-

Posts

2,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NMBROOK

-

I personally feel that the Renown builds into a nice,attractive little model.If you feel adventurous,it can also be made into a working RC model for calm water use Kind Regards Nigel

-

Apologies Nils for not being around much of late and having to play catchup again Your model is looking outstanding.I love and admire your decisions not to follow the 'norm' and produce something that is indeed your own style.I apologise if you have mentioned it already,but have you applied any clear finish to the brass parts to avoid future oxidization? Kind Regards Nigel

-

Hi Mr Pucko Brian is correct,but he is obviously refering to polyurethane resin,epoxy hardly smells,whereas polyurethane resins are horrendous.Epoxies are a 50/50 mix,whereas polyurethanes you add a waterlike catalyst at a percentage of around 5%.If you detect any smell with Epoxy,it is a very mild 'fish' like smell.I haven't used polyurethanes on models for years as the 'open' work time is subject to far too many variables and can result in the setting process starting before completion of the work.Industrial quality polyurethanes are a little better,but still need fastidious attention to mixing for the correct ratio. If the sealer you used is in a white tin with a blue label,I had problems with this crazing some months down the line due to natural timber movement.A superior product is called G4 and produced by the German firm Graupner.Unfortunately they recently went into administration,and whilst a new owner has been found,availability of their products is sketchy at the moment. Looking at your build,I would apply epoxy(I recommend Zap finishing resin due to the 3hr cure time,the pot life is actually less than that).You are correct,the openings cause an issue with using woven mat,it can be done,but would be very hard to stop the resin running through the holes and making a mess inside.For mat application,cutting apertures after glassing is the preferred route,although I feel your windows came as part of a precut section. If I were to do the job,I would apply several coats of epoxy finishing resin before adding any wales or details.With the zap product,you can apply coats at 90 minute intervals,this gives bonding between coats,but the next coat won't 'drag' on the previous coat.Several thin coats are prefered to a couple of thick ones,as this stuff goes on like paint and will run if applied too thickly.I would allow a full day for the job to be on the safe side and if working outside,avoid a warm sunny day. It will take some work to sand smooth as you do end up with mild 'orange peeling' as the thickness builds up,but you can get a finish like glass that is durable.I wouldn't go further than 320 grit,this will allow you to affix the wales,preferably with normal epoxy glue and for small details like etchings,thick cyano will suffice.The final abrasive marks are better removed using aerosol car spray primer and flatting with wet and dry paper used wet.I prefer to use a 'plastic primer' designed for car bumpers first,this has adhesion promoters and ensures the paint won't lift at a later date. I know this sounds long winded,but actually isn't as bad as it sounds,I just didn't wan't to miss anything out as it has taken me years of trial and error to develop a method that not only produces an exemplary finish,but will look just as good 30 years down the line,even if it is a working model and used in the water. Kind regards Nigel

-

Hi Larry You can apply whatever finish you are using on the rest of the build,be it oil,wax or poly.Just make sure you give it a light wipe with acetone before application.I have found though that in practice,for Ebony wales for example,they have been sanded and wiped so many times during construction that hardly any residual oils from the timber remain on the surface. Kind Regards Nigel

-

Thank you Vic Your sailing model is stunning .My priority was to obtain the hull lines through buying the model as I too could not find hull line drawings of this vessel.If I could have just bought plans with adequate information,I would have gone that route.There are drawings somewhere as the author of this site mentions them http://www.webng.com/moon2stu/index.html but hours of internet trolling have revealed nothing to me. Kind Regards Nigel

-

Truly fabulous work Michael!!!!!Those gun and carriages look fantastic.The final result is a testimony to the amount of skill care and patience you have dedicated to them.They really will be the 'icing on the cake' of your build Kind Regards Nigel

-

Hi Jason,looking forward to following along with your build. Once you have soaked the keel,try repeated ironing on both sides,using a hot domestic iron on a flat surface.Continually work along the keel with this alternating on both sides and keep going until the heat from the iron dries the ply out completely.This has worked for me with warped ply that won't succumb to simple soaking and weighting Kind Regards Nigel

-

I agree with both Piet and Brian.You can use epoxy finishing resin(I use a zap product as the 3hr drying time prevents thickening during application) or use the superfine woven cloth.The cloth does require experience and great care as unlike chopped strand mat,it takes a lot of work to conform to surfaces with compound curves.When using cloth,I always use a flexible credit card sized plastic scrapper to 'tool' the surface.This works out any trapped air and consolidates everything to give a minimum skin thickness.This also removes a great deal of resin in the process,it is surprising how little is actually needed.When this goes 'green' (set but still tacky) I apply one or two more coats of resin only,ensure no coat is fully dry between application,as epoxy does not stick to itself when cured without mechanical abrasion first.After leaving for at least two days(otherwise any abrasive will just clog up immediately) I sand by hand.Coarse wet and dry used wet with a little detergent added works best if you can get away with using it on your application. Kind Regards Nigel

-

Thanks David Yes the hull and deck are skinned in Mahogony veneer.Unsure as to the planking under the waterline as this is covered in 'crazed' paint at the minute.There is the remainder of the printed mahogony veneer sheets included,but these are in a pretty poor state and full of splits due to drying out for such a long time.I did consider replanking in Obechi strips to keep it in keeping with the current model,but Billings strips are unobtainable in any great quantity at the moment due to supply issues from the factory.I will see if this situation changes in the future. Kind Regards Nigel

-

Thank you Kester No plans to dive in on the model at the minute as I am attempting to progress a little more with Mordaunt.I will use the time to consider possible plans of action,but do know for certain that it will need stripping back to a skeleton.The hull was sheeted/planked and decks fitted and that was about it really.The pictures will explain better this weekend . Other than the lion figurehead,no plastic ornaments were supplied.The builder was expected to carve these from the printed Obechi sheet. I had every intention to go and watch the Tour de France in person,but common sense prevailed.Leaving home at five am to get a semi good position to see the peleton go past for several minutes put me off.Got a much better view on the Eurosport channel Kind Regards Nigel

-

Thanks B.E. ,some great pics and one great model.I notice you added the roundhouses,corrected the shape of the tops and rigged her in keeping with the correct period.I am wondering whether the shape of the bow in the kit is a little too pointed and needs to be more bluff,inline with other vessels of the period? Kind Regards Nigel

-

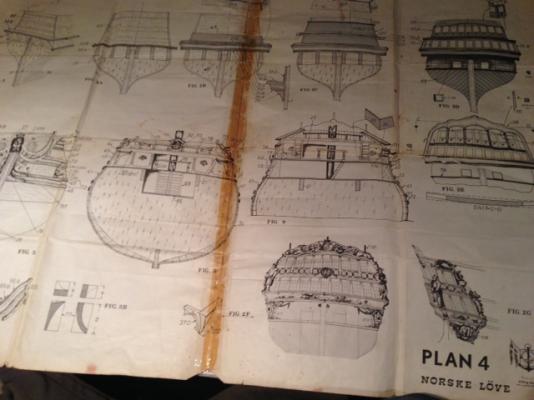

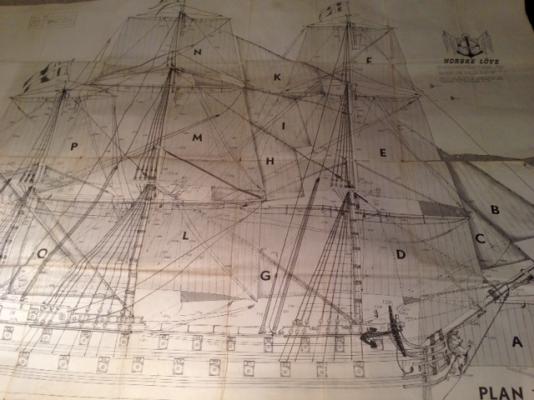

Just some pics of the plans and instructions included with the model.Note date on drawing,not quite as old as me,but older than my wife .The instructions actually include more information than some of the current ones from Billings!I will take pics of the model at the weekend as I have several bags of loose items to wade through. Kind Regards Nigel

-

Thanks B.E. pics would be great.I will post some of the model when I get the chance.I have one website covering a build mentioning there should be roundhouses on the beak bulkhead but unfortunately the build stops there and hasn't been updated for several years.I am also hitting a brickwall when searching for info on the real vessel using google. Kind Regards Nigel

-

Although due to weather,work and Tour de France,despite getting very little build time in on current projects,I have managed to acquire a part built Norske Love from the builder that has been untouched in Fourty!!! years.Since being a kid I have always wanted to build this model but choked at the current asking price for a new kit as most items would be changed.The outer hull has seen the effects of 40 years of movement and was not planked according to the rather fragile intact instructions,but clad in wide pieces of Obechi veneer.I will post some pics in the next day or two,it has only landed today.If anyone has any pics or links to an example of this vintage,please post them here.One distinct difference is the transom is flat and does not possess the round tuck of the current model.Aside from this detail,the rest of the model is almost identical to the current version. Kind Regards Nigel

-

Fabulous work Bob love the idea of doing the 'donkey work' away from the model Kind Regards Nigel

- 1,477 replies

-

- essex

- model shipways

-

(and 1 more)

Tagged with:

-

Hi Kester An interesting point.We were responsible for reinforcing the hull and jacking the ship up,another contractor did the glazed 'roof'.The glazed roof met with mixed opinions in our workshop.The ship resto was covered in a UK documentary and the architect did clarify his 'vision' that the glazing represented the sea.Personally I am not too keen,it is all a bit too 'Disney' for my liking and detracts from the vessel. Kind Regards Nigel

-

Great work mate I think your build is looking as far removed from Billings box art as is possible,fabulous! Kind Regards Nigel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.