-

Posts

1,484 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

- 1,127 replies

-

Here we go guys

-

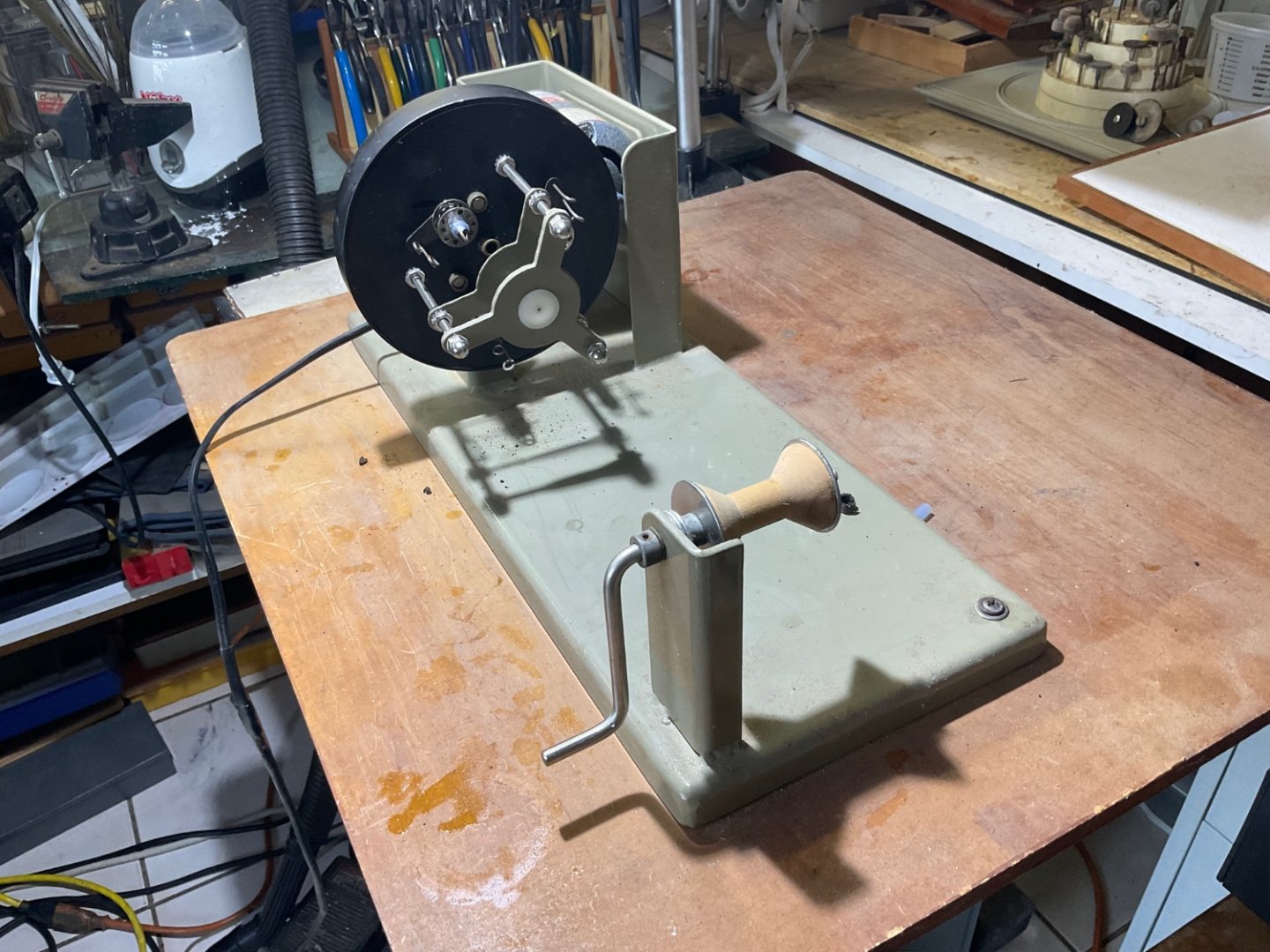

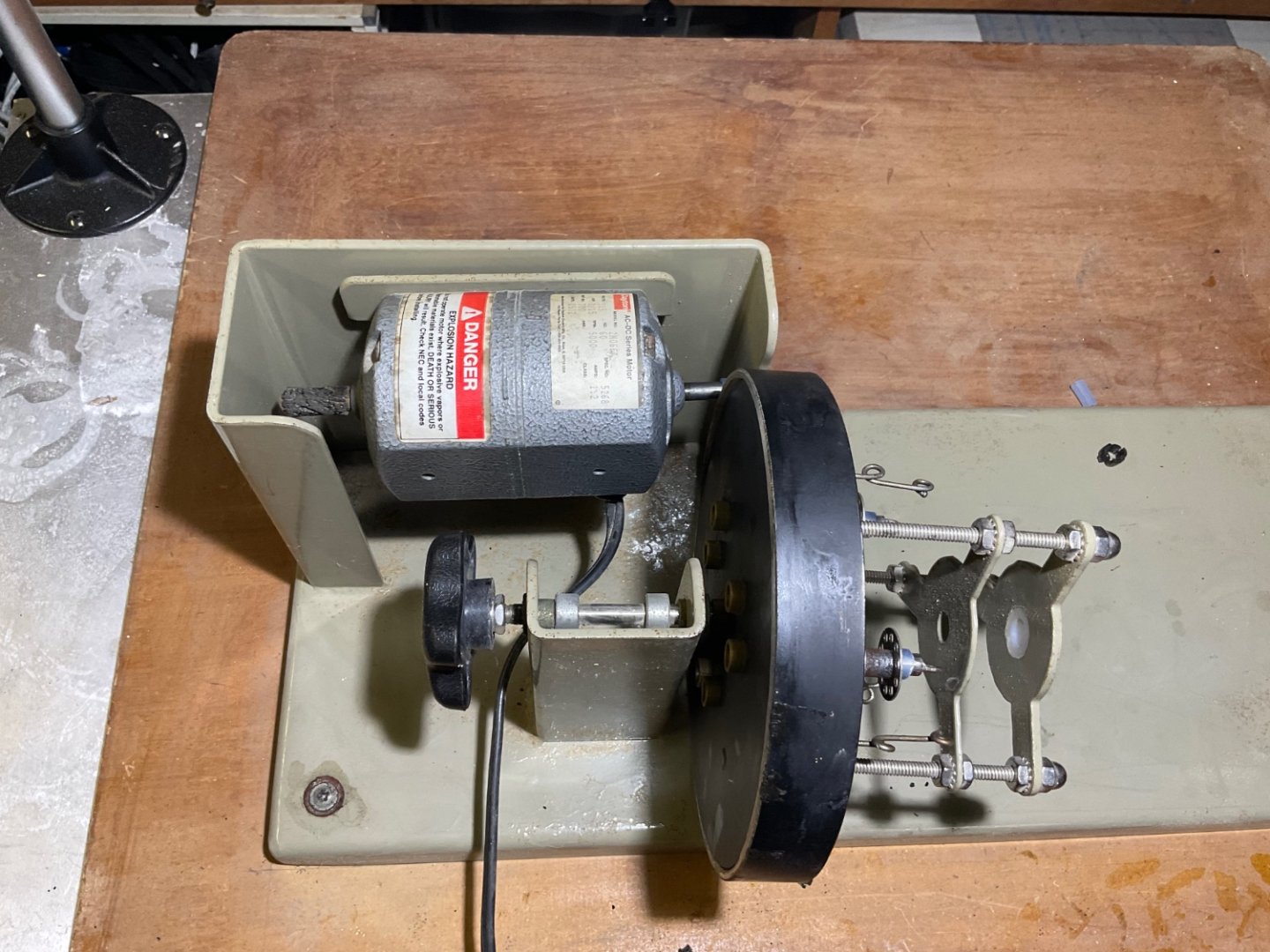

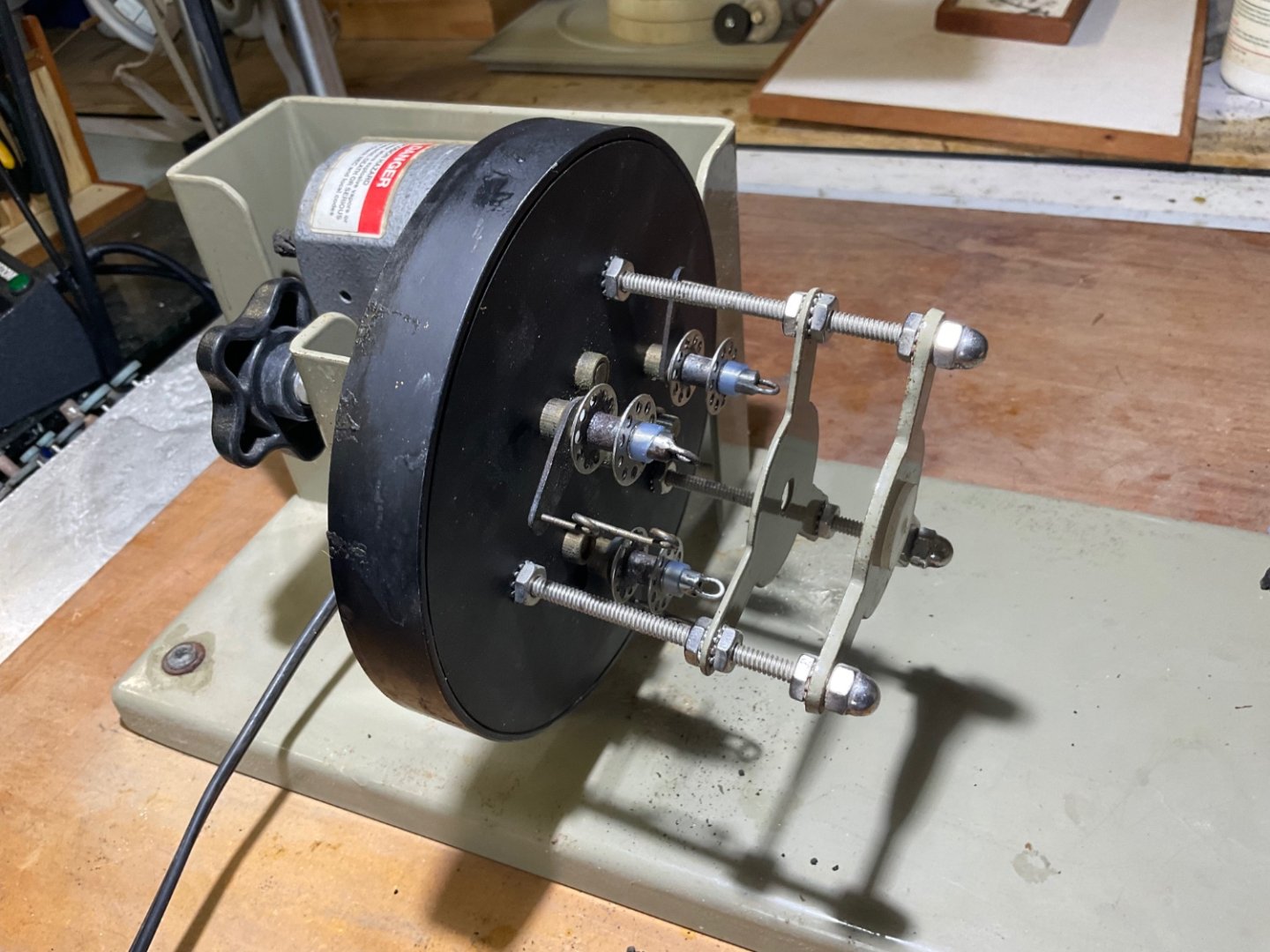

Has anyone ever come across this ropewalk? I purchased it 20 years ago and never used it and am now trying to get it up and running but have no instructions. Lots of the parts have rotted out and need to be changed.

-

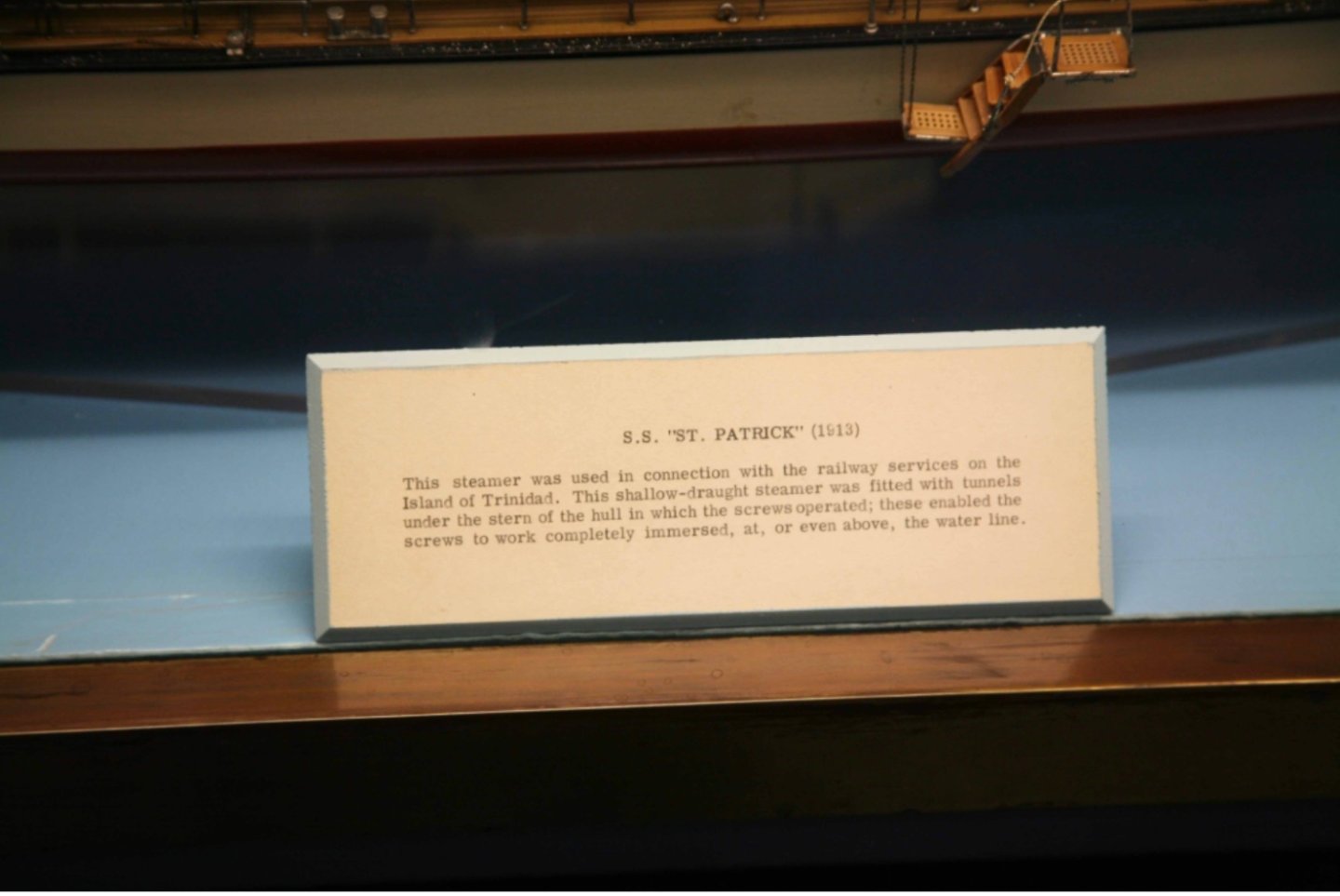

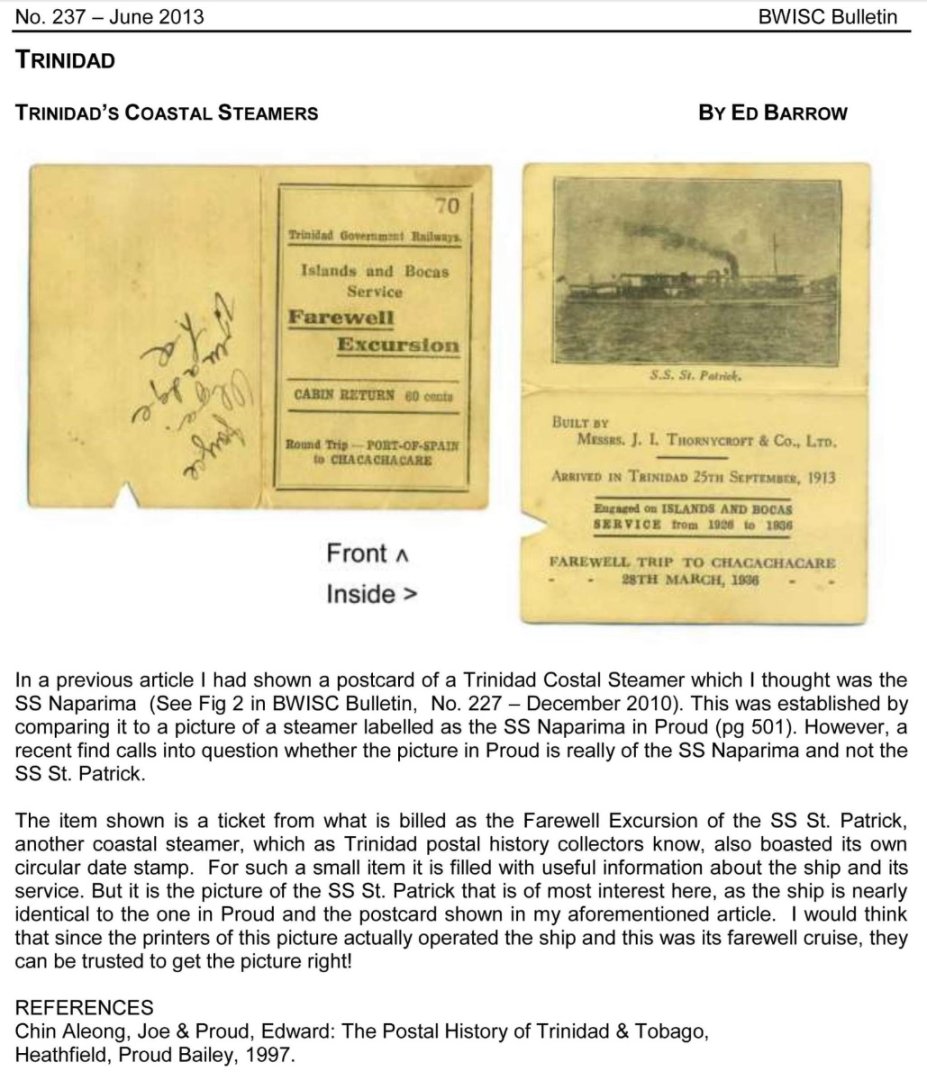

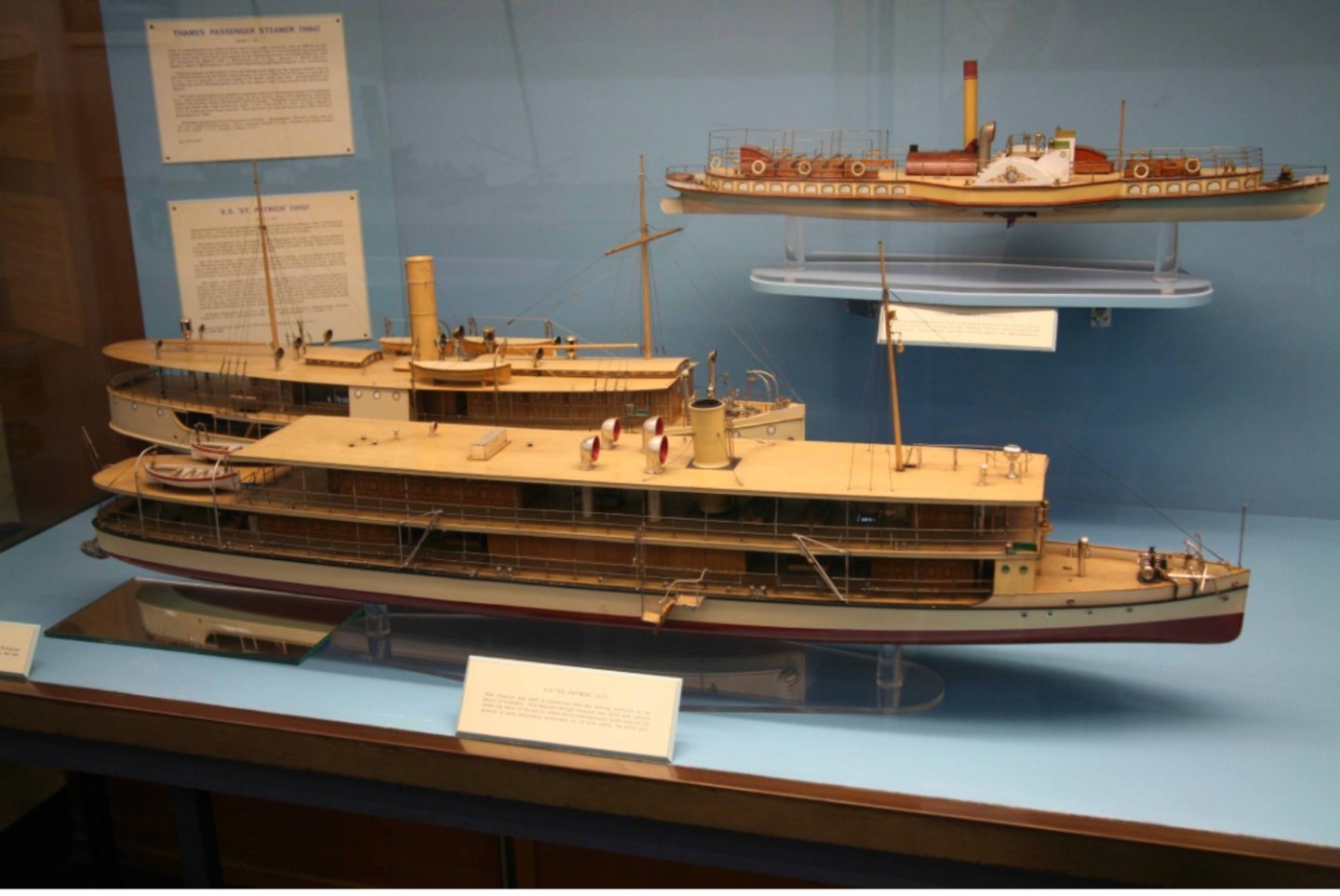

The result of this journey was my fully documenting the process in a paper and continues to evolve as more data gets discovered. I am now on the journey of looking for the plans of her sister ship the St Patrick. I came across a model that was in the science Museum in london and is now in Prison in a warehouse. This model could not have been built without access to the original ship plans. So far i have been unable to find the plans but the journey continues. I am in touch with the curator of the science museum but she has not been able to find the plans. The journey continues.

-

this came up in my memories today. Its an excellent history of the research that went into the building of this scratch built model of the steam ship Naparima.

-

So envious. Well done. Ill catch up some time later this year. The stern looks great.

- 475 replies

-

Brides are wonderful people.i used this video to make the shooting board. i should have made it 6” longer.

- 1,127 replies

-

- 1,127 replies

-

Gregs comment “Maybe an optical illusion but the first gunport (not the bridle port) looks a bit short.” i have checked all the gun ports. the forward gunport is 27” high and 18” wide, aft is 27” high and 24” wide and all others are 27” high and 28” wide. So unless i have my measurements off the plan they are all ok.

- 1,127 replies

-

Hi Toni when i buy a tool i usually buy all the accessories, so i have had the fence since i purchased the original saw.

- 1,127 replies

-

I have the Preac fence. Ill be checking all the ports this week. I hope not because i checked and corrected them before i started the planking.anyway if its too small thats an easy fix, if it too large thats a pain in the butt.

- 1,127 replies

-

- 1,127 replies

-

Large soldering pad/board arrived along with ceramic pins for holding stuff that will not provide a heat sink. The silver soldering station is now complete.

- 1,127 replies

-

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

- 1,127 replies

-

How Realistic Can One Make Sails?

Kevin Kenny replied to Julie Mo's topic in Masting, rigging and sails

I am a fan of Tom Lauria -

I have written to Jim to see if he has any suggestipns

- 1,127 replies

-

- 1,127 replies

-

Not sure if this is what Maury had in mind. I use to have various jigs for the Preac sander and most of the time had to remove the cover to keep the piece from flying off. Also the paper roll would turn the piece when i pushed it through. I would love to see what you guys do. Now that i am using this it would have been great if the aluminum base extended back another 6 inches, to make sure i push the sled in flat. It has a tendency to lift at the front.

- 1,127 replies

-

Maury i would love to see a picture of what you made

- 1,127 replies

-

- 1,127 replies

-

- 1,127 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.