The opening was formed from multiple drill holes, squared off with a #11 blade. The fid was made slightly smaller than the size of the opening and long enough to span the trestle trees. The sheave openings are 8” long and 1.5” wide. I simulated the sheaves on this model. These were trickier to drill accurately because they are on angled faces. Here is how I made them. The sheave opening was marked on both sides of the mast. I put the mast in a vise, clamping it in the upper octagonal area, just above the sheave opening. A small hole was drilled near the top and bottom of the sheave opening but I did not drill completely through the mast. The mast was repositioned in the vise and the holes on the other side were drilled. The holes on each side were enlarged to the correct width of the opening. I did this slowly, working a little bit on one side and then switching to the other side. The holes eventually met. Then, using a #11 blade, a shallow groove representing the sheave was formed between the two holes and the “sheave” was painted. The final step was to cut off the excess wood at the top and bottom of the topmast and apply a finish. This is how it looked installed.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

Most rings and eyebolts provided in kits are oversized, especially at the smaller scales. They are very easy to make. To make rings, temper (soften) brass or copper wire of the appropriate gauge by heating it in a flame. I use my gas cooktop. Let it cool slowly. Drill a hole larger than the wire in one end of a dowel that is slightly larger than the desired inside diameter of the ring. Thread the wire through the hole and tightly wrap the wire around the dowel. When you are finished, tape one side of the wire. This will help prevent the rings from flying away when you cut them from the dowel. Use a metal cutting saw to cut through the wire. If you don’t own the Czech-made JLC saw, get one. They are fantastic. No monetary interest in the company, so here is the link to their website. https://www.umm-usa.com/catalog/tools_JLC.html The pirated cheap imitations on Amazon are not the same quality. Gently bend the wire to close the gap left by the saw kerf. Clean and blacken. Easy! For rings that are going to be under a lot of tension, solder the ring closed before blackening. If you are making a lot of rings, you can chuck the dowel into a drill rather than hand wrapping it. Eyebolts are just as easy to make but you will need fine-tipped round-nosed pliers. Your best source for this tool is a jewelry supply store. Mark on your pliers the desired inner diameter of the eyebolt. Take a length of wire and file the end flat with a metal file. Grasp the wire between the jaws of the pliers without any wire protruding beyond the jaws and wrap it around one of the jaws until you have a complete loop. Sharply bend the wire back towards you to form the stem. Cut to length, clean, blacken and repeat.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

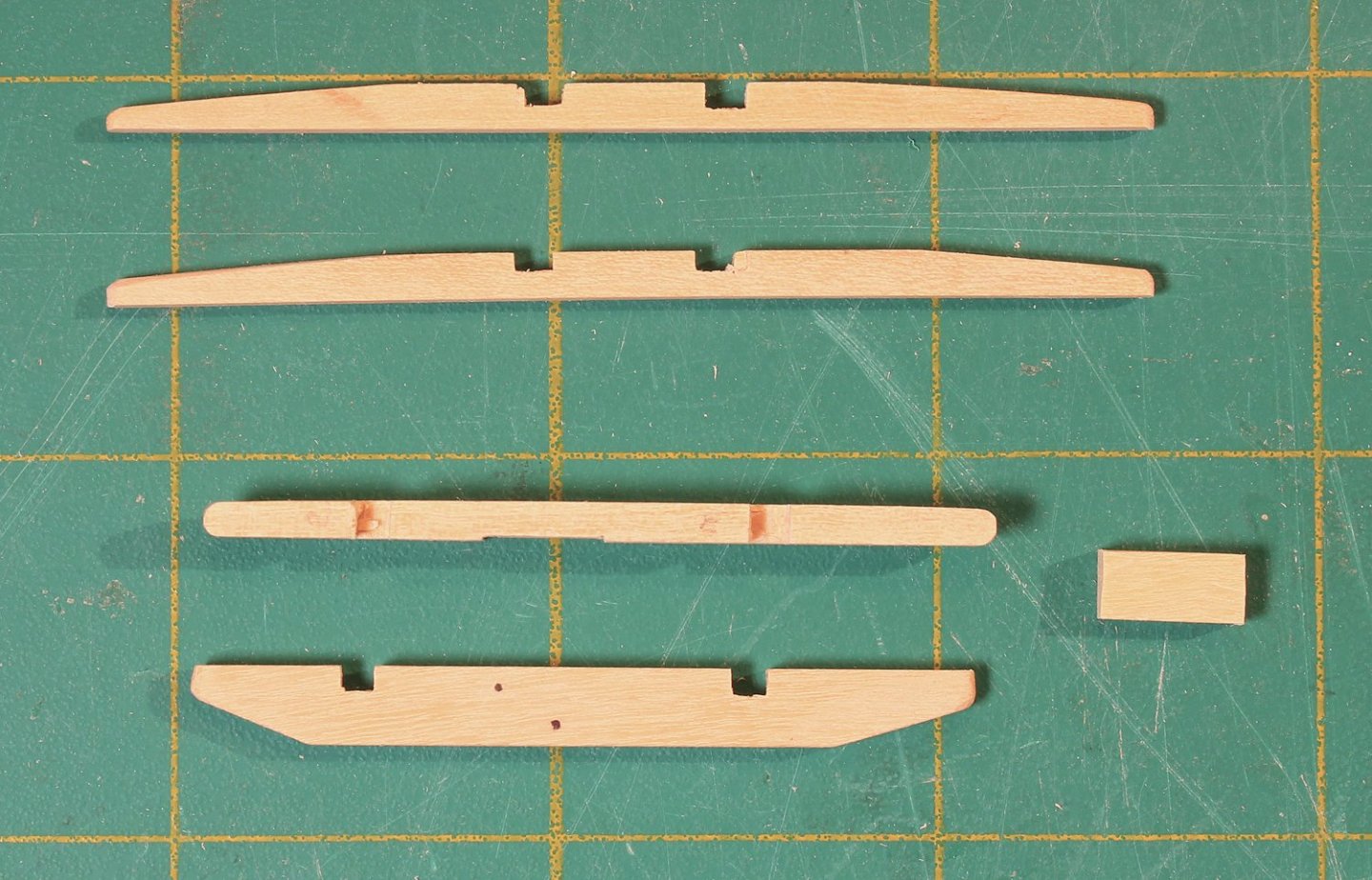

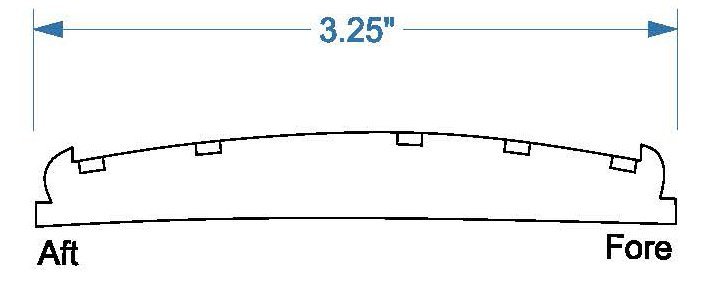

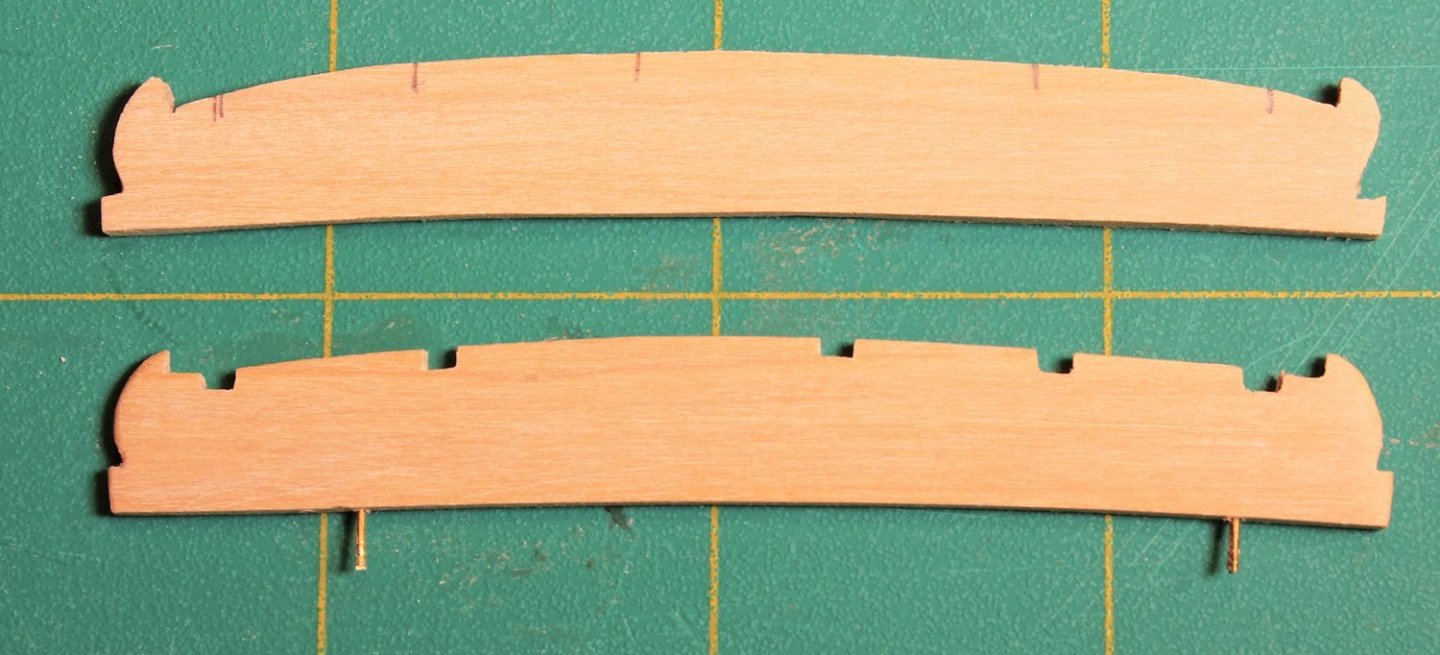

The dimensions of the top are determined by the size of the topmast; the dimensions of the trestle and cross trees are derived from the size of the top. The topmast on this ship was specified on the plans as 32’ 10”. The width of the top is 1/3 the length of the topmast wide and ¾ the top’s width fore-to-aft. The hole in the top is 5/12 the width of the top. The kit will provide a template for the top. The trestle trees run fore and aft; the cross trees run across the ship. The trestle trees are as long as the top. The cross trees are different lengths; the fore cross tree is shorter than the aft one because of the curvature of the top. Look at the following drawings. The dimensions of the trestle and cross trees are derived from the width of the top (W). There is a small notch on the inside face of the trestle tree for the mast head. I made them from 1/8” basswood sheet and sanded them down to the correct thickness. It is important to make sure that the top surface of the assembly is not twisted. The easiest way to avoid twisting is to turn it upside down and put a weight on top of it while the glue dries. Trestle Tree The small piece of wood between the cross trees is called the chock. It is a spacer between the mast head and the topmast. It is the same height and width as the trestle tree. I inserted the mast into the hole in the deck. As mentioned previously, the trestle trees are horizontal to the water line. The cross/trestle tree assembly was placed onto the bibs and the angle of the top of the bibs was adjusted with a sanding stick until the trestle trees were horizontal. They were glued to the bibs. The final pieces to install onto the trestle tree are the bolsters. These are quarter-round pieces of wood that prevent the shrouds from rubbing against the trestle trees. They are slightly wider than the trestle tree and one-third its height. Because the shrouds extend aft from the mast, the bolster starts at the fore end of the mast head and extends back to the aft cross tree. I have added bolts to the trestle trees using 24 g copper wire. Just as the bolsters protect the trestle trees, battens protect the mast head. There are two battens on each side of the masthead and end below the second hoop from the top. In order to lay flat against the mast head, small grooves were cut into the undersurface of each batten where it crossed a hoop with a #11 blade.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

Use of “other power tools”

tlevine replied to kgstakes's topic in Modeling tools and Workshop Equipment

I used a Cricut once to attempt to cut planks from 1/16" boxwood. There was not need for a second attempt. It worked fine on basswood. -

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

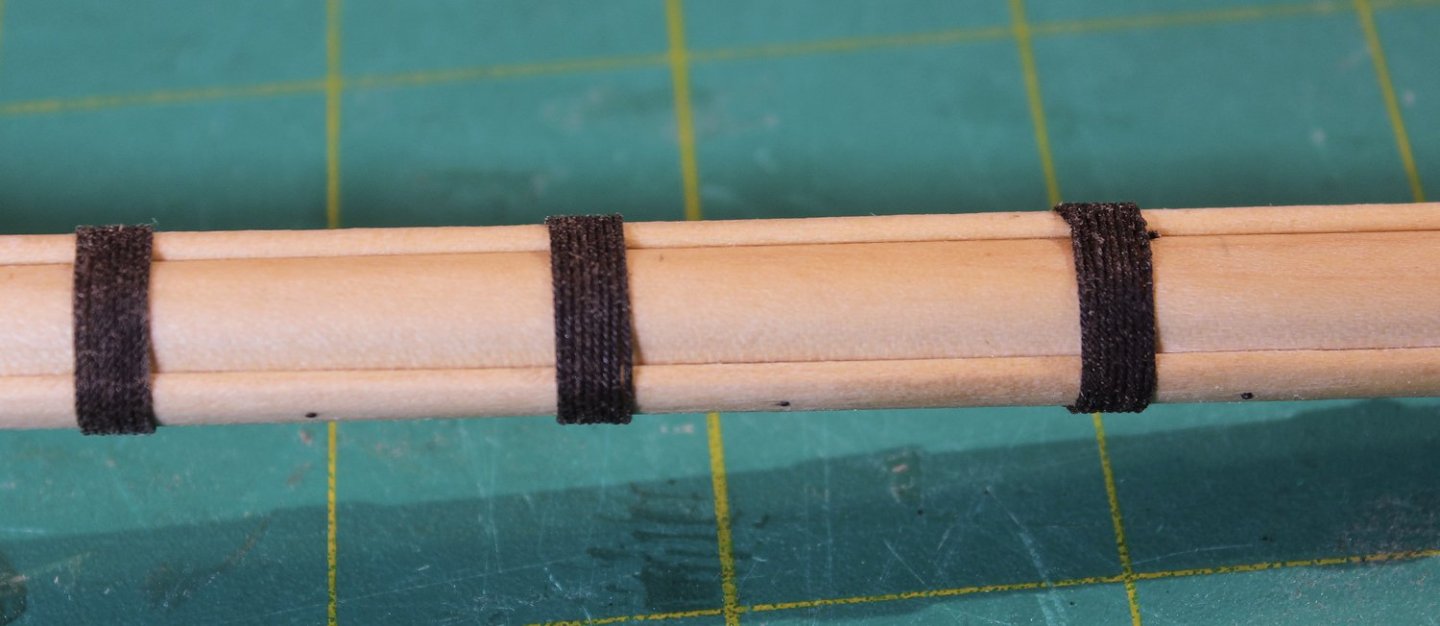

Time to build up the port and starboard sides of the mast head. I used the mast template to determine the dimensions. A real mast would have its top cut at an angle to lock it into the mast cap. This detail is not visible so I shaped it as a simple square. The full- sized dimensions are 9” square by 11”tall, which is the thickness of the mast cap. Iron bands were placed around the mast head at regular intervals. I used paper dyed with archival ink. On this photo you can see that I have added bolts to the cheek. The bolts are made from 24 g copper wire patinated with liver of sulfur. The wooldings provide extra strength to the mast. The number and composition varied based on the era. At this time, they were made of 2.5” tarred rope (all rope dimensions are circumference). Because I will be using several diameters of line in the build, I made a table consisting of the full-sized circumference, the circumference at 1:48 scale and the diameter at 1:48 scale. The easiest way to determine the diameter of your rope is to wrap 10-20 windings around a dowel, measure the distance and divide it by the number of windings. Remember, circumference is πd so the rope diameter is circumference/π. I used eight wraps for each woolding. To hide the ends of the wooldings, I tucked them in the gap between the mast and the cheeks. Above and below the wooldings are wooden hoops. I simulated them by cutting strips of paper and wrapping two layers around the mast. This gave the hoops the appropriate thickness.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

Thanks. I forgot to mention that.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

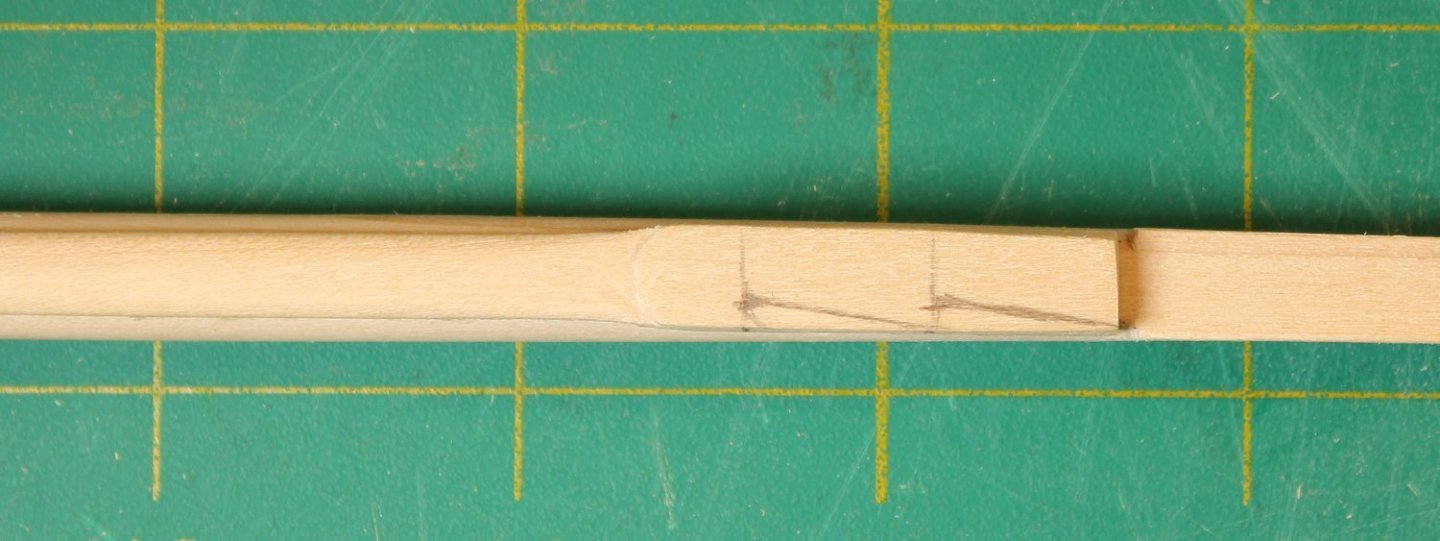

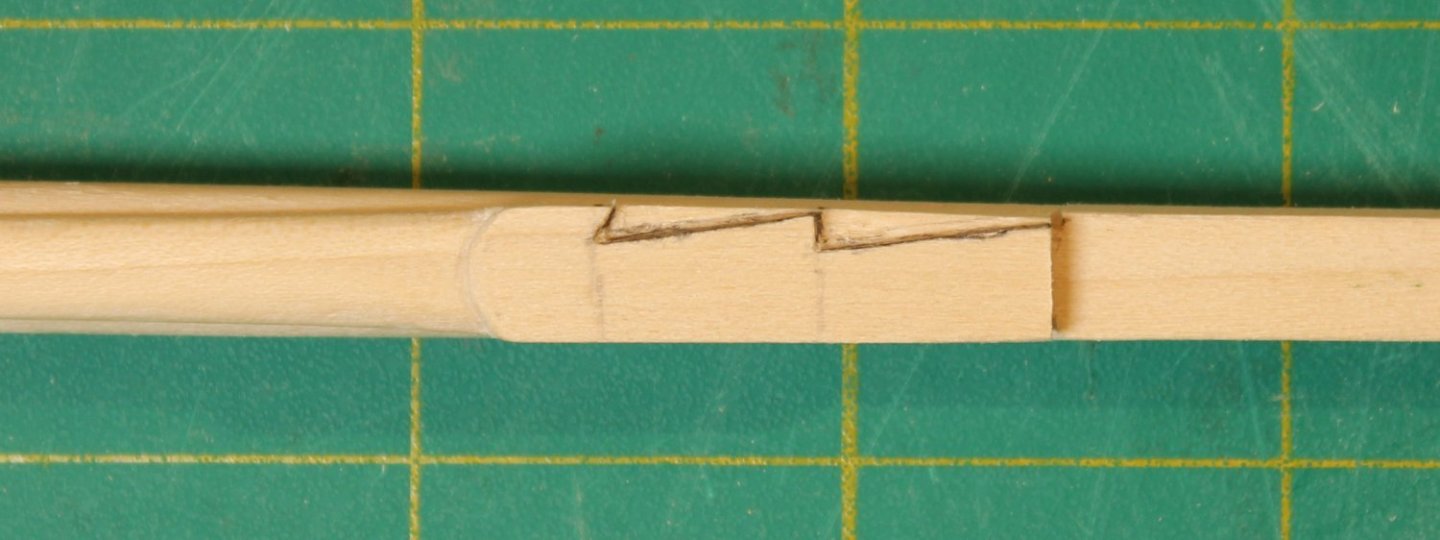

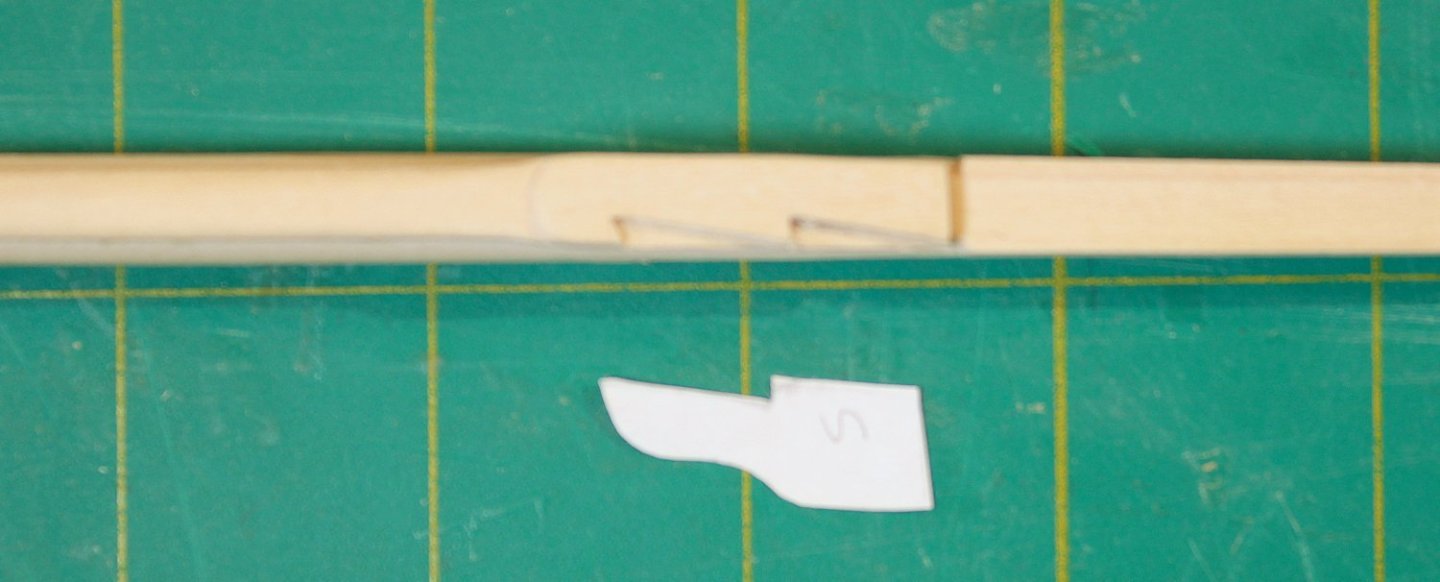

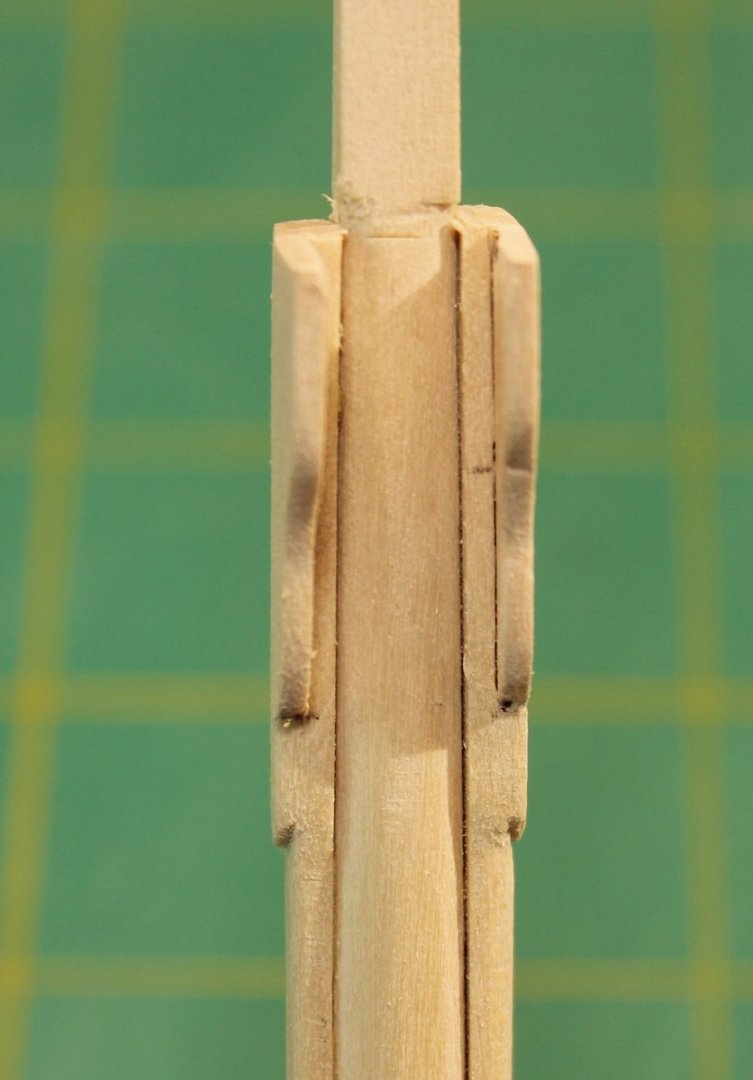

The cheeks are located on either side of the mast. Their inner surface is flat so the sides of the mast will need to be flattened. On this ship they are 25 feet long and extend from the bottom of the mast head to approximately 12 feet above the deck. At this scale, that is 6.25” long, ending 3” above the deck. A template is included in the practicum. The upper part of the cheek is called the hounds and is thicker than the rest of the cheek. The photo shows the cheek before and after shaping. The outline of the cheek was drawn onto both sides of the mast. This outline marks where the mast needs to be flattened. The hounds remain flat but the rest of the cheeks were rounded over. The apparent concavity in these cheeks below the hounds is an optical illusion. 0 The cheeks were then glued to the mast. Look at the straight line extending up the mast on the side view and the step-off above the hounds fore and aft. The next step was to make and install the bibs. These are forward extensions of the hounds and their purpose is to support the trestle trees. They are the same thickness as the hounds and are attached with a morticed scarf joint for strength. This is how I made the mortice. Start by drawing the zig-zag mortice onto the hound. It extends approximately three-quarters of the length of the hounds. Because the lower end of the bib is curved, the bottom mortice cut is also curved. Since I was using basswood, I used a #11 blade to inscribe the mortice. I did this a few times, deepening the cut with each pass. Once I was halfway through the hound, I used a chisel to remove the wood from the mortice. I have used pencil to make the joint more visible for you. This joint would not have been caulked and so the joint would not be very visible. It is important to keep the sides symmetric. Next, I drew the bibs on paper. The top of the bibs is 3/8” wide and it is half the thickness of the cheek. I laid the paper over the hounds and made a pencil rubbing of the mortice to get the shape of the tenon. Each side will be slightly different so two templates were needed. The one below is marked “S” for the starboard side. The front edge of the bibs was rounded over and installed; the top edge was left flat. There is a forward angulation to the bibs to allow the trestle trees to rest on them parallel to the water line. The top edge of the hounds and bibs should form a straight line.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

Welcome back! For templates I will use a combination of taping small pieces of paper together for one side and inserting the paper between the frames for the unplanked side. Still requires some tweaking, but it compensates for the thickness of the planking and any asymetry between port and starboard.

- 884 replies

-

- hahn

- oliver cromwell

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

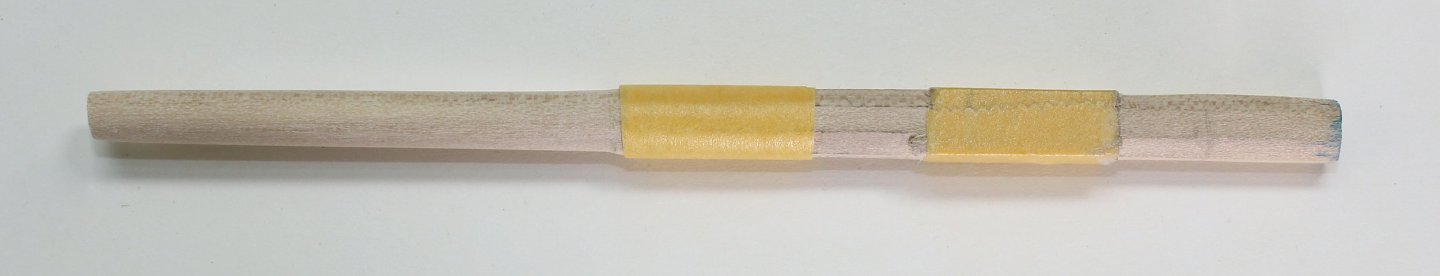

Masts are not the same diameter or shape from the mast step to the masthead. The Royal Navy had exact specifications for every section of the masts and yards and their rigging. Real masts were made up from multiple pieces of wood. This increased their strength and allowed the use of smaller diameter trees. My mast was made from a square poplar dowel purchased at a big box home improvement store. The mast head is square and the rest of the mast is initially round. To transform a square dowel into a round mast, the dowel will first be shaped into a regular octagon (all sides the same size). The instructions will go into detail on how to do this and will also include a scale template of the mast shape. It is easier to shape the mast if you have extra wood on both ends. I cut the dowel approximately 2” longer than the length of the mast. For the kit, glue 1-2 inches of scrap wood, the same or smaller diameter than the dowel, on both ends. The dowel was sanded down to just fit into the slot in the backbone. I used a level to make sure it was vertical. The dowel was removed and I drew the centerline on all four faces. Then, using the centerline as a guide, the templates were tack-glued to two adjacent sides of the dowel and the outline of the template was drawn onto the dowel. The templates were removed and I marked the transition from the round lower part of the mast to the square masthead with a few turns of masking tape to prevent damaging the masthead. I shaped the dowel below the masking tape to match the outside edge of the template with a chisel. The quarters were marked on all four faces of the dowel. The 7:10:7 ratio was drawn in at the quarters and a few other locations. I took the measurements directly from the template. Lines were drawn connecting those marks from the bottom of the mast up to the masking tape. You can see the marks in the photo. The wood outside those lines was removed with a chisel. Two very important things to keep in mind: your tool must be sharp and, as much as possible, the wood should be removed going with the grain. I rotate the dowel frequently, rather than finish one edge at a time. When using wood without discernable grain, it can be difficult to see the edge of the octagon. So when I am getting close to the lines, I run a pencil along the edge. You can see how well the jig holds the mast securely. And here is the final result. You can see how the tape protected the masthead. Now that the lower part of the mast has been shaped, it was time to start shaping the mast head. On the actual mast, the sides of the mast head are cut down, leaving the full thickness fore and aft. Then, after the cheeks are installed on the sides of the mast, the mast head is built back up to a square shape. The next photos show the mast head before and after the wood had been removed from the port and starboard faces. On the fore and aft sides of the mast head, I removed the wood outside the pencil lines, continuing the taper of the lower part of the mast. The next two pictures show the mast head marked out and tapered. Compare the appearance of the fore/aft faces versus the port/starboard ones. You will also notice that I have started to flatten the sides of the mast in preparation for the cheeks. Tapering the mast head was done with the Byrnes sander. Otherwise, this was all done with hand tools.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

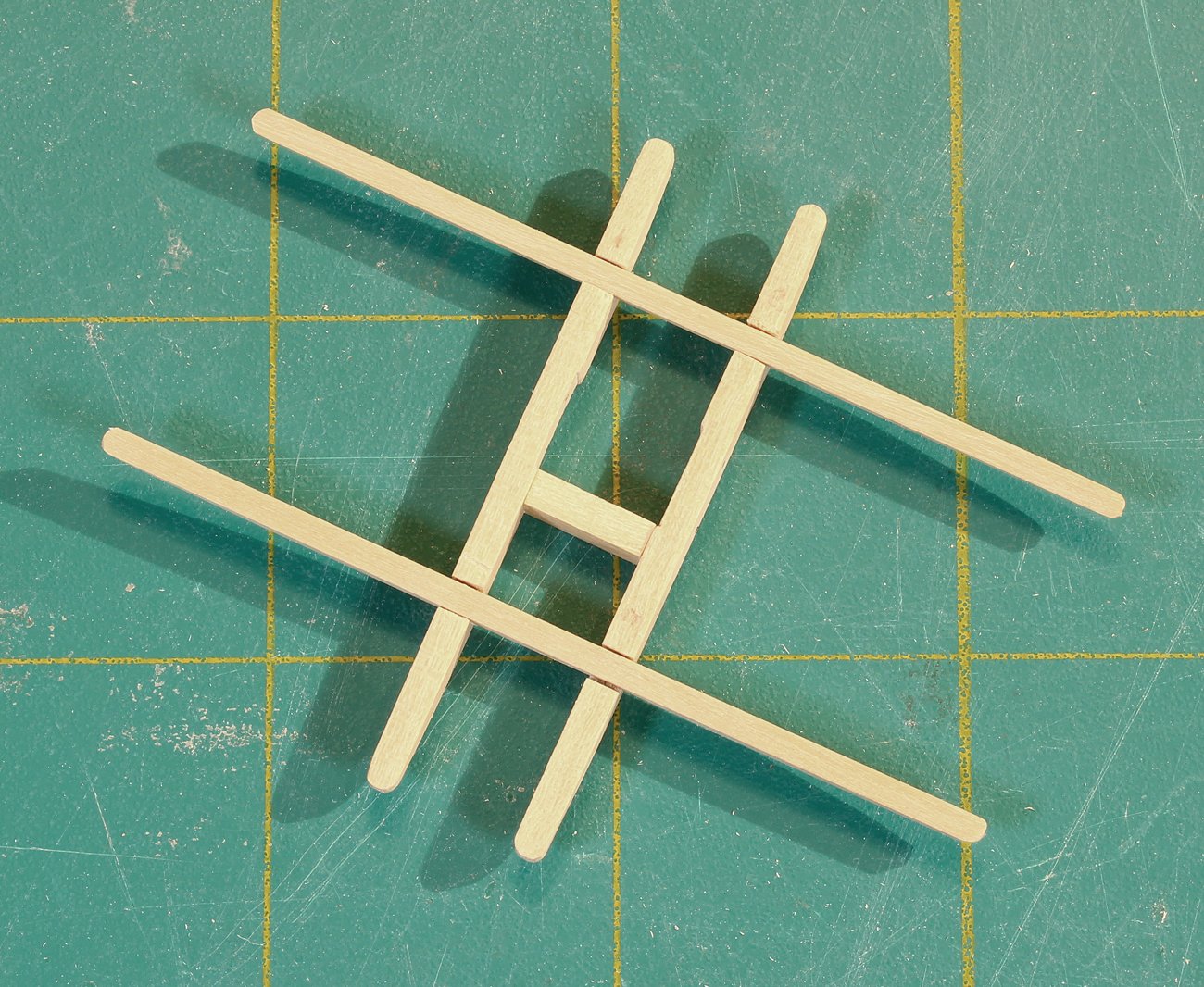

The lower mast and trestle trees must be made before installing the lower deadeyes. There are many ways to make masts and yards, including using a round dowel approximately the right diameter, turning a wood blank on a lathe or chucking a dowel into a drill and sanding it down to the correct dimensions. A fourth technique will be shown here. The only tools required are a caliper, a sharp chisel or plane and sandpaper. A jig is needed to hold the wood during the shaping process. The picture below shows two types of jigs. The top two homemade jigs only differ in the diameter and length of wood they can hold. The lower jig was made by Hobbymill, which is no longer in business. It is a single jig with multiple sized slots. I prefer the security of the single size jig. With either type of jig, the final diameter of the mast or yard must be greater than the height of the V-slot on the jig. The practicum will give instructions for making the jig. Before going any further, a few terms need to be defined. The part of the mast above the trestle trees is called the mast head. Below the trestle trees, the mast is divided into “quarters”, starting at the mast step in the hold. “Cheeks” (not illustrated) run on either side of the mast below the mast head and provide additional strength to the mast. The “hounds” are the upper parts of the cheeks. Later era ships have a “fish”, similar to the cheek but located on the fore side of the mast. The relative length and shape of these pieces vary by size and type of ship, country and era.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

NRG Rigging Project by tlevine

tlevine replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

This ship’s main mast channels are 13’ long, 18” wide and 4” thick. They are made by laminating three layers of 1/32” sheet together. The middle layer’s grain is oriented 90 degrees to the outer layers for added strength. I weighted the channel down while it was drying to prevent warpage. In actual practice, there would be a slight taper of the channel from the hull to its outer edge, but for this project I ignored that. The fore end of the channel is located just behind the aft side of the mast. There are recesses cut into the fore and aft ends of the channel. The deadeye strops fit into mortises cut into the channel and a decorative strip holds everything in place. The channel template shows the locations of the deadeye strop mortices. The location of the fore end of the channel was marked on the hull. It is 2.5 feet below the rail and runs parallel to the wale. Templates were used to get the exact shape. I used the template from making the cap rail as a starting point and modified it to exactly fit the shape of the hull. The openings for the deadeye strops were made by cutting shallow grooves into the channel and connecting them with a 2 mm chisel. A #11 blade will also work. The location of frames 4 and 6 were marked on the inner edge of the channel and 22-gauge brass wires were inserted at those spots for strength. The fore and aft edges were rounded over but the long outer edge was kept sharp. You may have noticed that the deadeyes are not evenly spaced. On the actual ship, a gunport was located between the third and fourth deadeyes. I decided to keep things simple and not model the gunport. If you want, the spacing between frames 5 and 6 will allow you to add one.With the channel installed, a clear finish was applied to the exterior of the hull. After the finish dried, I sanded the long outer edge of the channel to remove the finish. This will help adhesion when the decorative strip is added after the deadeyes are installed.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

.thumb.jpeg.fc5d633a7b34428fcf19419a73d56d55.jpeg)