-

Posts

381 -

Joined

-

Last visited

-

To those who stopped by or gave likes, thank you for your interest and support. Wheel world is calling. Now that the hull is planked, the tryworks and skylight are finished and the whaleboats are carved and pretty much sanded I’m taking a break to assemble a 1:8 scale Bugatti Type 57SC Atlantic car kit from IXO Collections. I received it as a gift for a “big” birthday (don’t ask how many). It just arrived after a trip from Hamburg aboard the Tubul container ship, by way of Southampton and New York. Final stop was Scale Auto Works in Raymond New Hampshire. A shout out goes to proprietor Brady Ward for keeping us well informed during many production and shipping delays. The kit takes me back to a build many years ago of a Pocher Bugatti, which took over 400 hours to complete. I’m hoping that time has given me better skills this time around for a more expeditious finish. The shipyard is still intact and if I get bored or frustrated with individual wire wheel spokes or hundreds of tiny screws I’ll have a place to relax making whaleboat seats. See you when I have something worth reporting. Thanks again Steve

-

yvesvidal reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

yvesvidal reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

-

yvesvidal reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

yvesvidal reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

-

Jack12477 reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

Jack12477 reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

-

Jack12477 reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

Jack12477 reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

-

Not quite there yet Nic but I imagine it’s not far off. In the meantime he’s thoroughly enjoyed visits to the USS Slater, the Constitution, the Erie Canal locks in Waterford, and striper fishing in small boats off Cape Cod, where a 16 foot great white swam under the boat! A trip to Mystic is on his radar. We’re having a ton of nautical fun while the skiff waits patiently in the shadows. Steve

- 18 replies

-

- skiff

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

ccoyle reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

ccoyle reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

-

Chris, Legodude is now almost seeing eye to eye with me (I’m well over 6 ft). The skiff is “temporarily” set aside in favor of a multitude of competing interests. The good news is he told me he can’t stop looking at the completed projects (Bowdoin, Chris Craft barrelback and Zebulon B. Vance) whenever he is at our house. And when I was musing over what might happen to them in the future he said quietly “Well I’d like to have them”. The spark’s still there and maybe it’s time to remind him of the skiff on his next visit. Who knows, he may even take it home and finish it on his own. Thanks for tweaking the cobwebs. Steve

- 18 replies

-

- skiff

- BlueJacket Shipcrafters

-

(and 1 more)

Tagged with:

-

Jeff preisler reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

Jeff preisler reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

-

Jeff preisler reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

Jeff preisler reacted to a post in a topic:

Skiff by Legodude with ESF - BlueJacket Shipcrafters - 1:12 - first build

-

JJUSNRET reacted to a post in a topic:

Charles W Morgan by ESF - Model Shipways - 1:64

JJUSNRET reacted to a post in a topic:

Charles W Morgan by ESF - Model Shipways - 1:64

-

Srodbro reacted to a post in a topic:

Charles W Morgan by ESF - Model Shipways - 1:64

Srodbro reacted to a post in a topic:

Charles W Morgan by ESF - Model Shipways - 1:64

-

ccoyle reacted to a post in a topic:

Charles W Morgan by ESF - Model Shipways - 1:64

ccoyle reacted to a post in a topic:

Charles W Morgan by ESF - Model Shipways - 1:64

-

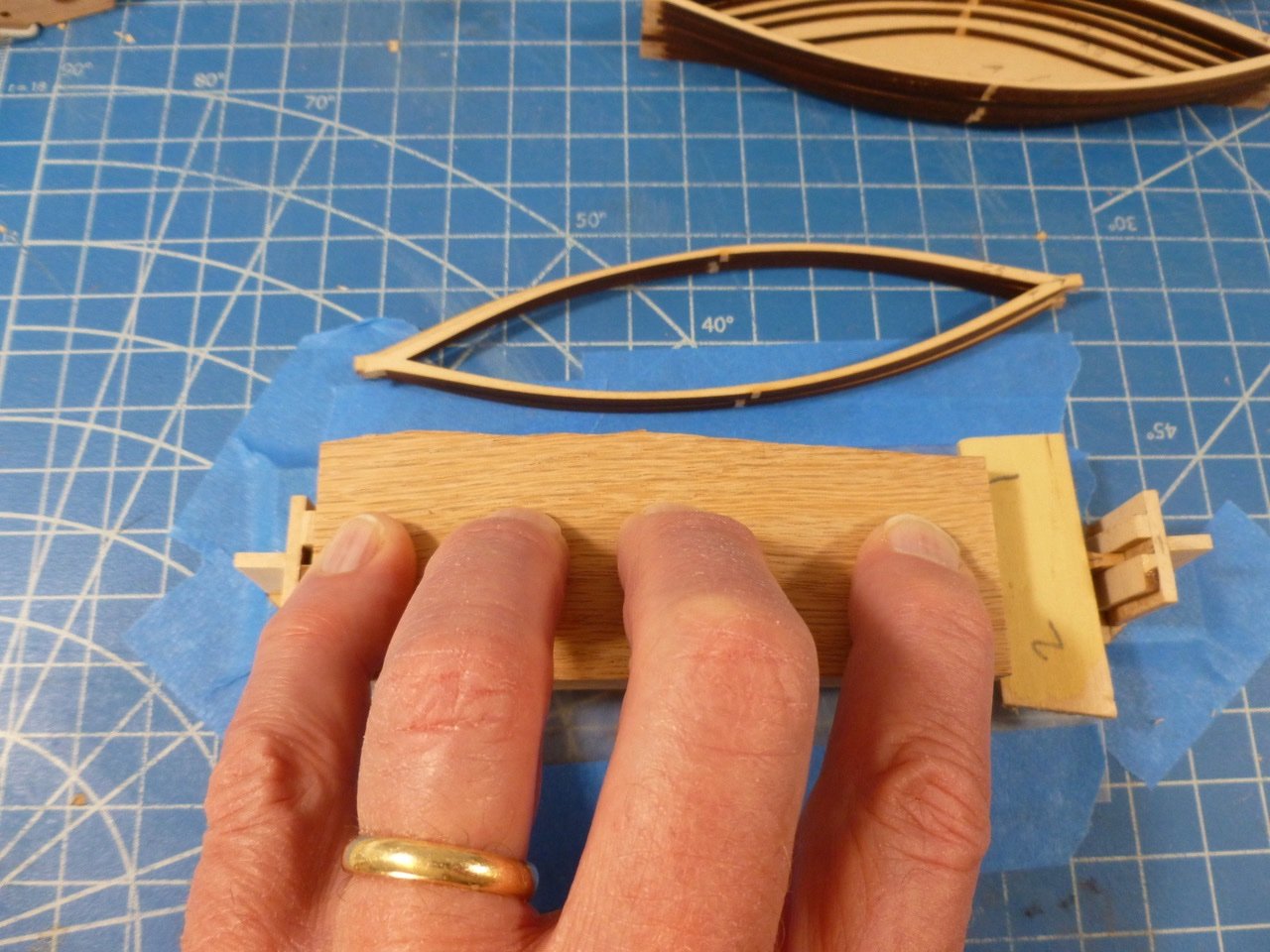

To those who stopped by or gave likes, thank you for your interest and enthusiasm. Whaaaaale Boaaaaat proggggggressss. It feels like I’m in slow motion working my way through carving and sanding the whale boat hulls, but considering ongoing family health issues, caregiving and the rather abrupt passing of a relative the carving process has been therapeutic. Three Dremel bits worked best, for me at least. The side cutter was good at knocking off edges and rough shaping; the orange cone blended and smoothed; and the tiny tip was helpful in the narrow spots at bow and stern. A sample shows reasonably good carving for the interior (I think). More work needed at bow and stern although some of it will be covered (I hope). Once I had the technique the remaining interiors went fairly quickly, maybe an hour or two each. The over-width bits of sheer line at bow and stern should disappear when I do the exterior sides. To keep the overall length of whale boats consistent I made another template to place along the keel line, taking care to cut the template on the hull line so I will have space to add the keel, which I expect will be a strip of styrene. I started the template with a copy of the profile, spray adhesived to Bristol board, but I didn’t leave enough meat along the bottom so I added a wood strip for stiffness. After sawing off the tabs at each end I sanded the curves with the Dremel drum sander, followed by sanding blocks. Once the boats are all the same length I’ll attack the exterior sides and bottom. The exterior sanding in the photo above is part of a test. Thanks for viewing. Steve

-

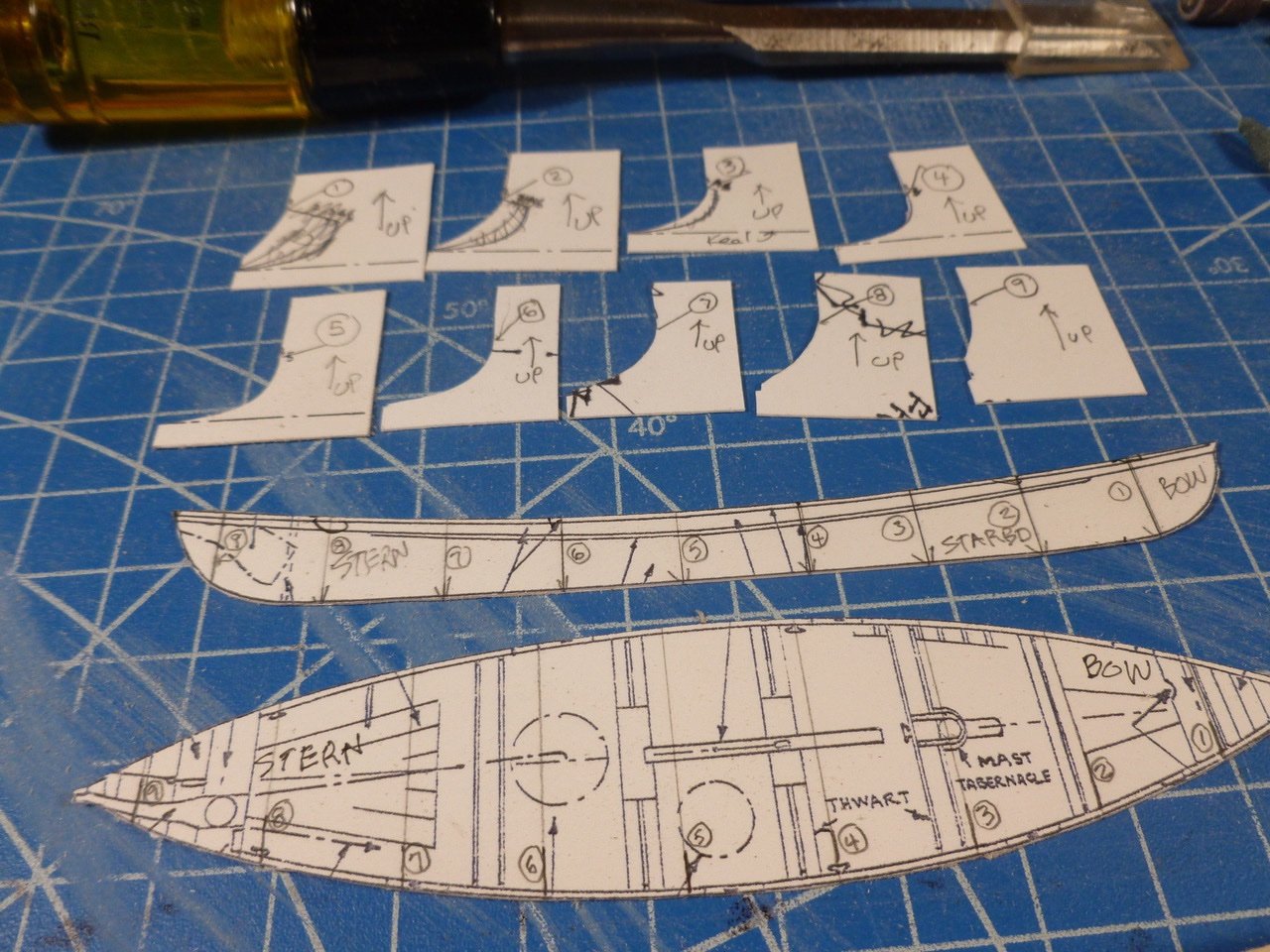

To those who stopped by or gave likes, thank you for your interest and enthusiasm. David, I did see your log comment about cutting the boats, but I was afraid I’d make a mess of the saw cut over the length of the boat, or end up making the halves less than symmetrical. Rookie, I used the side elevation template to draw a sheer guideline. There is a lot of material to be removed so I am using a full size chisel for the bulk of it, and the Dremel to get close to the line. Turning boats to dust. It’s amazing how much stuff I need to carve, gouge, plane and sand all the whaleboats. But I’m creeping ahead. Dremel bits have all been given an opportunity to shine. I copied details from the drawings and spray adhesived them to Bristol board. Station numbers are proving helpful but the ones I put on the outside bottom hull centerline have been most useful since they will be the last ones to sand off. I’m not sure what the endgame needs be at bow and stern but this is where I’m at on the first boat. The new Dremel detail tool was sitting on the shelf until my hand and wrist got tired trying to hold the main tool steady. The detailer is so much lighter it may make sanding almost fun. Thanks for viewing. Steve

-

Thanks Rookie. I appreciate your feedback. A Duh moment: While prowling around the shipyard this morning I found a wealth of whale boat detail on sheet 4, including a tiny lines drawing showing the station cross section profiles. The details also show just how thin the skin is intended to be. Frightening to say the least. Off to the copier to make some templates. Thanks for viewing. Steve

-

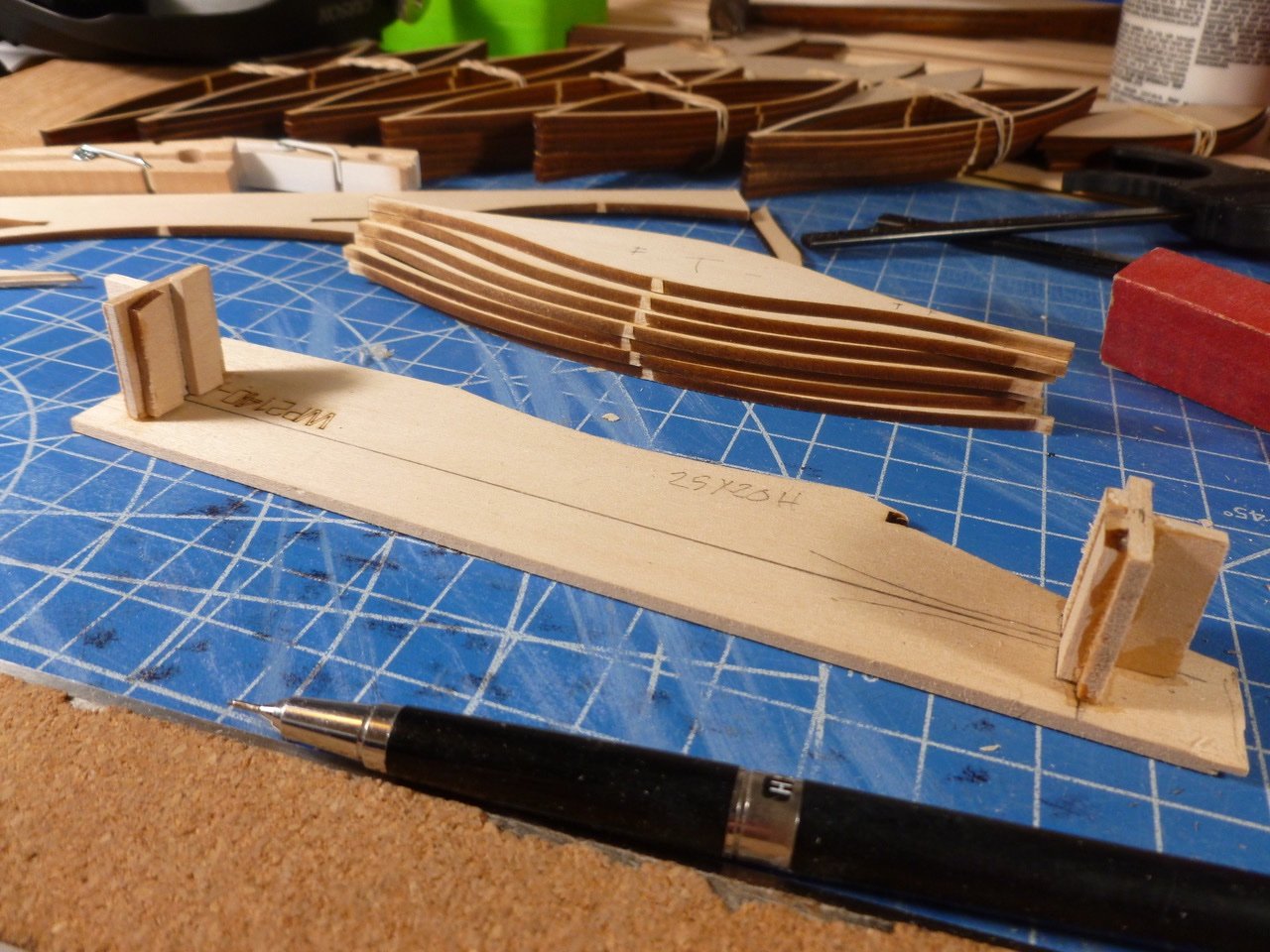

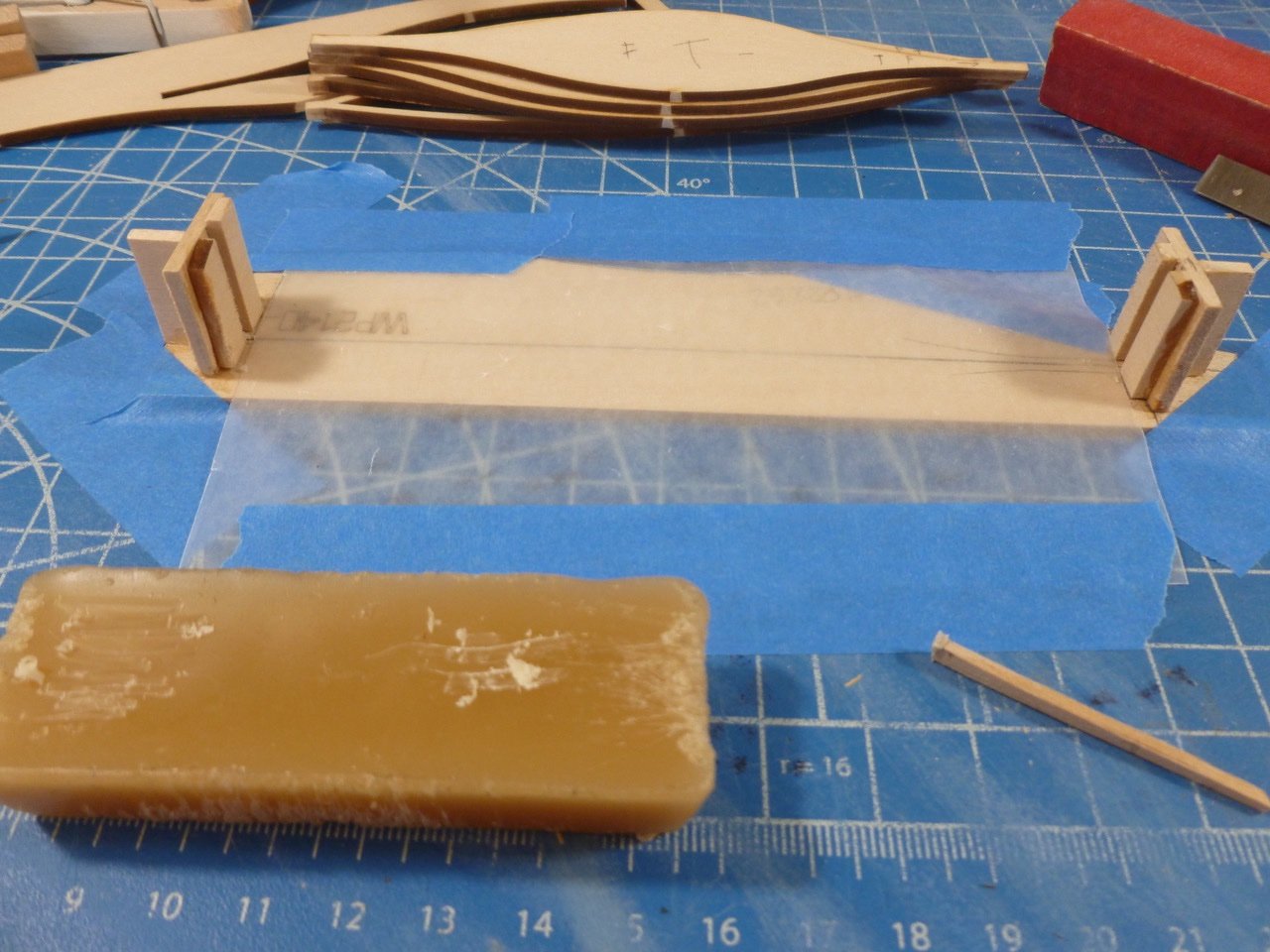

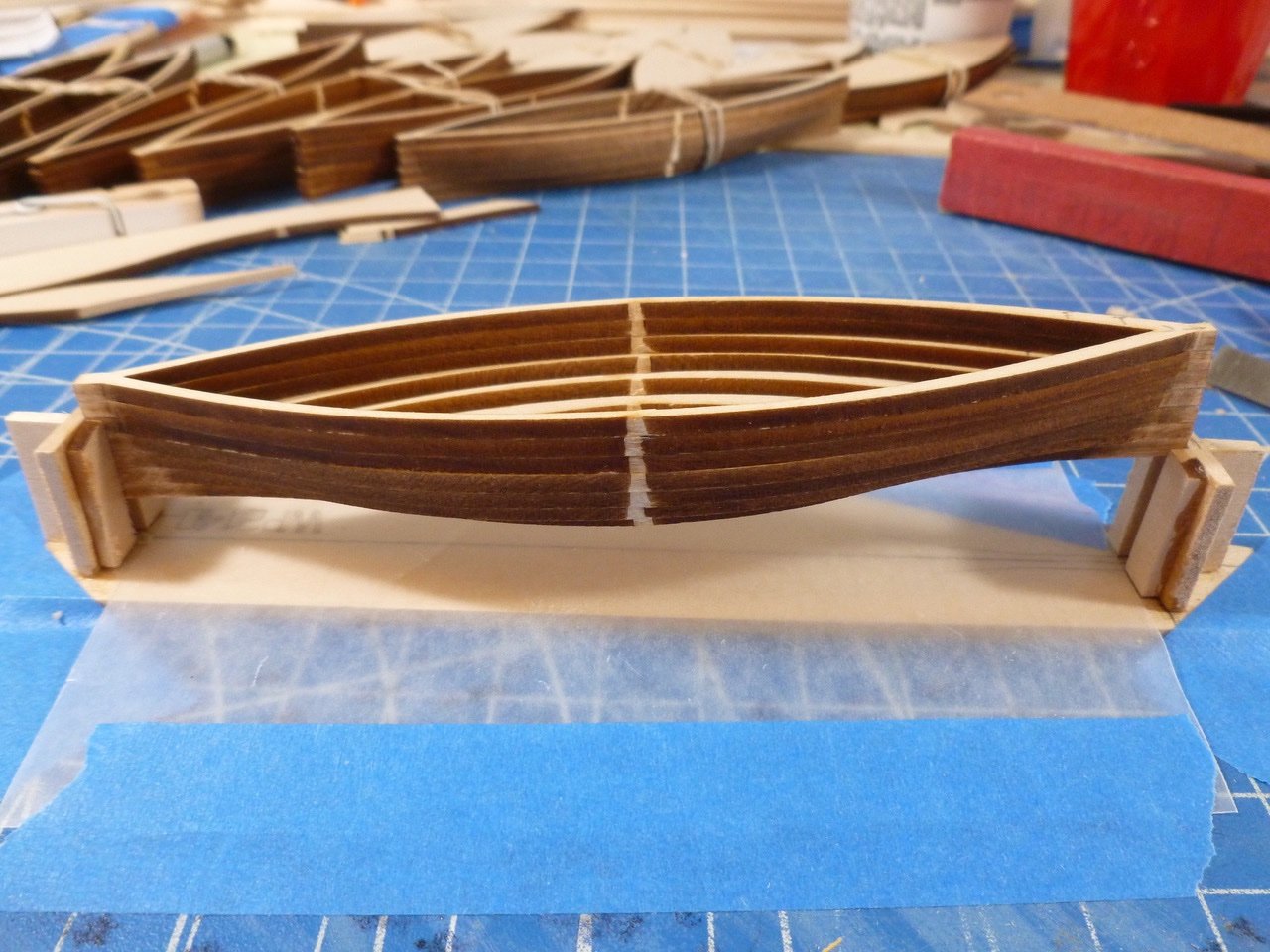

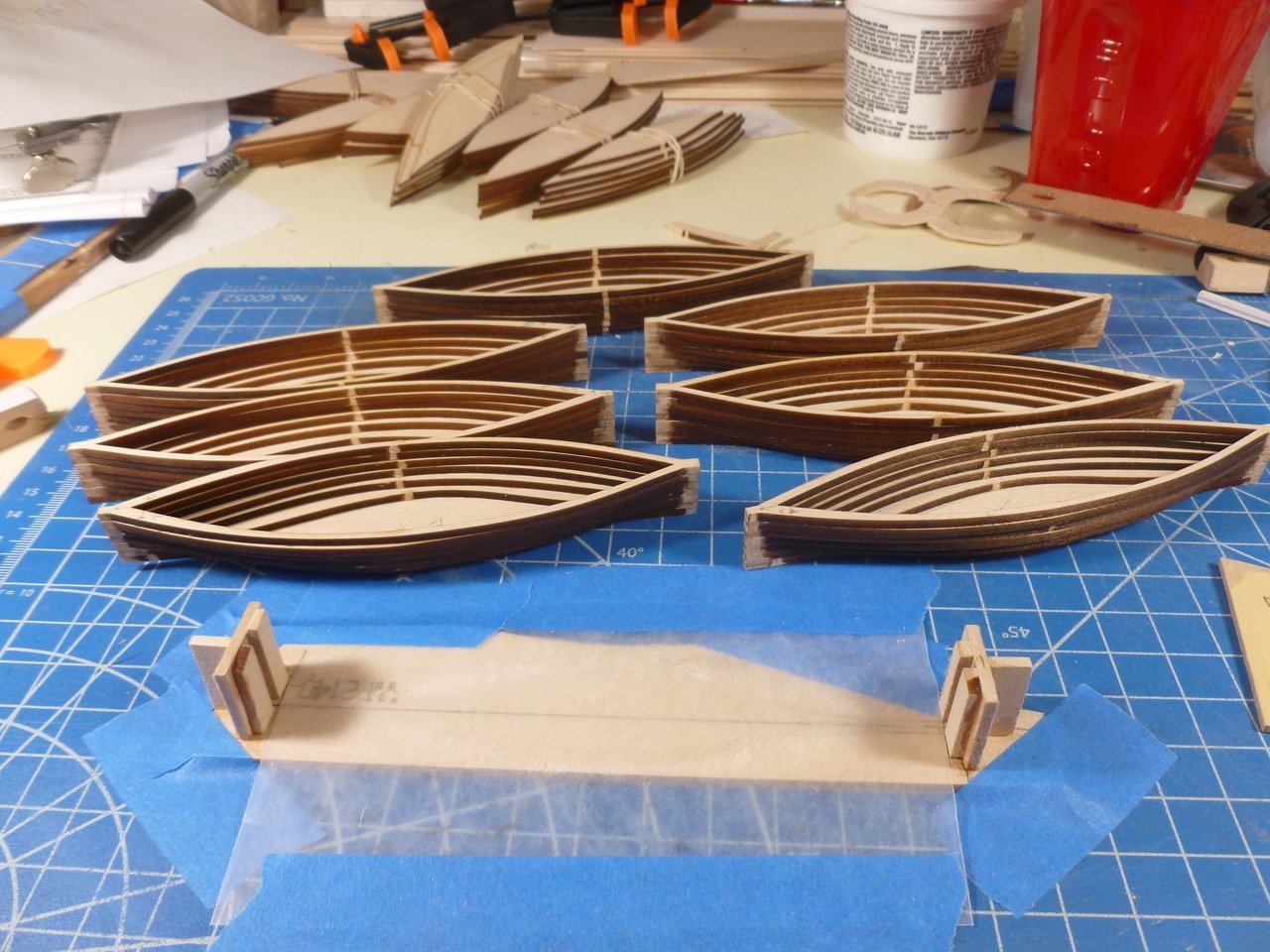

To those who stopped by or gave likes, thank you for your interest and enthusiasm. David, I'm glad I could brighten your day. Your CWM brightens mine every time I check the photos to see what's possible to achieve. Boats, boats, boats. Since I’m in the mode of building small bits and pieces I decided to tackle the whale boats. Seven laser cut pieces, with one boat per piece and seven “slices of bread” per boat make lots of opportunities to mess up. The first question was what order the slices should be in. Before I started cutting I labeled each boat slice with a letter to designate the boat, a T for “top” and an arrow pointing toward one end. One end is slightly wider than the other which helped the orientation. As I separated the slices from the carrier sheets I thought the waste pieces in the center of each slice might come in handy so I labeled each group of waste (A, B, C, etc) to match the corresponding sets of slices. Then I realized that the boat interior gradually gets bigger from bottom to top. I arranged the center waste pieces going from smallest to largest and matched them up to the slices. After that I added a number to each slice, again going from bottom to top. After loose fitting and rubber banding the slices the next questions were how to align them when gluing and how to clamp the thin edges so they wouldn’t slide out of position. I tried mini-bar clamps, with and without clothes pins but this looked awkward and would need to be assembled and disassembled for each slice. I settled on using a jig. At each end there were two vertical strips set to the width of the slice tabs, mounted on a backing piece and supported with a little strong-back. To help ensure I could remove a completed boat from the jig I rubbed a bit of beeswax in the end grooves and covered the base plate with wax paper. The jig turned out pretty tight fitting so I sanded the laser char from each tab end, then stacked the slices in reverse order starting with the bottom slice at the top. This way I could take a slice from the top, add glue (I used CA) to the underside (except at the bottom slice) and place it in the jig. I used a scrap piece of oak and finger pressure to clamp each layer for about 30 seconds. The other piece of scrap clamping wood is there only because the oak wasn’t long enough. And that piece has no finger because it is on the shutter release. And the first boat actually lifted out with very little encouragement. A bow view shows the layers were reasonably well aligned. In fairly short order all boats were glued up and ready for sanding. Now I have to figure out how to get them to all look the same. I have a book on order, The Whaleboat: A Study of Design Construction and Use from 1864 to 2014 by Willits Ansel, which I hope will give guidance on details. Thanks for viewing. Steve

-

Chris, I am humbled by your kind feedback and support. Thank you. David, your blog is my instruction manual. I have started on whale boats and have your pics in my reference folder; you’ve set a very high bar indeed. Thank you Rookie, thanks for your ongoing support. The rope eyes are just thin slices of half round. To all who stopped by or gave likes, thank you for your interest. Work is going slow but I’ll have a whale boat update soon. Thank you again. Steve

-

ESF reacted to a post in a topic:

Charles W Morgan by rookie - Artesania Latina - 1:50

ESF reacted to a post in a topic:

Charles W Morgan by rookie - Artesania Latina - 1:50

-

ESF reacted to a post in a topic:

Charles W Morgan by rookie - Artesania Latina - 1:50

ESF reacted to a post in a topic:

Charles W Morgan by rookie - Artesania Latina - 1:50

-

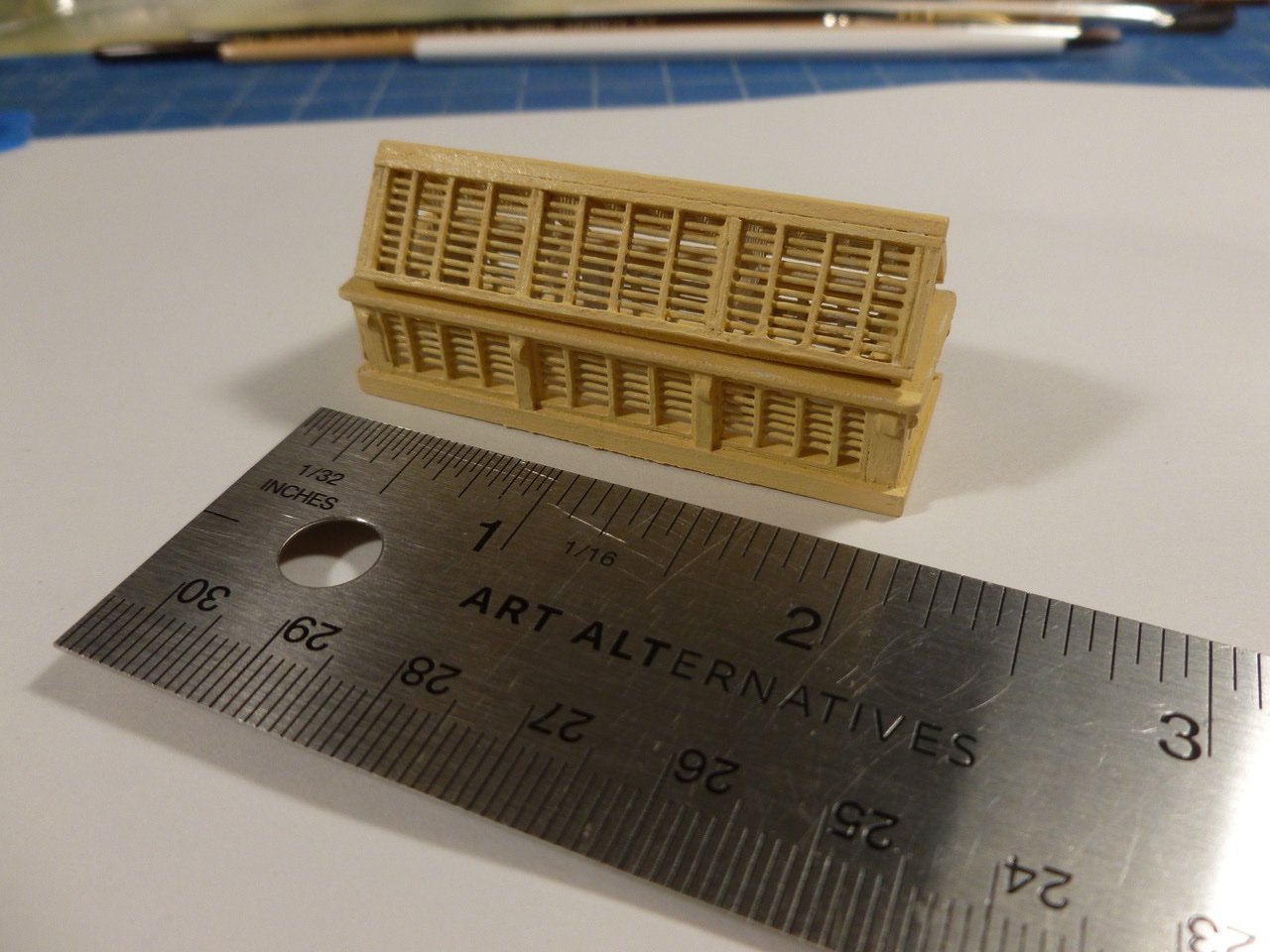

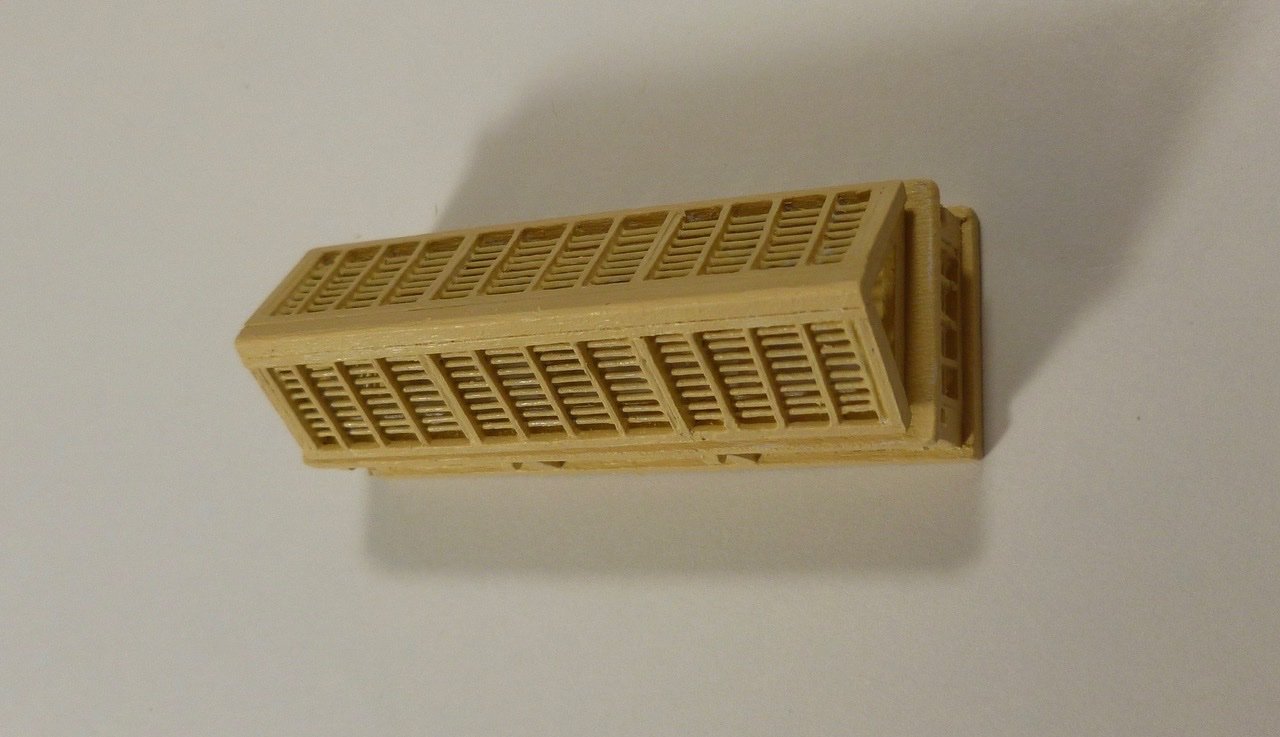

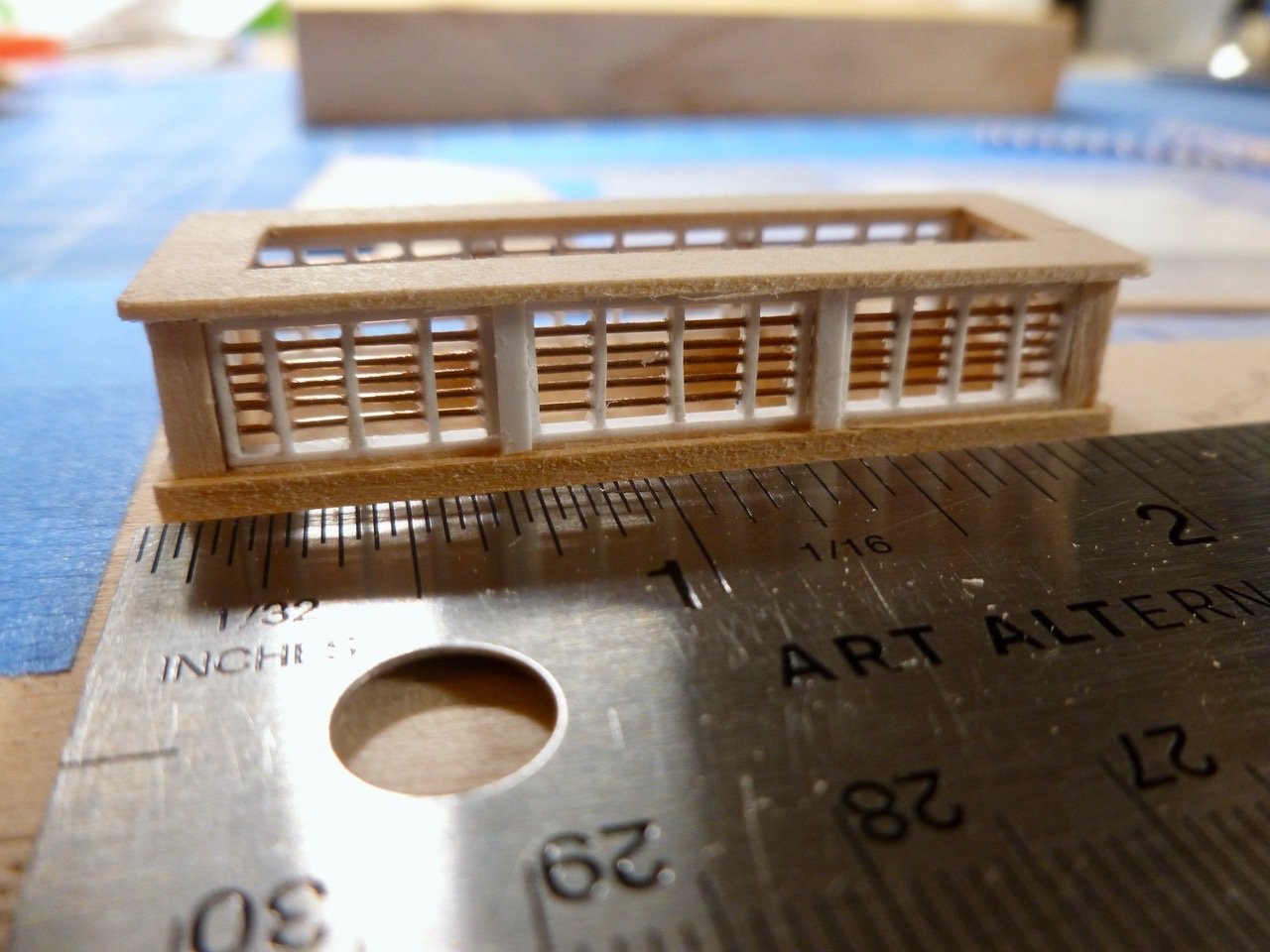

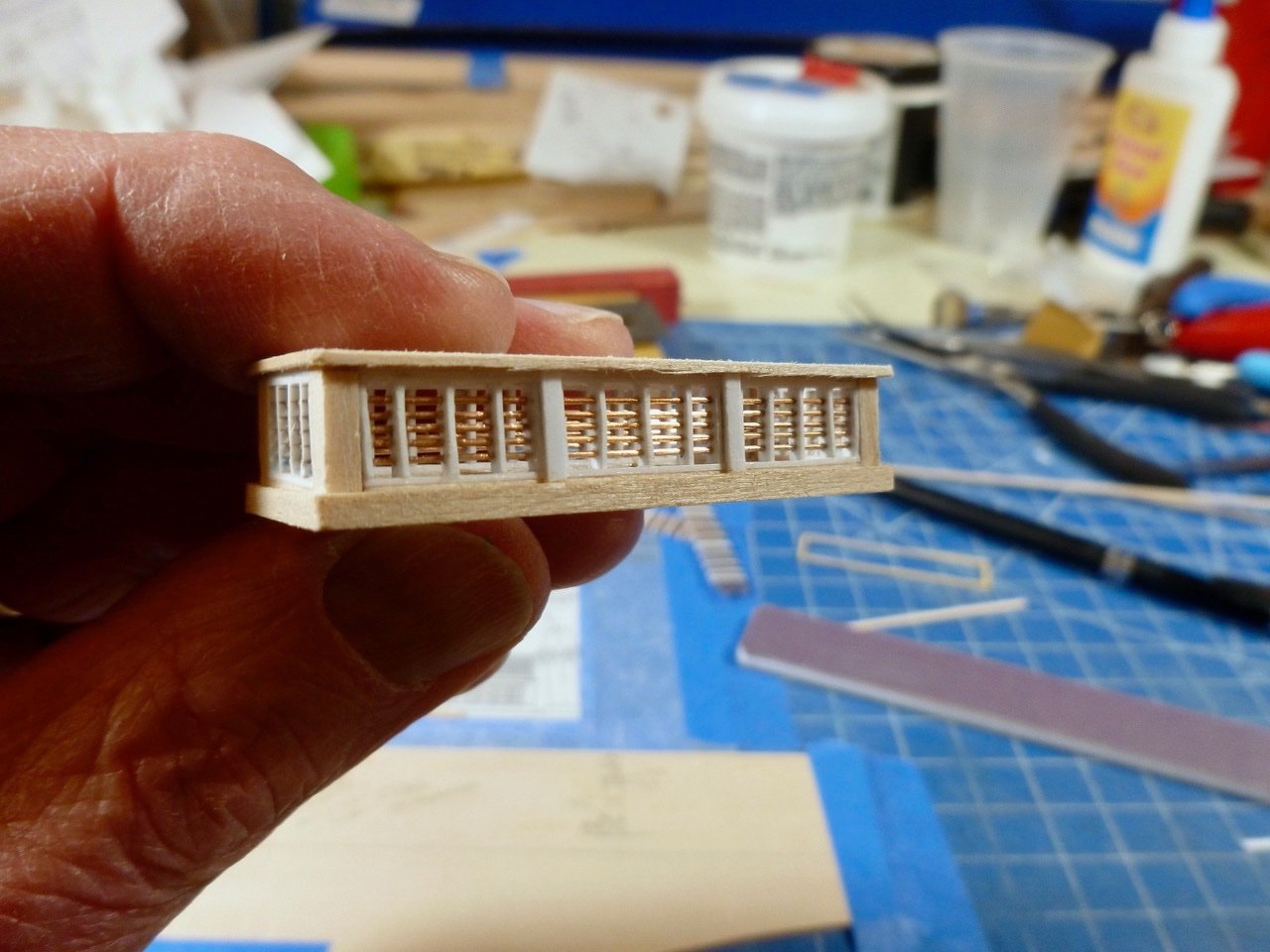

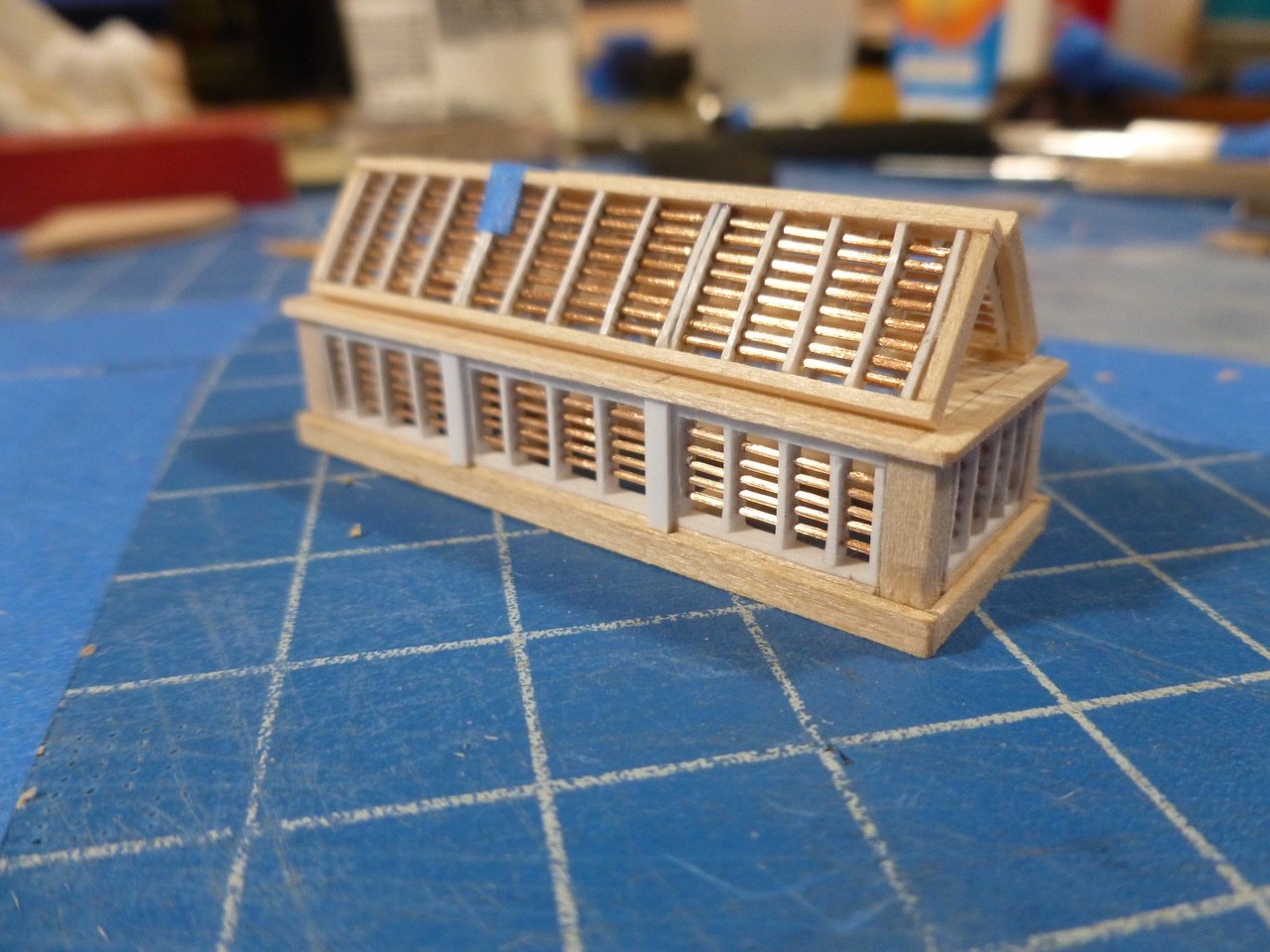

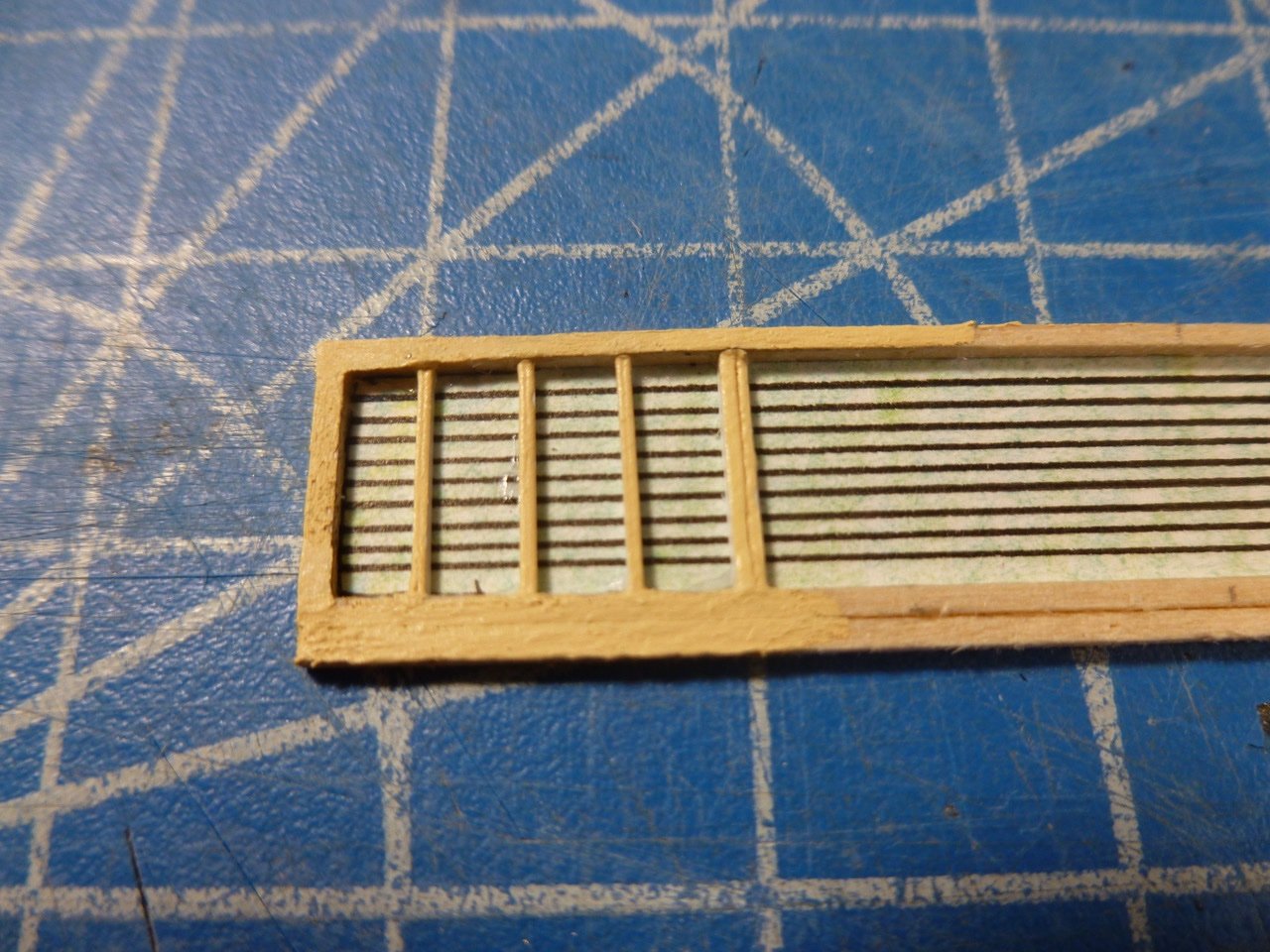

To those who stopped by or gave likes, thank you for your interest and enthusiasm. Rookie and JJ, thank you for hanging in there and for your kind remarks. After sanding, vacuuming and a swipe with the tack cloth I applied a primer coat of B-I-N to the skylight. This is very fast drying so I slowed it down a bit with a few drops of ammonia mixed 1:1 with water. Even then I had to rinse the tiny brush repeatedly with the same mix to keep it from clogging since the work was so slow, about three hours. I also primed the inside, mainly on the styrene bits since I understand they don’t like light. I applied a coat of acrylic house paint, which is also fast drying and a bit thick so I slowed it down with a few drops of retarder. It helped keep the paint from skinning over in the plastic palette cup and also helped the flowability. The retarder is Floetrol by Flood. The smallest available is a quart but at about $10 it was quite a bit cheaper than little craft size bottles of other stuff. I guess I'll be flowin' smoothly for life. The roof bars aligned well from one side to the other and with the side bars. I couldn’t resist throwing in another scale picture. The bump outs (poor terminology I know) on the side were cut from 0.020 half round styrene, which is out of scale but adds some interest. Now all I need is a ship deck. Thanks for viewing. Steve

-

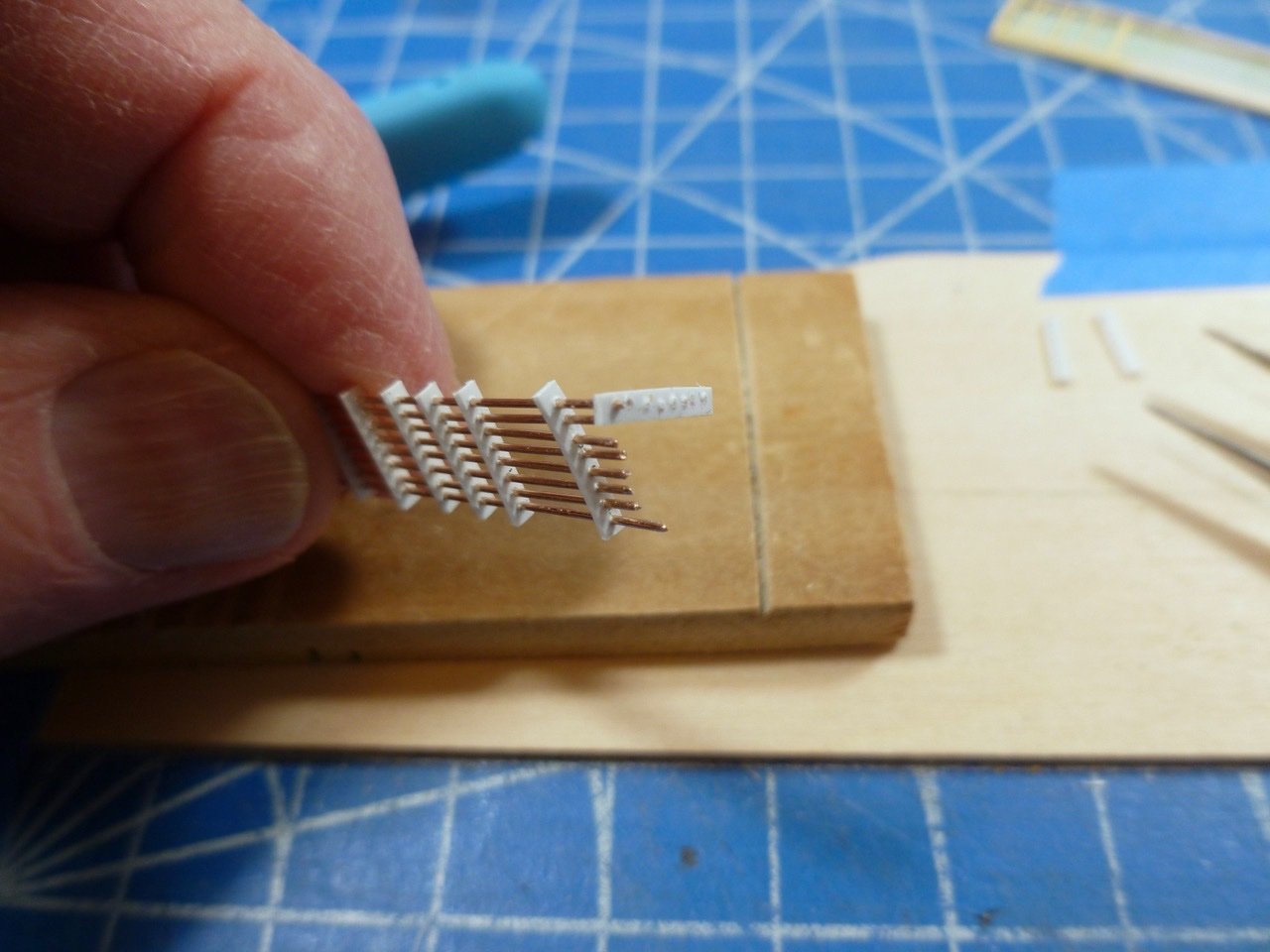

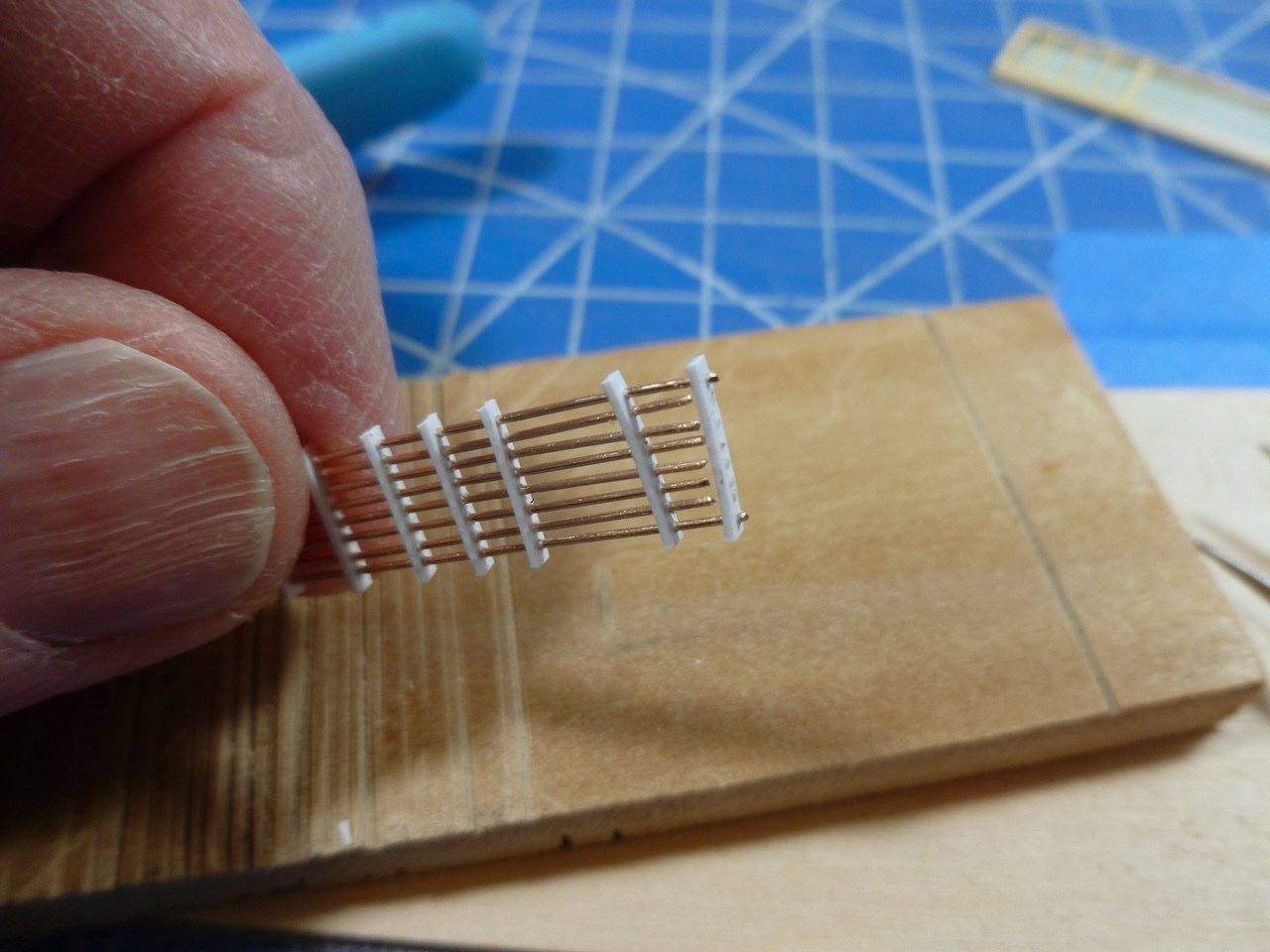

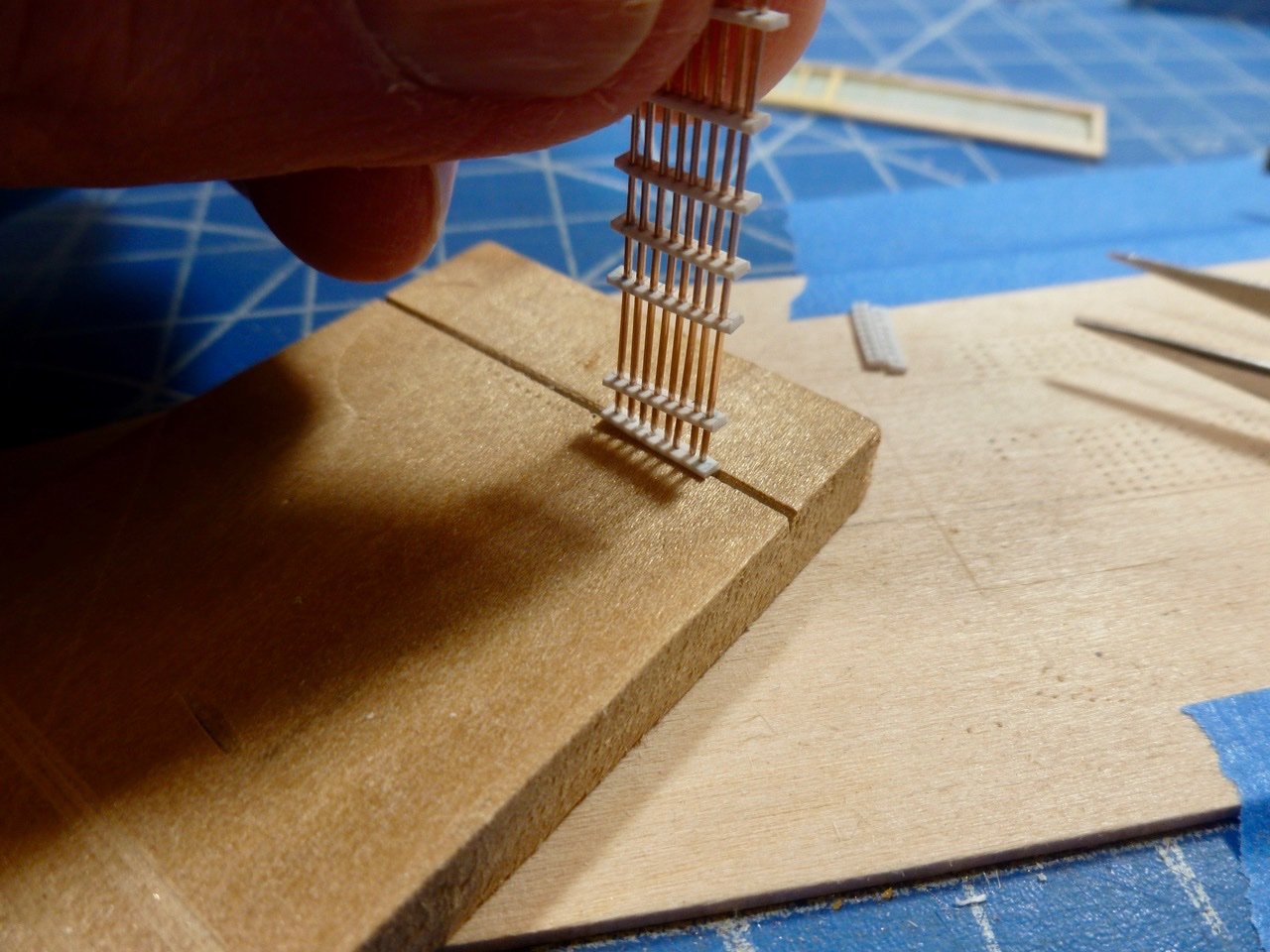

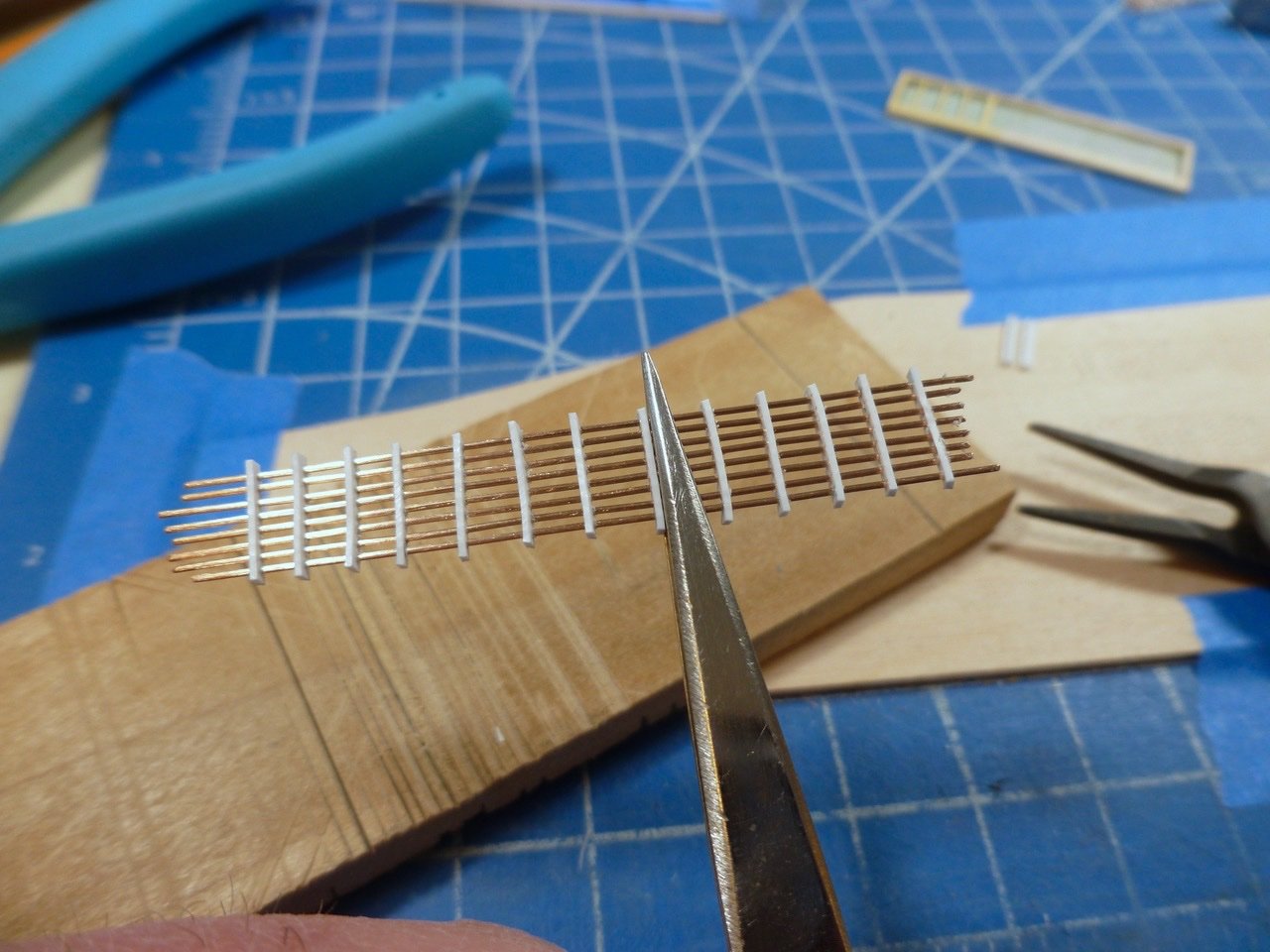

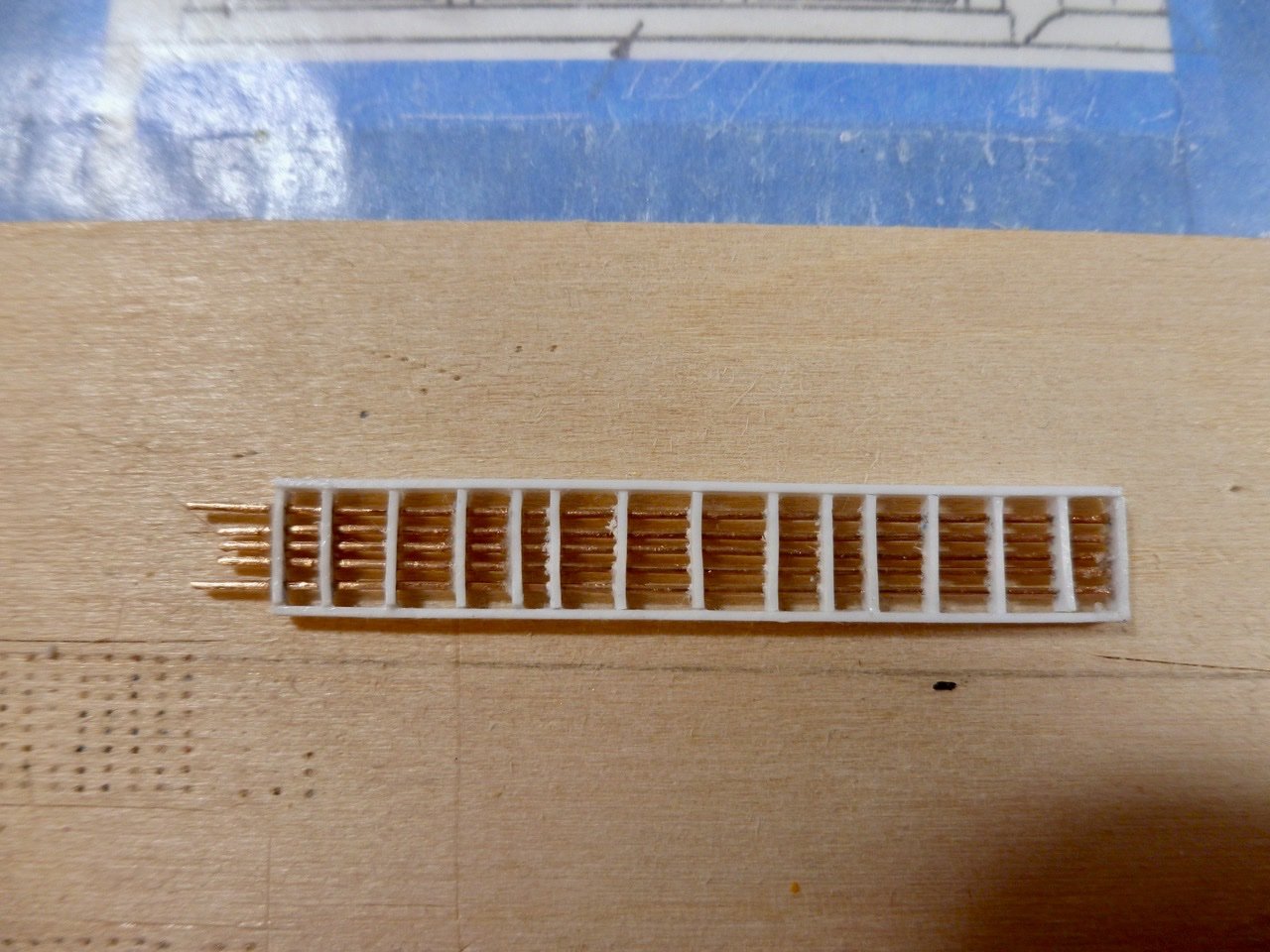

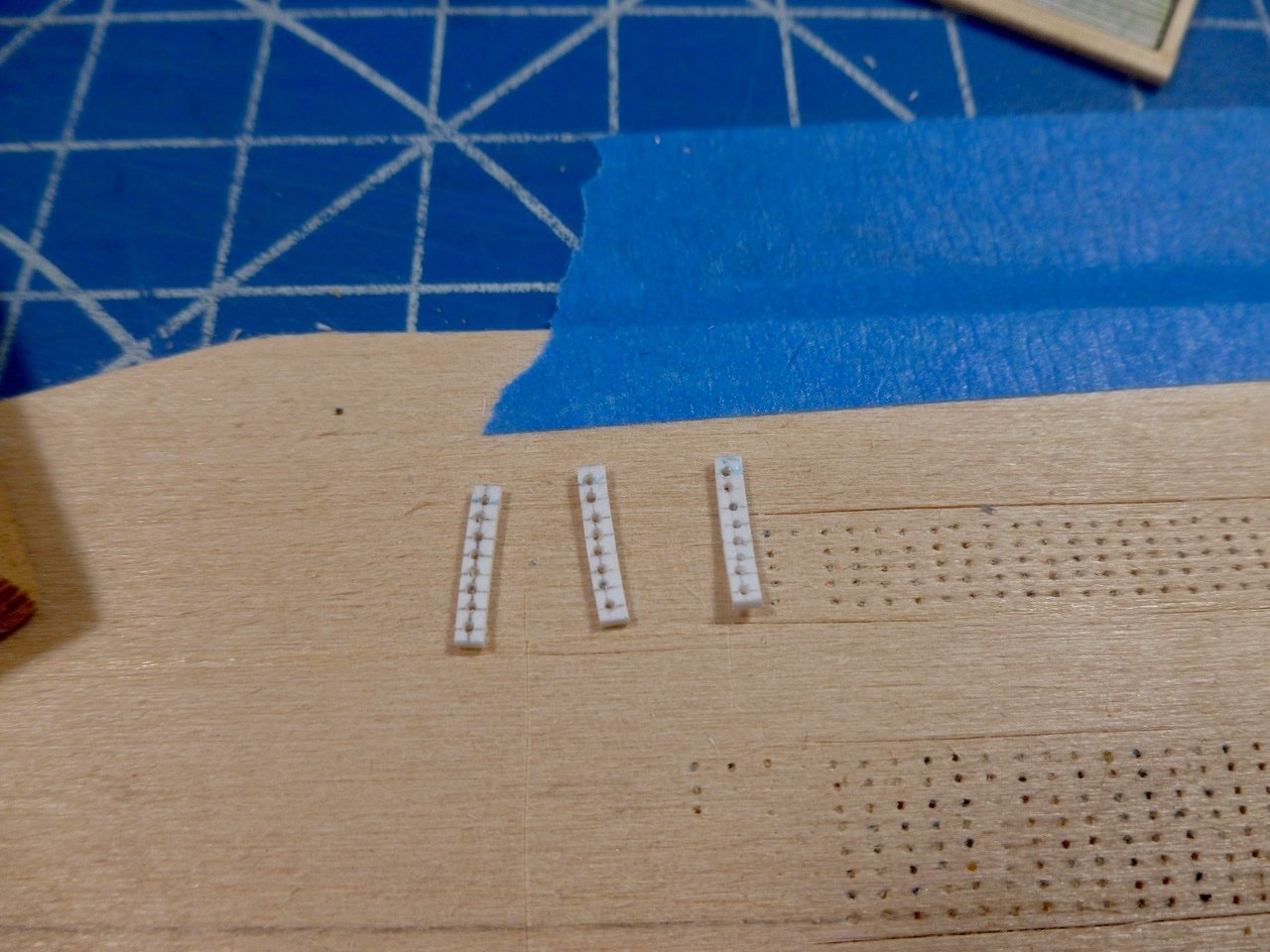

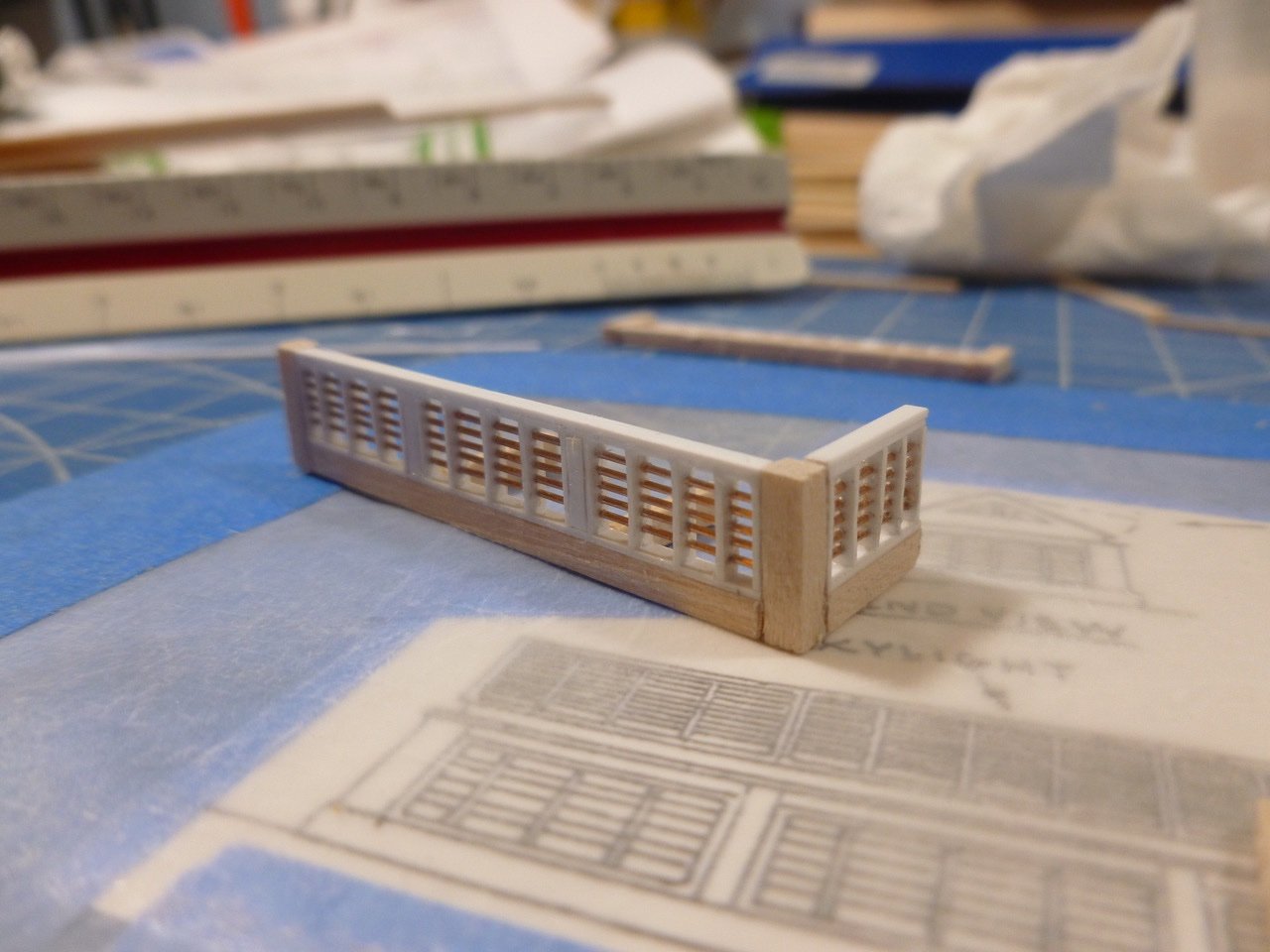

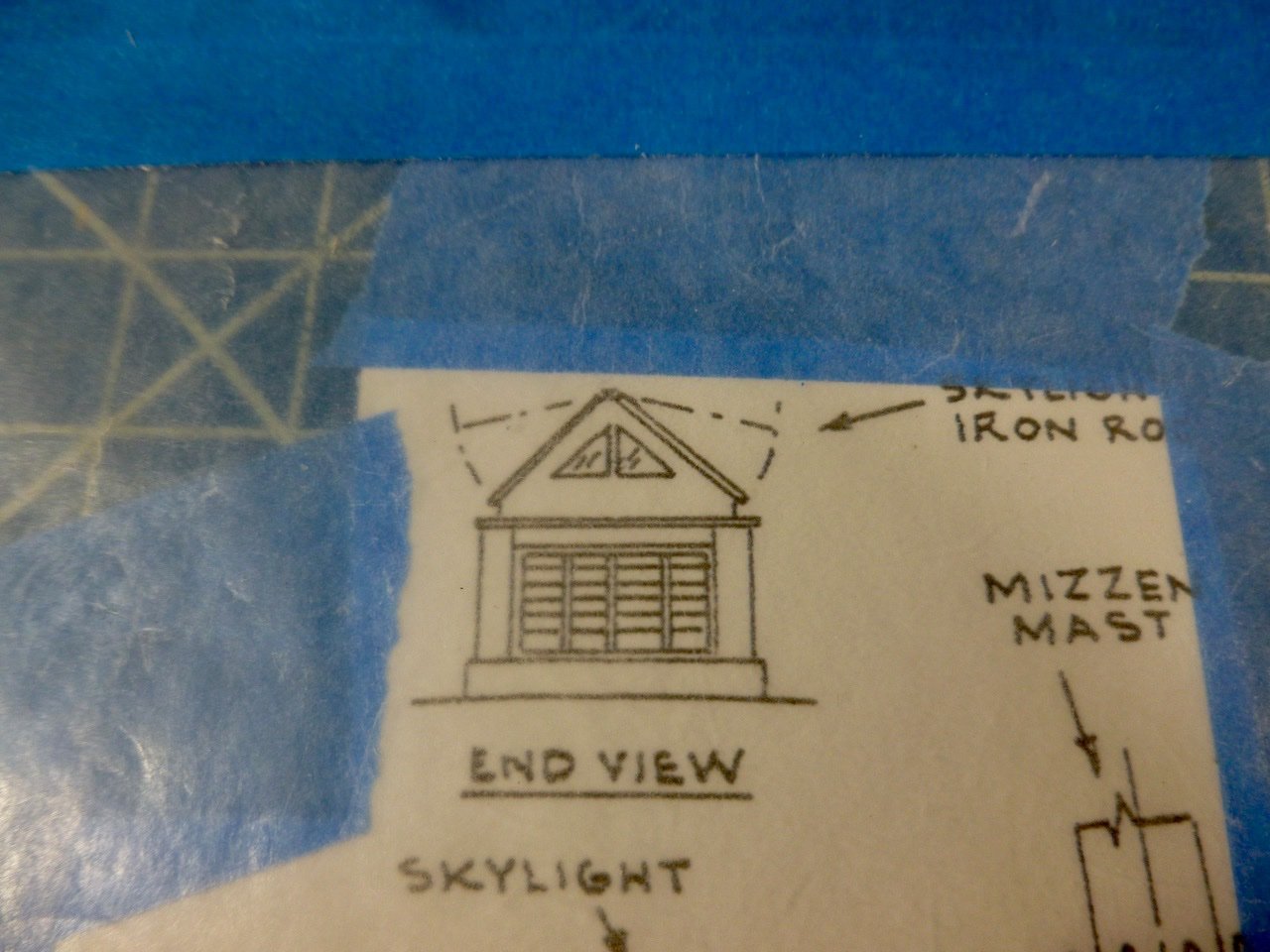

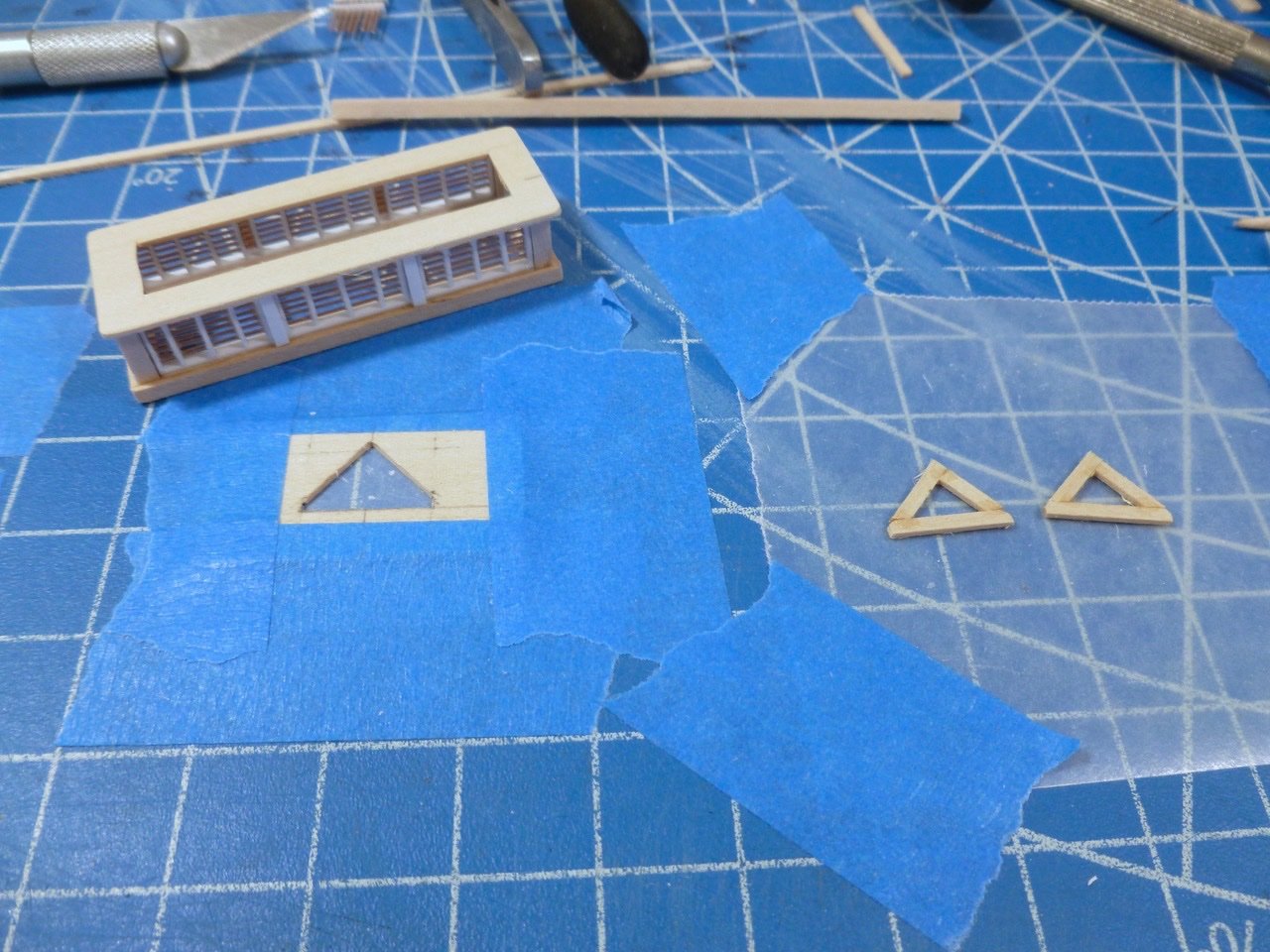

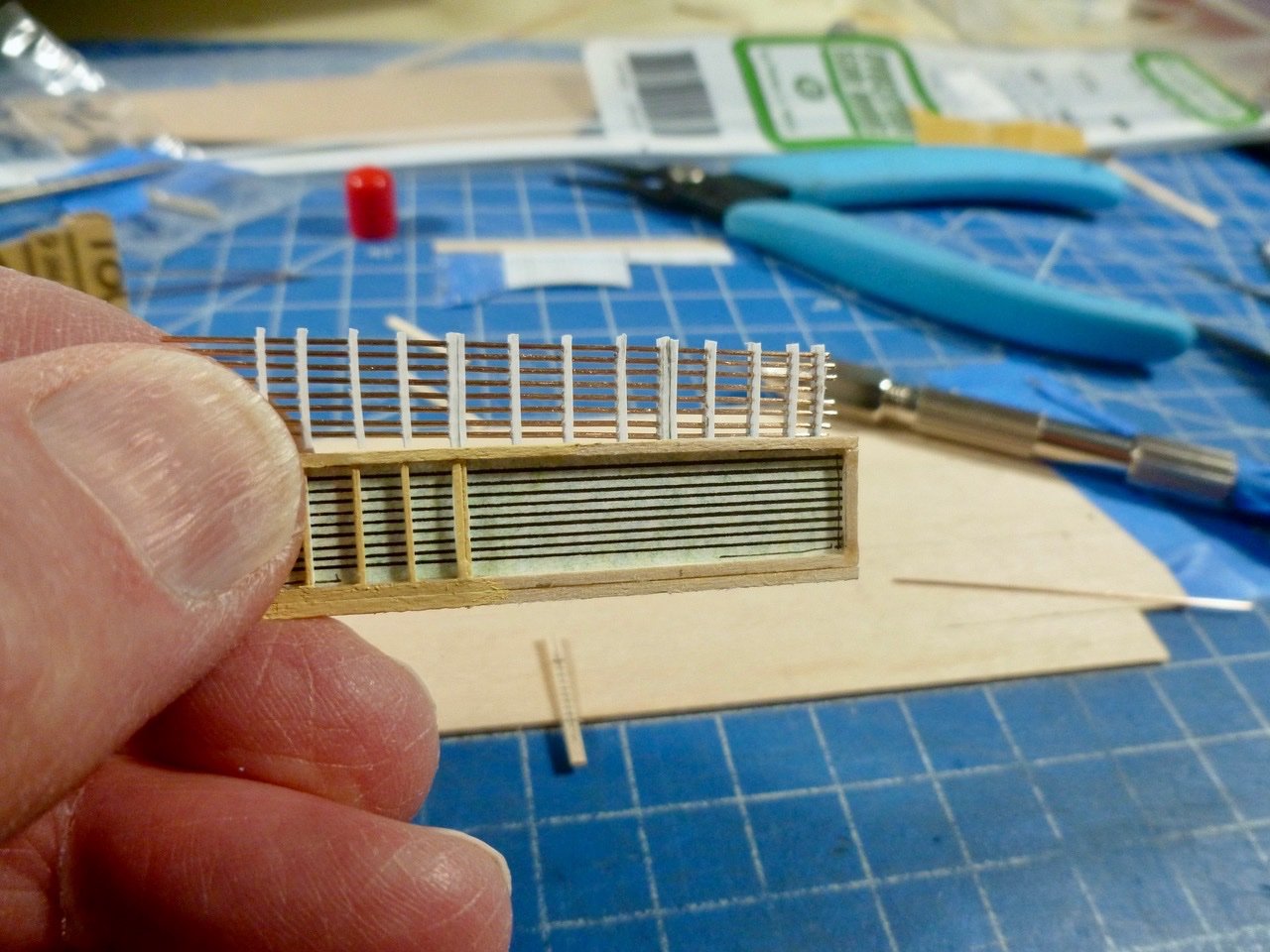

To those who stopped by or gave likes, thank you for your interest and enthusiasm. Rookie, thank you for your kind comments. I’ve seen your work. You deserve to upgrade “rookie” to better reflect your skill. The skylight is chugging along at a pace that my old eyes can focus on it. Many bars, many muntins so how do they all come together? There may be better ways but this is how I threaded all the muntins onto the bars. A handy jig was a shallow and narrow slot in a piece of wood to support the muntin while the bar was inserted. Two closely spaced razor saw slots provided room for the bar. Once all the muntins for a section are lined up with tops and faces all pointing in the same direction I worked across the first muntin to insert the bars. After the first muntin I started with the first bar of the second muntin after pulling the bar through so it was slightly longer than the others. The slightly wavy line of holes in the bar above shows why it is important to keep adjacent muntins in order, with tops aligned and facing the same direction. Otherwise it's a much bigger challenge to thread the muntins onto the bars. I swung the muntin and inserted the last bar, which was also pulled through longer than the others. Once the last bar was in place, and assuming the muntins are in the same orientation as they were when drilled, the muntin can be leveraged and the remaining bars should align with the holes. I found that keeping the adjacent muntins fairly close to each other helped to keep the bars pointing in the right direction. Since the spacing did not allow for using tweezers between muntins I used a small screwdriver to encourage recalcitrant bars to get in their holes. Smooth tweezers were helpful in sliding the muntins along the bars. The styrene muntin material is relatively soft with all the holes in it, and required much fussiness to get the muntins sort of straight. After a fashion the bar units were ready. Adjusting the alignment was a never ending battle. Won some, lost some. I added caps to fully enclose the muntin bar units. Bar ends were snipped and sanded after CA was selectively added to a few muntins to keep them in place. I added a subbase under each wall unit and a second layer of capping on top to maintain the vertical dimension shown on the drawings. I split up the sections of bars as shown on the drawing with strips face-glued at the third points. After the walls were stood up I added the coaming base and more strips to build out the dividers between bar units. I cut a piece of 1/32 inch sheet to make a one piece base for the skylight roof assembly. The second photo above shows scale, which anyone with a passing interest in Morgan already knows but it is still cool. The skylight end view drawing shows the gable profile. I made a jig to match the profile but added a little to the peak height to accommodate the as-built dimension of the skylight roof panels. I made one for each end and one at each third point to help support the roof panels. After completing the roof panels I mocked up the full skylight, less the roof framing and gable ends. A backlit shot is below. Now the question is, what to do, if anything, about painting the inside of the skylight. I’m thinking it needs it but since most of the skylight will be tucked away and partially hidden…. Thanks for viewing. Steve

-

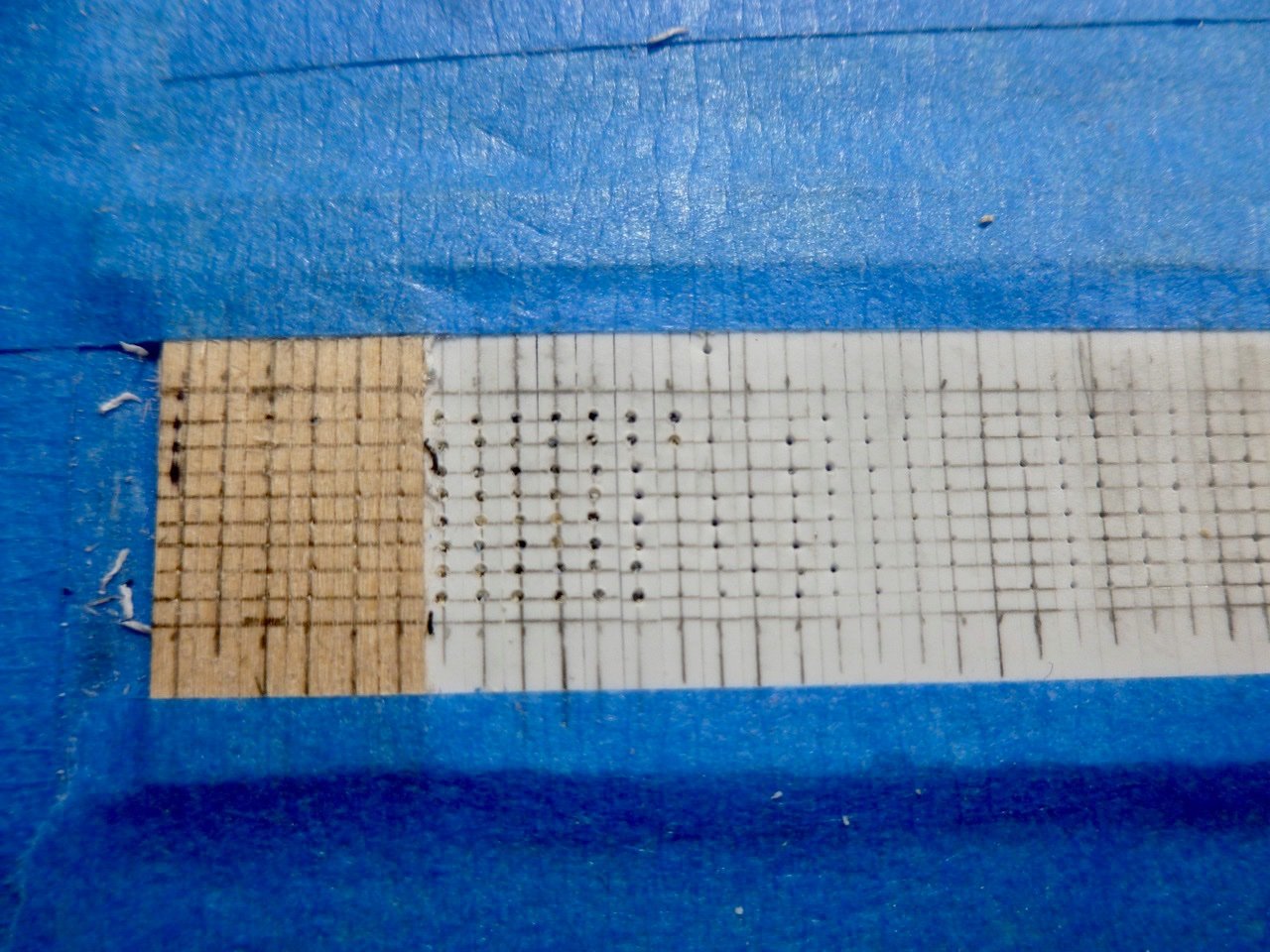

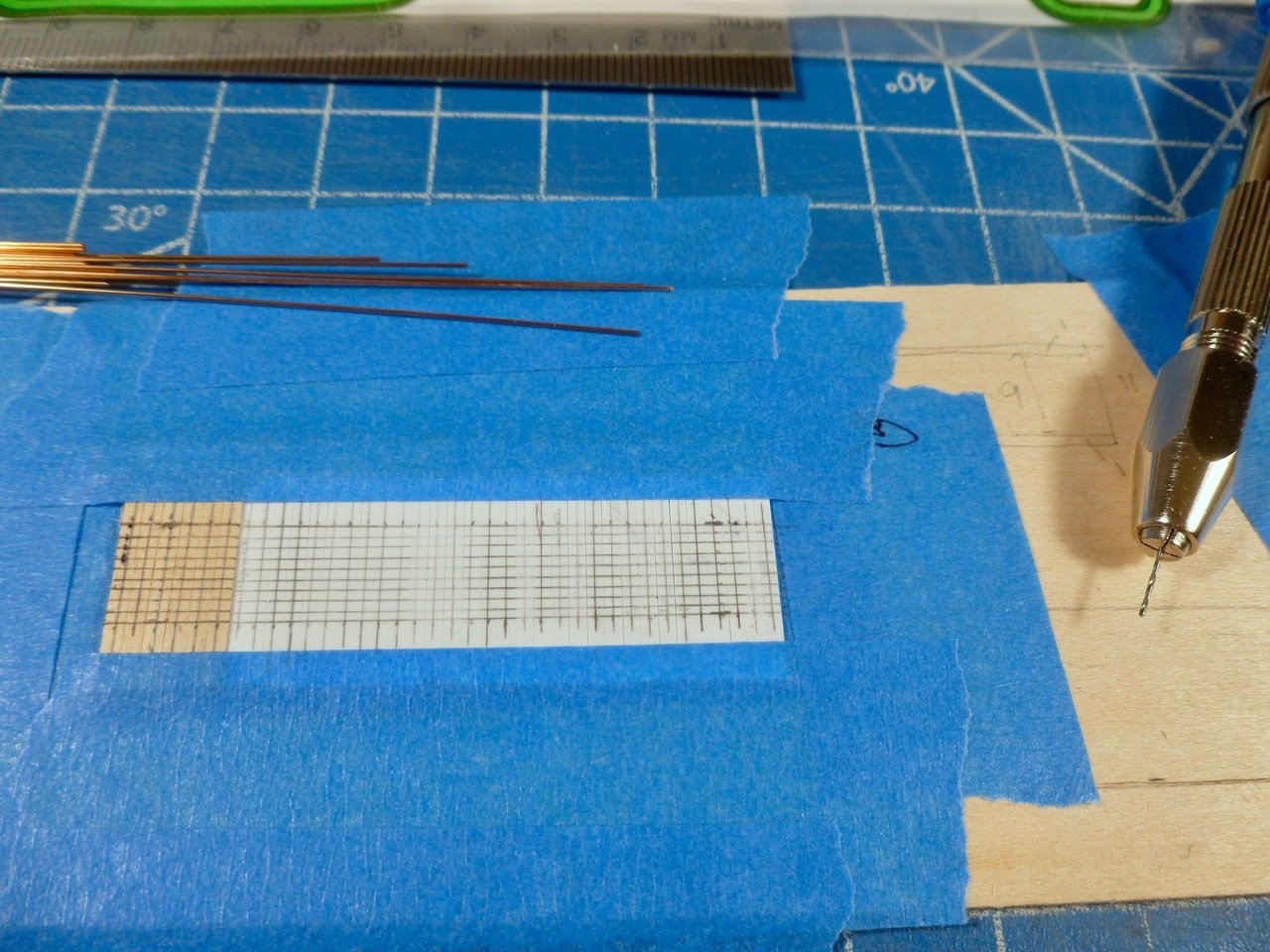

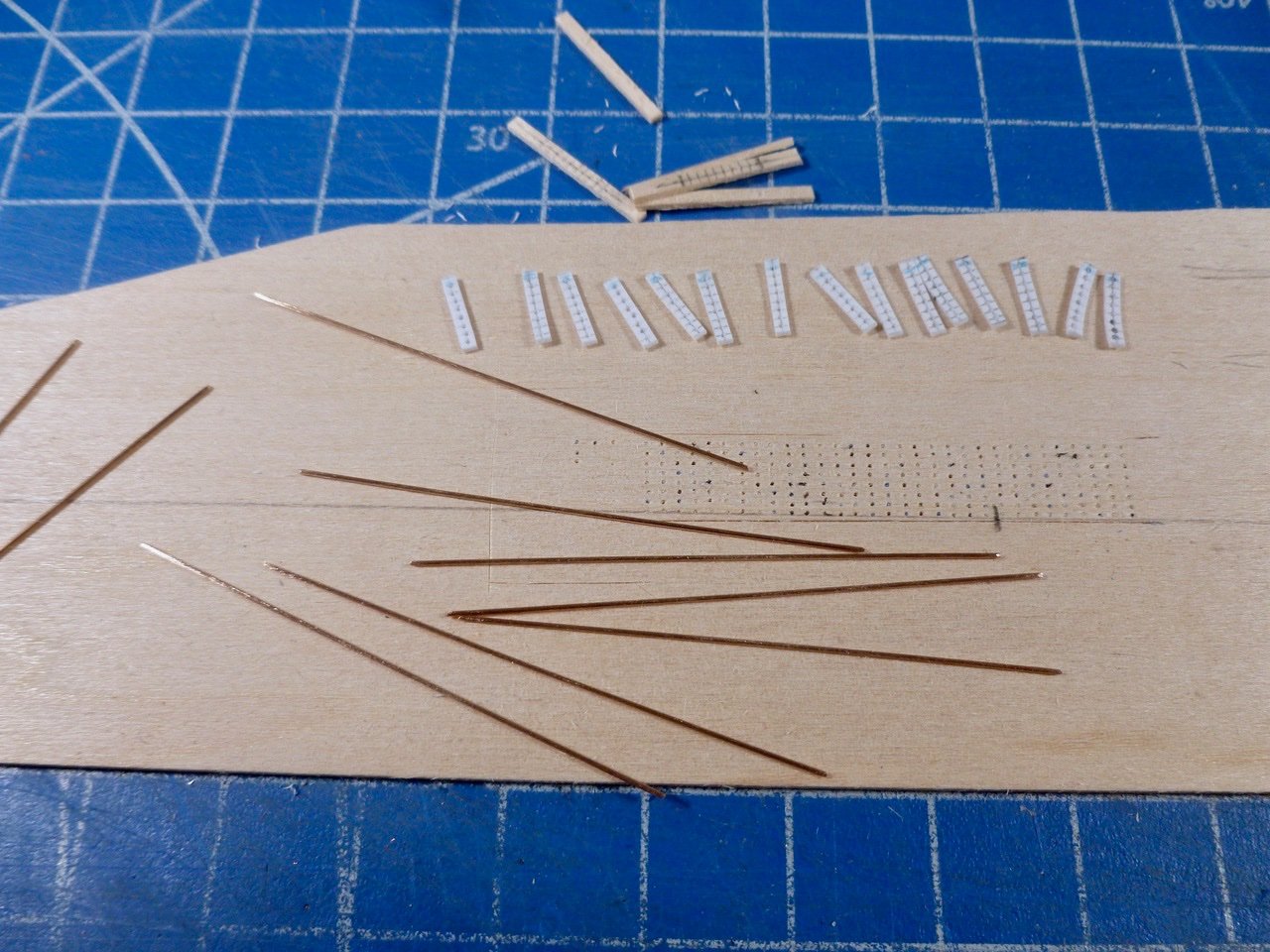

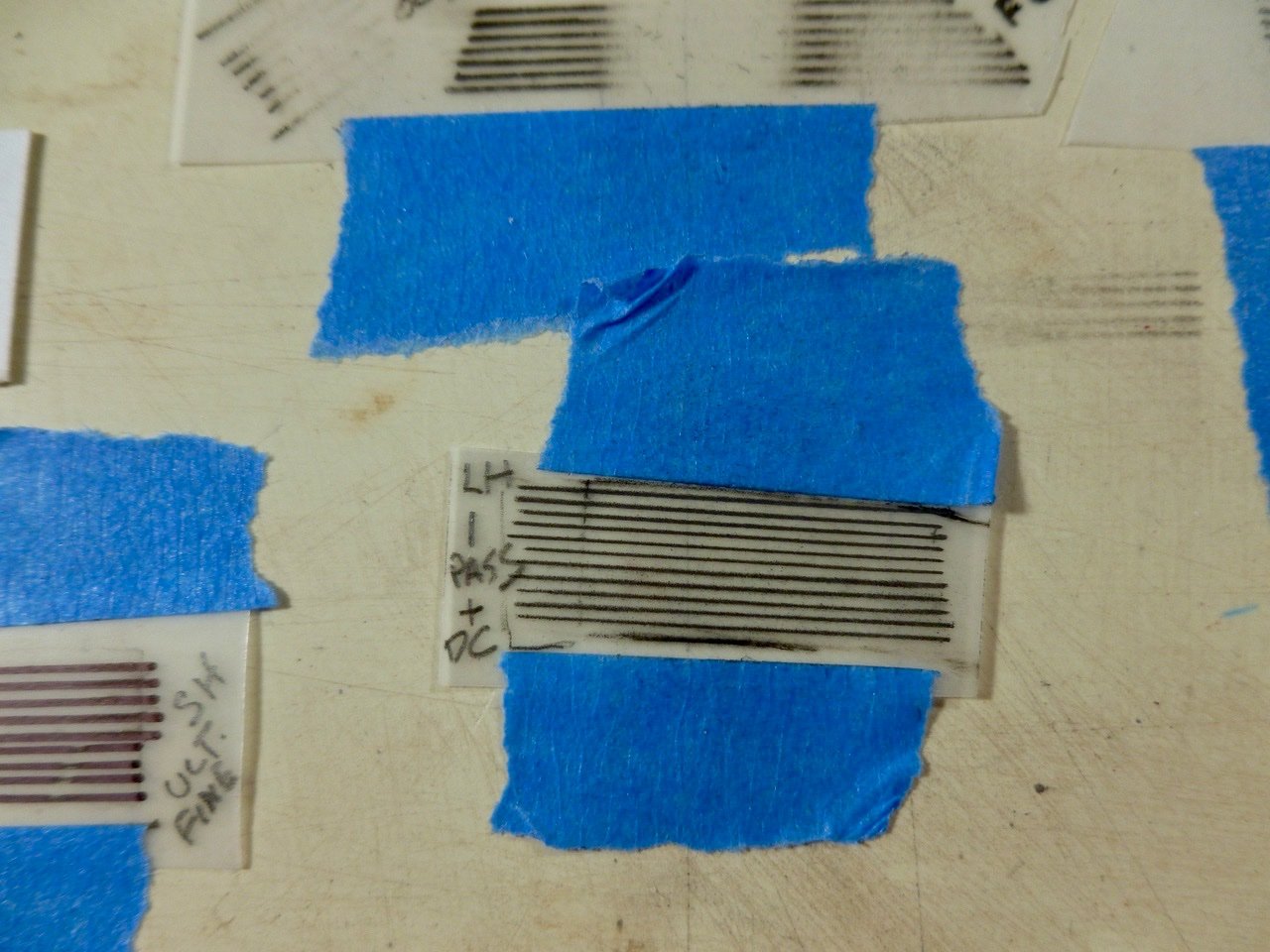

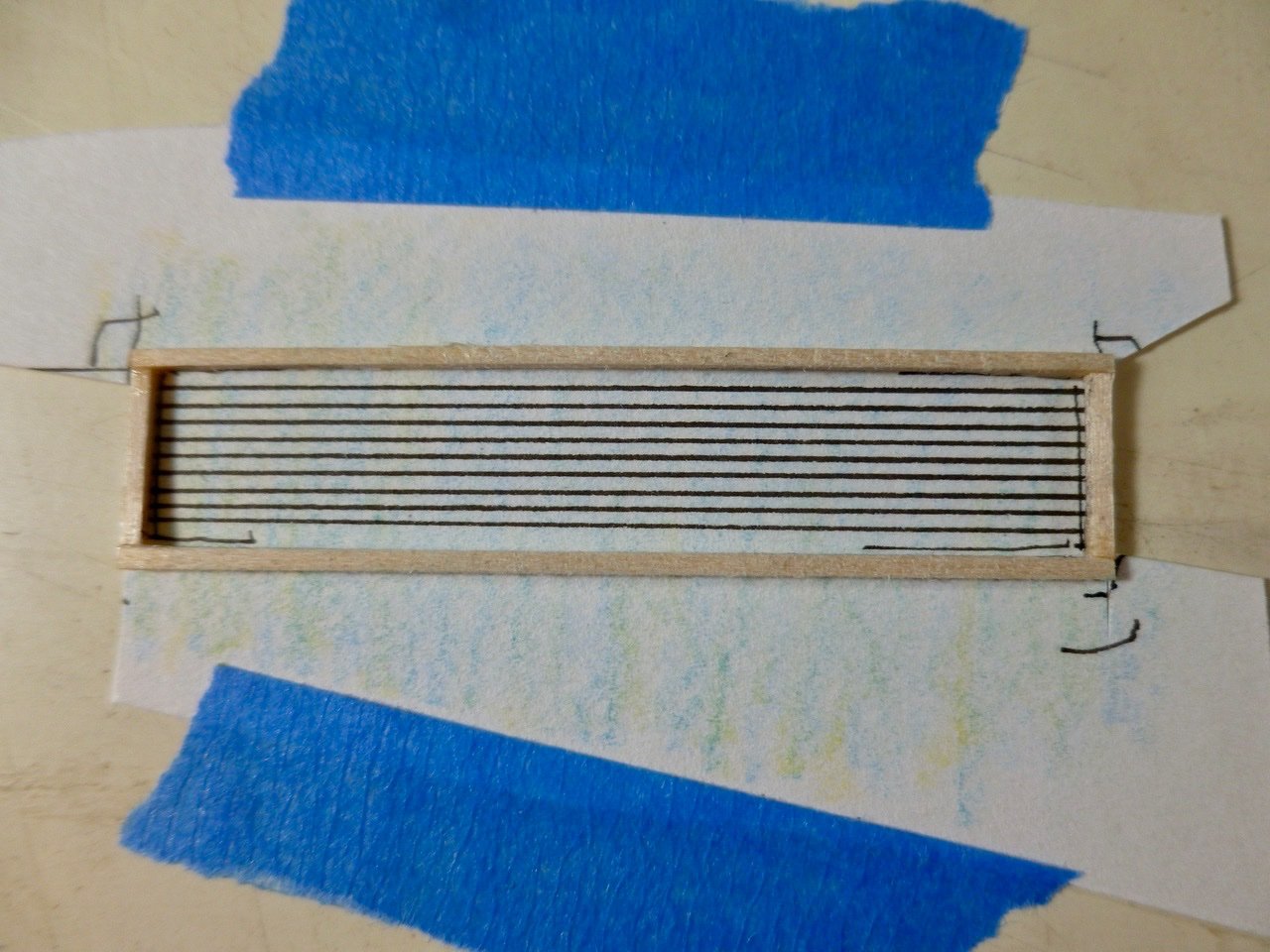

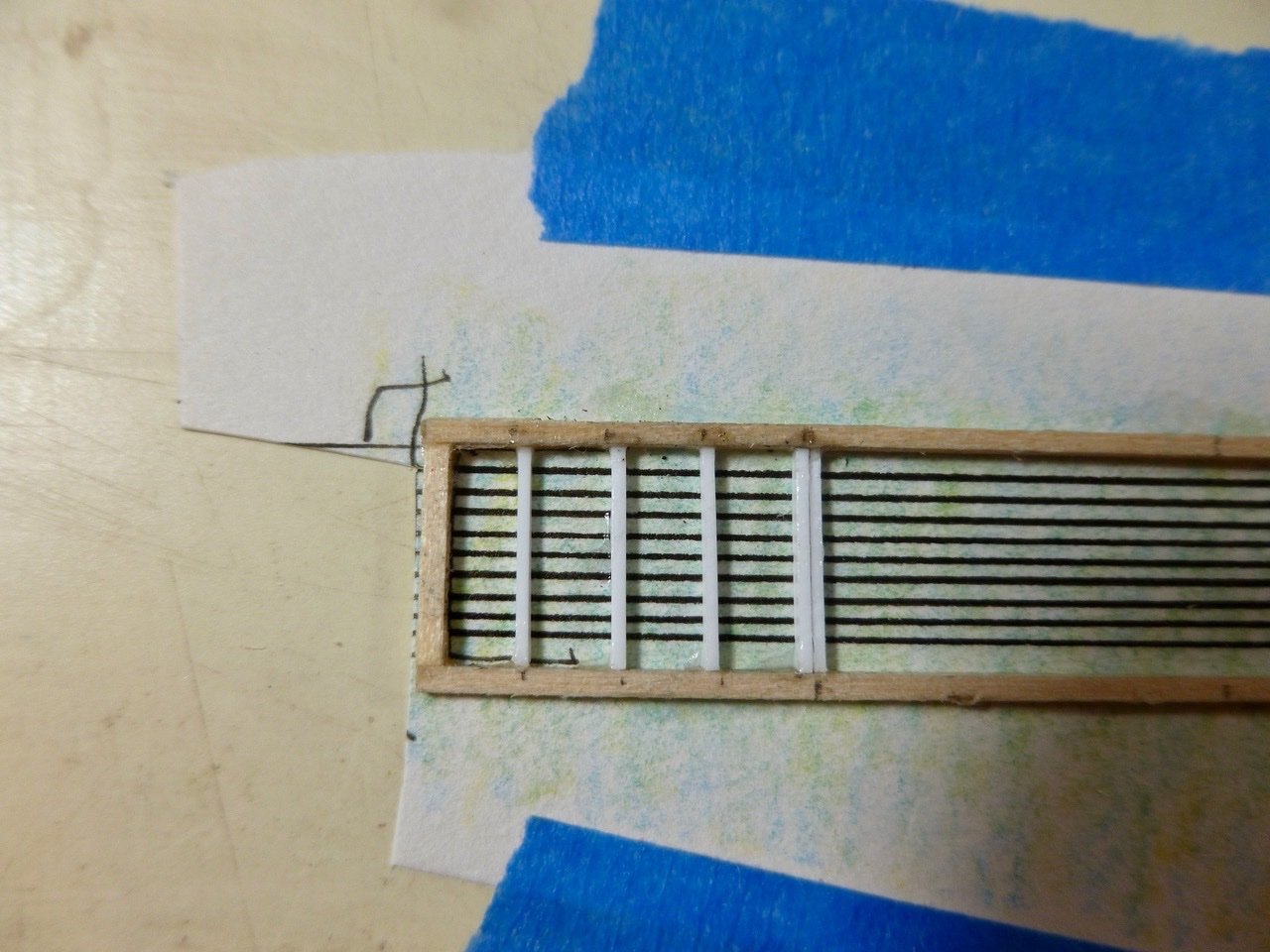

To those who stopped by or gave likes, thank you for your interest and enthusiasm. Rookie, thank you for your kind comments and suggestions, especially your note about 9 versus 8 bars. JJ, thank you for your ongoing participation and feedback. I’ve got another try at the skylight bars that I’m sharing today. I think either way could work. I’m not sure if I’m going to the darkside or the land of courage and enlightenment. I was leaning toward pen lines for bars, and holding off trying real skylight bars after the stacked muntin drilling disaster, and because I had no suitable drill bits. After the bits arrived I realized there might be a workaround to the stacked muntin drilling approach. I cut muntins over length to give some room for tape, then lined them up on a piece of tape using a strip of wood to keep them square. I drew vertical lines across the strips to establish bar spacing, then drew lines that bisected each strip. The crossing points gave the centers for drilling the muntins. This approach would require drilling of each hole (about 240 so far but who’s counting) but would hopefully keep the holes aligned for the bar and muntin assembly. Drilling tools included a sewing needle and ancient hammer for setting center points, and a pin vise with no. 76 bit. I added a bit of tape to the needle for better grip. The 76 bit (73 was my next and way too big) proved to be a very tight fit for the 0.020 bronze rod I had leftover from the Vance build so I poked each finished drill hole with the awl to give a bit more room. I was a “bit” exuberant with one awl poke which split a valuable muntin almost in half but a drop of CA and lots of gentle pressure restored it for use. Initially I included the vertical wood frames for each end in the drilling layout, but quickly realized they would likely split so I removed them from the drilling rotation. To anchor the bars at each end I added more drilled muntins that will be glued to the wood frames. Fortunately I had provided for extra muntins in the layout. Before detaching the muntins I added a colored pencil mark along one end to maintain the orientation during installation on the bars. I also made sure the muntin faces were oriented with the layout sides pointed in the same direction. The idea was to keep the holes in the same orientation vertically and horizontally. Since the muntins are about 1/16 inch deep I’ll have to change the wood frame from 1/32 inch square stock to 1/32 x 1/16. I caved to reality and reduced the bar count to eight. Nine bars (reality) were just too closely spaced for the bronze rod and I had so much of it that I didn’t want to buy a new pack of slightly smaller rod just for the sake of one bar. I think the lightness and transparency of bars will be preferable to nine black ink lines on solid backup. I’m anxious to complete the other bars and the wood framework to see if that proves true. Thanks for viewing. Steve

-

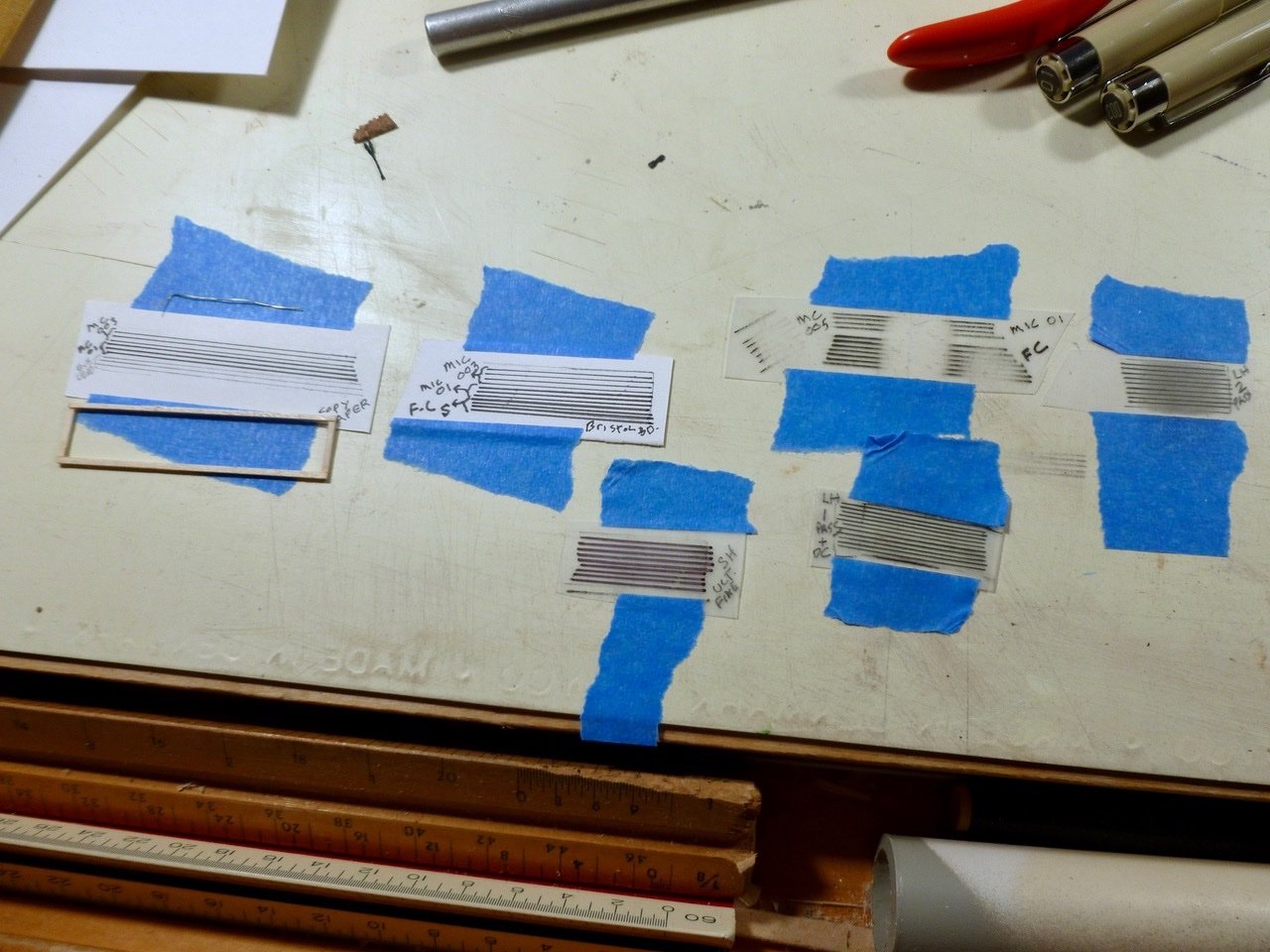

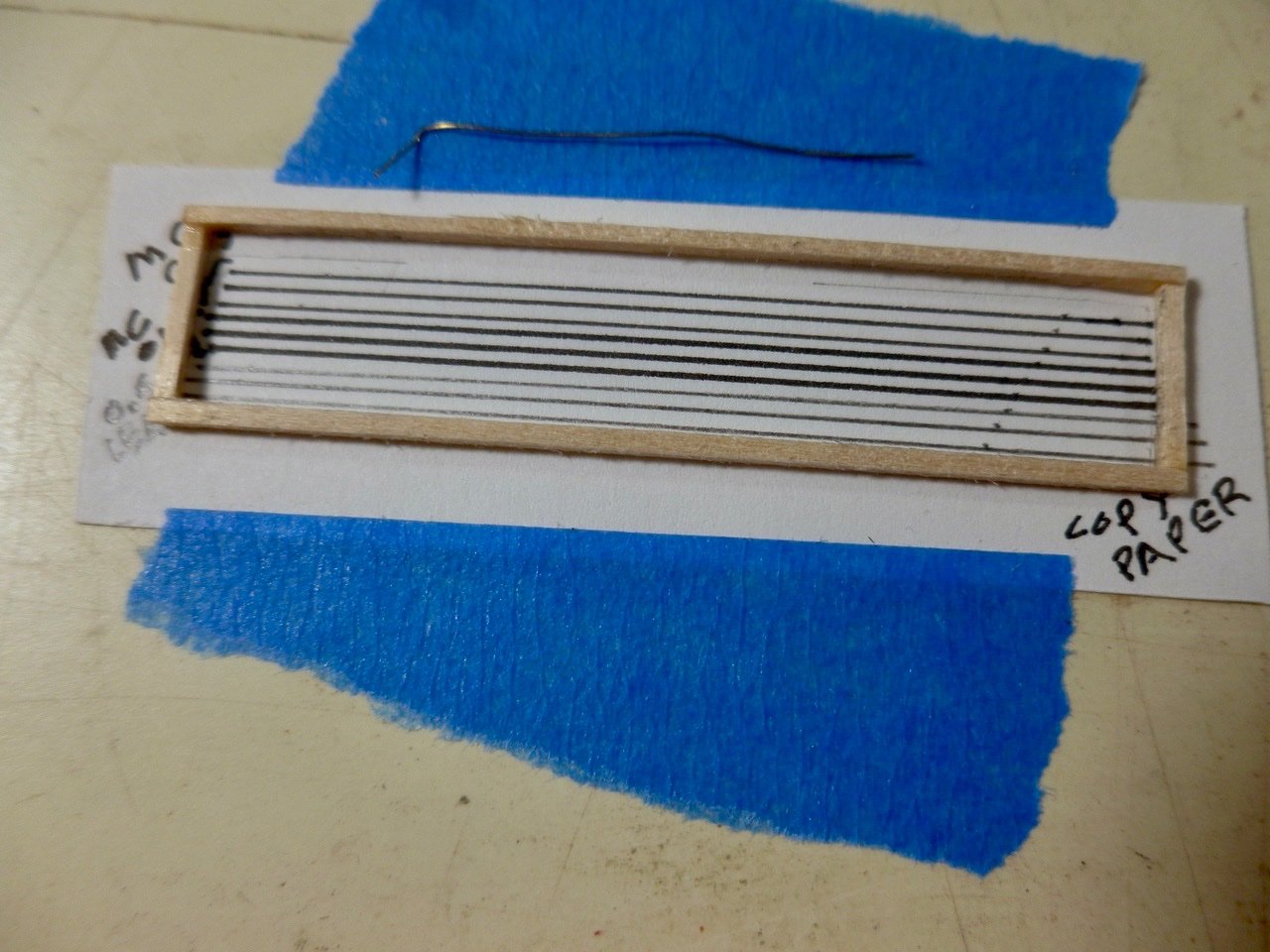

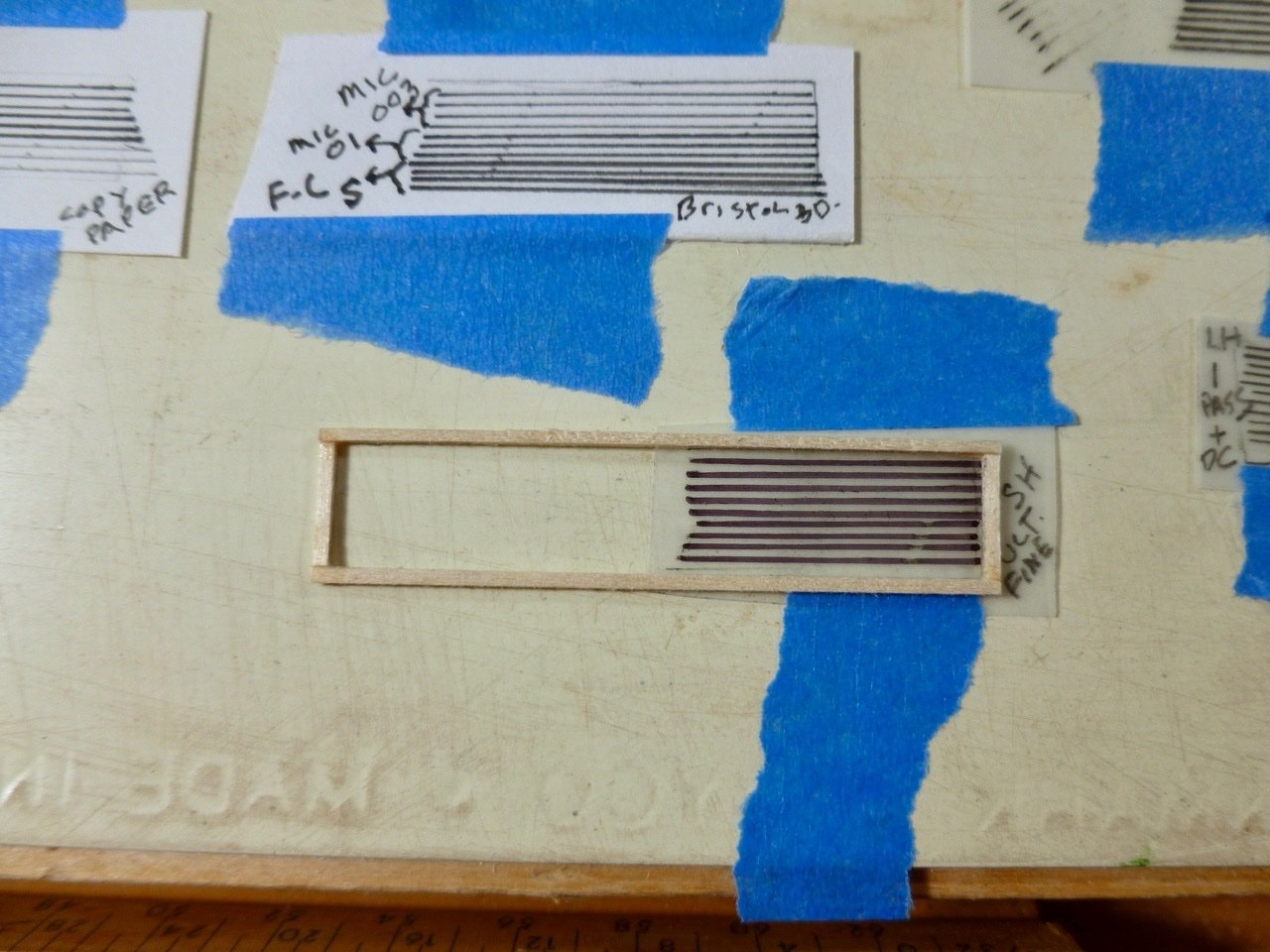

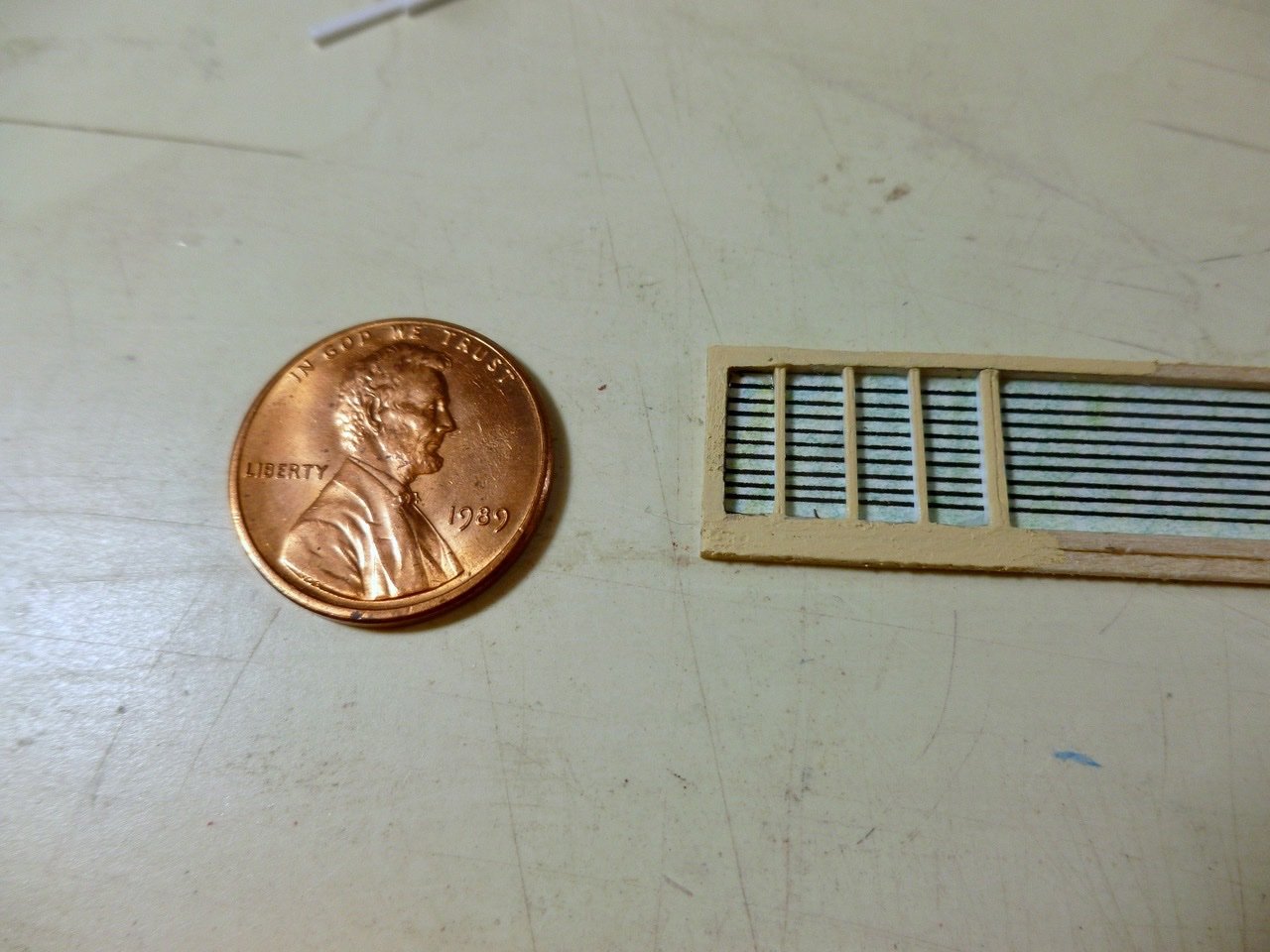

To those who stopped by or gave likes, thank you for your interest and enthusiasm. Waiting on tiny drill bits, but in the meantime I experimented with a skylight roof frame and bars to get a feeling for the scale. The question was whether drawn bars could effectively simulate tiny wire. The issues were what to draw with, what to draw on, what to do for background, and the proper sequence for assembly. The instructions indicate the bar diameter is 0.1 mm. Laughable, at least to me. Less than a pencil width and less than a skinny pen liner. An almost invisible wire. So I dispensed with fantasy and looked for narrow width pen liners, a variety of substrates, and what I had on hand. Tools included pen liners Sakura Micron 01 and 003 and Faber Castell PITT artist size S; an old Sharpie permanent ink Ultrafine, a sharpened wood pencil and a 0.5 size leadholder from my early drafting days. Substrates included clear sheet acetate, polyester drafting film matte one side, standard copy paper, Bristol board, Strathmore 300 series drawing paper and Strathmore 400 series sketch paper. I also grabbed a few Pentel Arts color pencils that we used for adult coloring during Covid, but more on those later. The Sharpie was the only one that stuck to the clear acetate and also to the drafting film. No ruboff, grayish line, a bit fat. The pen liners made skippy lines on the acetate and rubbed off easily even after a half hour drying, and a desperate shot of Dullcote turned them to liquid instantly. Neither pencil nor leadholder could mark the shiny surface. So clear background was a bust. Surprisingly the pen liners also didn’t work on the matte face (the drawing side) of polyester drafting film. This was our go to substrate for architectural hand drawing in the 1970s and 80s. It worked well with leadholders, better if you use “plastic lead” which had a binder in it that helped to prevent the dusting and occasional smearing of standard graphite leads. When we inked drawings, and we did that a lot, we used refillable Koh-i-noor Rapidographs. I don’t recall the ink brand but do remember that we dusted the sheets with pounce bags, which contained a fine powder but whether that was before or after drawing I also don’t recall. The leadholder gave a nice line on the drafting film but with a little dusting from the standard lead which was what I had on hand. The lines were not affected by Dullcote, but the dusting remained. This was a defect for such fine work because the graphite dust tended to obscure the area between lines. The pen liners came into their own on all the papers. Lines were clean and dense, even on the cheap copy paper, but I was concerned about long term durability of the copy paper so that option was tossed. I also canned the Bristol board, not because of appearance which was excellent, but due to the thickness of the sheet which I felt would create problems during assembly. The PITT pen line was a bit too thick so it went too. Below is a comparison of line widths on the copy paper. The top three are the Micron 003, the middle three are the Micron 01 and the bottom three are the 0.5 leadholder. I was down to two papers (the Strathmores) and two Micron pen liners. The 003 size Micron came closest to the 0.1 mm target but in reality was barely visible, even at 0.15 mm. I opted for the size 01 which was more visible at 0.25 mm but still looked in reasonable proportion to the skylight frame. The Strathmore 300 series drawing paper had a very slight edge in cleanliness of line so that made the final cut too. The final line sample is below. The next question was what to do about the background since the total obscurity of white was not desirable and a black background would be, how shall we say it, stupid when paired with black bars. I thought some color might imply a bright interior but when I added color over the ink lines the lines lost some of their pop. Adding color first (blended light blue, medium blue and yellow color pencils) and then drawing the lines was better. I glued the sample to the back of the wood frame using some CA, and added a second 1/32 inch strip along the bottom of the frame since real skylight pics show that part as wider than the head and jambs. Even 1/32 inch was too wide for the muntins (small vertical frames) so I used a 0.060 x 0.020 styrene strip cut in half (0.020 x 0.030) to fit the available frame depth. I globbed on some paint with no surface prep to see how the assembly might look. While doing this I realized the importance of painting the full frame before attaching it to the background. Otherwise the sides of the frame and muntins will either be bare or the paint will schmooze onto the background and bars. The sample photo does not pick up the background colors very well, nor does my eye. I’m thinking the colors may need to be more intense to compete with the closely spaced black lines, or perhaps the background should be a uniform gray. Jury’s out and opinions are welcome. Oh, and here’s the obligatory penny picture.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.