-

Posts

465 -

Joined

-

Last visited

About *Hans*

- Birthday 10/23/1962

Contact Methods

-

Website URL

http://www.kolderstok.com

Profile Information

-

Gender

Male

-

Location

Dordrecht, Netherlands

Recent Profile Visitors

-

Archi reacted to a post in a topic:

Cocca Veneta by Vivian Galad - Corel - 1:70 - modified

Archi reacted to a post in a topic:

Cocca Veneta by Vivian Galad - Corel - 1:70 - modified

-

SiriusVoyager reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

SiriusVoyager reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

Olli Sukunimisson reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

Olli Sukunimisson reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

Baker reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

Baker reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

cotrecerf reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

cotrecerf reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

Olli Sukunimisson reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

Olli Sukunimisson reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

In his 17th century book Aloude en hedendaagsche scheepsbouw en bestier (ancient and current ship-building and sailing) , Nicolaes Witsen gives an overview of the thickness of various ropes and rigging for ships. These thicknesses are related to mast diameters or circumferences. An indication of the thickness of the ratlines that can be obtained from his tables gives a value of about 1/4 to 1/3 of the thickness of the shrouds. So, with a shroud thickness of 0.8 mm for this model, a ratline of about 0.2 to 0.27 mm thickness can be used. And yes - this is quite thin 🙂

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

Ondras71 reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

Ondras71 reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

Olli Sukunimisson reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

Olli Sukunimisson reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

*Hans* reacted to a post in a topic:

Duyfken by Olli Sukunimisson - Kolderstok - 1:50

-

catopower reacted to a post in a topic:

A Dutch 17th century pleasure vessel by Ab Hoving - CARD

catopower reacted to a post in a topic:

A Dutch 17th century pleasure vessel by Ab Hoving - CARD

-

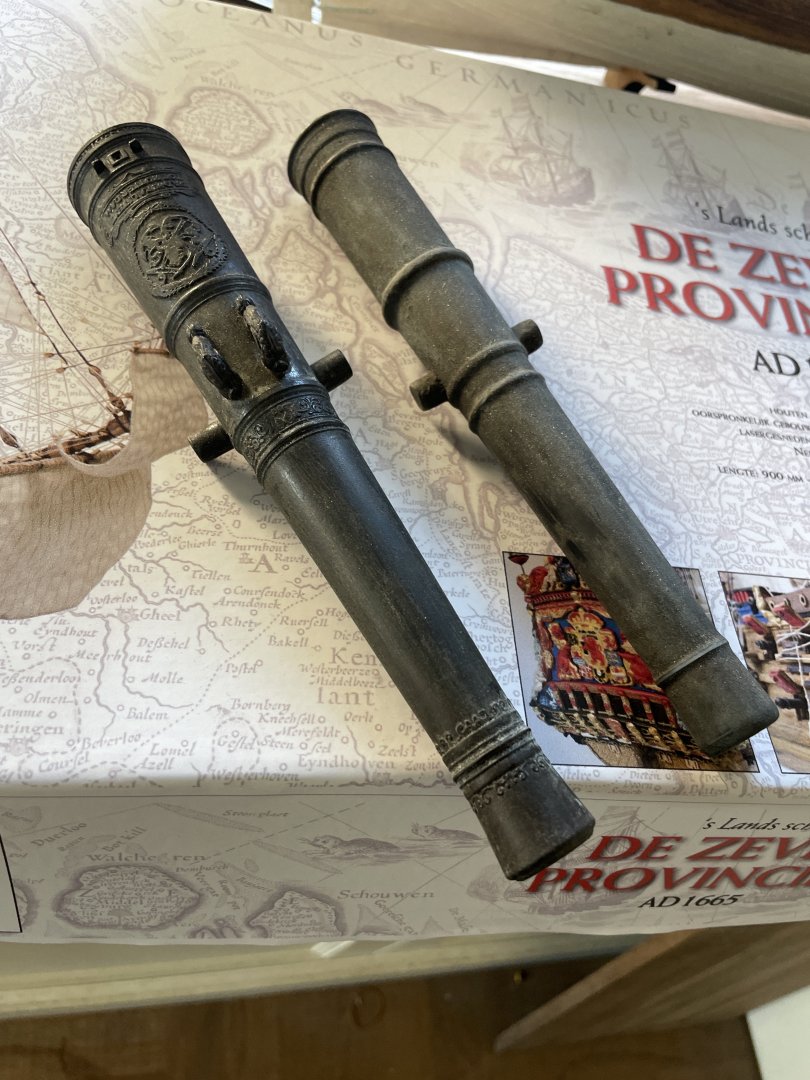

It is resin (credits to my son who designed it after an original 17th century canon), 3D printed on a resin printer. I coated it with real bronze powder, soluted in schellack, and gave it a ammonia treatment to give it the authentic weathered look. We can print in in almost any scale, but the maximum length is roughly 20 cm. The carriage is made out of oak, but for the kit this will be most likely elm (which was the most used wood for carriages, according to Blom). I am still “struggling” with the size of the weels, as they might be a bit to large.

-

Looking very fine! Regarding your photo of the deadeyes: make sure they all are mounted in the correct position, with two holes on top and one on the bottom. They should look like a surprised young lady. A deadeye is called a “juffer” in Dutch, and this is an old fashion word (17th century) for a young (unmarried) lady. If you look at it you will see.

-

A little bit late from my side, but yes, it is available!

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.