-

Posts

2,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NMBROOK

-

TBH,I wouldn't know where to start,he has picked a good un Could possibly be a customs vessel,but as to what nation .I don't get much chance to scour the net at the moment other than weekends,so haven't 'attacked it with all guns blazing' Kind Regards Nigel

- 1,039 replies

-

- ballahoo

- caldercraft

-

(and 2 more)

Tagged with:

-

Looking good mate Yes the hooked scarphs can be a bit of a challenge.Like you say,have another go on the next vessel of the Arklow fleet Kind Regards Nigel

- 1,039 replies

-

- ballahoo

- caldercraft

-

(and 2 more)

Tagged with:

-

Mmmm I was kinda in the vicinity,first googled Arklow buoy tenders and discovered the Irish lights bit,but then had to go out .Eamonn you are going to have to stray from your native land with your choice of posting,I think we may have sussed your stratergy Kind Regards Nigel

-

Oops should have mentioned the other piece is reversed when you clamp it together,i.e. both on top of one another and the ends inline. Kind Regards Nigel

- 1,039 replies

-

- ballahoo

- caldercraft

-

(and 2 more)

Tagged with:

-

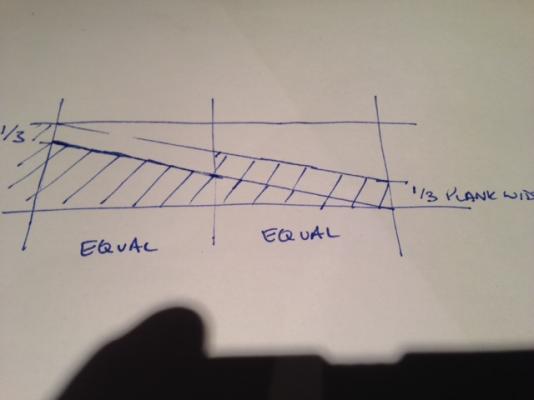

Ok buddy here is a diagram(actually a photo of a pretty rough sketch by me of how I set them out.The two measurements along the plank want to be the same and the nib and recess both want to be 1/3 of the plank width(this is not following the rulebook,but rather something achievable and looks convincing.Join the points up as on the sketch.This gives the outline of one half.The longitudinal measurements you can play around with until you are happy with the angle,as long as they are the same that is the important thing.To give you an idea I have just done some on 6mm wide pear and they worked out at 2 x 10mm.The clever bit is you clamp the marked out end with the piece you are joining it to ideally in a vice.Ensure the edges of the planks are inline and cut both ends at once.I do the cuts across with a razor saw down to the line and then shave away the material with a scalpel.Carefully file down to the line ensuring the faces are level.Providing the two 1/3 width sections are cut and marked accurately,the two ends should join together in a perfectly straight line.A couple of goes on some scrap will help but once you get in the swing it is relatively straight forward Kind Regards Nigel

- 1,039 replies

-

- ballahoo

- caldercraft

-

(and 2 more)

Tagged with:

-

When to stain wood?

NMBROOK replied to Keith_W's topic in Painting, finishing and weathering products and techniques

Hi Keith Personally I would apply some stain prior to assembly.When you do rub the hull and treenails down,removing areas of stained wood,you will have no problem restaining as the sanding will have removed any potential glue marks in those areas.The problem is areas that you can't get to to remove glue,but you won't be able to sand these areas either,if you catch my drift. Kind Regards Nigel -

All scarph and no play I like that Eamonn.They are purely optional and quite easy when working with straight lengths.If you do fancy having a bash,give me a nod and I will give you some pointers Sorry if that sounds like something from the 'EastEnders script,not that I watch it mind Kind Regards Nigel

- 1,039 replies

-

- ballahoo

- caldercraft

-

(and 2 more)

Tagged with:

-

Congrats Jason,it is indeed the Atlantic conveyor Kind Regards Nigel

-

-

Looking good mate For me,I would consider another run each side of maple,then the beech plank.The origins of the 'go faster stripe' on model decks is related to the two king planks used either side of the hatchways (there is another name for them but it evades me as I write this)which were made of oak,whereas the deck planking quite possibly would be fir.The difference in colour on the model is indicative of the two different timbers on the real vessel.In reality these planks would run either side of the hatches and would not be split at an opening.If you wanted to add another feature,you can incorporate hooked scarph joints in them. Oh and unless the deck planks need to be much longer than a full plank,no butt joints are normally used Kind Regards Nigel

- 1,039 replies

-

- ballahoo

- caldercraft

-

(and 2 more)

Tagged with:

-

After having a thoroughly enjoyable read through your log,I have to say wonderful work Jack!! I have two model requests for my wife to fulfill one day,Mary Rose and a Viking ship,this kit looks like a very nice way to meet the later.Having also looked at your website,I have to say some of the pictures are positively awe inspiring,outstanding! Kind Regards Nigel

-

Soulanges? Kind Regards Nigel

-

Hi Dominic I think your planking looks great.It is super neat.If you are happy with it and you didn't set out to create a build that is historically accurate,more something that is a display piece,then good on you,it is your model. I understand other members wanting to 'push' you in the right direction,but I think this hobby is a bit like stopping smoking,i.e. you will do it when YOU want to. Please don't think of this as an elitist forum,because it isn't.As you know there are a great many builds on here by modelers of varied experience.Sometimes posts may come across not as intended.I left the modelspace forum because I kept getting PM's asking for advice including links to other members work allegedly showing how not to do it,this is not nice.I have been doing this longer than most members but not as long as some,I will offer help in spades to anyone that wants it,but never criticize.I don't think any of these posts are quite in the same league. I am certainly not wanting to fuel any arguments as model building is meant to be relaxing. Nat is correct in what he says in that there isn't the help and experience when YOU wish to take your model building to the next level,on the other forum.You will no doubt reach a stage when you want to stretch your ability further as things do become routine,that is the only reason I push myself in terms of what I want to achieve.In the meantime enjoy what you are doing. Kind Regards Nigel Oh and Mark,we will have to agree to disagree,but 99.9% of hatch combing joints were 90 degree half lapped not mitred

-

Well done Andy and I thought you would like that Eamonn The answer was there to be seen,literally Over to you Andy,your turn Kind Regards Nigel

-

-

Cheers buddy I am off to bed,I shall post a new one first thing Kind Regards Nigel

-

Asgard? N

-

I can't find a pic including the yacht though,it isn't a holiday snap of yours is it? Got sidetracked thinking of the blue riband and ended up reading about a 100m yacht being built in Devon to beat the record N

-

Mmm,Flower class in background is le Macha,one of three purchased by the Irish Navy from the British after the war N

-

first guess Moonraker Hope I am on the right track,there are loads to go at Kind Regards Nigel

-

I know this!it was on telly recently,current owner has sold up.Yacht was used in the evacuation of Dunkirk despite being told by the navy to stay away,at least that is what I think it is Kind Regards Nigel

-

Tis indeed correct sir I knew it was easy,but that easy Your turn buddy Kind Regards Nigel

-

Wasn't sure mate,I have a Smit Rotterdam in the loft from a good few years back,the box had the lasercut sticker on,but only the bulkheads were lasercut,everything else was to fret out.I wonder whether all their kit's are fully lasercut now? Kind Regards Nigel

-

-

Ok bit of humble pie for me I have this vessel's name down as Plycor,but am not 100% convinced this is this case.As I bow my head in shame,I shall allow someone else to take the helm,not quite sure of the rules in this instance Kind Regards Nigel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.