-

Posts

166 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Philg88

-

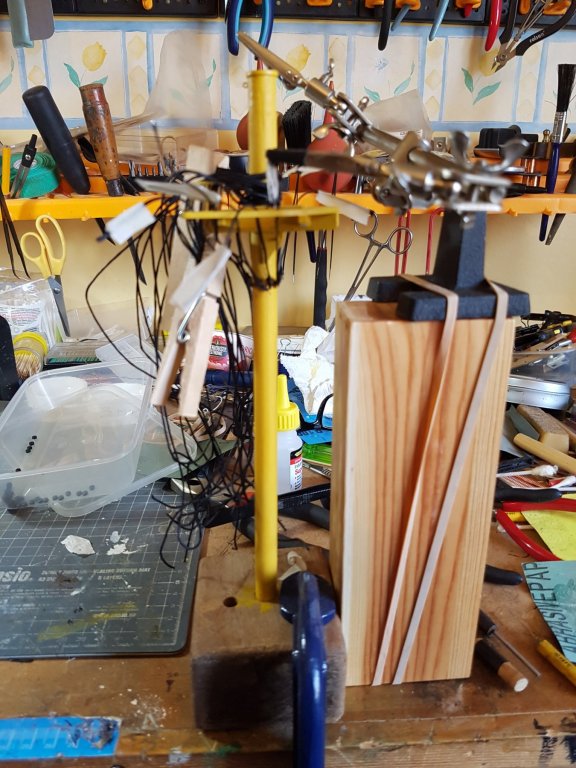

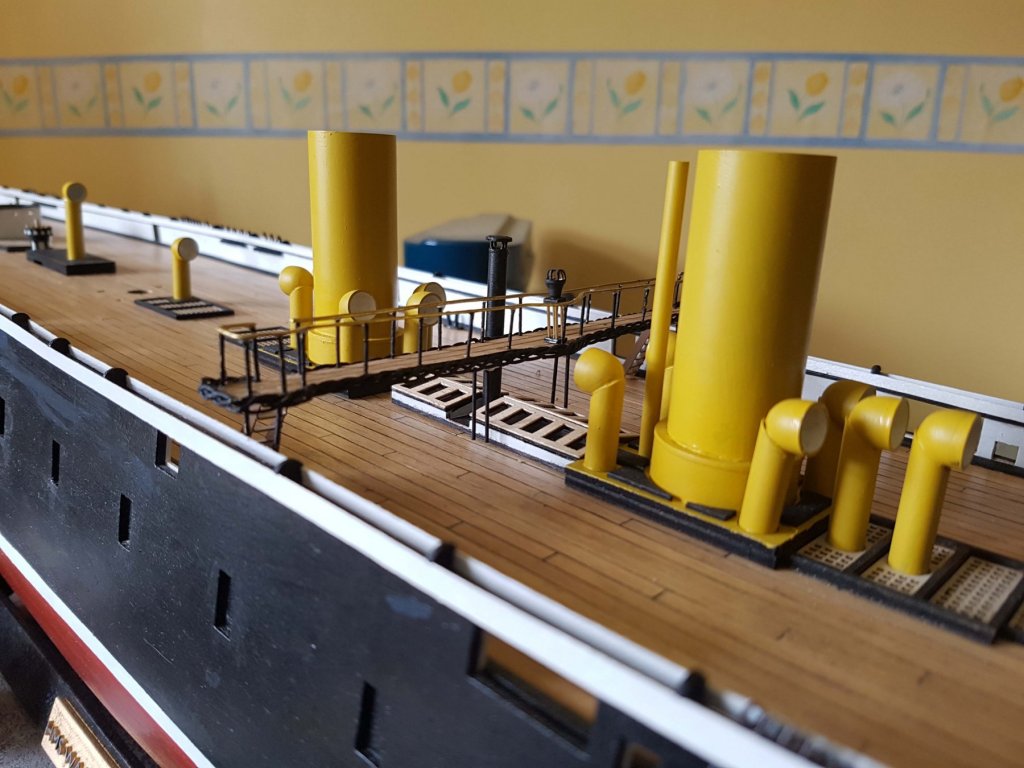

Forward bridge complete and fitted. This is a time consuming and fiddly job to say the least! The decoration that runs around the bridge edge is made by twisting three strands of 1 mm brass wire together then hammering them flat on an anvil block. The handrail is 2 mm brass wire hammered flat. These were then bent into shape using a forming template. Billing's instruction for the edge decoration was to use rigging thread - yuk!

-

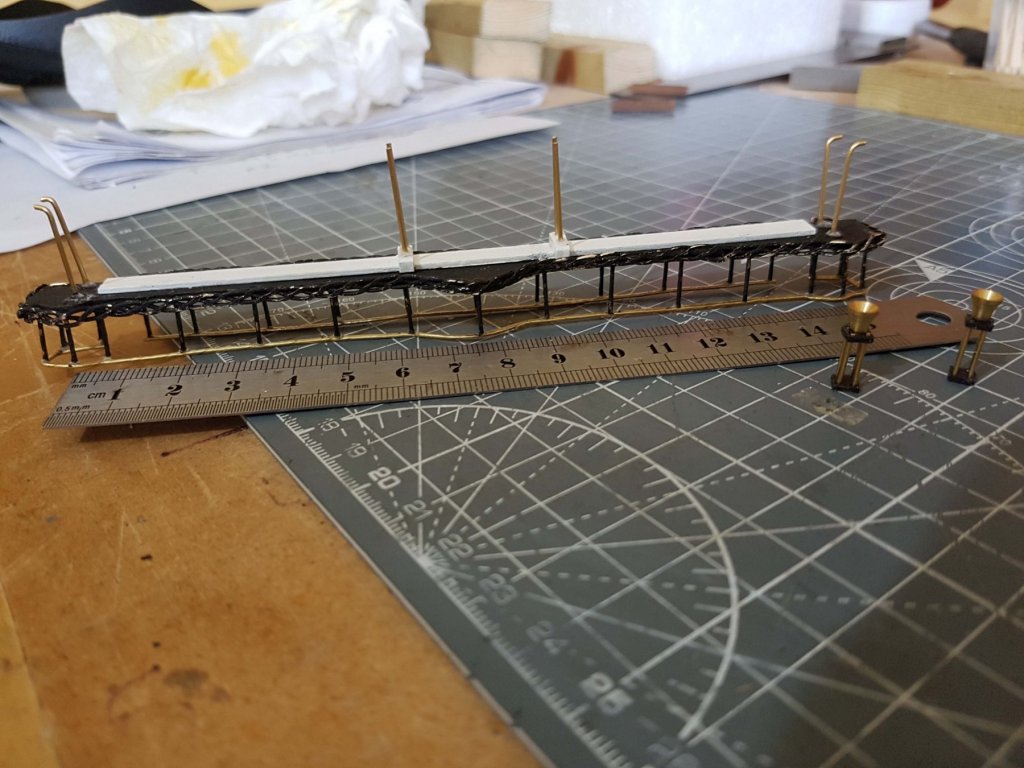

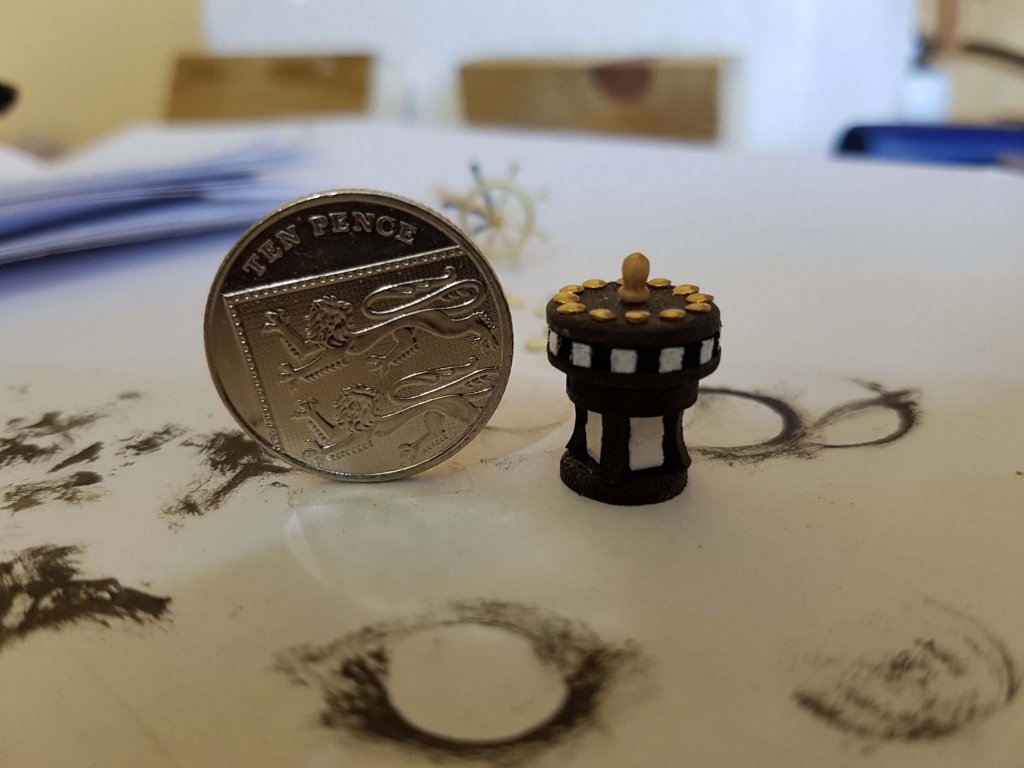

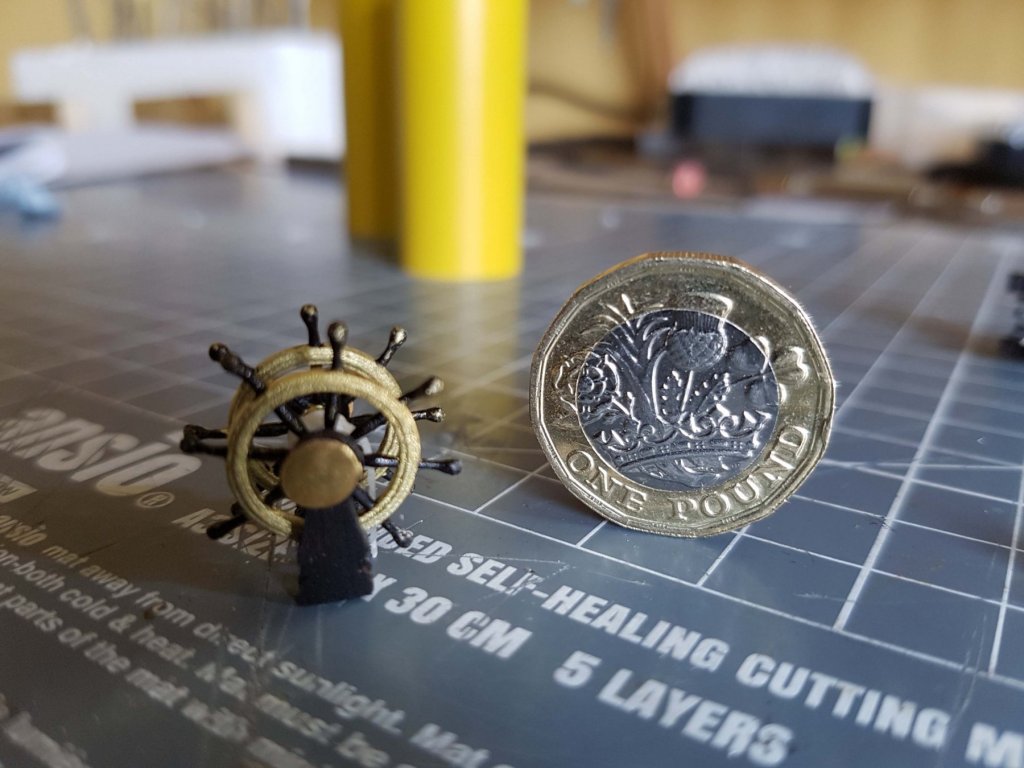

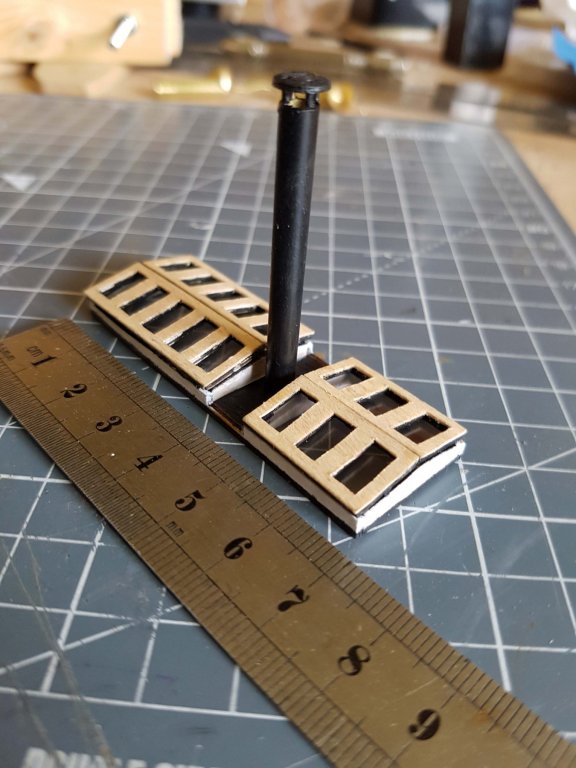

Chainplates and handrails now all fitted so its onto the deck. I ended up making the rifle proof conning tower out of plasticard, as I defy anyone to bend the 2mm plywood provided to the required shape without it delaminating, splitting or warping. It was then lined with 0.8x3mm stripwood. Conning tower, compasses and main vent dry fitted to the deck Now fabricating the deck stairs and capstan.

-

Aye Aye! There is a deadeye pair attached to the top of each one, which then connects to the shrouds. On the real ship the connection was hidden in the middle of the double handrail. I thought about doing that but there is only about 3mm to work in so with a 1mm gap either side its nigh on impossible.

-

OK, Having checked the reference books I have, there was definitely a pitch on the propeller. So I've modified the blades, thankfully with no damage. As a side note, the propeller pitch wasn't adjustable - when the ship was under sail it would be hauled up into the well in the stern. As the model is in steam mode (because the funnels are up) the representation of the propeller is now correct. Thanks for the input guys! Best, Philip

-

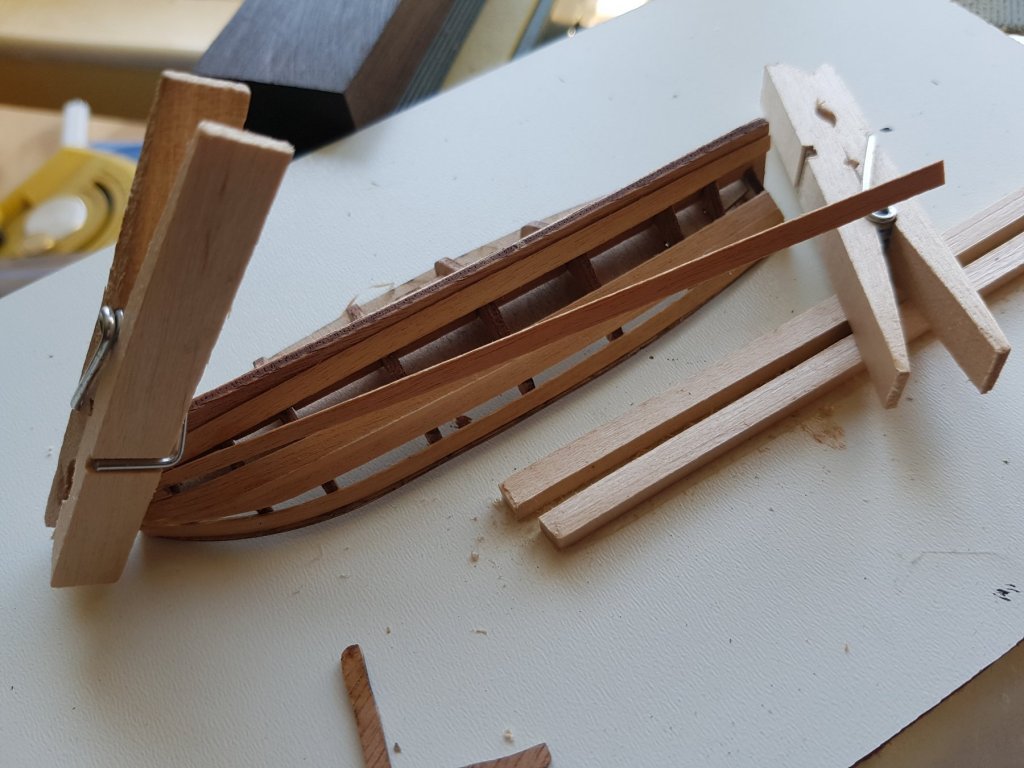

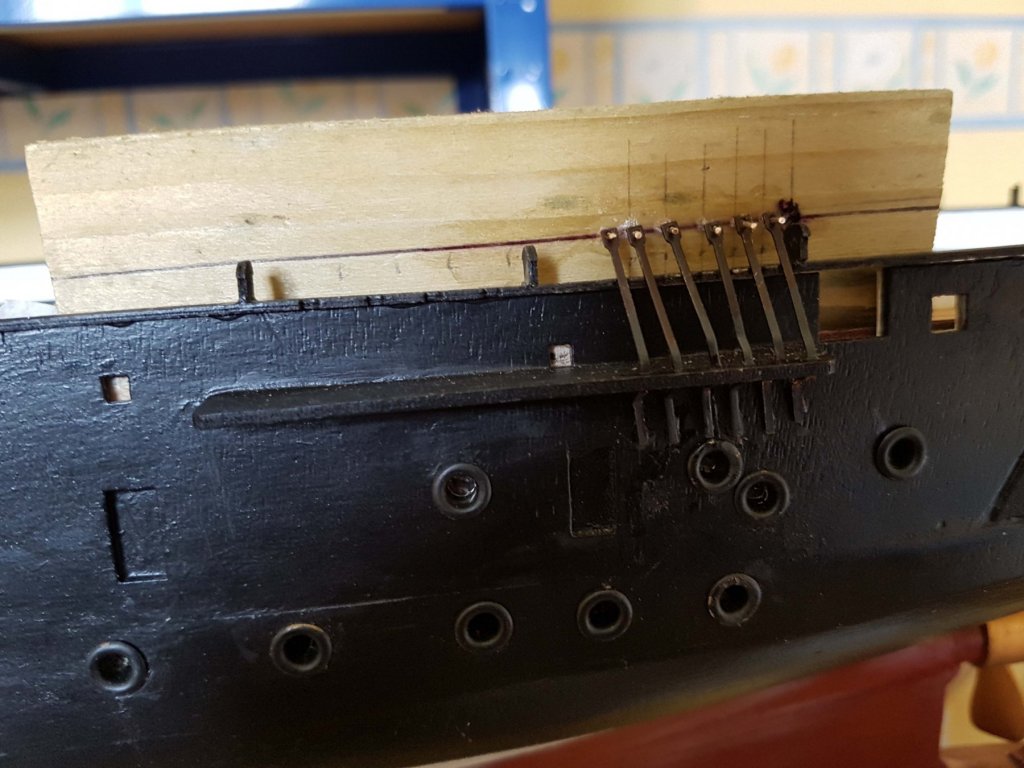

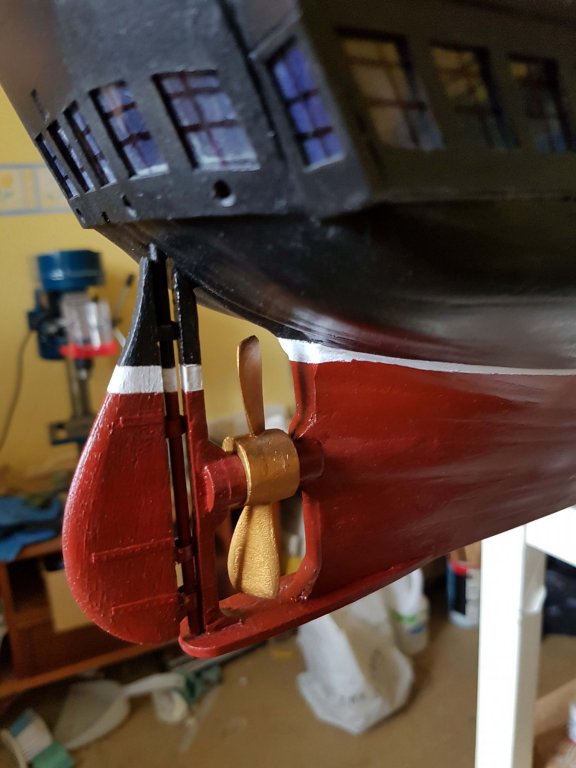

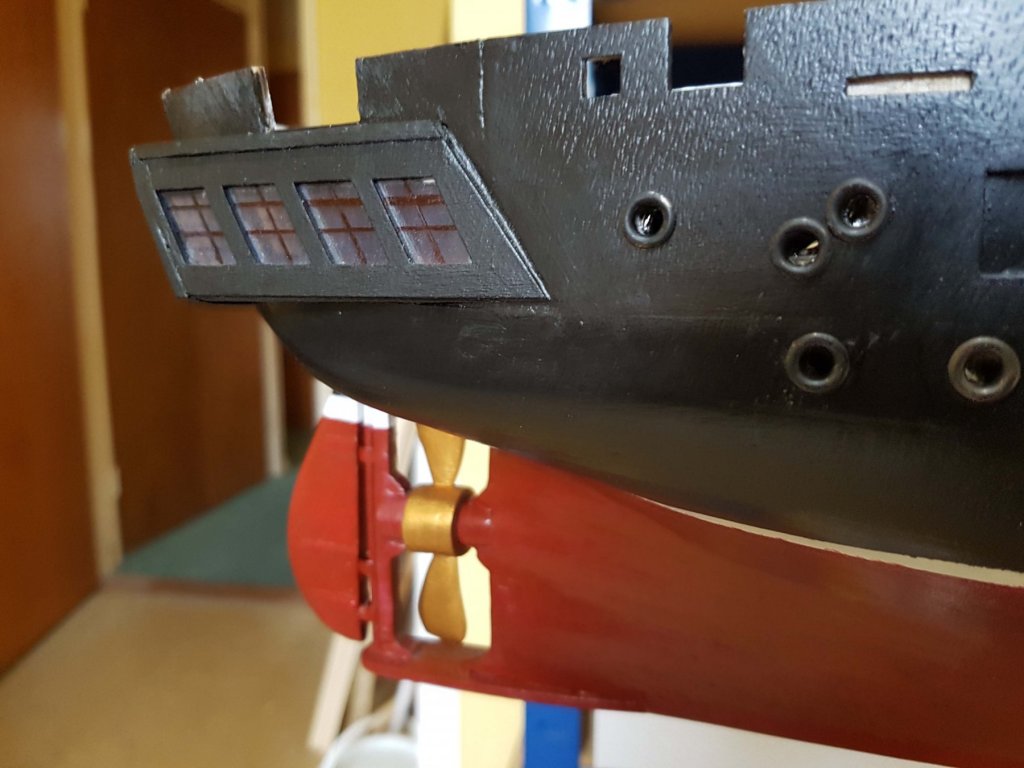

Hi All, Internal gunwales and deck channels added ... Propeller and rudder completed. I modified the hinge of the latter using 5mm brass tube fashioned into faux hinges with the horizontal supports cut from .5mm plasticard and run over with a pounce wheel to simulate rivets. The porthole surrounds are 4mm eyelets painted gunmetal and glued in. And a couple of general views showing the paintwork.

-

All the bulwarks are now in place - some convoluted gluing required! For the propeller well (whence the prop was pulled up into [manually!] when the ship was preparing to move under sail), Billing seem to think that it's possible to bend a 2mm piece of ply into an elipse without damage/delamination. I don't concur so I designed and printed one in ABS instead. Once it's painted black and buried under the stern no one will be any the wiser and it will hold the keel planks nicely.

-

Sorry for the delayed reply Gerhard but I missed your post. As far as plans are concerned I have failed to track anything down beyond the two books mentioned at the start of this log and another small booklet called Warrior: The first modern battleship by Walter Brownlee ISBN 0 521 27579 2. This has some good detail drawings while the other two both have rudimentary keel plans. The originals are in the National Maritime Museum based in Greenwich, London but they are not available online. Bear in mind that there were two major Warrior iterations: 1791 and 1860. Best, Philip

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.