-

Posts

1,484 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

- 1,127 replies

-

- 1,127 replies

-

Hi Alan I put it the coffee pot and boiled it. It still broke, so i put the heat gun one it after the coffee pot and got it to bend with out it breaking. hopefully ill get the starboard side to do the same as its a very sharp bend.

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

I just finished putting on the scrolls with the acrylic ink. Once that dries i will apply another layer this time with some of the tube acrylic to thicken up the paint. This will be followed by the addition of the burnt sienna, then the highlights, And finally touching up with the Prussian blue and cleaning up all the lines.

- 1,127 replies

-

- 1,127 replies

-

Greg at this point was planning to leave them natural

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

Yves i used Prussian blue which was recommended in the book.

- 1,127 replies

-

The journey https://youtube.com/watch?v=I6Z8lJQRcOM&feature=shareb

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

-

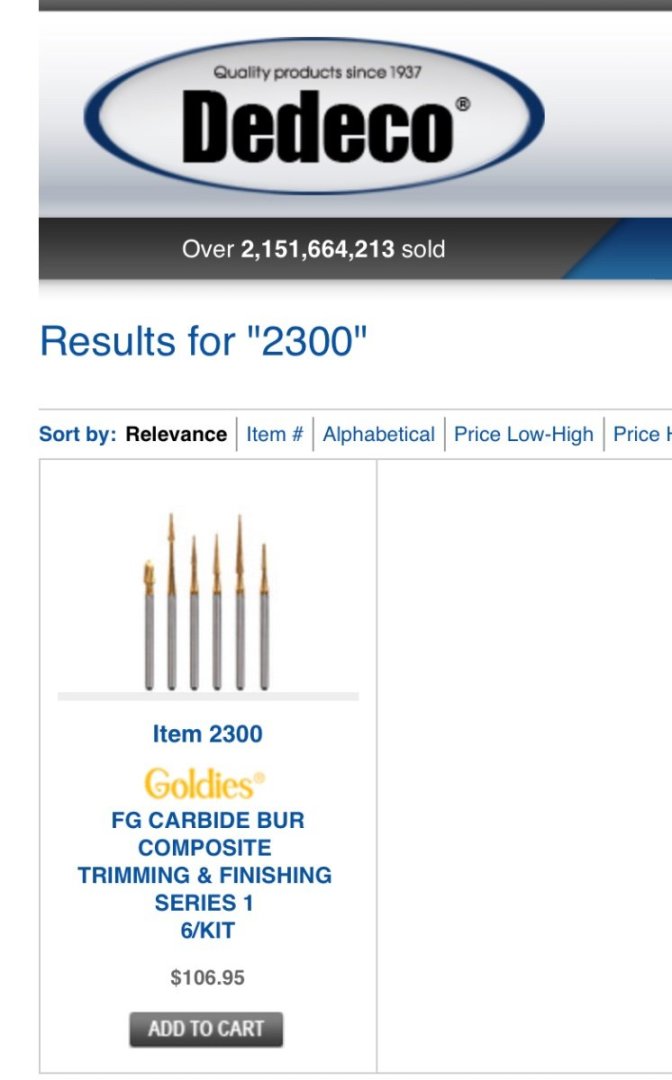

Sorry for the miss spelling Zak Jewelry tools zakjewelerytools.com

- 1,127 replies

-

The reason i get so many nice tools from new york is that one of my daughter lives there and i send all my on line purchase tools to her apartment. Tools for woodworking. I’ve actually only found two great physical stores to visit. The first is “tools for woodworking “ . Its located in a bit of a grubby area so don't take your wife as i did. 112 26th Street, Brooklyn, NY 11232. They also have a web site toolsforwoodworking.com so you can see what they have. The other is. jak Jewelry tools 37 west 46th street in Manhattan. You have to walk up a number of stairs and there is lots of security all around the place . I guess they must make jewelry around the area. Again they have a web site jakjewelrytools.com. My usual on line store is Lee Valley which has some wonderful miniature tools that i have shipped to her home.

- 1,127 replies

-

- 1,127 replies

-

Starting to figure put how to paint the scrolls. Using acrylic paint. 000 paint brush. Pencil in the scrolls on the blue acrylic and painting over the pencil lines. . Any suggestions My Movie 18.mov

- 1,127 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.