-

Posts

166 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Philg88

-

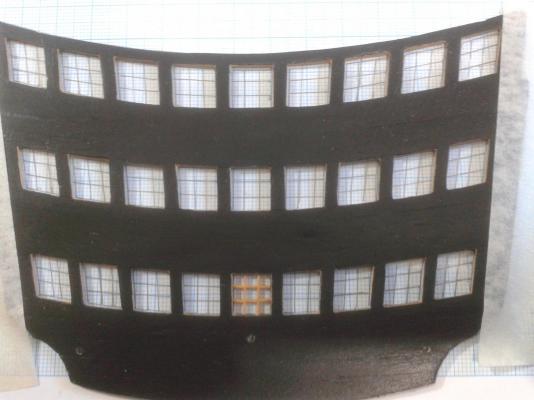

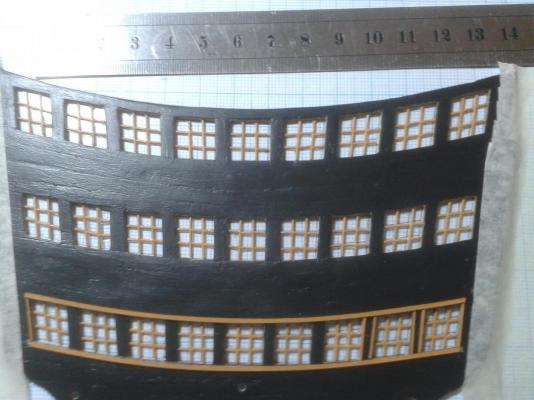

The deck has now been glued on and the upper front bulwarks fitted - note the cantilevered section in the middle for the foremast (there is another one at the stern surrounding the mizzen mast). Quite what function they served is beyond me. There is now some work to do on enlarging the slot for the bowsprit since it doesn't fit or rather does not sit in the same place as on the real ship The stern gallery windows are in production on my new 3D printer and make things a lot neater than the previous constructions using 1mm wood or styrene. These were drawn in Illustrator, exported as SVGs then extruded in a free CAD program. Each window is around 13.5 x 11mm (since I forgot to put the ruler in the pic!)

-

Side heads were featured on the original design and included at launch, one port, one starboard roughly aligned with the fore funnel and overhanging the gunwales. For reasons unknown, they were removed shortly afterwards (meaning a long walk to the john ). When the restoration started in the 80s, they were not rebuilt as they are at the exact point of entry for visitors along the fore gangway. In a typical show of Victorian ingenuity, there was a hatch in the roof where a hose could be inserted and the whole things flushed with nary a mop in sight! Understandable that Billing left them off but I think they will add interest - as will the ash chutes just behind them, which are also missing from the kit.

-

To save the world's egg-laying population you could use copper carbonate dissolved in ammonia for the ageing

- 30 replies

-

- bluenose

- billing boats

-

(and 1 more)

Tagged with:

-

One of the tools I use most often is cheap and home made. Get some 10mm dowel and a pack of domestic sewing needles, chop up the dowel into handle size pieces (60mm is OK), drill a suitable hole in the centre of one end then glue in a needle with CA (aka Superglue). The resulting tools are incredibly useful for applying tiny drops of glue (keep the end clean with a knife) and for generally positioning and poking things. I hope you enjoy your new hobby! Philip

-

Looks like nothing a bit of TLC can't restore to its full glory! Have fun! Cheers, Philip

- 30 replies

-

- bluenose

- billing boats

-

(and 1 more)

Tagged with:

-

I've glued the four deck sections together before planking rather than fit them individually as the instructions show. It is much easier to plank before attaching it to the hull. The "caulking" is 0.3 diameter linen thread, which doesn't fray the way cotton does. A slight modification needed to support the formers for the fore and aft convex sections of the deck - without these supports the formers (part no 120) would be almost impossible to position properly.

-

Copper tiling in progress. c 900 tiles done, only another 900 odd to go. These are the Caldercraft tiles from CMB at £2.34 per 100. I'm using a general purpose glue rather than CA as it gives more movement time, although CA is used where necessary. Also a snap of the £20 surface gauge I just bought - not sure how you can mark horizontal lines without one of these.

-

Hey Clarence, Just dropped by to say congratulations on a stunning build! What's next?

- 39 replies

-

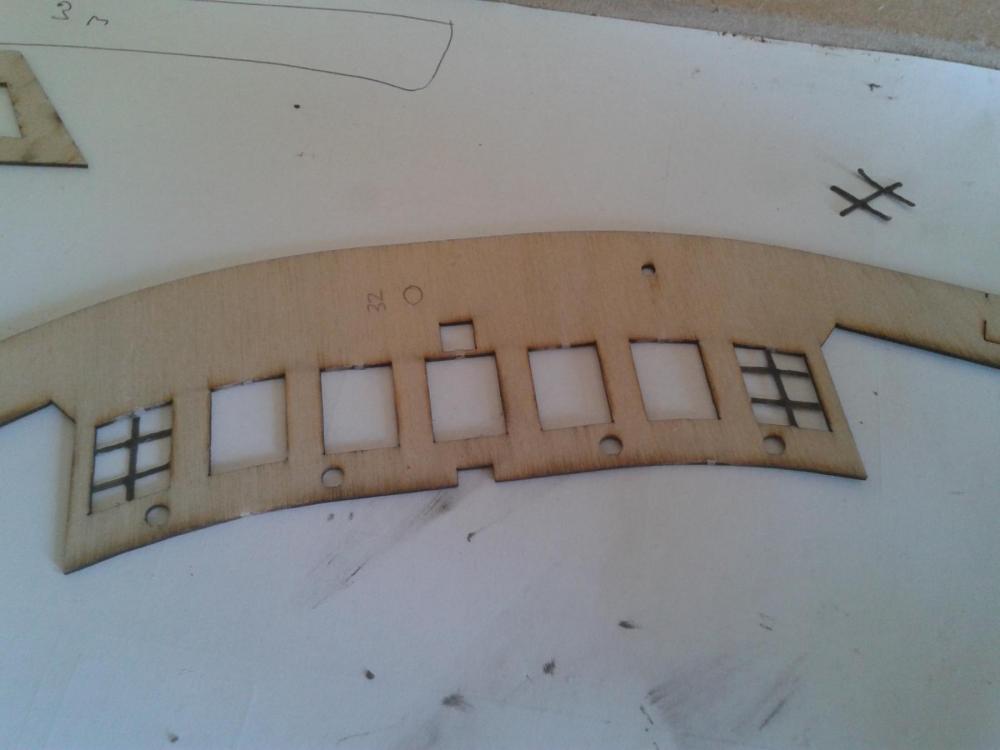

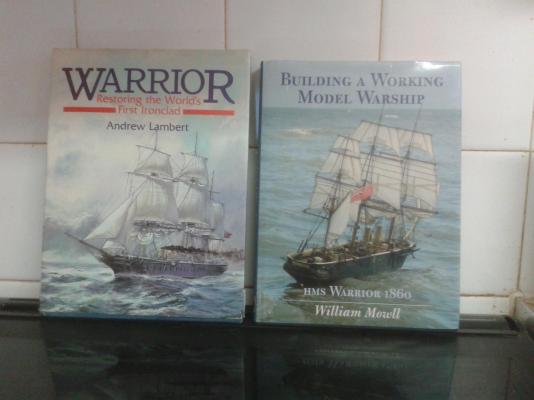

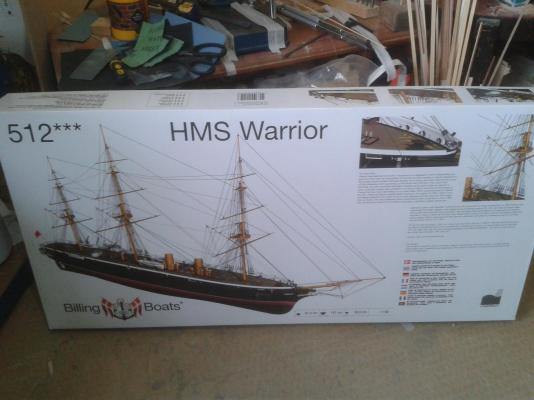

For my latest build I have chosen the Billing Warrior 1860, the first British ironclad battleship, which was powered by both steam and sail since those good folks at the Admiralty didn't quite yet trust something that belched smoke. I would have liked to make this a scratch build, but I couldn't find a set of decent plans and the two research books I've purchased don't go to that level of detail on the hull. So, another Billing kit with, as it turns out very poorly done laser cutting - half way through on a good day. Never mind, there are some decent drawings and the usual sparse instructions. She is a monster though and dwarfs the Victory at 1.47 m. Still, at least the hull wasn't copper plated. The box The contents The research books Spot the laser cut Dry fit of keel

-

Not sure why this is posted here ... that isn't the King of the Mississippi ...

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Thanks Bob, The timber wasn't too bad - I had to order some more for the hull as there wasn't enough but apart from that it was OK. If you think AL's timber is poor, I recommend you stay away from Billing kits! On my Victory build it was so bad I had to substitute better stuff for both the decking and the hull. Cheers, Philip

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

- 65 replies

-

- artesania latina

- king of the mississippi

-

(and 1 more)

Tagged with:

-

Nice looking sander Boyd, even nicer looking ship! Cheers, Philip

- 413 replies

-

Yes, it can be difficult to work around the wiring but I think that the end result is worth it, as shown by your pics above. Cheers, Philip

- 39 replies

-

Nice work! Are you sure you have enough monitors?

- 39 replies

-

@Napoleon: I kind of made up the lighting as I went along so it wasn't based on someone else's plan. As I recall there is at least one Victory build documented here that has LED lighting but I drew a blank trying to find it ... @Clarence: Plexiglass is cool but wood and brass cover a multitude of sins. The wire I used for both the Mississippi and Victory is AWG 30 with a diameter of around 0.5mm, which allegedly will carry up to 10A (I don't recommend trying it with that load!). That makes it small enough to run two power lines through a 5mm brass tube with an M4 bolt up the middle. Cheers, Philip

-

Boyd, Warrior aside, I was thinking of doing a scratch build of of one of these: http://www.cocatrez.net/Water/FerrisShips/FerrisShips.html of which some schematics are available. Between us ( and anyone else who's interested) we should be able to come up with a credible plan. Thoughts? Philip

- 413 replies

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.