-

Posts

166 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Philg88

-

Nice job with the hammock cranes, Boyd. You'll soon be on to the masts and rigging then she'll finally be done ... Cheers, Philip

- 413 replies

-

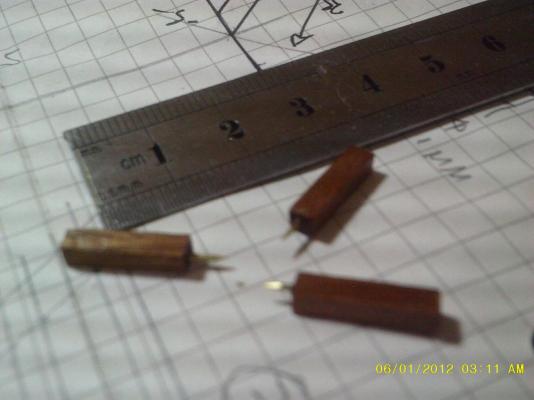

Small update as the Victory seems to be taking up most of my time at the moment. I connected the paddlewheels and made the small posts that carry the railings at the stern. These are 3x3x14mm and were drilled 5 mm with a 0.7 mm diameter drill then a snipped up off tack was CAed in the hole. These posts are not mentioned in the instructions or the parts list, which is a bit naughty of AL. However, they do appear in the instruction booklet and on the supplied drawings if you look very closely.

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Nice piece of research Izzy,. The other bonus is of course that you can drink what's left over of your blackening solution. Cheers, Philip

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

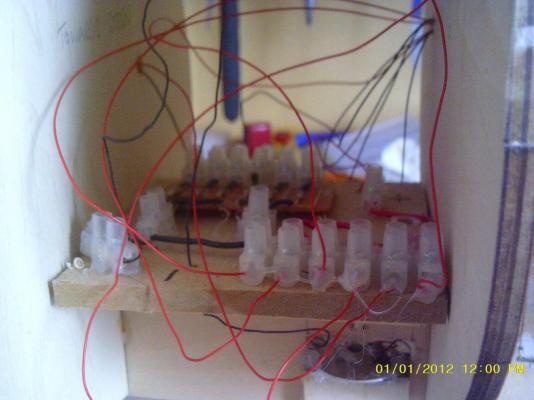

Planked the now split quarterdeck, leaving spaces for the planks that will mate with the waist section once installed after hull planking and coppering. Mounted the LED's for the two cabins on the end of some brass rod and cut out a bit of the framing so that the light will shine up through the skylight. I have also installed the rest of the wiring for the stern cabins so it looks a bit like Spaghetti Junction in there. Poop deck also now installed ready for planking ...

-

Finally finished the quarterdeck cabins! The window bars were made by rebating 0.5.mm styrene strips into the face of the bulkhead, painting them walnut brown then adding a layer of 0.6mm walnut veneer with a cut out for the window. Next, another layer of veneer with holes cut out around the edges of the panels. Finally, small infill pieces were glues into the centre of the holes to give the panel effects. I only did the dual layer veneer for the front bullheads as it's an incredibly fiddly and time consuming task. Besides, the others will be largely hidden once the binnacle, mast and ship's wheel are installed. I also went ahead and cut out the quarterdeck waist to maintain access to the upper deck - so far so good and the cut out pieces slot back in very neatly with no distortion.

-

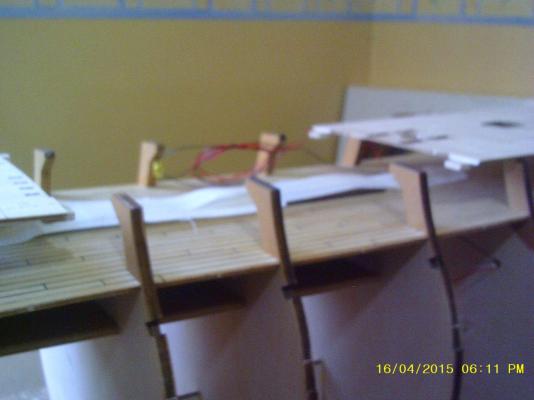

Support posts installed on the first deck and the third deck planked, varnished and fitted. Don't trust the dimensions given for the deck posts in the parts list - I found it best to measure and cut each one individually. It's much easier to fit the triangular fill pieces with the ship flipped upside down.

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

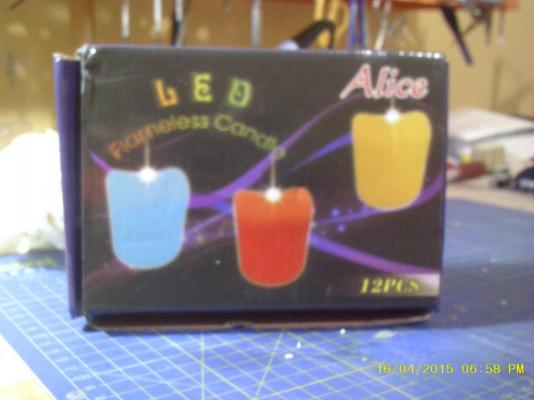

Flickering LED Tea Lights These are ideal for simulating candle/lamp light in period ship builds. They are cheap (I picked up this box of 12 for £2.99 on Amazon) and have the advantage that you get the flicker effect from the LED itself rather than via a complex and expensive external circuit. Once taken to pieces, which is trivial, the yellow LED can be desoldered or snipped out and used like any other 2.2V/15 Ma LED in a lighting circuit. As a bonus you get a miniature switch and three AG13 1.5v batteries with each light.

- 396 replies

-

- Idea

- Bright Idea

-

(and 1 more)

Tagged with:

-

Thanks Boyd. Although I love the detailed work on this build, I am trying to tear myself away to get on with the quarterdeck cabins for the Victory - those will have some really nice details. Watch that space! Cheers, Philip

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Thanks Capt, looking forward to your restart on the Connie! Cheers, Philip

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Hey Boyd, we missed you! Glad you're back to show us more shining examples of the model shipbuilder's art. Cheers, Philip

- 413 replies

-

Banisters constructed and fitted. The beads for the post- top ornaments are terrible quality and vary in size by up to 2 mm. Shame on you AL.

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Thanks for the kind words Robert. The decking is all down to the fishing line - crisp lines, doesn't fray and is easy to cut at 90 degrees. Well worth the one month wait for shipping from China for just short of two and a half quid inc p&p. Search "0.45mm Black Monofilament Cable Spool 100m Fishing Line" on Amazon if you want to get hold of some. Cheers, Philip

-

Thanks Rick. I like Billing kits too, it's the documentation that leaves a lot to be desired. Fortunately, there is so much reference material out there for the Vic it isn't really an issue. I also had a warp problem at the stern of this build, which I fixed by gluing in a 30 x 30mm strut between two of the rear bulkheads that was cut a couple of mm too long to force the frame back into shape. That seems to have fixed it. Cheers, Philip

-

Stairs installed and second deck lighting installed and operational. The construction and fitting of the stairs seems to be the trickiest part of this build (so far!)

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

There is a colour chart for the Victory at the end of this document http://www.billingboats.com/instructions/Modeling%20Hints%20EN.pdf which cross references to the diagram at the end of this document http://www.billingboats.com/instructions/BB498%20HMS%20Victory_Instruction.pdf Same ship, different kit but the colours are the same Cheers, Philip

-

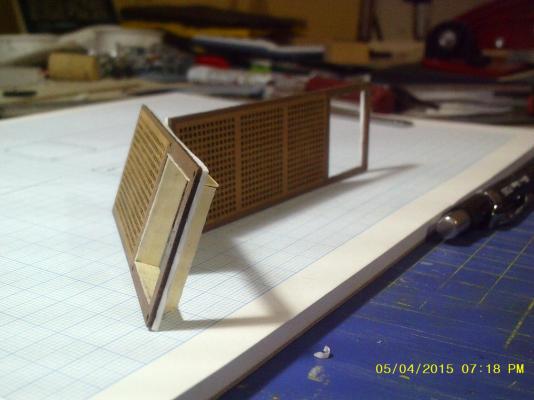

Gratings installed along with the stairs. Precut gratings were glued to 1mm plasticard to raise them above the level of the yet to be fitted shot garlands. Access holes were lined with 0.7 x 5mm lime (subsequently painted walnut brown). Stair balustrades were 14mm (just short of 1 meter at scale) and cut from a toothpick, drilled with a 0.5 mm hole through which was inserted plain hemp thread of the same dimension. The fixing end was filed flat and glued with CA at 45 degrees at the bottom of each flight.

-

I agree. What I've decided to do is to cut out the waist sections of the quarterdeck, which will preserve access to the upper deck. The cut lines are shown as red dotted lines in the picture while the green squares are 4mm plywood tabs glued to the underside of the planked front and rear sections that are then glued to the framework. Planking, coppering etc can then proceed and once finished the cut out sections can be glued in and planked. Sound like a plan to you or an instance of congenital insanity? Philip

-

Ha ha! Could be either! What I'm not looking forward to is trying to fit the cannons on the upper deck once the quarterdeck is glued in place. With the restricted access it will be hard to rig the cannons but fitting them now means that they have to be prealigned with the gunports and be at risk from damage during planking etc. Decisions decisions ... Cheers, Philip

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.