-

Posts

2,305 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by NMBROOK

-

Hi Kevin There are some outstanding tutorials on youtube by some of the japanese modelmakers.Many are ship related and although in japanese because the way they are filmed,you can pick quite a lot up.I even started to realise what the japanese was for certain processes .Unfortunately I no longer have the link as it was before meltdown of my last laptop However I think they would be quite easy to find using the search engine. Kind Regards Nigel

-

As Joe says I think a lot falls down to personal preference,there are pluses and minuses to every machine.The deciding factor for me was next day spares backup with the proxxon.Had I lived in the states my choice might have been different. Kind Regards Nigel

-

Announcing the Model Ship World Ship Kit Database Project

NMBROOK replied to SkerryAmp's topic in Wood ship model kits

I think this is fabulous Adam.Good on you for deciding to do this.This will be a valuable tool for many members. Kind Regards Nigel -

Hi Michael Yes the miller is a handy tool.I have recently started a thread on using it and jigs that can be produced with it.I have the pantograph attachment landing early next week and I have just received a digital readout for the vertical axis. You seem to have the most vital thing of all,plenty of light! Arrr whiskey,unfortunately can't drink it,you are correct plenty to choose from Been round the Highland Park distillery on Orkney but had to refrain from the free tasters .You have got me thinking now,I am not sure if oddbins are still going?They were everywhere and I know there aren't any left in my neck of the woods Kind Regards Nigel

-

Very nice and concise write up Theo.I do agree that one improvement that proxxon could make to the mf70 is the facility to be able to tilt the milling head. Kind Regards Nigel

-

Very nice work Michael Slotting those blocks is not the easiest of jobs without a milling machine.Even if they won't be used as you don't plan on fitting sails,they add a lot to the build. Kind Regards Nigel

-

Sorry Jan as well,been very busy with work stuff,you have not been forgotten Kind Regards Nigel ps I think Eamonn is still recovering from that mad dash game last week

-

Hi Ben As Mark says dremel make a chuck for their machines and it is available seperately.Have you tried removing the cap or collets from the other end of the pinvise and clamp the pinvise in your chuck of the drill press? Kind Regards Nigel

-

I thought they would be just as strong,but didn't post anything for fear of walking into a hornets nest The ash produced by laser cutting is on the floor under the machine.The black is purely discolouration unless it was 4pm on a friday when they were cut .You still end up cleaning the edges though because the laser cutting pattern is tapered just like waterjet,This means all cut edges aren't square anyway unless of course you buy a kit that is cnc routed. Kind Regards Nigel

-

Fabulous Matti Looking forward to seeing if you take up the 'blue thingy' challenge Kind Regards Nigel

-

What do you use your mill for ?

NMBROOK replied to captainbob's topic in Modeling tools and Workshop Equipment

Thank you. I hope it gives members food for thought who are debating whether to buy a mill.Some members who already possess one may find it helps them get more from their machine and maximize it's potential. Kind Regards Nigel -

What do you use your mill for ?

NMBROOK replied to captainbob's topic in Modeling tools and Workshop Equipment

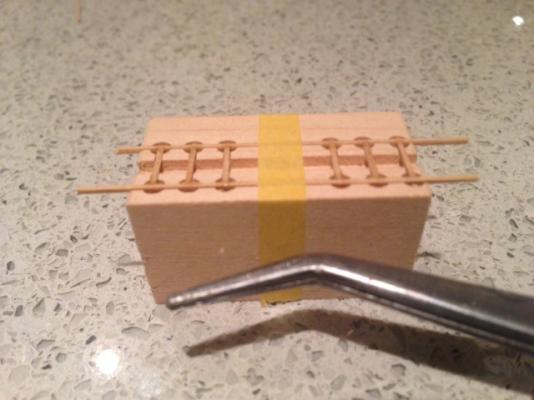

Cheers Martin This jig is for skylight frames,see finished pick in my new thread.You could make one very similar for ladders.I will be making the 'rolls royce' jig for inclined ladders a bit later so I can use steps and stringers of scale thickness as opposed to the overly chunky ones supplied with kits. Kind Regards Nigel -

What do you use your mill for ?

NMBROOK replied to captainbob's topic in Modeling tools and Workshop Equipment

Hi Richard It is in the forum next door Tips and jigs etc. Kind regards Nigel -

What do you use your mill for ?

NMBROOK replied to captainbob's topic in Modeling tools and Workshop Equipment

Hi Richard I have started a new thread 'milling and miniature jig making'.early days but I will keep adding as I produce items Kind Regards Nigel -

What do you use your mill for ?

NMBROOK replied to captainbob's topic in Modeling tools and Workshop Equipment

No problem,my pleasure Richard.If there is enough interest,I may start a new thread illustrating what can be done and showing what simple and not so simple jigs can be made.If people may find this helpful then let me know. Kind Regards Nigel -

What do you use your mill for ?

NMBROOK replied to captainbob's topic in Modeling tools and Workshop Equipment

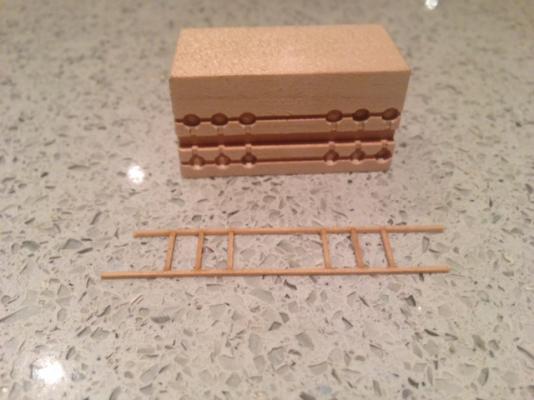

I thought I would bump this topic as I have a couple of pics showing an example of what can be done with a miller that would be awkward to do by hand.I made this rather small jig to produce glazing frames for the skylight of a Royal Caroline build(log coming very soon).This jig took literally 10 mins from start to finish.The circular recesses are for glue clearance and the central slot is to provide clearance for tweezers,shown in picture for scale.The boxwood is actually 0.7mm square and the jig enables me to make two at a time.The long sides will be cut after removal from the jig.Tamiya masking tape provides the hitec clamp. Kind Regards Nigel -

Dutch brig Morgenster? Kind Regards Nigel

-

Col. James M Schoomaker? Kind Regards Nigel

-

You are correct Andy,congratulations ,over to you Kind regards Nigel

-

Right then,I apologize for picture quality,but this is the only picture of the event,good luck! Kind Regards Nigel

-

Hehe got the name as well Got to lay down,that was like being on supermarket sweep sorry guys quiz show in the UK I will see what I can find Kind Regards Nigel

-

Jose Luis Diez? Kind Regards Nigel

-

Churruca class Alcala Galiano? Kind Regards Nigel

-

You were right Jan Kind Regards Nigel Arklow Trinnidad?

-

I think Eamonn's stuck a sneaky one in and it belongs to Luxembourg's Navy I think there is a chance it's Dutch because a lot were built in Barrow in the UK which will explain the similarities to British Vessels.The designer must have gone to Germany on his holidays for the Narvik influence Kind Regards Nigel

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.