-

Posts

2,652 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by JSGerson

-

Another quick update on brass drilling. Yes, the new bits drilled through the brass...until they didn't. If you look back, I made a diagram of how I was going to the drill brass blocks. Basically, each block requires two holes, some passing all the way through the block, and others only halfway. Each block required two set ups on the drill press. I was lucky if my new drill bits lasted two blocks before they quickly dulled up or broke. On moment they were drilling, the next they weren't. One didn't even drill from the start. I actually bought bits from three sources, my original bits from either Model Expo or Micro-Mark, a full set from AliExpress, and two Gyros #75 packages and one Gyros #67 each containing 12 bits/pkg. The AliExpress #67 bit broke immediately upon touching the brass and the #75 went dull. The Gyros went dull after a couple of holes. I was using a light touch, not jamming the drill into the brass. After all this, I don't have much to show for my efforts, just two cleanly drilled brass blocks. So I will admit defeat and go to plan B, Styrene plastic. The drill bits cut through in seconds, and cutting the blocks off from the bar requires just a sharp knife instead of a fine tooth saw or cutting disk. Hopefully, the brass painted blocks will blend in with all the brass rod that make up the canopies.

-

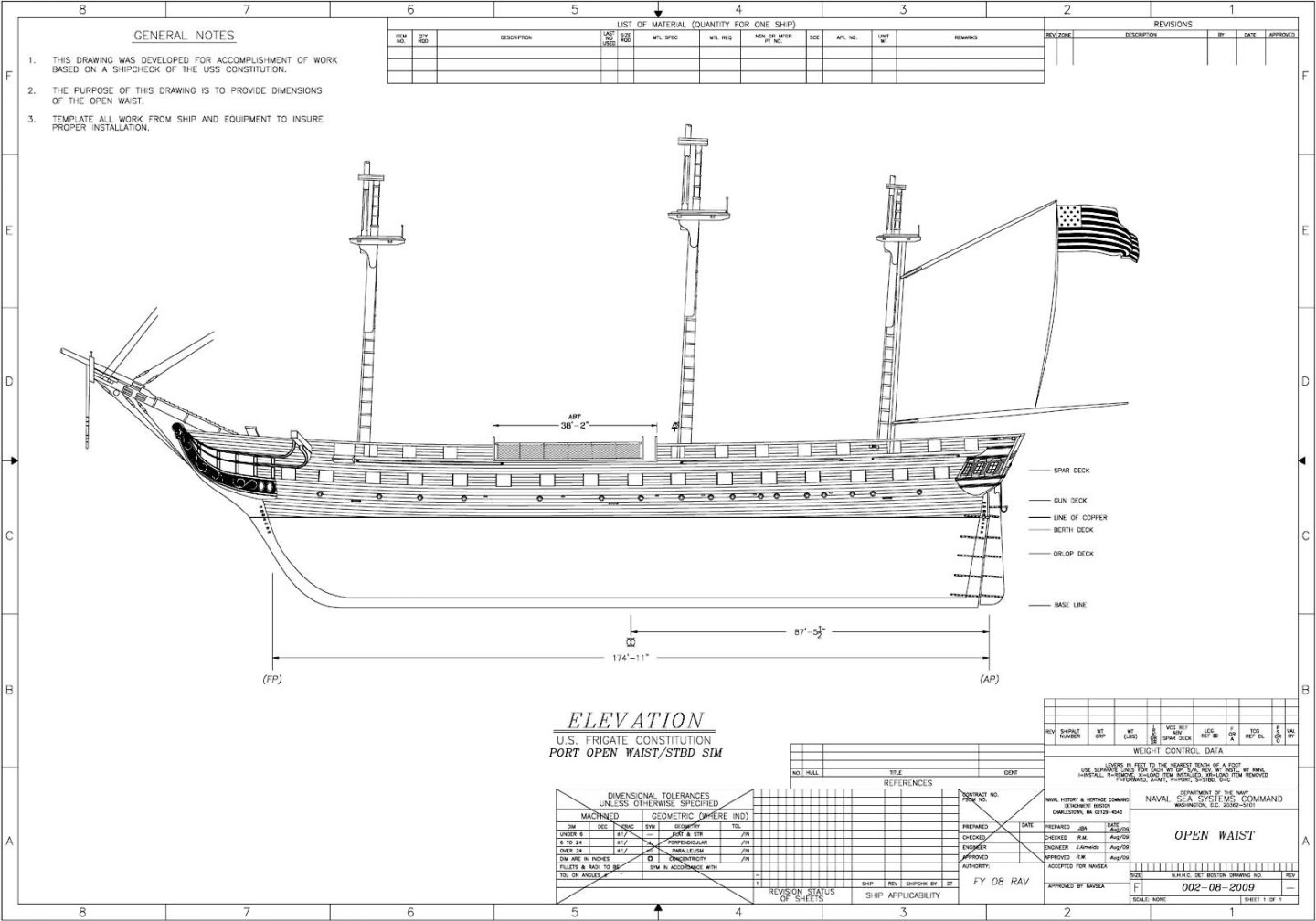

TBE - I have Olof A. Eriksen's book Constitution - All Sails Up and Flying that you linked to in your post, but the link was for the whole book excerpt and not anything specific, so I don't know what specifically you wanted me to see. The book deals and rigging and sails, with a little history, and not so much the structure of the ship. He also has a few photos of his various models of the Constitution. His masterpiece was his 1:24 1812 scale model. Unfortunately I could not find any detail photos of his models. The USS Constitution Museum talks about the 1812 Hull model exhibited in the Peabody Essex Museum. Although the Peabody Museum does not show any images of this exhibit, a good collection of them can be found at Fine Scale Modeler Magazine's website. I have found a few more images over the years. The open waist was reintroduced by the US Navy with this plan below. It was an attempt to return to the 1812 configuration. The 1992 cross section plan showing the waterway and plank sheer was drawn the same time the open waist returned. You could use this as a guide. I am not an historical expert, but I just have a lot of "stuff." Nobody really knows what the ship looked in her early days, just educated guesses, so you have some artistic freedom. As I have always said, your making a model of the ship, not a miniature reconstruction. I hopes this helps Jon

-

The topgallant rail was added during the 1927-31 restoration. It was subsequently removed during the 2007 -10 restoration (I believe) after it was determined to be historical inaccurate. The MS kit is based on the 1927-31 restoration which why its part of the MS model. So, all USS Constitution builders must decide what era their model represents...the earlier in the build the better. Jon

-

I met Ken (a professional model builder) and his wife at the 2016 NRG conference in San Diego CA while he was still building his USS Constitution model (you'll find my two cents comments and contributions in his build log). Since he finished that build he designed, built the prototype, and wrote the manual for the Model Shipways' USS Constitution cross section model kit. And to top that off he did the same for the Model Trailways 1869 Allerton Steam Fire Pumper. He also written a couple of books on how to machine brass parts on a mill and lathe. He is an awfully nice guy and would probably answer any questions posed to him, but I doubt he still follows Conny build logs because he moved on to other projects. Jon

-

With lots of tenacity and patience, I was able to place the four wire pieces in ascending order, longest to shortest, from base to the top of the windowpane. The wires were initially held in place with a very fine drop of PVA glue at one end of each wire. This glue was used so I had time to maneuver the wire into their final positions. Once the glue set up, CA glue was used to secure the wire at their other ends. In the end, the skylight which fits on a US quarter coin, is comprised of 82 separate parts: 1 Base with six faces each base face - 4 base frame pieces x 6 f aces = 24 pieces 1 Dome support wire 1 Dome 1 base plate 6 Window panels each consisting of: 4 window frames = 24 pieces 1 piece mica = 6 pieces 4 pieces wire = 24 pieces I’m not trying to make excuses, but with 82 separate parts, those tiny precision errors add up. On this scale, my novice workmanship is showing with these closeup images. It’s something I’ll have to live with it. The skylight will put aside till it’s time for its installation. Now, back to working on the canopy frames.

-

As I was about to add the Infini Model Micro Fine Brass Wire 0.1mm IBW-1000 (0.004”) wire to protect the windows, I realized that the 0.1 mm wire I ordered was not the wire I received. I got Infini Model Micro Fine Brass Wire 0.2mm IBW-2000 (0.010”). Although technically a bit oversized, as it turned out it looks better for the model and that is what counts. The four cut wire parts per panel were of four different short lengths due to the trapezoidal shape of the windowpanes. They were very thin which made it difficult to pick up. My two forceps tweezers were just about useless. Compared to the working space on the panels, the tips of the tweezers looked like tree stumps in comparison, and I couldn’t pick up the wire pieces off the workbench surface due to their rounded tips. I ended up using my rarely used sharp but relatively heavy needle-nose pliers I had bought some years back. It was a bit awkward to use, but it got the job done.

-

The skylight’s side and top window framing was made from 1/32” x 1/32” boxwood stock. The bottom was made from 3/32” x 1/32” stock. An outline was drawn on paper and covered with wax paper. The frames were lined up with drawing and fastened with PVA glue so the parts could be adjusted before drying.

-

The skylight sits on a 1” thick round platform protruding about 1” wider than the skylight structure footprint. Because this component will be painted black, be mostly covered by the skylight, and I didn’t have a readily available piece of 1/32” basswood or boxwood wide enough, I used 1/32” plywood. NOTE: The practicum calls for the round platform to be painted Bulwark Green. Why, Mr. Hunt chose this color I don’t know because I could not find any images showing a green platform, just black.

-

Then, the wire and dome were removed, and the base was hollowed out halfway down. This was done to create the illusion the base was totally hollow. The top piece was rounded off to create the roundness of the dome. Now, when the base, wire, and dome were assembled, I had a solid structure to support the windows. According to the US Navy plans, the dome was made from mahogany. No mention what type of wood the rest of the structure was made from, so I assumed it was the same. However, the photo images seem to show the skylight was the same color as most of the wood on the spar deck which was not mahogany. The mahogany stain I had gave a deep reddish tone, almost black looking which I didn’t want. Therefore, I initially stained the wood with Miniwax Gunstock, then applied a light coat of Miniwax Red Mahogany.

-

The skylight windows invited numerous methods from a variety of builders depending on whether the skylight was solid wood mimicking a glass enclosure or an actual framework. My method is also a bit unique. Because I intended to make actual windows with a frame and glass (mica), the window frame would only be supported at the base and top of the window frame. Therefore, I had to create a “floating” top support. The actual skylight has a wood dome with an internal mechanism to facilitate the opening and closing of the windows. So, that inspired me to have my dome supported by a pole paying homage to the real thing. An extended dome was fabricated out of boxwood with a hole drilled about halfway through to accept a piece of music wire. Another hole was drilled through the base to support the wire. The dome was stuck on the wire, inserted into the base, tweaked so that the top of the dome was ½” from the bottom of the base.

-

As usual, the first thing I did was gather my materials needed for this endeavor. One of the items was brass wire for the horizontal 3/8” brass bars protecting the glass windows. This scaled down to 0.005” or 36-gauge brass wire which Mr. Hunt did use on his construct. However, try as I might, I could not locate 36-gauge identified brass wire to purchase. I did find Infini Model Micro Fine Brass Wire 0.1mm IBW-1000 (0.004”) online at A-Z Toy Hobby in Texas. I don’t think anyone will notice the 0.001” difference in thickness. Using the template from the practicum, the skylight base core was cut from ¼” thick basswood stock.

-

While I waited for the new drill bits to arrive, I put the canopy stanchions on hold and started to work on the captain’s skylight. This took longer than I had expected, and the time was also interrupted with my annual Thanksgiving weeklong trip to my sister’s home where the family gathers for the holiday. I studied the practicum method, xKen’s method and others. Since I am a glutton for punishment, I chose not to take the simple route. I wanted transparent windowpanes and close to scale details which meant, I would be using Ken Foreman’s as a guide more than Bob Hunt’s. Also, Bob did not fabricate the brass railing surrounding the skylight which Ken did.

-

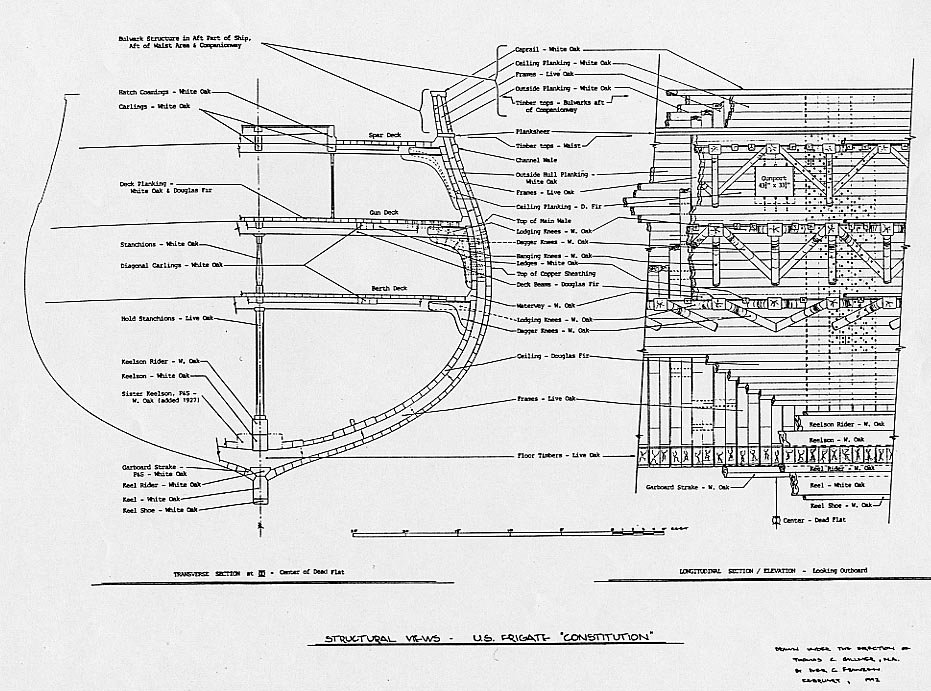

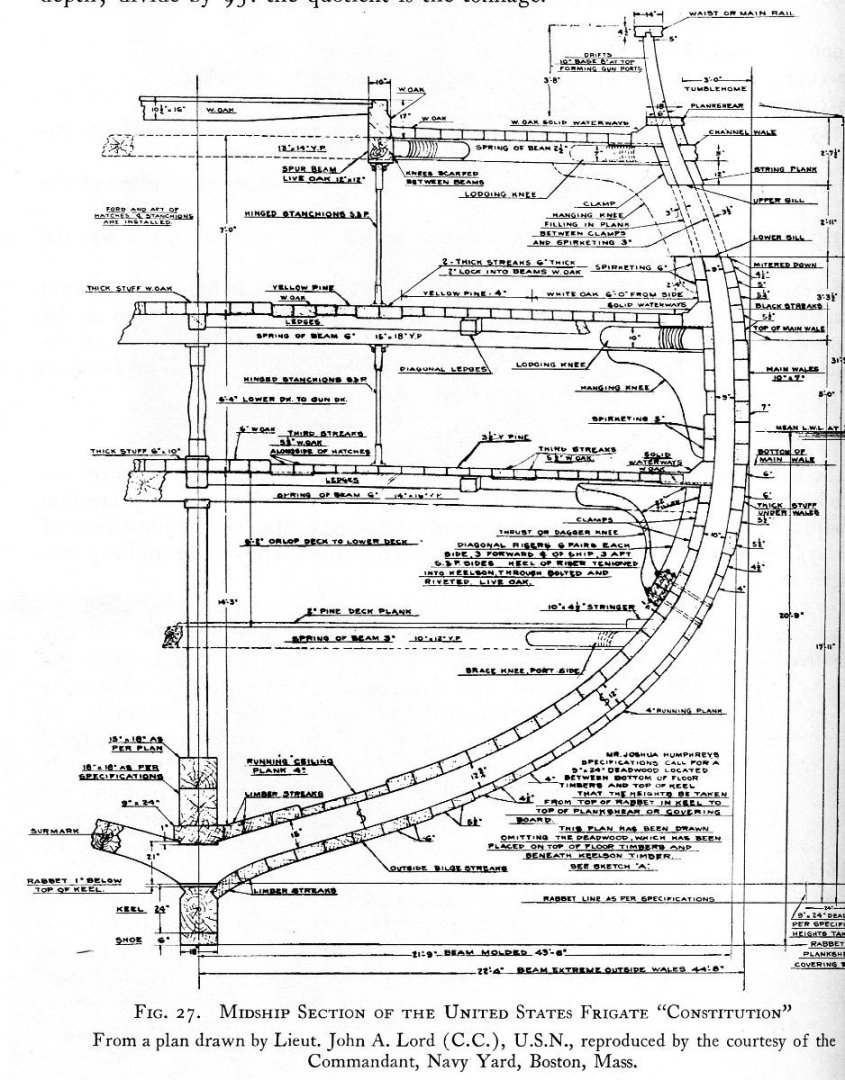

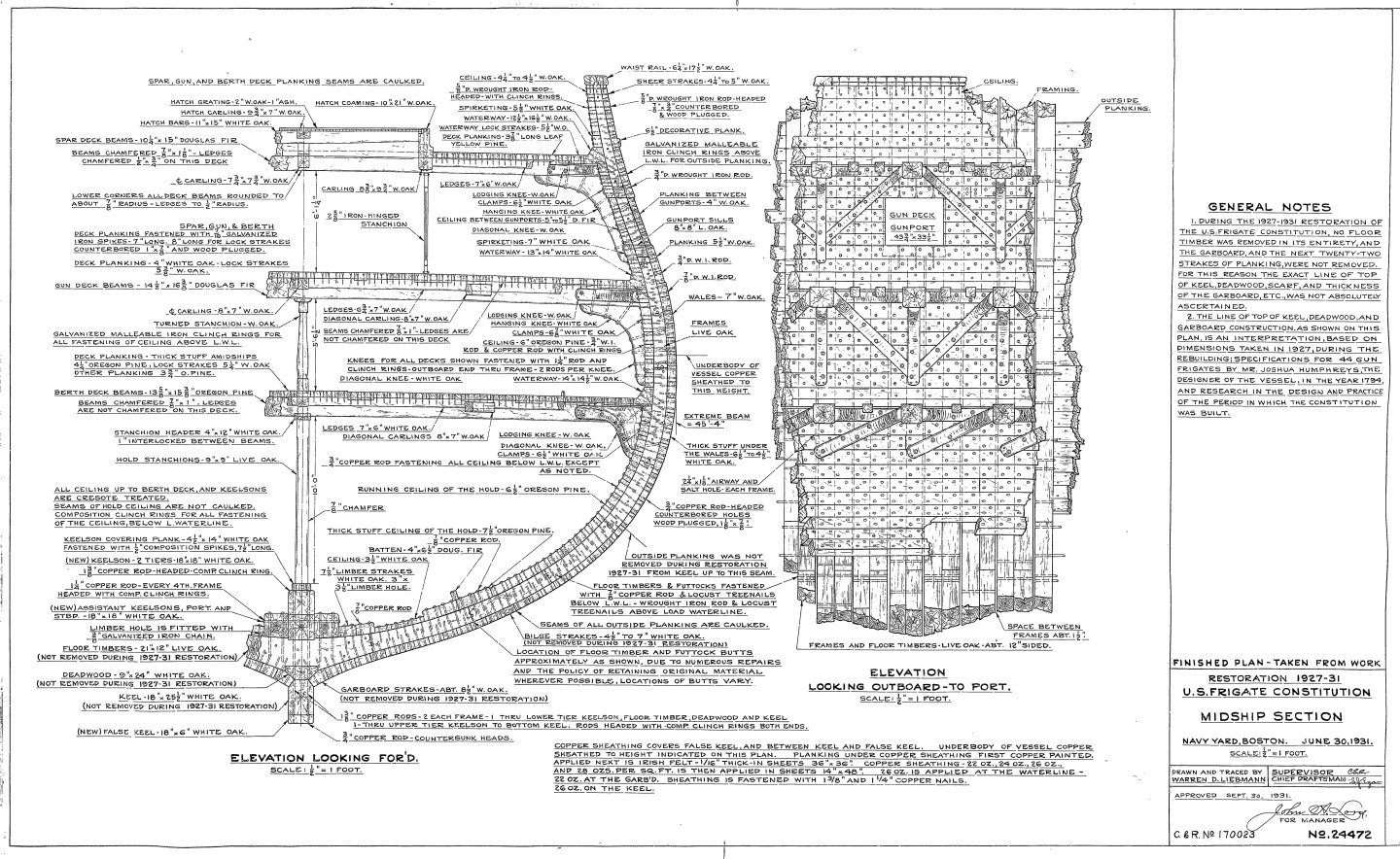

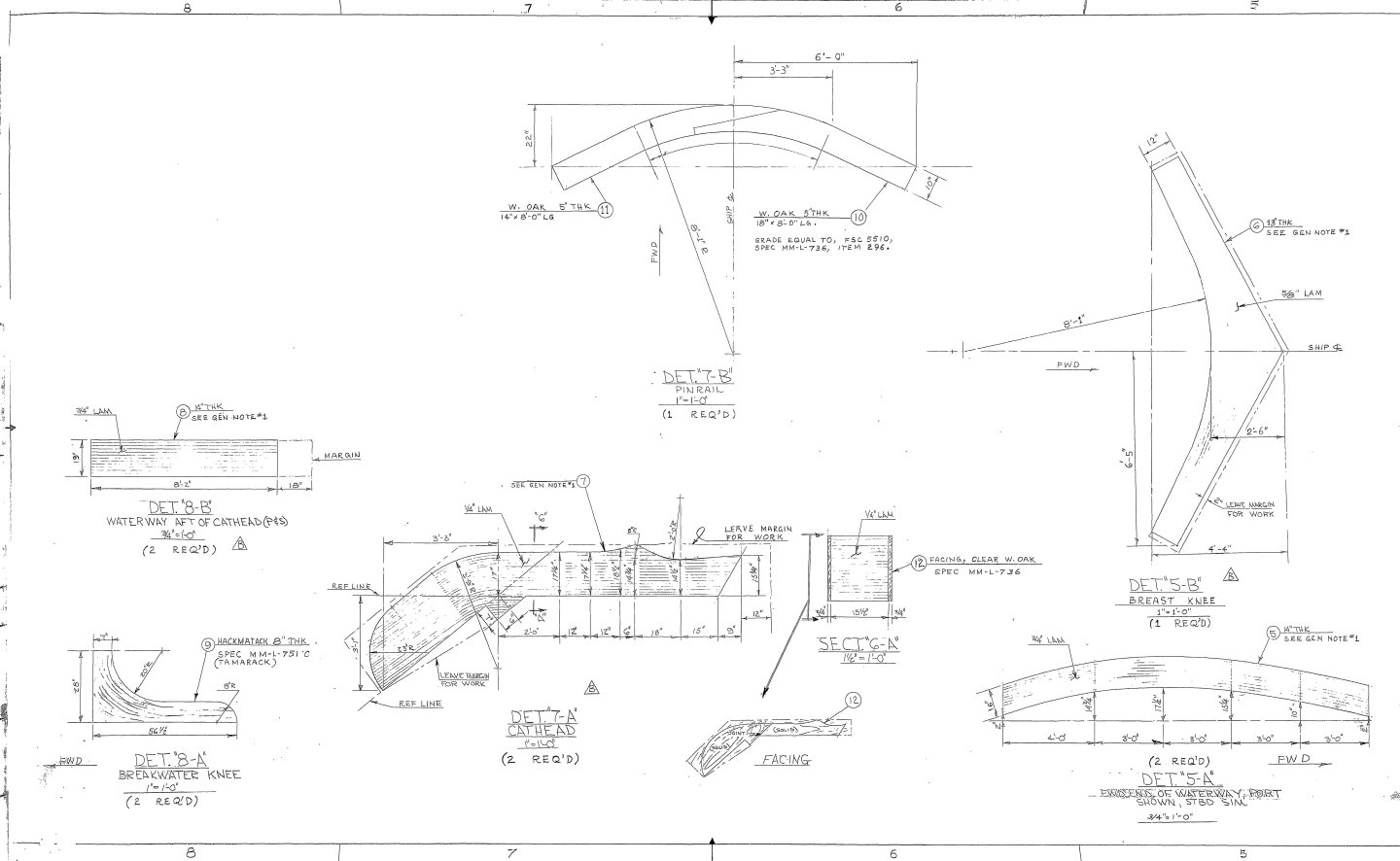

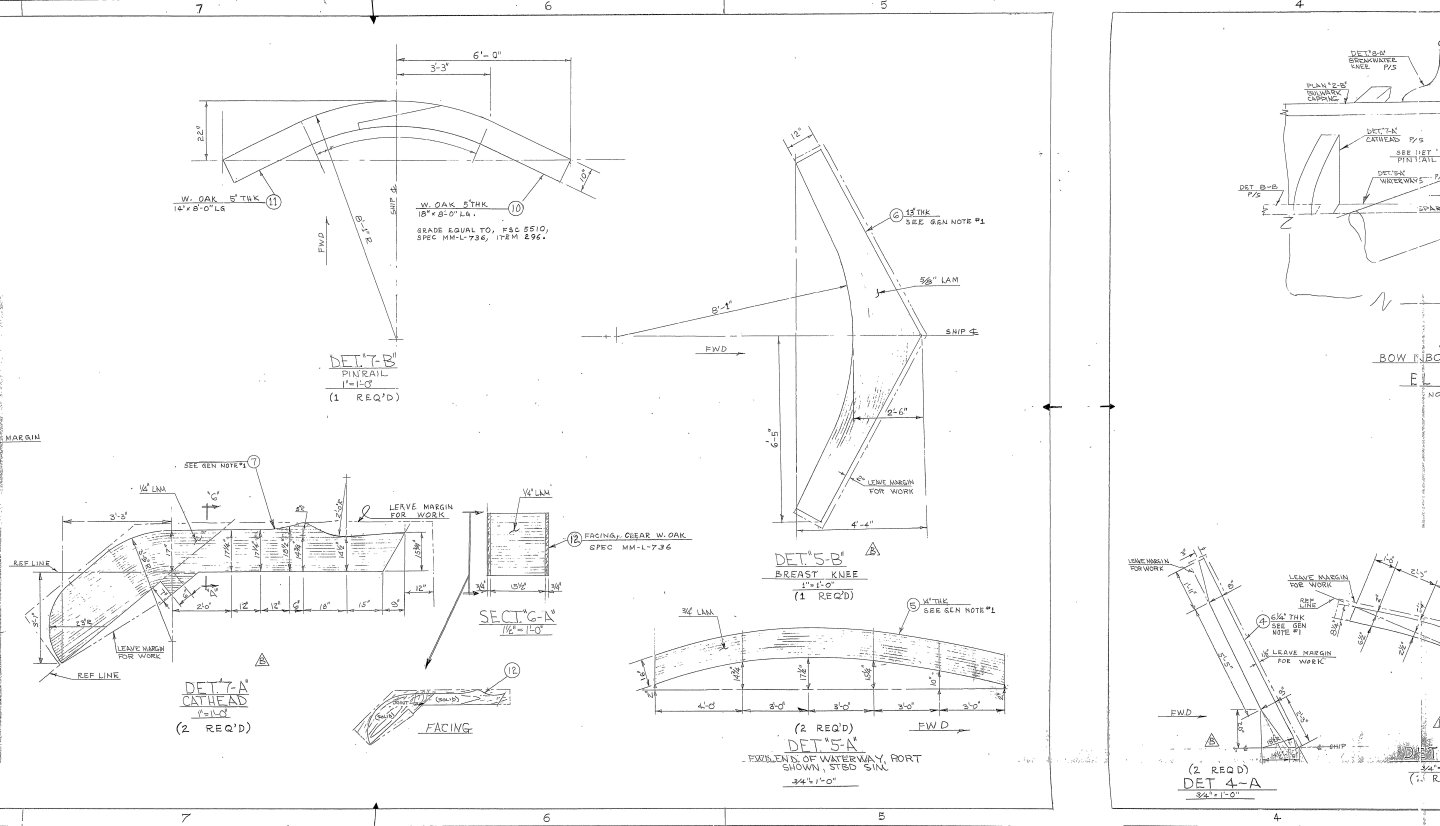

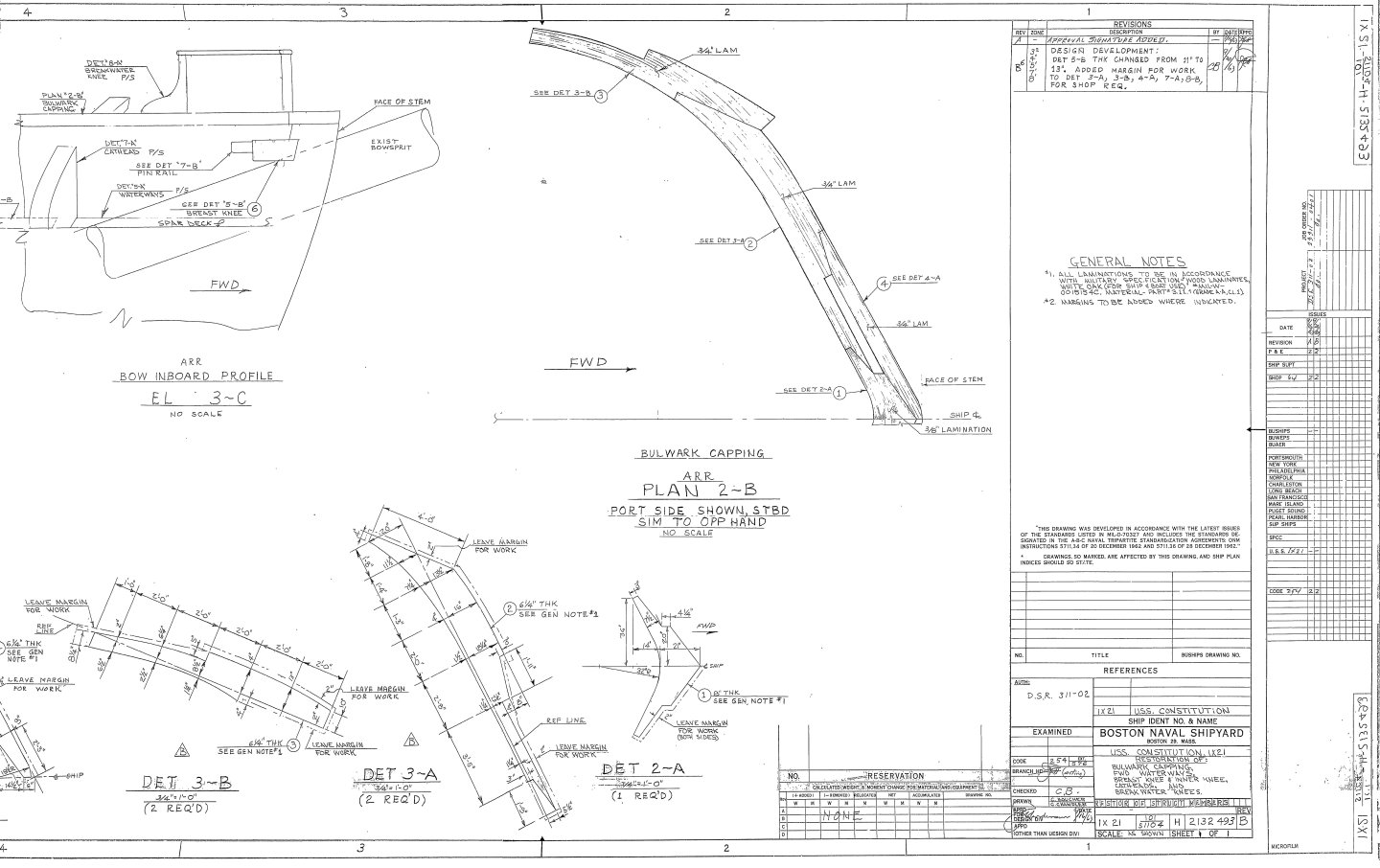

I didn't find any additional detail on the waterways other than this 1927 version of the midsection section which just states "solid waterways" & "white oak," with a clear image of the waterways cross section. As for the joints, they are probably some sort of lap joints. but any detail would be perpendicular joint lines and those be barely visible on bare wood. Your model would get the same visual effect from a simple butt joint. I think any effort to make them more prominent, would render them out of scale and not help the model. Jon

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

Click here for unegawaya One of the reasons the waterway is installed first is because that's the way the actual ship was built (see cross section plan). I see no reason you couldn't plank first then add the waterways second for a model. You would have to modify the waterway cross section to account for the planking under it. Jon

- 233 replies

-

- Model Shipways

- constitution

-

(and 5 more)

Tagged with:

-

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Just catching up on a week's worth of everyone I've following's build logs. Beautiful work as always. Jon -

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

We are making models, not miniature reconstructions. I didn't cut the waterways either. It just has to look right no mater how you do it....and you do it very well. Jon -

USS Constitution by mtbediz - 1:76

JSGerson replied to mtbediz's topic in - Build logs for subjects built 1751 - 1800

Well, I got home late Monday afternoon and saw that you completed(?) fabricating the catheads, but as promised here are the US Navy plans. Jon

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.

andmooringchains.jpg.0df7eb2599f2e92128e3a961b91b72b1.jpg)