-

Posts

239 -

Joined

-

Last visited

About kostas_gr

- Birthday 01/06/1971

Profile Information

-

Gender

Male

-

Location

Athens, Greece

-

Interests

Outdoor sports

Shotokan Karate

SUP

Recent Profile Visitors

-

TimF reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

TimF reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

kostas_gr reacted to a post in a topic:

HMS Victory by Pfälzer - Corel - 1:98

kostas_gr reacted to a post in a topic:

HMS Victory by Pfälzer - Corel - 1:98

-

brunnels reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

brunnels reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

PaddyO reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

PaddyO reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

vossiewulf reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

vossiewulf reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

eatcrow2 reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

eatcrow2 reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

Knocklouder reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

Knocklouder reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

ccoyle reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

ccoyle reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

KARAVOKIRIS reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

KARAVOKIRIS reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

KARAVOKIRIS reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

KARAVOKIRIS reacted to a post in a topic:

Hermione La Fayette by kostas_gr - Artesania Latina - 1:89

-

Knocklouder reacted to a post in a topic:

HMS Victory by Pfälzer - Corel - 1:98

Knocklouder reacted to a post in a topic:

HMS Victory by Pfälzer - Corel - 1:98

-

kostas_gr started following HMS Victory by Pfälzer - Corel - 1:98

-

kostas_gr reacted to a post in a topic:

HMS Victory by Pfälzer - Corel - 1:98

kostas_gr reacted to a post in a topic:

HMS Victory by Pfälzer - Corel - 1:98

-

I’m building the same kit, but I believe Corel's version is somewhat outdated. After reviewing numerous build logs and pictures, I’ve noticed several differences. I found the stern gallery particularly challenging to complete, so I decided to take a break and work on another kit for now. I’ll be following your build log closely to gather ideas from your progress

-

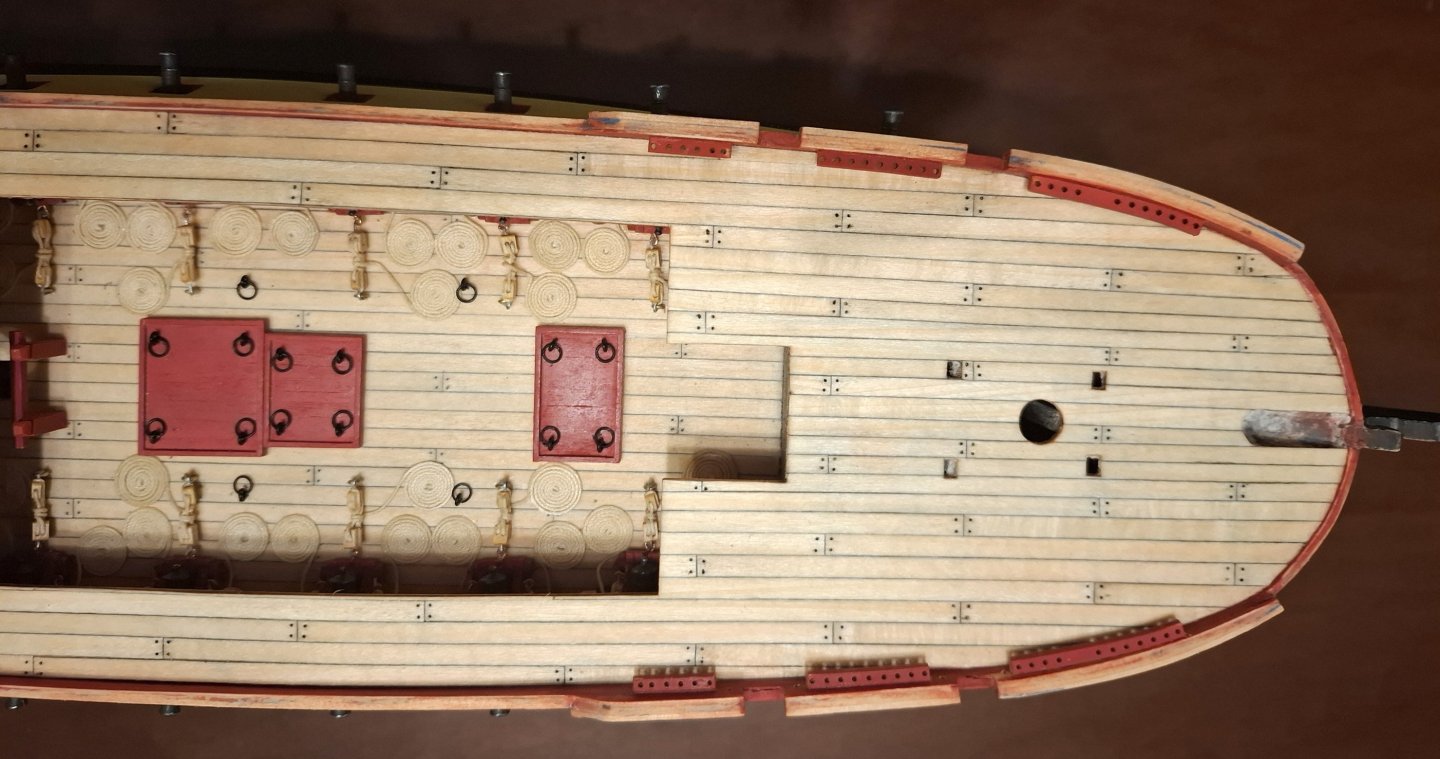

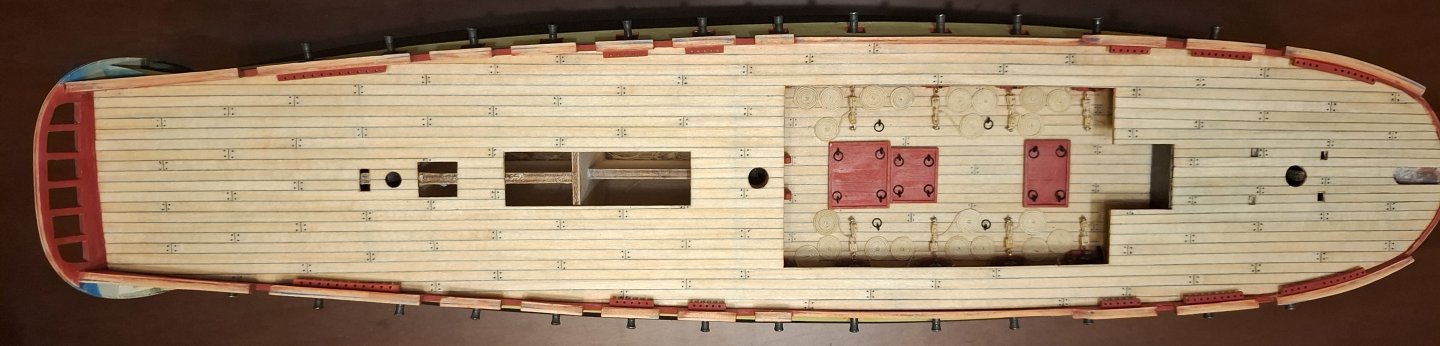

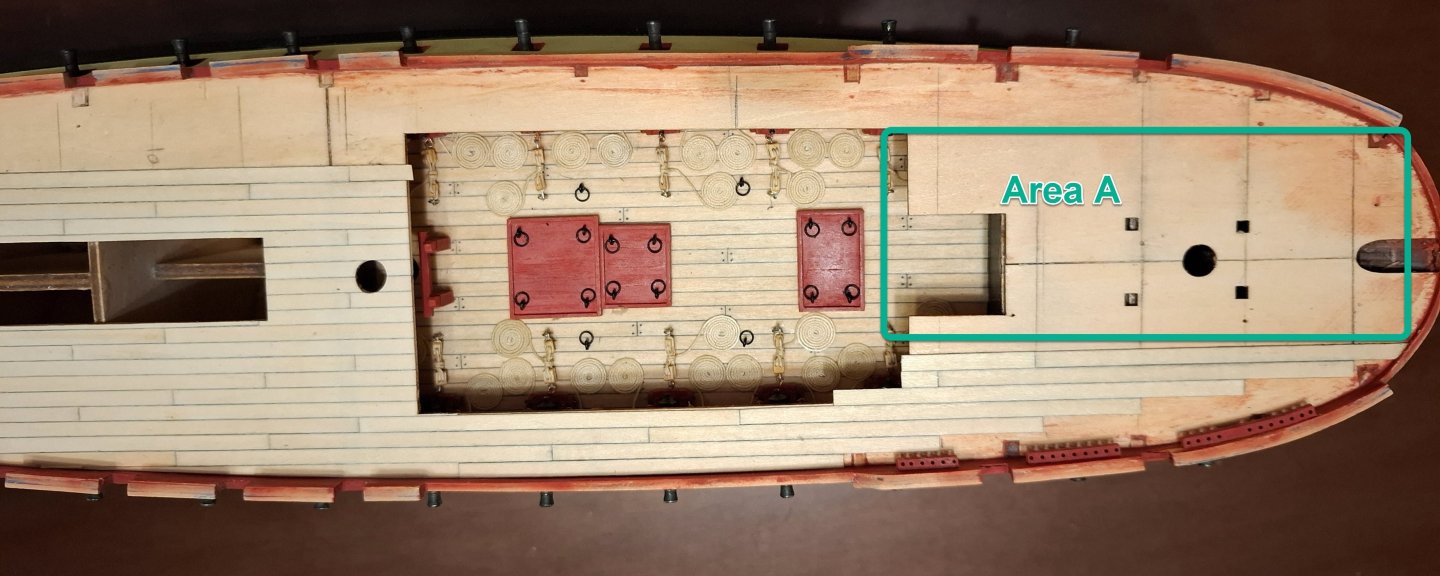

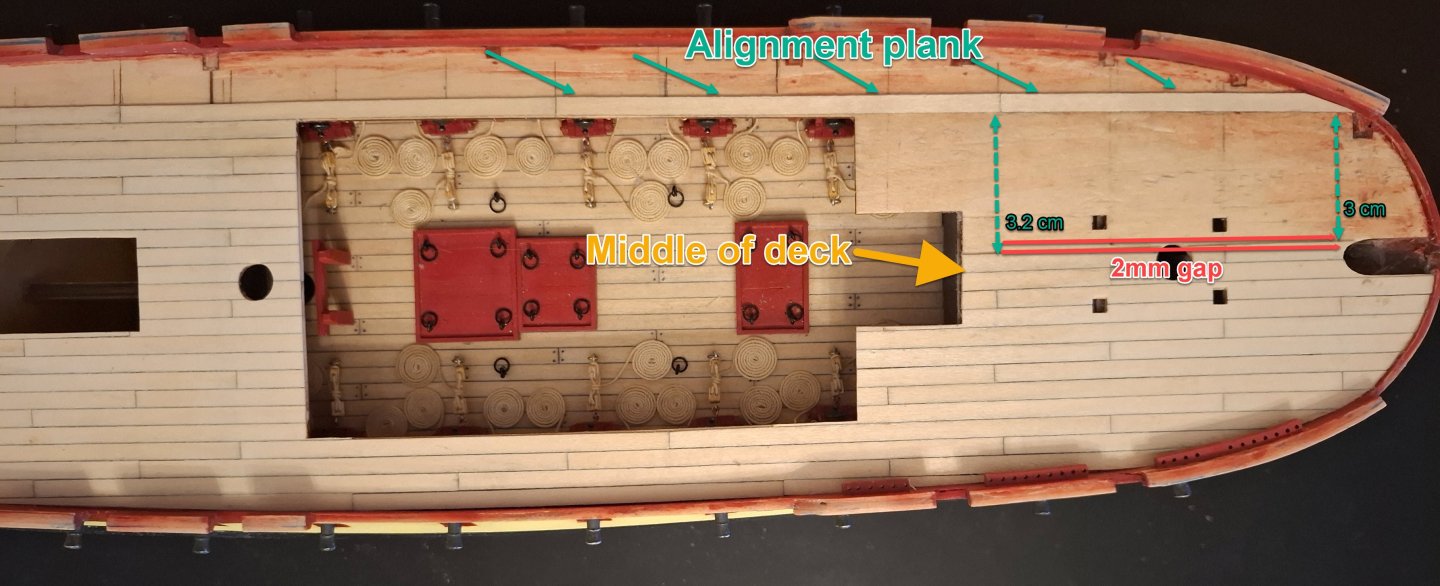

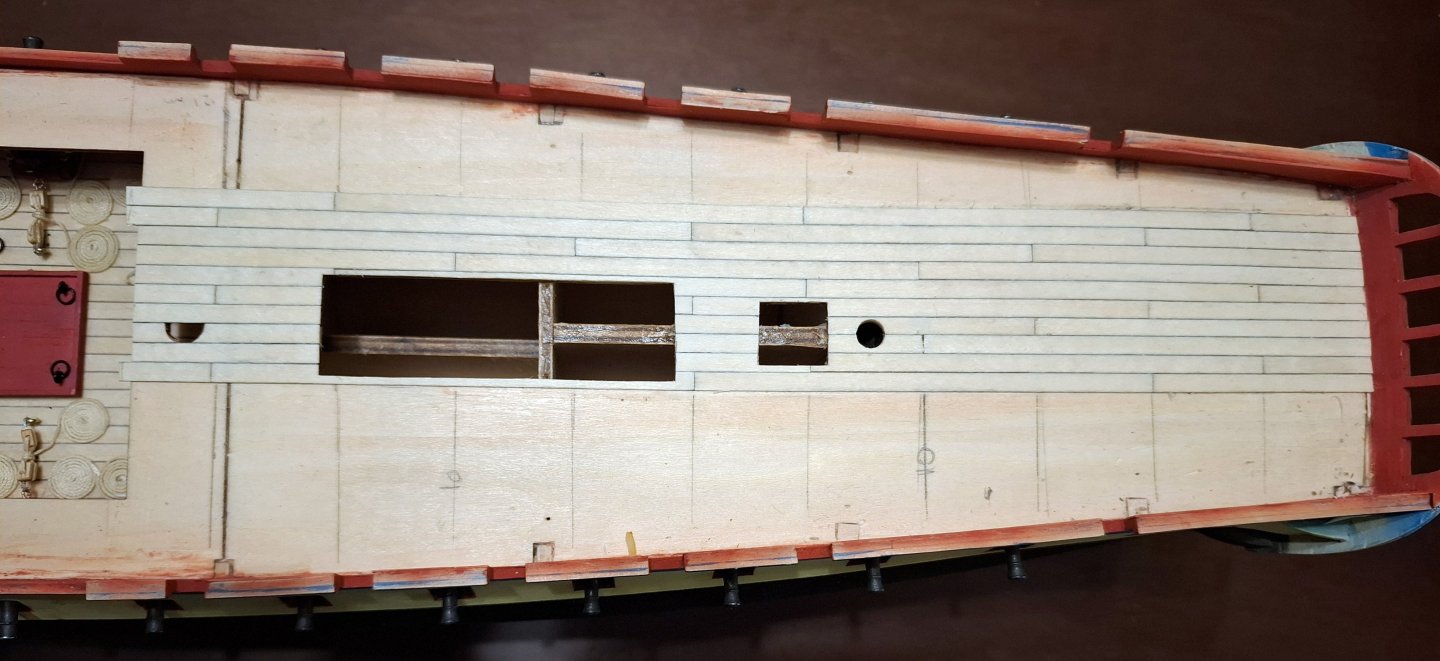

Feeling excited about completing the upper deck planking, I wanted to speed up the process. So, I decided to finish Area A first before continuing with the rest of the deck. After taking numerous measurements, I was confident that all the planks were properly aligned. However, in the end, I realized there was a 2mm gap error. With little I could do to fix it, I had no choice but to remove all the planks from Area A. By placing an alignment plank, I can get a clearer view of the corrections needed in Area A A top-down view shows that everything looks fine now

-

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

-

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

-

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

-

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

-

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

kostas_gr reacted to a post in a topic:

Hermione La Fayette by jks1981 - Artesania Latina - 1:89 Scale

-

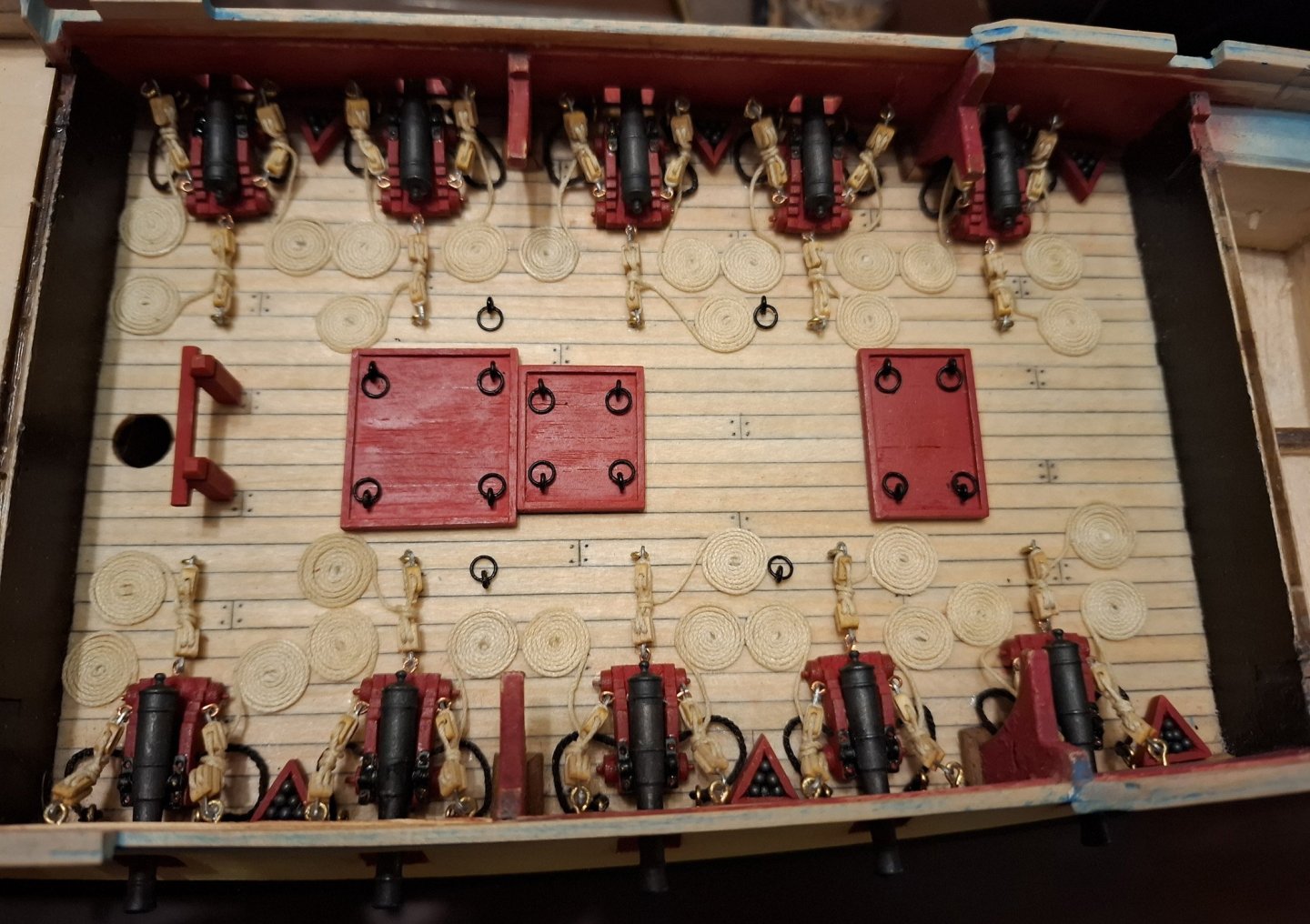

I’ve been considering whether to add treenails to the main deck or not. The reason I’m hesitant is that I’m not satisfied with how they usually turn out. Even when I drill the holes to the correct size, inserting the wooden treenails often makes the holes expand unevenly, resulting in inconsistent sizes and an out-of-scale appearance. Perhaps there’s an issue with my technique, but I’ve decided to try something different instead. My plan is to drill small holes and fill them with a thick paste made from white glue mixed with black acrylic paint. Using acrylic is crucial since white glue is water-based, and this approach will make it easier to clean up any excess paste with a damp paper towel, avoiding black stains on the deck fisrts holes are ready, drilled, filled up, cleaned. The rest of treenail are almost ready, in this picture you can see how the holes are looking before cleaning up the excess paste This is the final outcome, and I’m quite pleased with the result. I’m considering keeping this pattern as it is and not adding any additional treenails

-

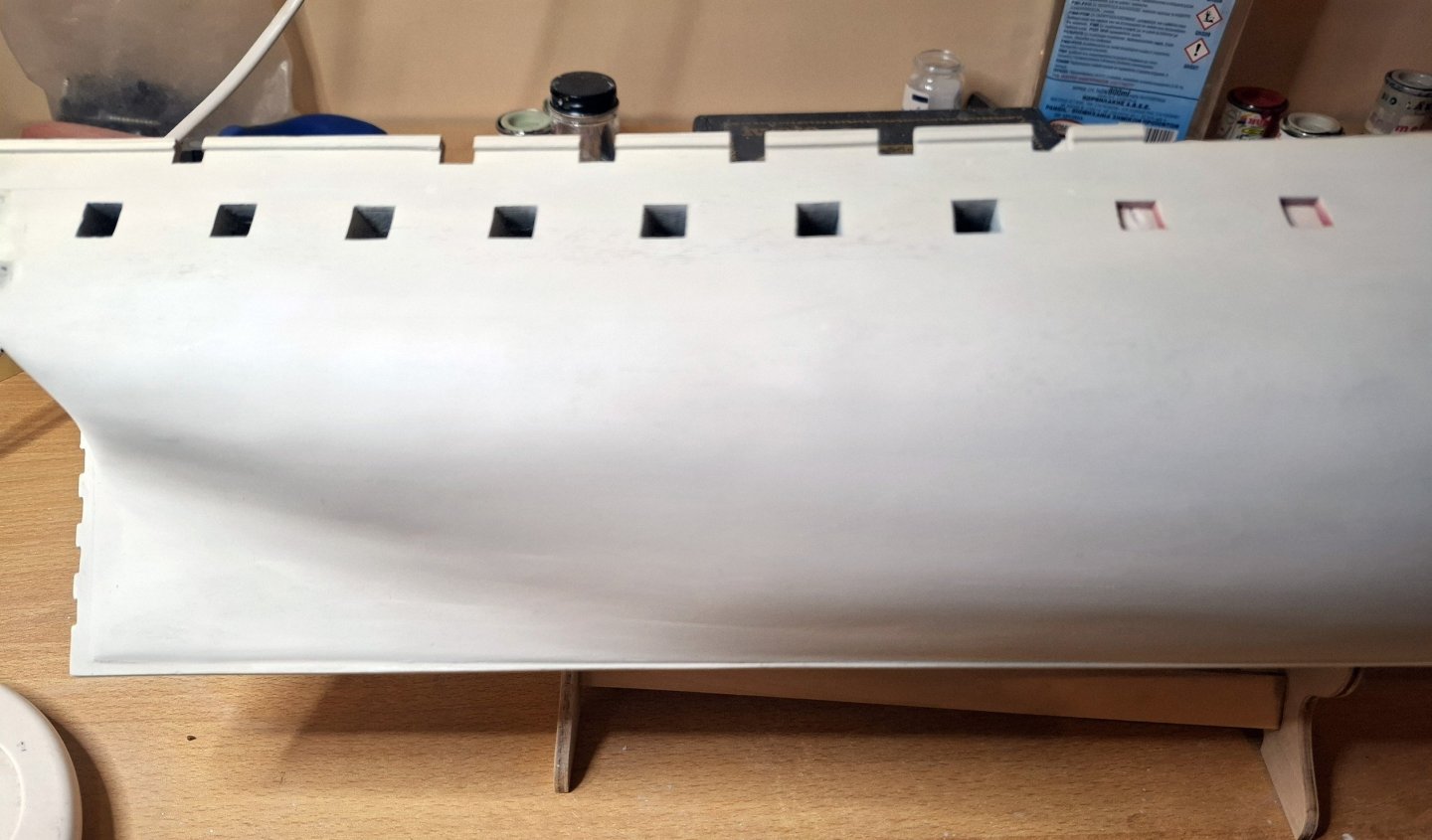

The main deck will be planked following the "rule of 4" using 10 cm planks. I encountered a staining issue caused by a blue acrylic paint spot that I hadn't fully removed by sanding. When I oiled the deck surface, the blue paint somehow seeped into the planks. I believe this wouldn't have happened if the paint had been enamel. As a result, I had to remove and redo 4-5 rows of planks.

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.