-

Posts

2,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NMBROOK

-

I could be wrong Eamonn but I think she is either Van Speijk or Kortenaer class.Pretty much everything else is of a 'stealth' design,but it is a bit like trying to name which Leander frigate Kind Regards Nigel

-

HNMLS Tjerk Hiddes? Kind Regards Nigel

-

You might be right Jan,that's why she isn't on their current ship list,but she is on page 129 on this thread I can't decide whether the bridge wings have still to be fitted after the launching Kind Regards Nigel

-

Arklow Freedom? Kind Regards Nigel

-

Can't keep away can I Going out on a bit of a limb here,the pedalo would have been easier Eamonn I think we are looking at another Arklow shipping vessel and the shipyard is Barkmeijer Stroobos BV.The problem being they have built several vessels of this type for Arklow,and I can't find the pic. Kind Regards Nigel

-

That is quite correct Eamonn congratulations.She was also referred to as the 'Great Harry'.Over to you and I am having a little break,this is becoming addictive . Kind Regards Nigel P.S.I hope you find a right 'stinker' as I am sitting this one out Kind Regards Nigel

-

Ok final clue and this is making it real easy 'grace of god' Kind Regards Nigel

-

Ok first clues,I don't think I have to say what nationality it is due to the rather 'subtle' flags.It is Tudor and it has two names Kind Regards Nigel

-

Hi Natan you are off to a nice start.If I may offer some advice.As your planking is fairly thick,I would be tempted to allow it to dry in position overnight after soaking.If there is any moisture left in the wood from it's soak,the plank can shrink even more and you may end up with gaps appearing between the planks the day after.I know it is slow doing it that way,but you could always pin a few strips in place at once and let them dry together. Kind Regards Nigel

- 16 replies

-

- Constructo

- Albatros

-

(and 1 more)

Tagged with:

-

I am hoping this is an easy one as it is nearly bed time for me so I would rather someone else was in the 'hot seat' to continue this ship nameathon Kind Regards Nigel

-

The only gripe I have with mine if I am being very picky and this may not apply to all the MF70's out there.There is about 0.2mm backlash on the vertical feed,I can work round this,It doesn't move you just have to compensate when using the dial scale.I have found a cheapish solution from Chronos engineering tools in the UK.It is a straight vernier scale with digital readout and zero function that fits to the pillar and head.It is fairly inexpensive at about 40 quid but makes life easier anyway.You can actually fit one to all three axis if you wish as they come in different lengths.I may yet do that so I don't keep having to do sums in my head whilst working

-

Thanks Jason.I actually found the painting on a navy site and that is what the explanation was,they also mentioned the ship behind the Becentaure was Victory. Best see what I can come up with Kind Regards Nigel

-

Hi Dragzz I am biased but if you want to use small cutters then the MF70+precision vice+dividing head and have plenty of change.For larger cutters then choose something else from the many 'slower' machines.It all boils down to what you want to use it for,so that is the real question.I will invest in a larger proxxon machine for bigger cutters/cuts at a later date but for the majority of what I do,it would be useless because of the slow speed. Kind Regards Nigel

-

No Problem Tony,I think he uses the other small proxxon xy The one you refer to is the same as mine Kind Regards Nigel

-

Ok then.the demasted ship is Bucentaure.The ship to the right is HMS Sandwich.The 'twist' as I understand it,is that the painter Auguste Mayer painted this depiction of the battle of Trafalger did not realise that HMS Sandwich did not take part in the battle. Incidentaly the ship to the left is HMS Temeraire.How many is that today? Kind Regards Nigel

-

No Problem Chris,it isn't a case of Having to have one,I managed for thirty years without,but as I am sure you are aware,producing the above without a mill takes a lot of time to do accurately.Having the machine speeds up the not so interesting jobs so you can spend more time doing the bits you really enjoy. Kind Regards Nigel

-

Hi again JPett humble pie for me The MF70 is direct drive,but what I said holds true for larger millers. Kind Regards Nigel

-

Hi J Pett They are not the same.The dremel's motor armature is in line with the spindle reducing effective spindle length and distance between bearings,on a milling machine and pillar drill for that matter the spindle is full length of the casing,this being driven by belt or gear indirectly from the motor.This puts the bearings much further apart increasing the resistance to sideloading.I know that if I put my dremel in a stand it would snap my 1mm cutter.When you add up the cost(in the uk at least)a high end dremel a stand with no movement and some sort of vertical indexing and the xy table it comes to the same price as the MF70. Kind Regards Nigel

-

In answer to your question Tony I suggest you PM mij (sussex scratchbuild)as I know he is using the set up you refer to. An example of what I use and will be using mine for Housing joints Gang milling of gun carriage sides(can machine 50 at a time all identical) Machining square section of masts(octagonal using the dividing head I have) Spiral staircase pillars using dividing table Scarph joints Capstans using rotary table Cutting slots in knightheads Housing joints Keel rabbets I could go on and on Kind Regards Nigel

-

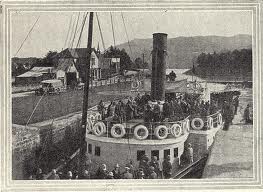

Congratulations Jason you are correct.Like I said there are plenty of old photos of Loch Ness steamers,but few have names to them. Kind Regards Nigel

-

Not the PS Mercury but it is the Caledonian Canal Jason.Bit early for clues because there aren't all that many steamers that are named on the net for this part of the world. Kind Regards Nigel

-

I had posted a which miller topic a while back.Having weighed up the options I went for the Proxxon MF70.Love it to bits.A lot depends what you have in mind but 90% of the work it gets used for is with cutters between 1 and 3mm.I know from when I was trained in using machine tools(for metals)everything is about the correct cutting speed.Cutting speed is not rpm but the actual speed between the cutting edge and workpiece.Obviously the smaller the cutter the higher the rpm to reach this cutting speed.The disadvantage with using a Dremel is that the main spindle is not designed for milling and can result in bearing run out problems. Kind Regards Nigel

-

I think if we stopped people from using google,then a lot of the posts would exceed the 2 week timelimit before posting a new image.I think the key to posting is not using google to find your chosen ship.I think that you need a very exhaustive reference library at home to be able to answer these without google or wikipedia.Anyway it is a scottish steamer,but which one? Kind Regards Nigel

-

-

Well actually no sorry Eamonn,I was away from the PC up until 30minutes ago,I read your post and then chuckled when I saw the pic,I had seen it while searching for one of the others,anyway beats looking at pictures of someone having a BBQ next to their Airstream caravan .I may be a little while I have something in mind to beat 1hr 40 mins Kind Regards Nigel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.