-

Posts

4,564 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Blue Ensign

-

Thank you Timmo, Chris's design talent give modellers at all skill levels the best chance of creating highly detailed and beautiful ship models. I just love 'em. B.E.

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Ah if only it were that simple Ron, all the best riggers set up with oars don’t you know.😉 ps that’s oars with an ‘o’ not a ‘w’ M.

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

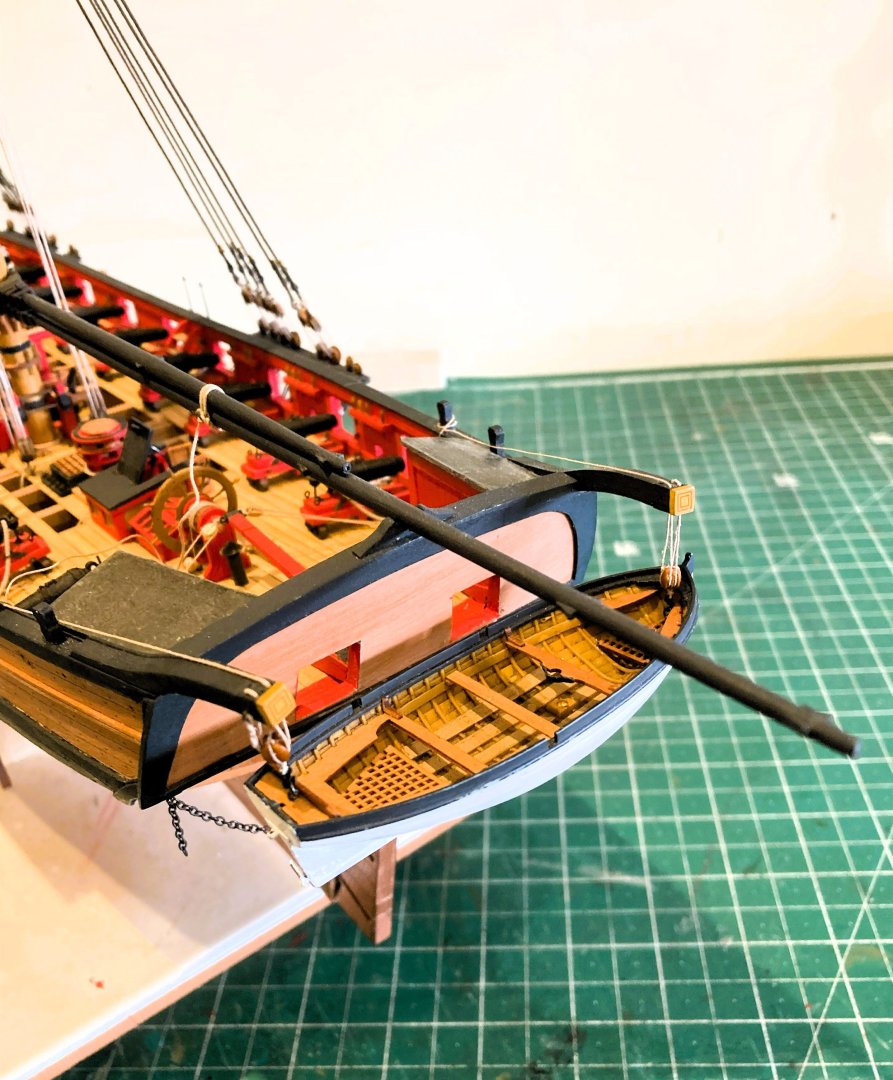

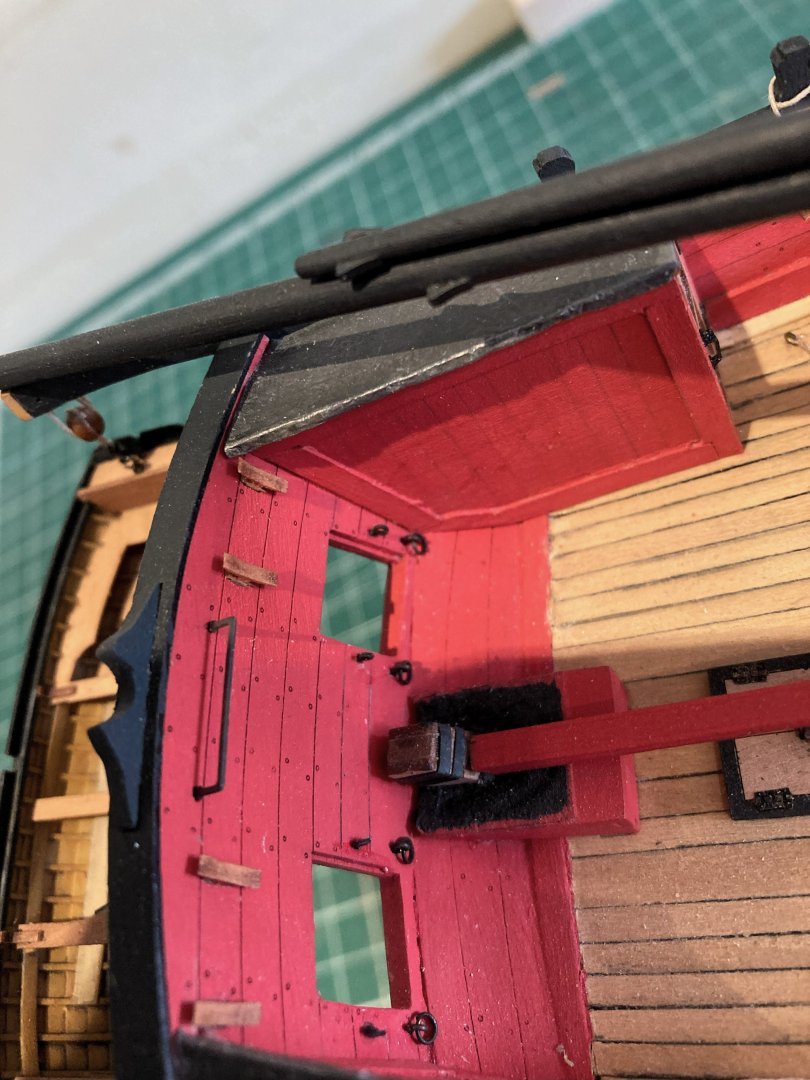

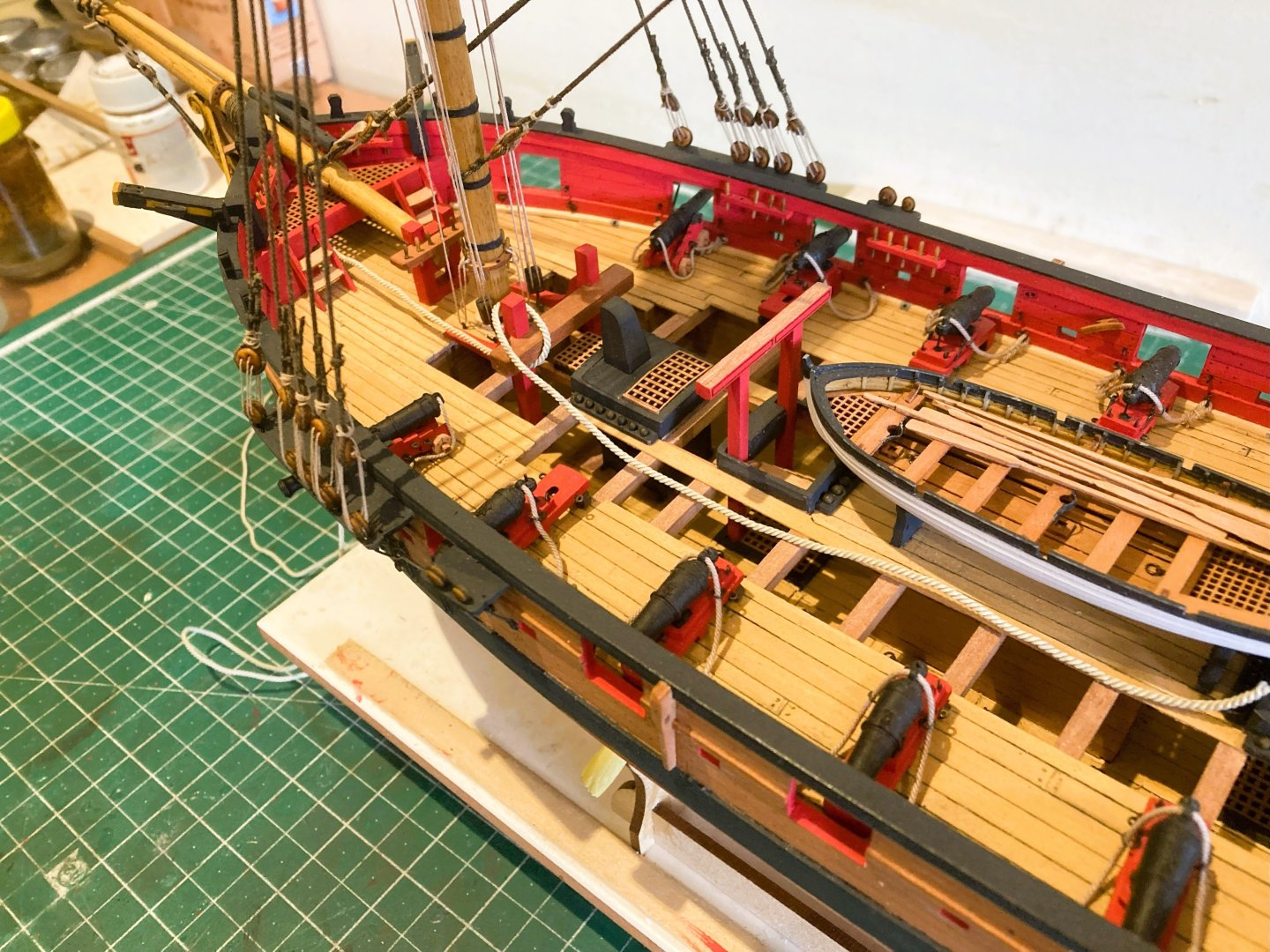

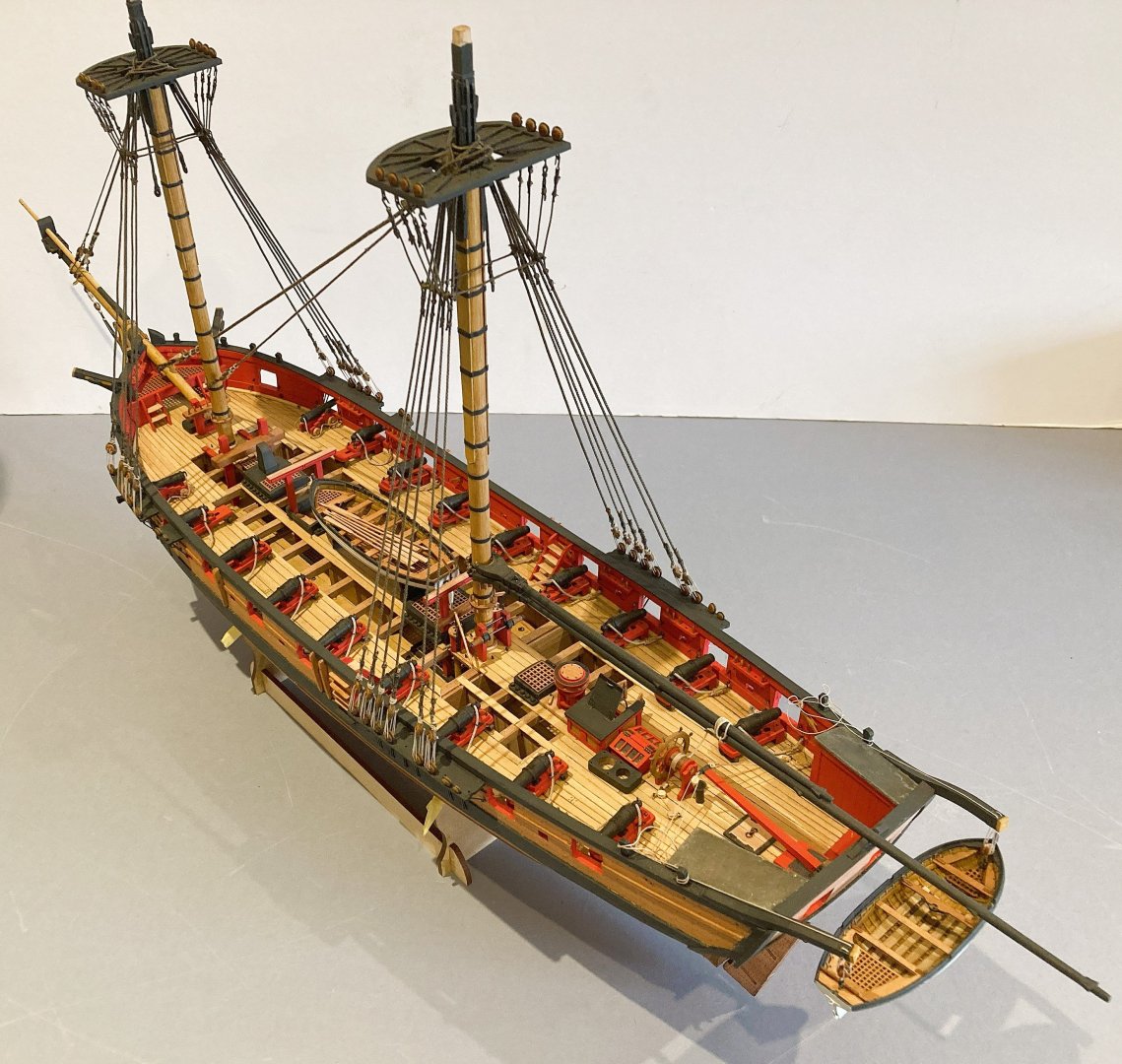

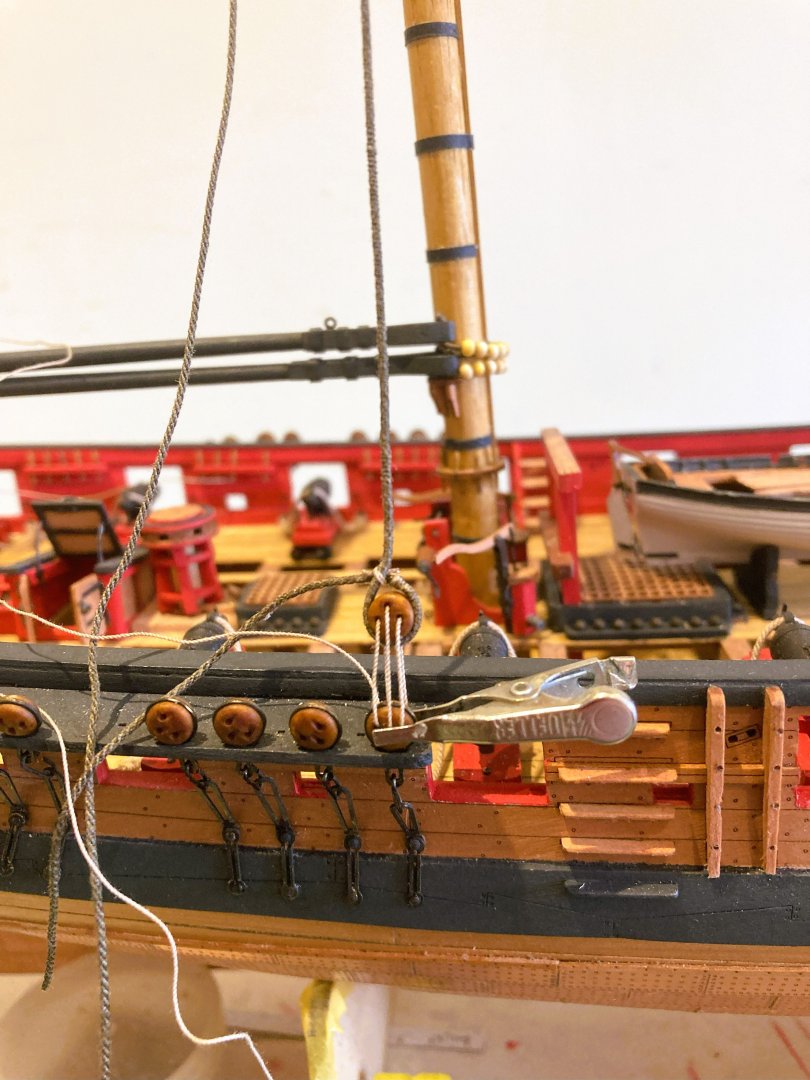

Post 104 At this point I am attending to small additions and tweaks as the model nears completion. 5238a 5235a The stanchions and guard rails are added to the Mast tops, a perfect fit with nicely shaped rails in Pearwood. 5271b The Iron horse has been added to the transom. I am still pondering whether to add limited rigging to the booms and fit the sheets. 5266a I added Entry steps stanchions, not sure if they were indicated on the plans, but I have a lot of these items in my spares box. 5277a The Rudder chains are added but I have omitted the pendents. The chains of 1mm size were in my chain stock. 5253a 5265a 5261a I had to re-visit the stern davit rigging which had become twisted. Attaching the boat is like working one of those Fairground crane grab machines, multiple goes, but at least success is obtained eventually. 5279a 5280a The one major job remaining is attaching the Ratlines, what deep joy. B.E. 04/08/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you, Alan, I can’t reconcile the set-up either. Such an arrangement seems more appropriate to smaller vessels where a windlass is used to raise the anchor and also act as the riding bitts. 075 This arrangement on my Pickle build makes more sense, altho’ I did puzzle about the use of Navel pipes in that era, but visually it worked for me. Thanks for chipping in Richard, your Harpy is looking very good.👍 The photo’s indeed clearly show the problem, how is the cable to be handled in that short space. The large cable rising vertically thro’ a very small grating so close to the stove, just doesn’t sit right to my eye. Using the Riding bitts does involve using the bitt post as well as the cross piece. As you gain knowledge of the subject over the years it becomes harder to ignore apparent discrepancies but then find you can’t resolve them because of gaps in historical information.🙄 The Harpy set-up is a mystery to me, but I will dodge the issue by not fitting anchor cables. Were it fully decked I would have run the cables down thro’ the Main Hatch. To keep things in perspective this is a minor fitting on the model that doesn’t detract from the overall appeal of Harpy. I have made many changes to my kit for my own interest that the casual eye wouldn’t even notice. I very much doubt that in many years ahead nautical historians will be poring over my model wondering why did he do that! Regards, B.E.

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

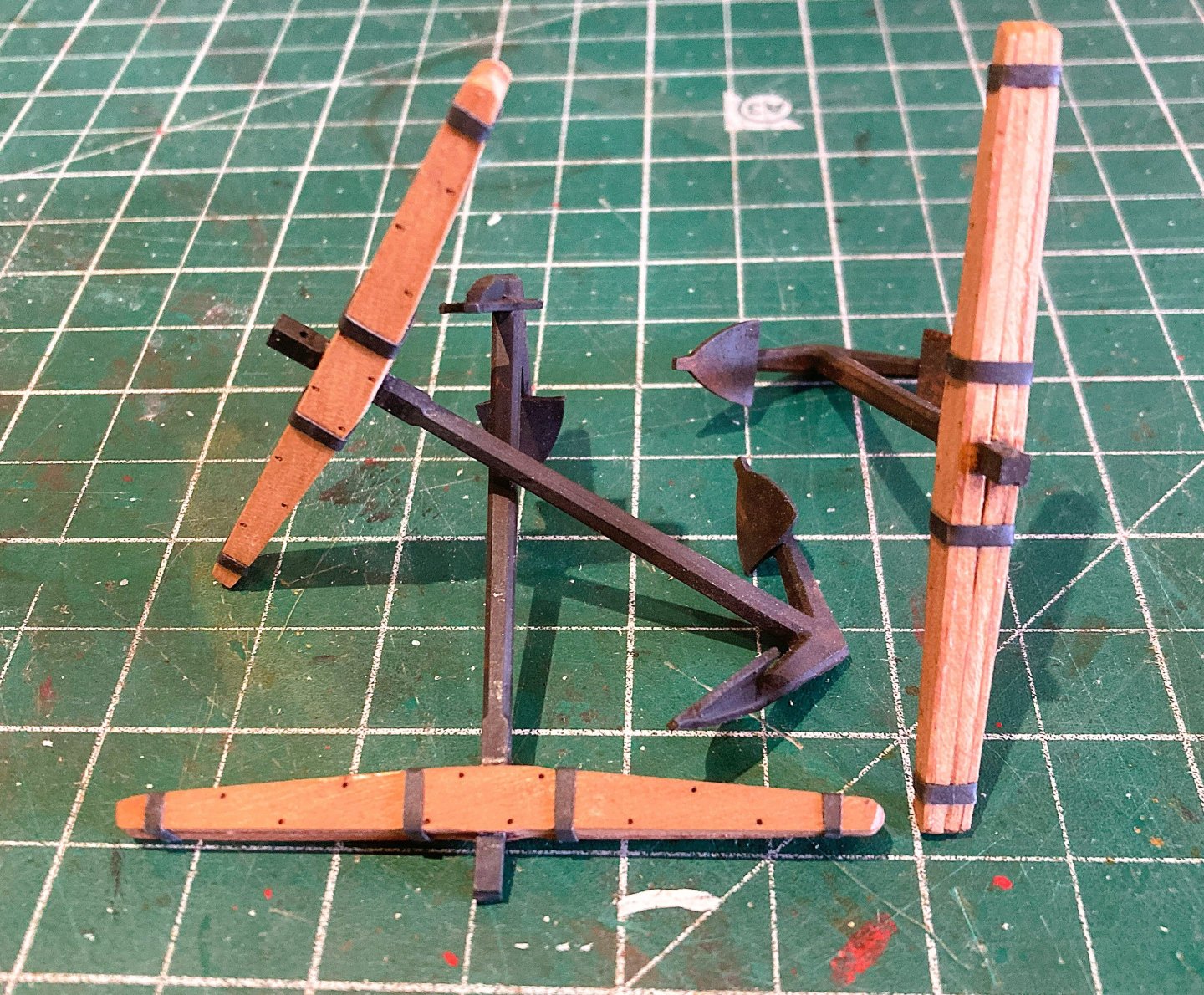

Post 103 Looking at the Anchors The anchors in Resin are accurately detailed and are close to scale for a 20cwt anchor. The stocks have very nice Pearwood facings detailing the strap positions, bolts and treenails. For a ship the size of Harpy:- Steel indicates three anchors at 20cwt, a stream at 7cwt, and a kedge at 3cwt 2 qtrs. Anchor cables A short length of 2mm ø line is supplied, sufficient for the kit arrangement. The anchor cable circumference may be determined by the formula ½” of circ for every foot of the beam of the vessel. In the case of Harpy with a beam of 28’ 1½” this works out at a 14” circ cable - 1.76mm ø line at scale. The business of anchors and cables are a puzzlement to me where Harpy is concerned. I have doubts about the kit set-up where the large cables are shown feeding thro’ a small grating just above and forward of the Galley stove above the open hearth. I think this is a steam grating for the stove and a fair run of these heavy and often wet cables would appear to be impeded by this arrangement. 5205a The cables with the kit arrangement would exit the lower deck almost vertically to the Riding Bitts in a position that would involve tight bends of the cable if the Riding Bitts are used for their purpose. The run of the cables also risk fouling the rigging connection points around the partners of the Foremast. 5203a My view is that the cables would run to the Main hatch as was the usual practice. 5204a With this arrangement stoppers could be used to take the strain whilst at anchor. I usually like to display anchors with the cables secured to the Riding bitts but there are issues that preclude this with Harpy. On a fully decked model this would not be a problem as the cables would run below decks unseen. With Harpy the lower deck is on view so simply feeding the cables down the main Hatch with a short loose end is not an option. It is difficult to imagine how an anchor cable with a scale length of 120 fathoms would even fit on the Harpy model. We know from the Adm. plan the location of the cable storage compartments running either side of the ship on the Lower deck. These are nicely depicted on the model, but as with the Adm. plans there is no indication how the compartments were accessed to stow the cables. Assembly of the Anchors The anchor stocks are correctly formed in two halves fitted either side of the shank. I found it necessary to broaden and deepen the slots on the stocks and also file down the resin shank so that the stocks fitted together allowing for a narrow gap between them adjacent to the shank. 5207a I assembled the stocks and shanks before adding the facing pieces. A slight taper was formed toward the stock ends. 5216a I used Vallejo Black/grey to paint the anchors followed by use of Dark Brown and Rust weathering powders. 5219a The iron bands are represented by Heat shrink tubing on the model. 5220a The Anchor rings are provided in etched pe. I replaced these using 1mm brass wire with an outer diameter of 8mm. For the Puddening I used 0.30mm line. 5223a Applying the puddening can be a bit of a faff unless the Anchor ring can be held secure during the process. 5231 The anchors are now completed, and I’ll decide on the display later. B.E. 02/08/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Hi Ronald, the gap does look a little wide to my eye. I didn't use the kit set-up on my build of Sphinx, I opted for a working version of gudgeons and pintles and tweaked the set up until my eye was satisfied. On Indefatigable I did use the kit simplified version but they look a little closer than on your photo. Could you perhaps countersink the holes on the stern post to allow the gudgeon to sit further in? B.E.

-

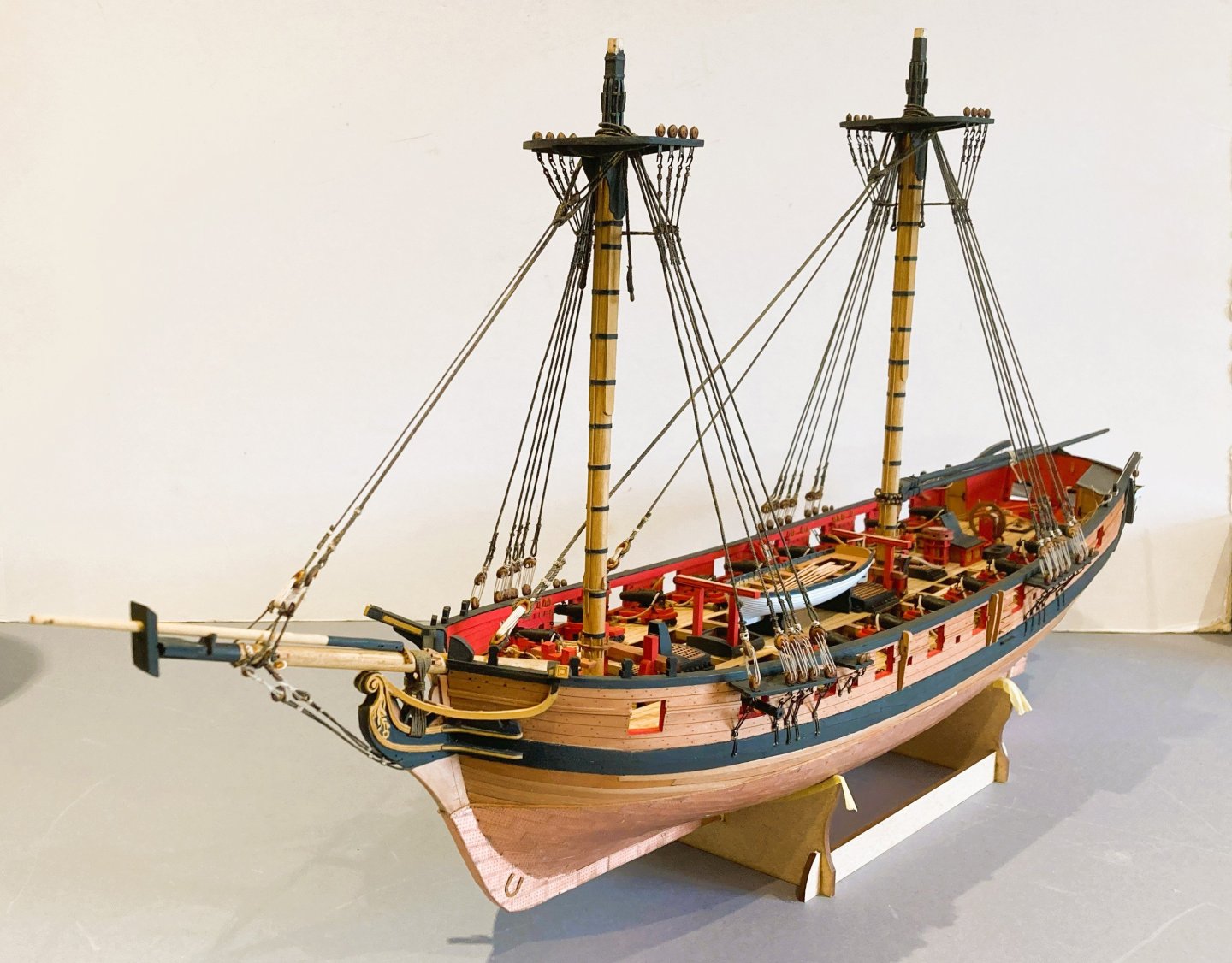

Post 102 Thinking about display At this stage I am beginning to formulate how the completed model will be displayed. I have decided She will sit on keel blocks, an arrangement I used both in my Pegasus and Pickle builds. Sections of 12mm and 8mm Walnut square stock are used to form the blocks, and cradles of reduced profile cut from 2mm Pearwood sheet. 5172a Two lengths of 12mm square walnut are slotted to take the cradles. 5174a 5175a A fair bit of tweaking required to get a reasonable fit. 5177a 5179a 5180a 5178a Trying out the keel blocks. The tricky part will be setting them out on the base board, yet to be made. 5176a An Acrylic cover to protect Harpy has been ordered. The dimensions of 800mm (w) x 450mm (h) x 190mm(b) are the minimum I can get away with, but a significant saving on space. B.E. 26/07/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Thank you David and Don, and for those who have followed and 'Liked' @David - I think you may have begun a new trend . Needs must in my case, but if you go down that road it does involve adding extra detail to the lower sections of the Topmasts in the form of octagonal/ square sections and the cutting of sheaves at an angle thro' the mast, a bit of a tricky exercise.🫤 Cheers. B.E.

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

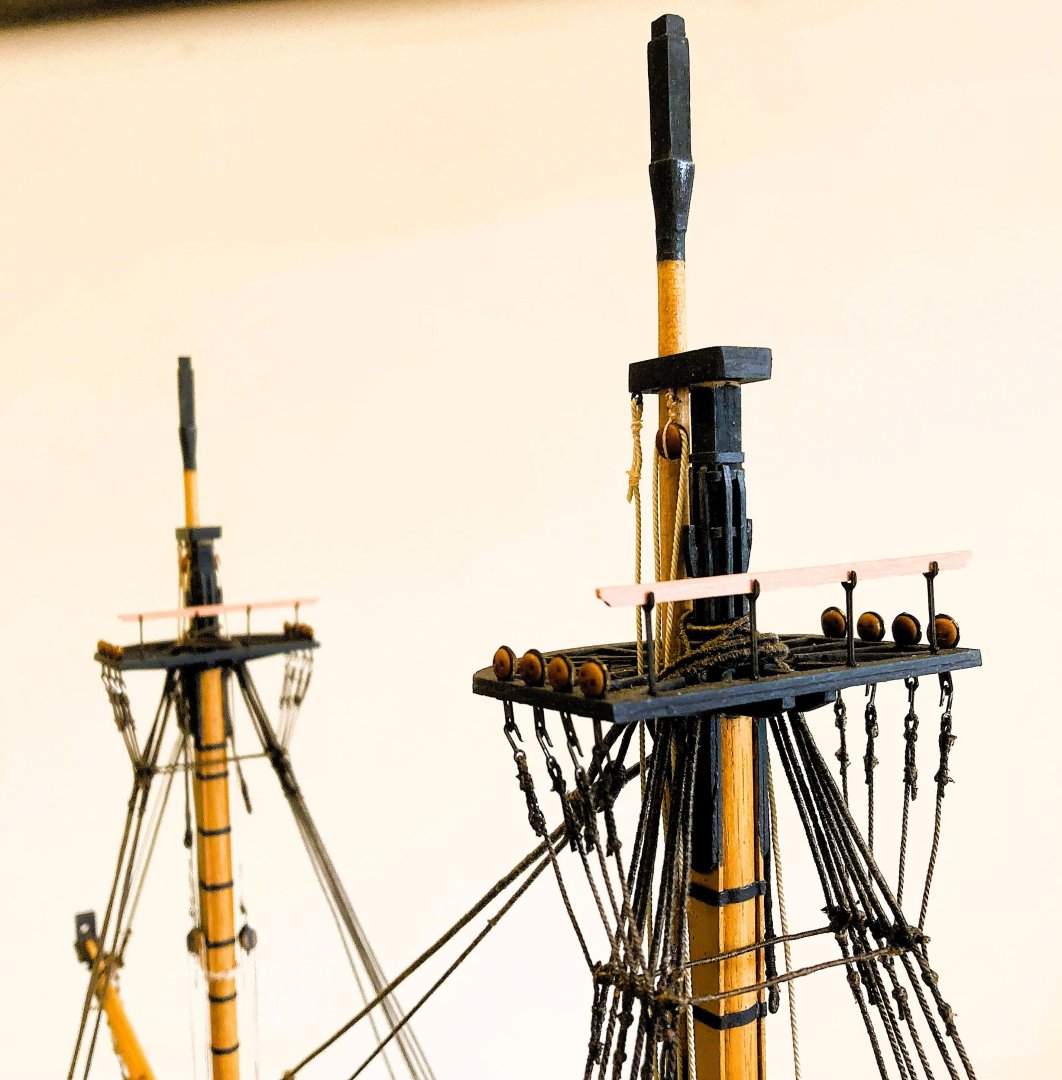

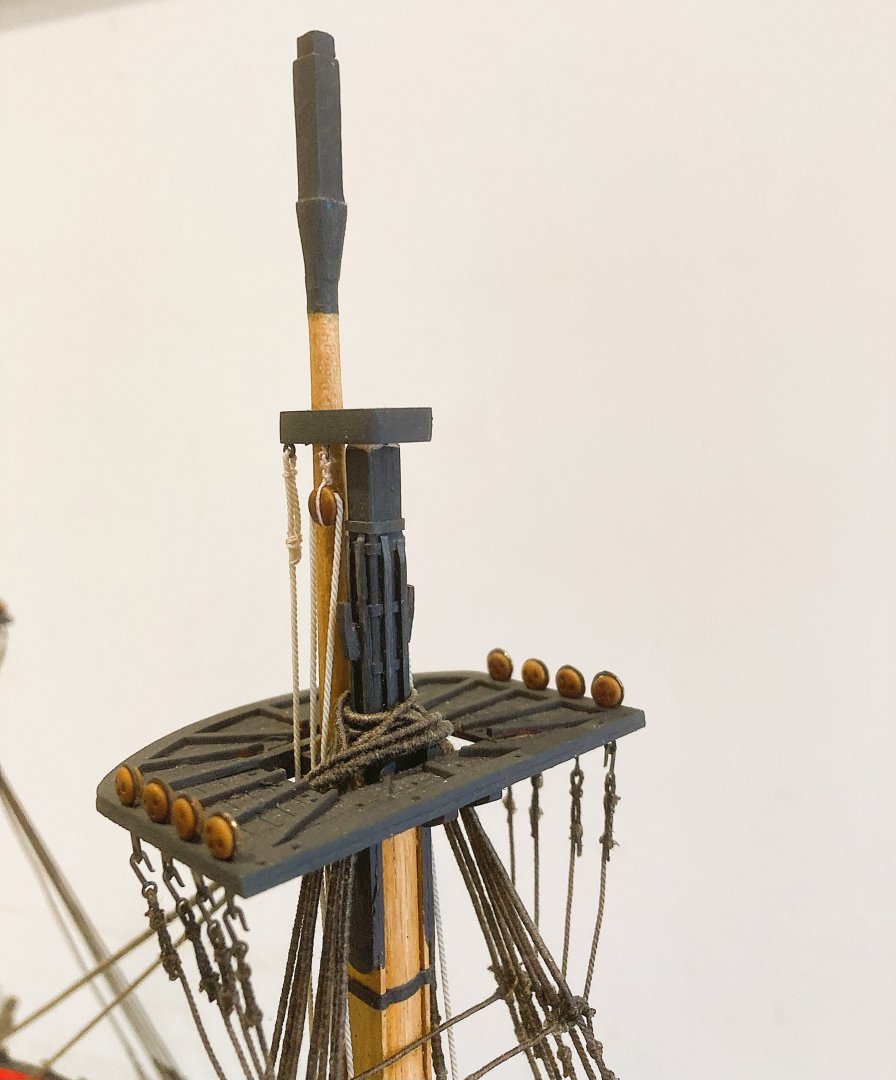

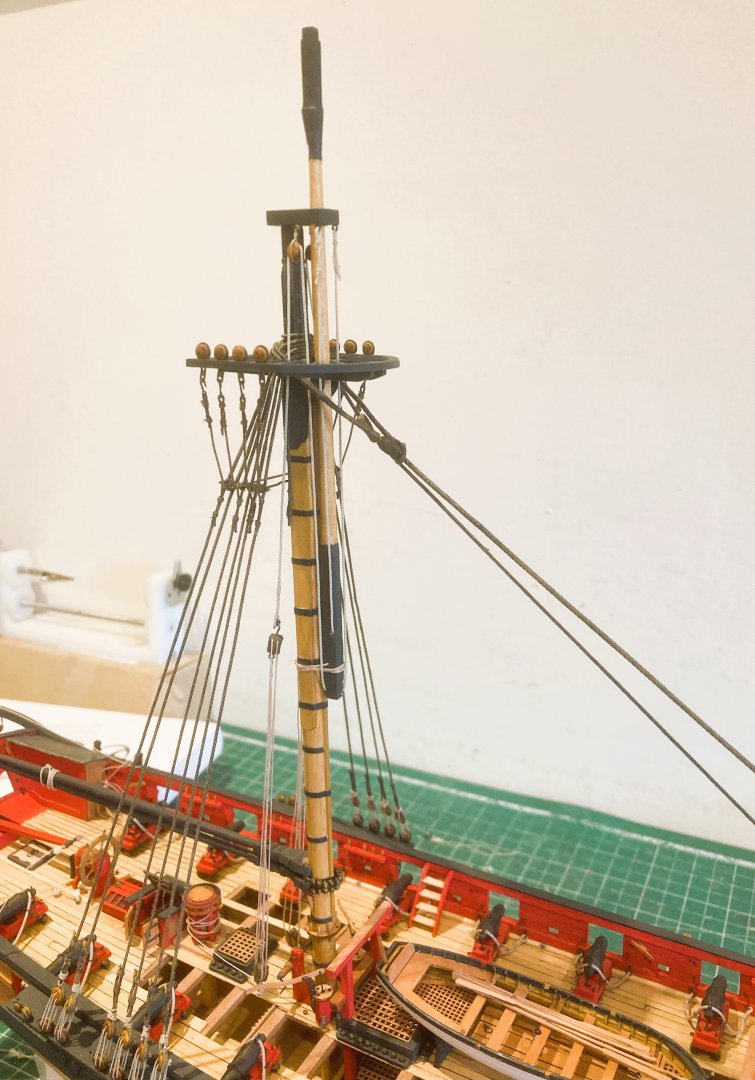

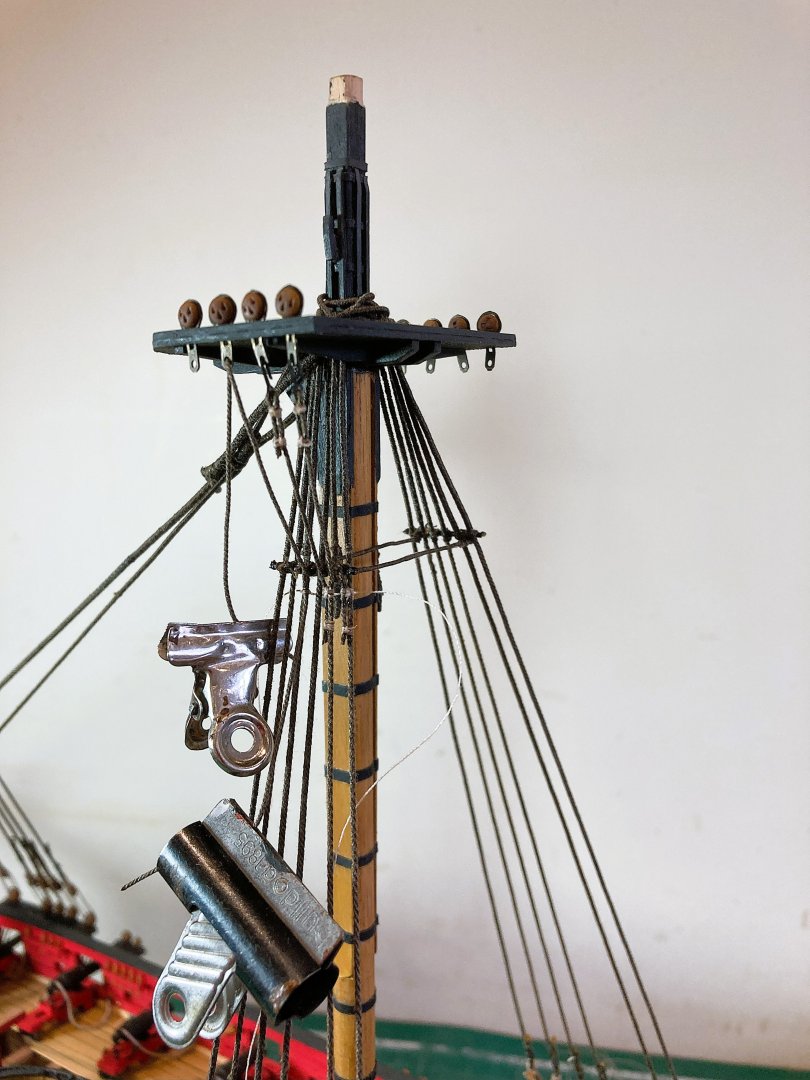

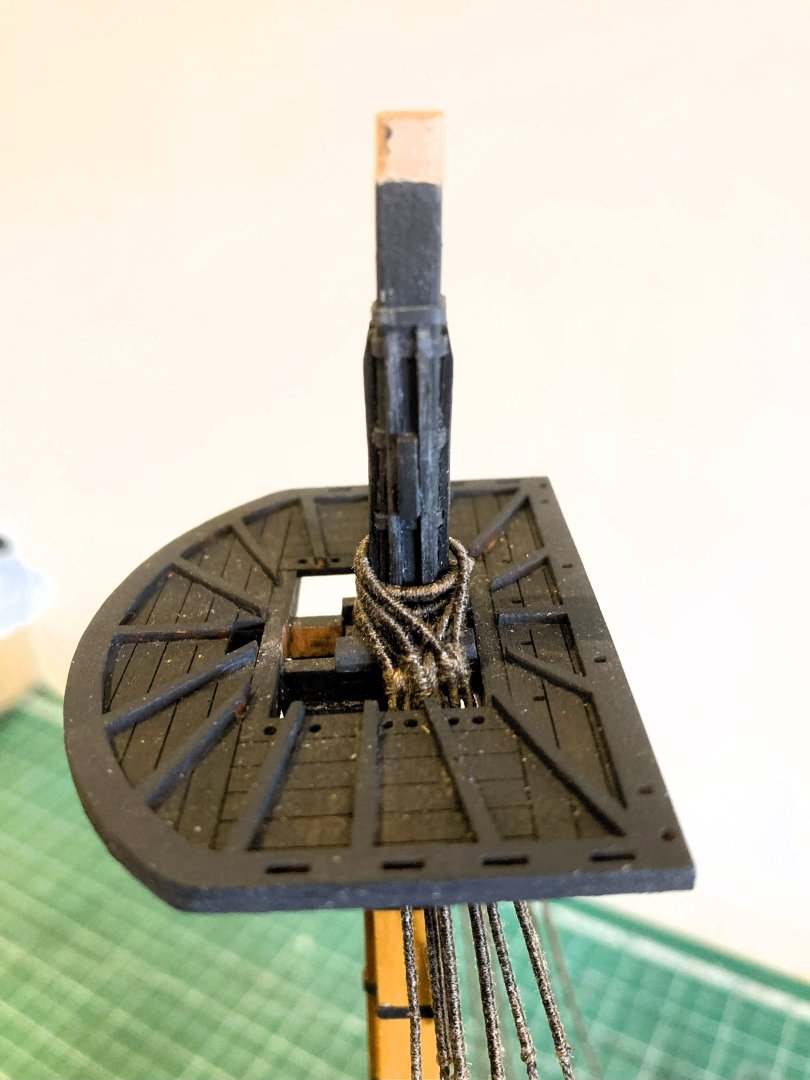

Post 101 Topmast Rigging I have rigged the Topmasts in a lowered position mainly for space saving purposes, but also as an alternative to storing them on the Gallows. This involves rigging the Topropes to support the masts. Fortunately this procedure is covered in the books Seamanship in the age of sail by John Harland, and The Masting and rigging of English ships of war by James Lees. For the Toprope Pendents I’m using Morope 0.8mm polyester line, coupled with Syren 3/16” resin blocks, and 2mm thimbles. For the Falls I am using Syren 0.3mm line coupled with ¼” Boxwood Double blocks. Strictly speaking these should be iron bound blocks so a sliver of heat shrink tubing will be used to represent the ‘iron’ The masthead caps are fitted with eyebolts for the Toprope pendent blocks which are attached prior to fitting of the cap. The caps do not require gluing, as they are a snug fit to the masthead. 5151a 5152a These photos shows the Standing part of the Port side lower sheave pendent, and standing and running part of the starboard side pendent. 5157a Here the Port and Starboard pendents can be seen running respectively thro’ the lower and upper mast sheaves. The falls of the pendent are hooked to deck eyebolt aft of the mast. A lashing is applied thro’ the fid holes to secure the Topmast. 5158a This photo shows the falls and double block tackles attached by hooks into thimble spliced to the pendent ends. 5166a Main Topmast tackle. Consideration has to be given to the length of the tackles to at least give the impression that in the position fixed they would raise the Topmast sufficiently for fidding. 5164a 5165a The run of the pendents through the mast sheaves. 5171a 5170a The Topropes would not normally be seen on a model as they were generally removed once the Topmasts are in place. B.E. 24/07/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post 100 The completion of the Futtocks at last done, with some relief I move on. 5075a 5092a For my purposes the standing rigging has been completed bar the ‘rattin’ down. An opportune point at this eight month build stage to record the state of play. 5079a 5080a 5084a 5086a 5088a 5096a 5098a 5100a 5113a 5117a The next stage is fitting the Top masts. B.E. 20/17/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post 99 Futtock strops and Catharpins. By scale the topmast deadeyes are 7” – 3mm at scale. 5011a The kit provides 3mm deadeyes(F16) which in reality are closer to 4mm, and the provided Futtock strops would be too large for true 3mm scale blocks. I substituted Syren 4mm blocks which are a good fit for the strops. 5013a On a visual level the kit/Syren deadeyes look better than a true 3mm would. I blacken the strops prior to fitting the deadeyes and then re- blacken post fitting. Catharpins -3½”c line – 0.44mm ø at scale. These prevent the Futtocks pulling the shrouds out of shape, therefore they are fitted before the Futtocks. 5014a It is far easier to make these from 0.5mm brass wire served with line. An eye formed at each end makes fitting fairly straightforward. 5031a I say straightforward but they are quite fiddly to make and serve, and use of a needle to do the fitting certainly helps. 5028a 5034a Usually there were four Catharpin legs per mast but the kit plan indicates only two. 5035a Looking at the model it would prove quite tricky to fit a set of four in the available space, so thankfully I’ll move swiftly on… Fore and Main Futtock shrouds From Steel Futtocks 4½”c line - 0.56mm ø at scale. I am using Syren 0.63mm ø line. 5049a My approach is to firstly attach the line to the lower shrouds below the stave and then tauten the line thro' the hook eye whilst attached to the futtock strap. The line is then seized. Care is required to avoid pulling the shrouds out of line. 5042a 5054a I am using the kit supplied Gütermann line for the seizings. They will be blackened once completed. 5051a 5055a There is no doubt that rigging the Futtocks is a tiresome business with a set of four round seizings to each one. Onto the Starboard side… B.E. 17/07/2024

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Well done, interesting comparison shots with Harpy. 👍 I suspect your next project may slow you down a little - but I'm not putting money on it.😉 B.E.

- 52 replies

-

- Grecian

- Vanguard Models

-

(and 1 more)

Tagged with:

-

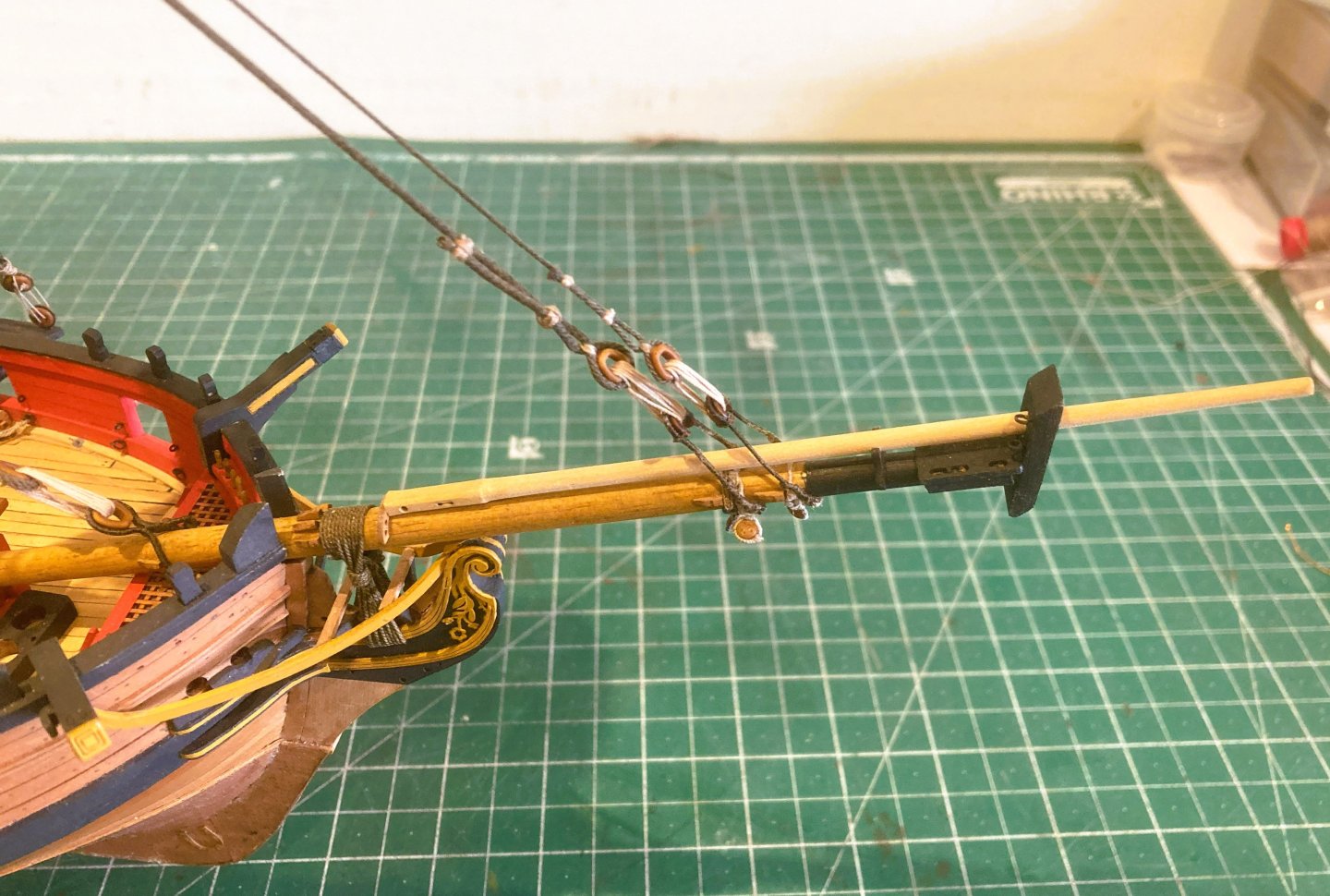

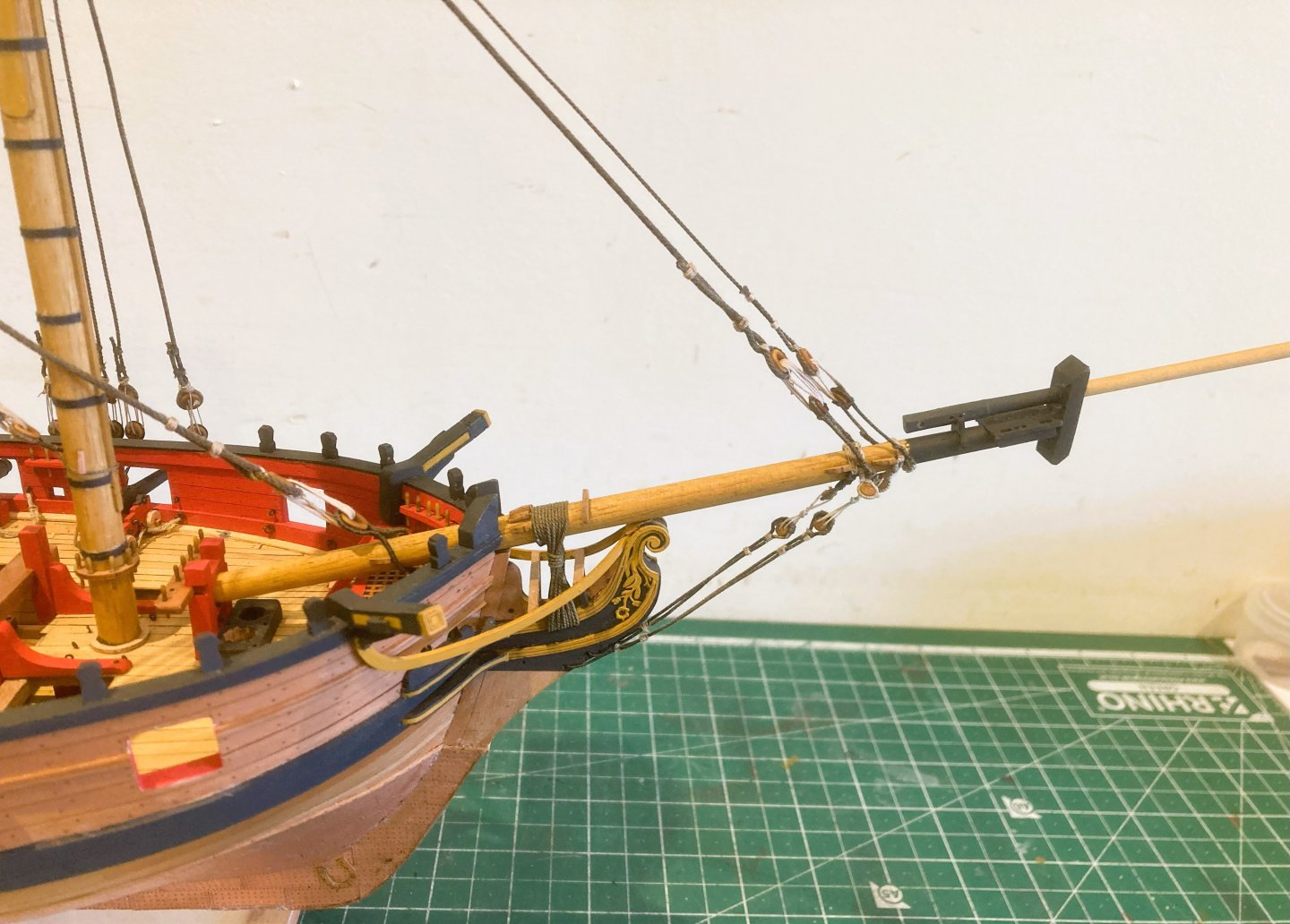

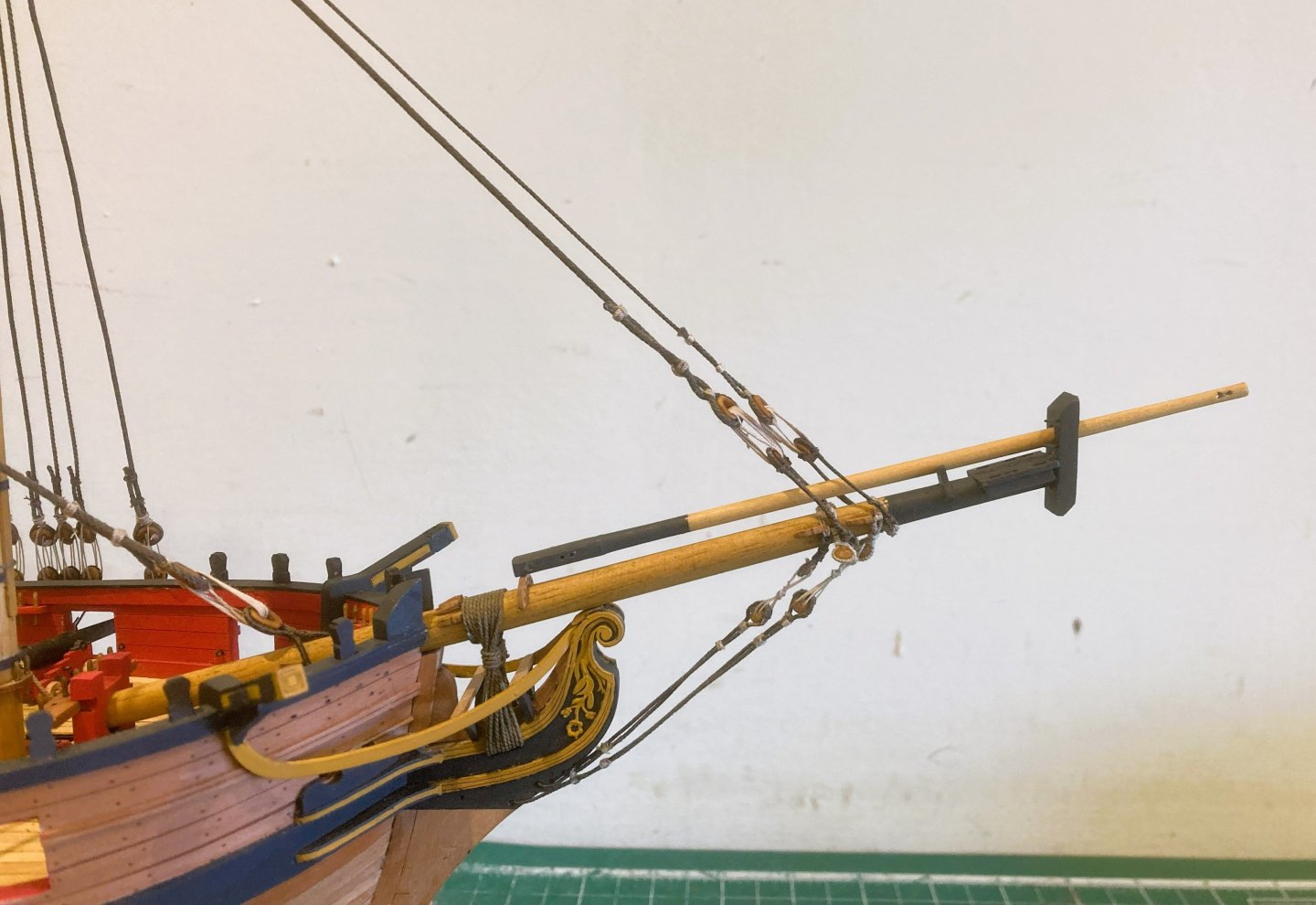

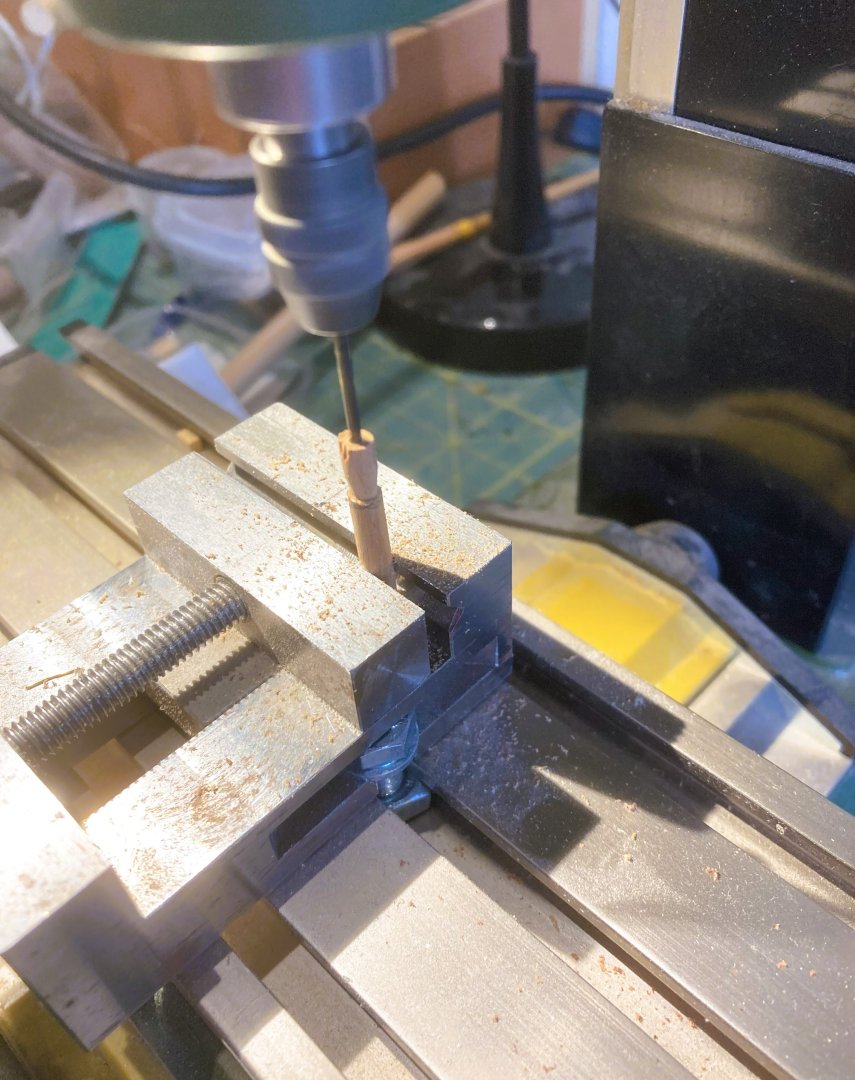

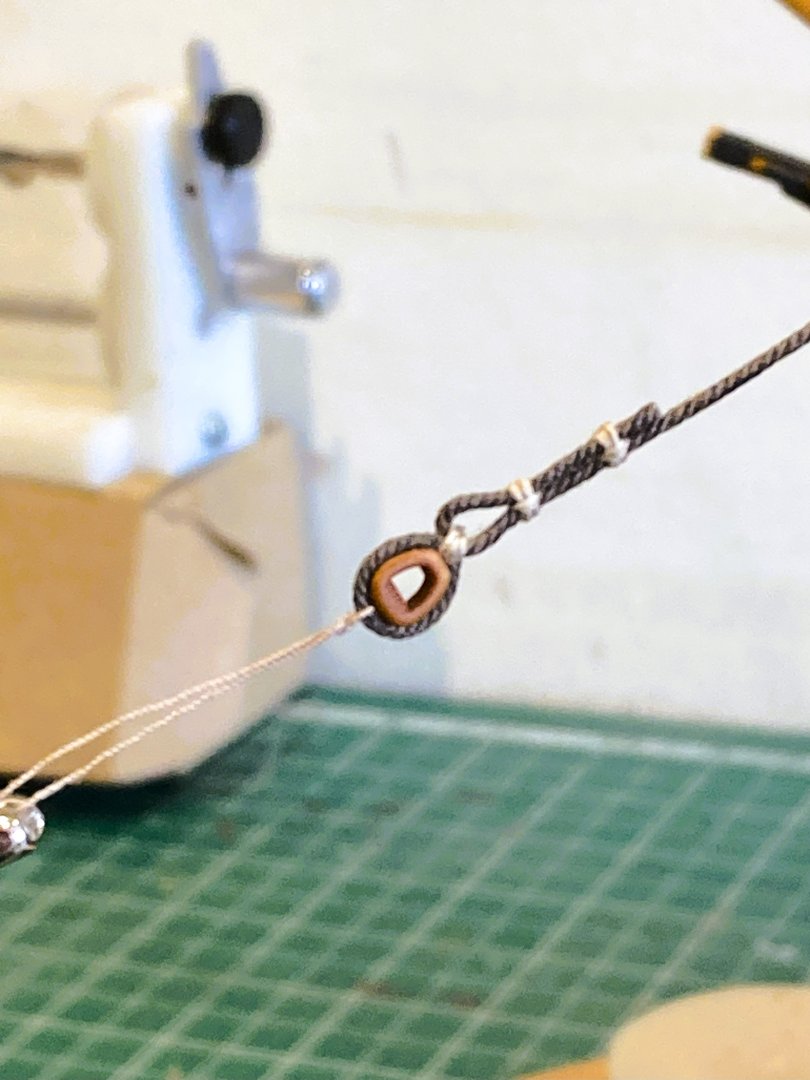

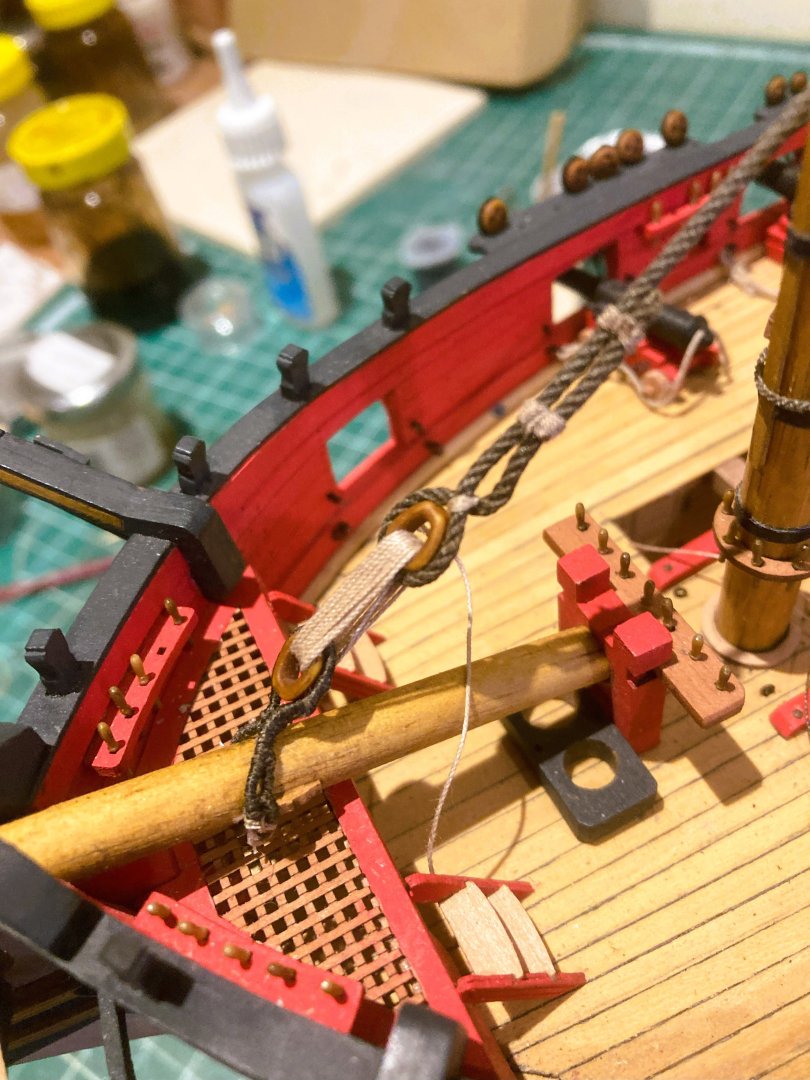

Post 98 Bobstay and Bowsprit shroud fittings I have decided to add these because the strops are fitted against the stops before those of the Fore Stays. The Bobstays will also be fitted. The kit indicates the use of 3mm deadeyes to secure the Bobstays and Bowsprit shrouds which is an acceptable alternative to hearts. As the smallest hearts I have are 5mm, a tad on the large side, and as I have no appetite to make tiny 3mm hearts, I go with deadeyes of which I have a supply of the Syren 3mm resin versions. Bobstays 4993a These are quite tricky to represent authentically, as they involve served line passing through a hole in the Knee of the head before being spliced to itself, with a Deadeye or heart seized in its bight,with the splice sitting in the top groove of the Deadeye/heart. The now double line is seized together below the deadeye/heart and above the knee of the head. 4997a You sometimes have to get inventive to hold the lines taut for seizing. 4995a 5001a The 3mm deadeyes are tiny things to secure within the served line and look a little overwhelmed in the bight. They also don’t take the 0.30mm line which is the correct scale size for the lanyards. I used 0.1mm line as per the kit plans, but which seems very under size for these important stays. I’m not entirely happy with these and may revisit using slightly larger hearts and lanyards. Jib boom I have decided to include the Jib boom albeit in the inboard position. This allows fitting with a minimal increase in the overall size of the model. 4984a The boom was formed from 4mm square stock. The heel is of octagonal shape with sheave holes for the top ropes. There is also a crupper hole for lashing the boom to the Bowsprit. 4988a 5002a 5004a 5006a B.E. 08/07/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post 97 The Fore stays The stays are made up as per the Mains. I am using Syren 1.14mm line for the Fore stay and Morope 0.80mm line for the Preventer. The Morope has better definition than the kit kit line which otherwise is spot on for scale. (1mm and 0.75mm.) From Steel. Fore stay - 9½” (1.19mm)-13” Heart. (5mm) lanyard 3½”(0.4mm) Collar – 5” (0.63mm) seizing 1” Mouse 3x diameter of stay = 3.6mm An open heart (Syren Resin 5mm) is used for the Fore stay collar, stropped with Syren 0.63mm line. Quite often double strops were used but the hearts have only one groove so for Harpy it is single. 4948a Still a tricky little exercise forming two eyes either end of a 50mm length of served line The heart seizing is also simplified, there is only room for a couple of turns of 0.1mm line. 4963a Fore stay collar in place. 4964a 4968a 4956a I carved the Mouses from dowel. 4967a Fore stay mouse fitted. Fore Preventer stay - 6” (0.75mm) - 10” heart (4mm) Collar – 4”(0.50mm) lanyard 2½”(0.31mm) lashings 1” Mouse 3x diameter of stay = 2.4mm. This is handled in the same way with slightly smaller fittings. 4982a 4981a 4980a 4979a 4975a 4974a Onto the Bobstays…. B.E. 06/07/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post 96 Completing the Fore shrouds. Shrouds are a very fiddly business, and applying the throat seizings is a tedious thing. 4915a I find that using a fine needle helps with the threading of the line between the shroud and its return. 4924a 4921a 4922a The Fore shrouds gave me more trouble than the Mains; I seemed to spend an inordinate amount of time tweaking the shroud length before the Lanyards are eventually tied off. This involved unpicking previously seized upper deadeyes and re-setting. On a model a sloppy line of deadeyes is not a pretty thing. 4930a The next step is the application of the futtock staves. According to Steel these are set as far below the trestletrees as the mast cap rises above. 4931a In reality the staves were of 4” circ served line, but it makes sense to use something more solid for model purposes. I used 0.7mm ø Brass rod served with 0.1mm line. 4932a ‘Quad hands’ are a useful tool for this job, holding the bar steady whilst the outer lashings are applied. 4936a The Futtock staves are a great device for evening out the shrouds, as well as providing the anchor point for the Futtocks and Catharpins. The Fore stays beckon…. B.E. 02/07/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post 95 Main stay. (Part 2) The lower end of the stays have hearts turned in. I am using Syren Resin versions, (6mm) for the Main Stay and (5mm) for the Preventer. The kit provided deadeyes for this purpose are easier to fit than hearts and lanyards, but were an old fashioned option by the time of Harpy. 4901a It is easier to fit the Preventer stay and collar with the Main stay and Fore shrouds out of the way. I had fitted the Preventer stay at this point but found I had fed it incorrectly through the mast top. Annoying when you have spent time doing tiny seizing and fitting of lanyards, but I couldn’t let it stand. 4895a 4897a 4898a Lashing of the Main stay I used Syren 0.45mm line. For the collar 0.88 mm line served with 0.1mm line was used. The tricky part of the collar is forming the eye in one short leg. Main Preventer stay 4904a Stropping the Preventer stay heart. 4905a 4908a 0.3mm line used for the Lanyard. 4909a 4910a I can now attend to the Fore Shrouds. B.E. 27/06/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Blue Ensign in his build log has gone into some detail about this. I will probably position the binnacle off to one side and slightly forward of the wheel. I also left the chimney off the cabinet. It made no sense where there is no space for a lamp.🤔 No lamp compartment, no smoke, and no requirement for a chimney. I am looking at making two smaller single cabinets that will stand each side of the wheel. B.E.

-

Post 94 Main stay. (Part 1) The kit plans show a simplified form of the Main/Preventer stays. A more authentic version includes serving of the stay collars including the eye splice through which the stay passes, and a more stylish mouse to replace the kit plastic version. The kit indicates use of deadeyes for securing the stays but I have opted for hearts which were more common during this period. I am using Steel’s tables for an 18-14 gun ship. Mainstay - 10” - 1.26mm - 15” Heart (6mm) Main Preventer Stay - 7” - 0.88mm - 10” Heart (4mm) The kit line dimensions are close to this using 1.3mm line for the Main stay, and 1mm line for the Preventer stay. For the Mainstay I am using Syren 1.37mm line, and for the Preventer 0.88mm line. The lines are stretched under weights to remove the spring before fitting. 4880a The position of the mouse needs to be tested on the model. 4881a 4884a Here the un-dyed Preventer stay serving is apparent, and the ‘weave’ of the mouse shows through. 4889a I have been thinking about the positioning of the stays. The kit arrangement has the Main stay fixed by a collar to the Foremast, and the Preventer stay running above it and beyond it to a collar on the Bowsprit. I have some doubts about this arrangement, generally Mainstays run beyond the foremast to the bow. Steel says that The main Preventer stay is lashed to the Foremast and the Main stay to the Bowsprit chock. Lees comments that the Preventer stay was usually carried above the stay but that on small ships was sometimes carried under it. 4888a Full details of my preparing and fitting of the stays and the related Mouses is fully covered in my Pegasus log, so I won’t repeat it all here. 4883a 4890a 4885a In the case of Harpy I have decided to run the Preventer stay below the Main stay, and reverse the locations of the lashings. Onto the lower end stay fixings. B.E. 25/06/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

-

Post 93 Fitting the shrouds. It has been some five years since I last did any shroud rigging and I’m feeling a tad ring rusty, and getting the first shroud rigged took a while, including a full ‘re-do’. 4878a Each pair of shrouds were stretched before fitting. 4828a The first shroud is slightly more awkward due to the thicker ‘served’ line. 4847a My approach is to set the first shroud deadeye (Starboard side) to the distance that suits my eye bearing in mind the norm of around 2-3 times the diameter of a deadeye. The finished space between the deadeyes worked out at 7mm. 4868a The tricky part is getting the shrouds level along the channels. 4872a I prefer to rig the shrouds purely by eye, carefully adjusting the upper deadeye to suit the line as I move along the channel. 4869a Not decided yet whether to dye the round seizings to match the shrouds. 4875a 4877a The next stage is to make up the Main stays which are fitted before I attend to the Fore shrouds. B.E. 23/06/2025

- 332 replies

-

- Harpy

- Vanguard Models

-

(and 1 more)

Tagged with:

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.