-

Posts

93 -

Joined

-

Last visited

About rcweir

Profile Information

-

Gender

Male

-

Location

Lexington, MA, USA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

rcweir reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

rcweir reacted to a post in a topic:

HMS Sphinx 1775 by cdrusn89 - Vanguard Models - 1/64

-

rcweir reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

rcweir reacted to a post in a topic:

HMS Sphinx by KurtH - Vanguard Models - 1/64 - First POB Model

-

rcweir reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

rcweir reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

rcweir reacted to a post in a topic:

Sloop Speedwell 1752 by Capt Morgan (Steve) - Syren Ship Model Company - 1:32 Scale - POF Sloop

rcweir reacted to a post in a topic:

Sloop Speedwell 1752 by Capt Morgan (Steve) - Syren Ship Model Company - 1:32 Scale - POF Sloop

-

rcweir reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

rcweir reacted to a post in a topic:

HM Cutter Alert by Thukydides - Vanguard Models - 1:64 - first build

-

rcweir reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

rcweir reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

-

rcweir reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

rcweir reacted to a post in a topic:

HMS Indefatigable 1794 by Glenn-UK - Vanguard Models - 1:64

-

rcweir reacted to a post in a topic:

Sloop Speedwell 1752 by Rustyj - Syren Ship Model Company - 1:32 Scale - POF Sloop

rcweir reacted to a post in a topic:

Sloop Speedwell 1752 by Rustyj - Syren Ship Model Company - 1:32 Scale - POF Sloop

-

rcweir reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

rcweir reacted to a post in a topic:

HM Cutter Trial 1790 by BrochBoating - Vanguard Models - 1:64

-

rcweir reacted to a post in a topic:

HMS Flirt by ECK - Vanguard Models - 1:64

rcweir reacted to a post in a topic:

HMS Flirt by ECK - Vanguard Models - 1:64

-

Ryland Craze reacted to a post in a topic:

NRG Rigging Project by tlevine

Ryland Craze reacted to a post in a topic:

NRG Rigging Project by tlevine

-

thibaultron reacted to a post in a topic:

NRG Rigging Project by tlevine

thibaultron reacted to a post in a topic:

NRG Rigging Project by tlevine

-

hollowneck reacted to a post in a topic:

NRG Rigging Project by tlevine

hollowneck reacted to a post in a topic:

NRG Rigging Project by tlevine

-

mtaylor reacted to a post in a topic:

NRG Rigging Project by tlevine

mtaylor reacted to a post in a topic:

NRG Rigging Project by tlevine

-

CiscoH reacted to a post in a topic:

Master in Sail by Captain James S. Learmont

CiscoH reacted to a post in a topic:

Master in Sail by Captain James S. Learmont

-

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine

robert952 reacted to a post in a topic:

NRG Rigging Project by tlevine

-

Canute reacted to a post in a topic:

NRG Rigging Project by tlevine

Canute reacted to a post in a topic:

NRG Rigging Project by tlevine

-

NRG Rigging Project by tlevine

rcweir replied to tlevine's topic in - Kit build logs for subjects built from 1751 - 1800

I share the enthusiasm, in spades! Toni's half hull project came at a perfect time for me and this project does, too. I can hardly wait.- 31 replies

-

- rigging/masts

- NRG

-

(and 1 more)

Tagged with:

-

rcweir started following Masthead shape on early 17th century ships , NRG Rigging Project by tlevine , Master in Sail by Captain James S. Learmont and 2 others

-

mtaylor reacted to a post in a topic:

Master in Sail by Captain James S. Learmont

mtaylor reacted to a post in a topic:

Master in Sail by Captain James S. Learmont

-

I've just finished reading Learmont's Master in Sail, and since I didn't find any mention of Capt. Learmont on MSW, I thought it was worth adding a note about his book. It's an autobiography of a Scottish merchant captain who sailed deep sea ships from 1887-1910. Learmont is a no-nonsense writer, but his accounts of his voyages are rivetting. I think anyone who's read and enjoyed The Last Grain Race or Two Years Before the Mast will find Learmont's book is a great companion to them. His details of navigation, sailing, handling cargos and owners, all are fascinating. My edition is, I think, the first one dated 1950 and published by Percival Marshall. It's not illustrated, but the book is easily findable on bookfinder.com and some editions do have photos. I also note that Alan Villiers mentions Learmont in several places in The Way of a Ship. It's clear that Villiers thinks highly of Learmont, and one of his comments about how to be successful sailing around the Horn is almost a direct quote from Learmont. All in all, I found it a wonderful account.

-

Canute reacted to a post in a topic:

CV-59 USS Forrestal Carrier

Canute reacted to a post in a topic:

CV-59 USS Forrestal Carrier

-

I'd use baltic birch plywood for the bulkheads and clear white pine for the hull planking and most everything else. I once made a 17' kayak, with 1/4" strips for the hull (red cedar & white pine) covered in plexiglass, and that project has some similarities to your hull. For the strongback longitudinal I carefully chose a long, straight, clear piece of structural grade Douglas fir. The strongback was the most expensive piece of wood in the project, but it ensured the resulting boat was straight.

-

I have a copy of McKee and he says 9 inches. He terms it chasing, where a sloping rabbet is cut into the top edge of the strake below the one being installed. At this point he's talking specifically about his 10' example boat. I haven't found anywhere that he gives more general guidance on chasing, though he does mention that there are other ways than a sloping rabbet to get the plank end down so it can fit into the stem or stern rabbet. I don't think I have the terminology completely figured out, but the 9" measurement is definite for his 10' boat. The McKee is a pretty neat little publication. It includes a card half-hull model of his 10' example boat.

-

Navy coffee, on the other hand, was for connoisseurs! We made port visits in Australia a few many years ago and a cup of the wardroom java was a must-have for visitors. (I highly recommend choosing a service where you can take your diningroom and bedroom on every trip.)

-

Ditto on the mini-saw recommendation - I have long wanted a tiny keyhole-type saw like this one! Glenn, your progress on the model is impressive! It's part of my daily routine to check how the Indy models are progressing - they're quite an inspiration to me. The opportunity to watch four different, skillful modelers work their ways through the same build, in parallel is unique. Thanks for sharing!

-

Masthead shape on early 17th century ships

rcweir replied to rcweir's topic in Masting, rigging and sails

Thanks Mark, That's very helpful. I'm moving ahead on the "round above" principle. I'm also continuing to study those photos of Mayflower II's mast; there are subtleties in the transitions from round to flatish to round and back to flat that my eyes couldn't pick out so easily, initially. I don't think it will make any difference in what I produce in the model, but it's still very interesting. Bob -

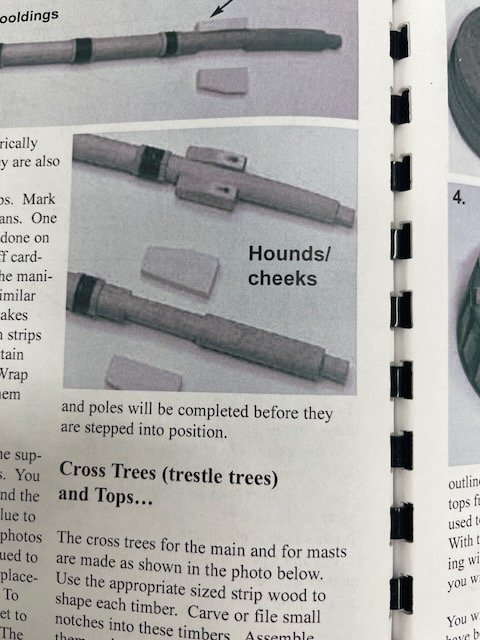

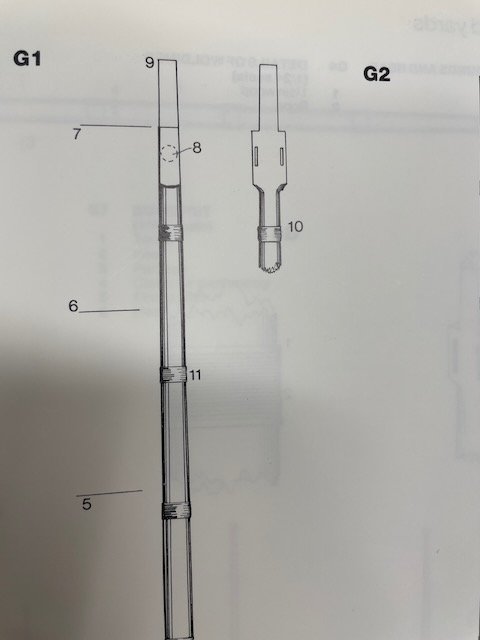

I have finally started on the rigging of my (Model Shipways) Mayflower, and this weekend's task is to start working on the mastheads, i.e. the area from the hounds to the cap. I've got three reputable authorities to look at for how to do it and I'd appreciate some opinions as to which is preferred. The first example is how the kit instructions show that area. As you can see below, Chuck (our Chuck Passaro is the kit designer), has flats for the cheeks and then a tenon for the cap. Otherwise the mast is round. This is a straightforward way of dealing with a mast that started out as a round dowel. The next photo is from Brian Lavery's AOS on the Susan Constant, a ship 2/3 the tonnage of Mayflower, but nearly identical dates. (And note that Lavery is creating his design 30 years after Baker's Mayflower II.) Lavery's mastheads are square from the hounds to the tippity top. Looks entirely sensible to me, but the practical problem is that the sides of the square area are about the same width as the mast diameter and I don't have the meat on my dowels to do this. So I'd have to build it up. For that reason, I don't think I'll do it the Lavery way. The third example is from the real Mayflower II. Here's one of the mastheads on the pier during its recent major overhaul. (I wish I'd taken measurements with these pics.) It looks like the flat area for the cheeks and trestletree is slightly less than the diameter of the mast. Above that the mast is round again, and is finished with a tenon for the cap. I think this construction is basically the same Chuck's, except that he's simplified the details a bit for the kit builder. I think I'm going to do something as close to the Mayflower II form as I can. But, regardless of what I do for this model, I'd like to know whether one or the other is more correct. And I'd also like to know how others tackle the problem of large square sections on masts that start out as kit dowels.

-

HMS Victory Renovation - Outer Planking Removed

rcweir replied to Steve20's topic in Nautical/Naval History

-

I don't know if there's an official way to ask that question, but I'd consider these things: 1. Post the question in the ModelWarships.com forum in the USS Nimitz topic area, http://www.shipmodels.info/mws_forum/viewtopic.php?f=46&t=4705. 2. Search on the internet for photos of the Nimitz in the dates you think she might have been on the transit. 3. Ditto, if you know some of her stops along the way, look for press coverage of the visit: the escorts might happen to show up. 4. Write a letter or send email to the PAO (Public Affairs Officer) on the Nimitz. It's possible that there are reasonably convenient records they could check (they probably won't be able or willing to root through the deck logs). 5. Look through this: https://www.navysite.de/cruisebooks/cvn68-86/001.htm It appears to be her cruise book for the period that includes the move.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.