-

Posts

1,487 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Kevin Kenny

-

- 1,132 replies

-

- 1,132 replies

-

Hi Maury you are absolutely correct that if there is a lot of pressure when pulling the stock through the draw plate that mounting it in a table top vice helps greatly with the stress of pulling it through the plate. I found this particularly true with hard wood stock where it is difficult to get the raw stock small enough. But with Bamboo i found it quite easy to reduce the size of the stock down to say .030 which means that you can literally pull the treenail stock through the plate without using the thong puller to get down to .020. Most of the time i was able to get to .020 without any pulling device at all, just with my fingers. The technique was getting to split the bamboo and the hammer was the tool that did that so effectively. Also if for some reason i was having difficulty getting it into the next hole, simply backtracking to the previous hole easily solved the problem. I any case my wife would not allow a bench top vice to be located on our porch in Tobago while i sat on the chair in our porch , on the golf course. Haha.

- 1,132 replies

-

Sorry, but I could not resist ascit was such a gorgeous day

- 1,132 replies

-

- 1,132 replies

-

This is how i get the bamboo squares split. The dowels in the draw were made in half an hour watching the world cup. IMG_9210.MOV

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

I actually wrote him and he confirmed that he was pulling the dowel through the plate the wrong way. I was glad that i was not the only person to film things the wrong way.

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

You will find that after you’ve recovered you can get those down to .020, you’ll just have increased breakage. I now have another draw where I keep the .020

- 257 replies

-

- pegasus

- Swan-class

-

(and 1 more)

Tagged with:

-

Repairs to the stern inner counter timbers a result of turning the model over and being careless. Thank goodness for PVA glue and alcohol

- 1,132 replies

-

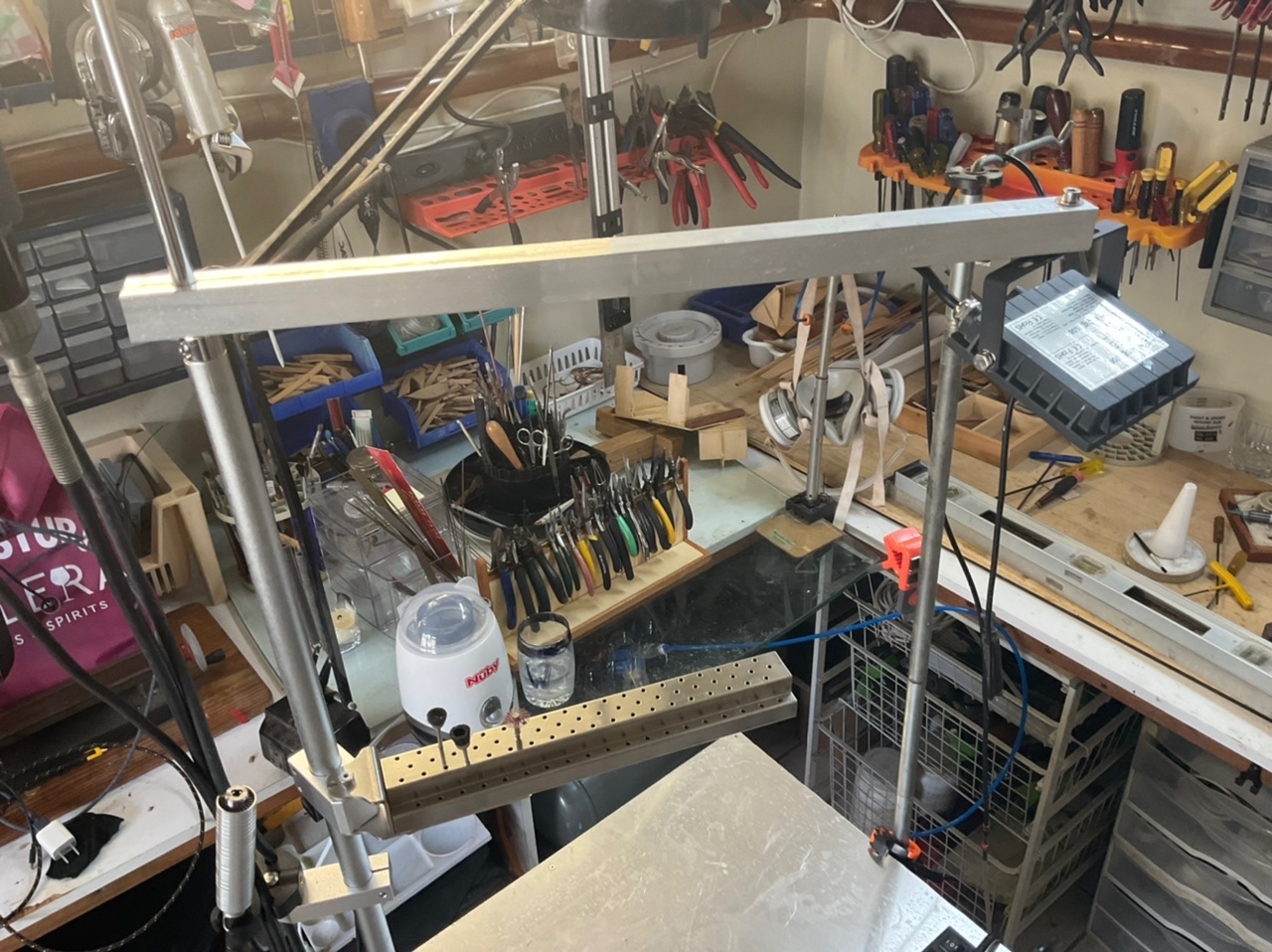

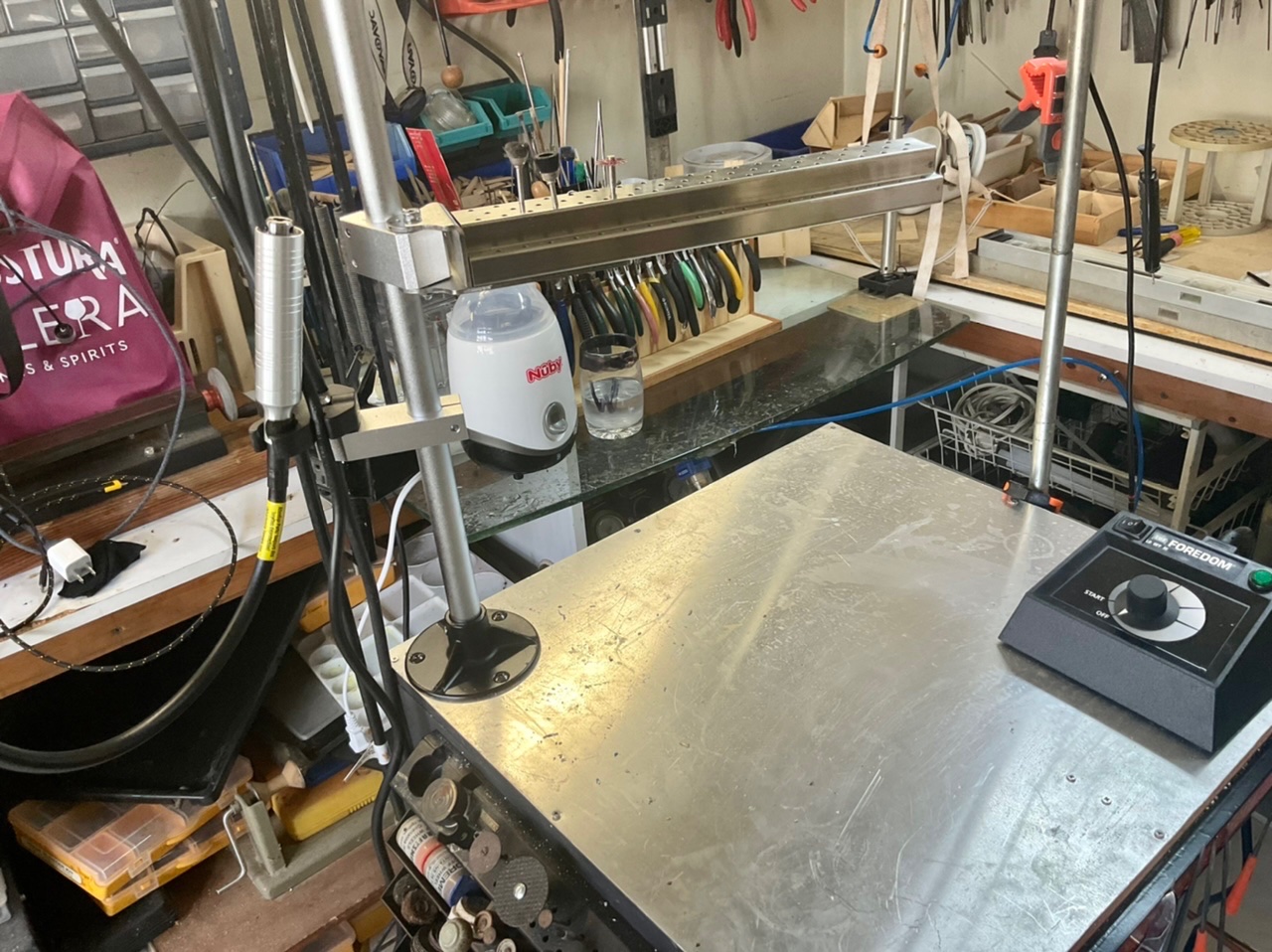

I have 4 drill presses in the inside shop and the same number of vices. I have two vices that can clamp onto the table top of the pendant table making sure that the table top is clear of perminant clutter. My rolling tables have allowed me the luxury of keeping all the parts and accessories with the main power tool. In the past i could never find them when i needed them. My main work bench draws only keep the tool needed for the project o am working on. Its a constant fight and i am always looking for ways to make the shop more efficient.

-

Just the Jim Byrnes thickness sander to add and we are basically up to date with my power tools wish list. In planning my retirement i had been trying to get my shop to the point where i dreamt of adding no new toys. Its taken me 12 years to get the shop complete. Of course there will always be some temptation.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.