-

Posts

1,492 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

How Realistic Can One Make Sails?

Kevin Kenny replied to Julie Mo's topic in Masting, rigging and sails

They look great. I like how they hold the shape. -

-

-

How Realistic Can One Make Sails?

Kevin Kenny replied to Julie Mo's topic in Masting, rigging and sails

I would have to see them to understand how realistic they are. -

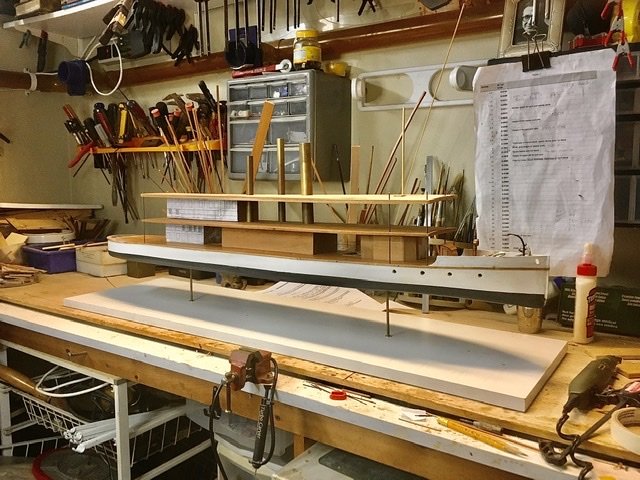

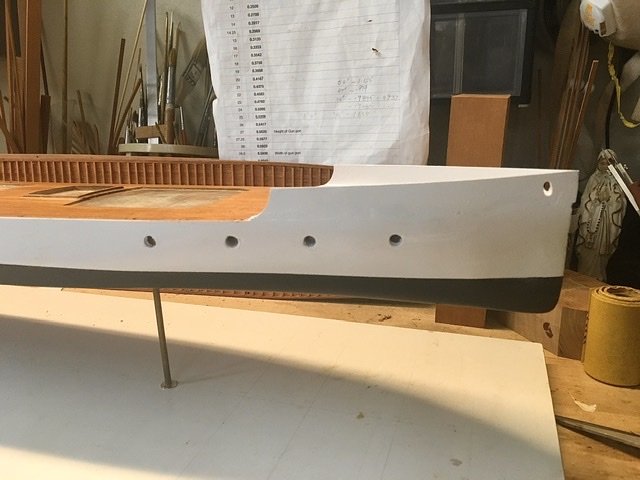

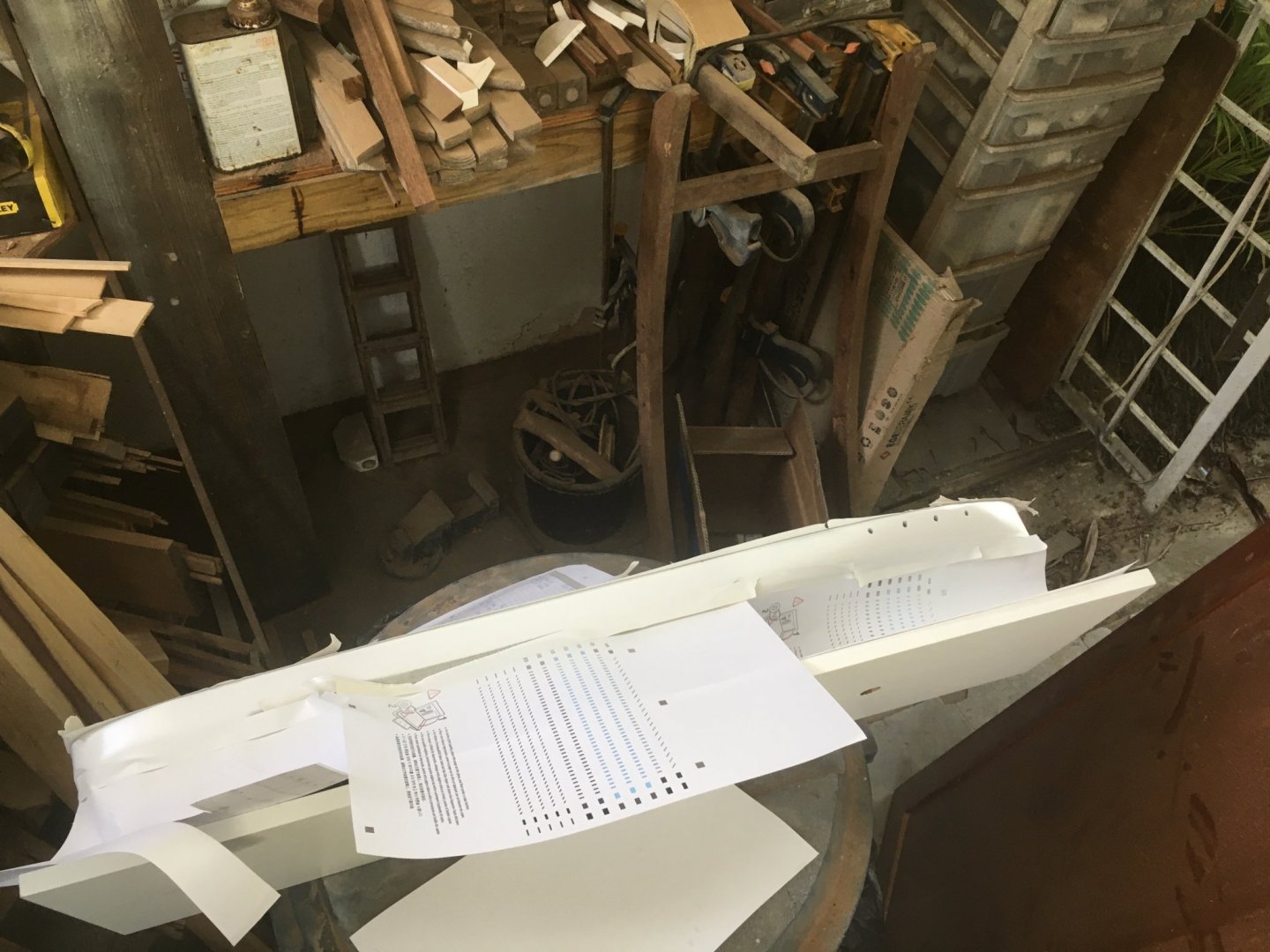

I had a rough time with the imperfections of the bottom. Different surfaces, wood, glue, glaze putty, Bondo filler, scratches etc. finally got it to an acceptable level. Will sand and apply 3 more coats then mask to put the sides in white.

-

Roger i am not going to show the plates on this one maybe when i build the plank on frame i will reconsider. In the mean time i will do some experimentation like you are doing. On another note I got this book on marine steam engines. Should be interesting reading over the next month. I am still fighting up to find the exact design for the boiler and fire box.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.