-

Posts

1,308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Gallery

Events

Everything posted by Gaetan Bordeleau

-

Building WOOD model ships is a process I enjoy very much working with wood. Photography is also another process I like to experiment. And lastly, milling and turning metal like aluminium and plastic is also something I enjoy. As a side note, you can turn plastic with high precision. Just like in car products, where you cannot install a door mirror of a car from one kind to another kind; the same thing appears with photography adaptors. Fitting adaptors or adapting some new ones to experiment further in photography of model ship is also an interesting avenue that I like to explore. Some examples are following to show trying to take photography a model ship and getting a photo with exactly the same colors as what you see. Of course you do not need all these adaptors to take photos but I like to experiment.

-

Roebuck from the plans of H. Hahn With the help of his book Ships of American revolution, I jumped in the scratch built models. I remember when I did it more than 30 years ago, It was very scary for me to enter in this category, there are so much details in the construction of a ship. Harold Hahn even if he did simplified the details was a very good builder and carver too.

-

Here is what I have left from boxwood. The biggest part which is good for a figurehead, was paid 5 pounds ... probably 25 years ago in Canada. It is sad to see that boxwood is harder and harder to get. This is a fact that boxwood is perfect for carving figurehead because the grain can retain the edge of the smallest details. Boxwood was largely use in France and UK. There are probably other exotic woods which could be suitable for carving. I do not think that fruitwood which are often harder than our domestic hardwood are suitable for carving. I tried apple tree but it does not compare to boxwood. It could be interesting to make some try in species like ebony, pernambuco, may be bloodwood and surely some others.

-

Thank you Albert, Beginning the nicest room on the ship. Building walls is fun, making tools also. One of the reasons I did tools, especially for the lathe and milling is simply, because I could not afford all these tools at the time. I like to watch video on You tube, and often about tools. Recently, I saw one where to hold the part which was too large for a live center in the tailstock, the guy did adapt a 4 jaw chuck as a live center. I like the idea, because it is unusual to see a 4 jaw chuck at the opposite end of the lathe, soI tried it.

-

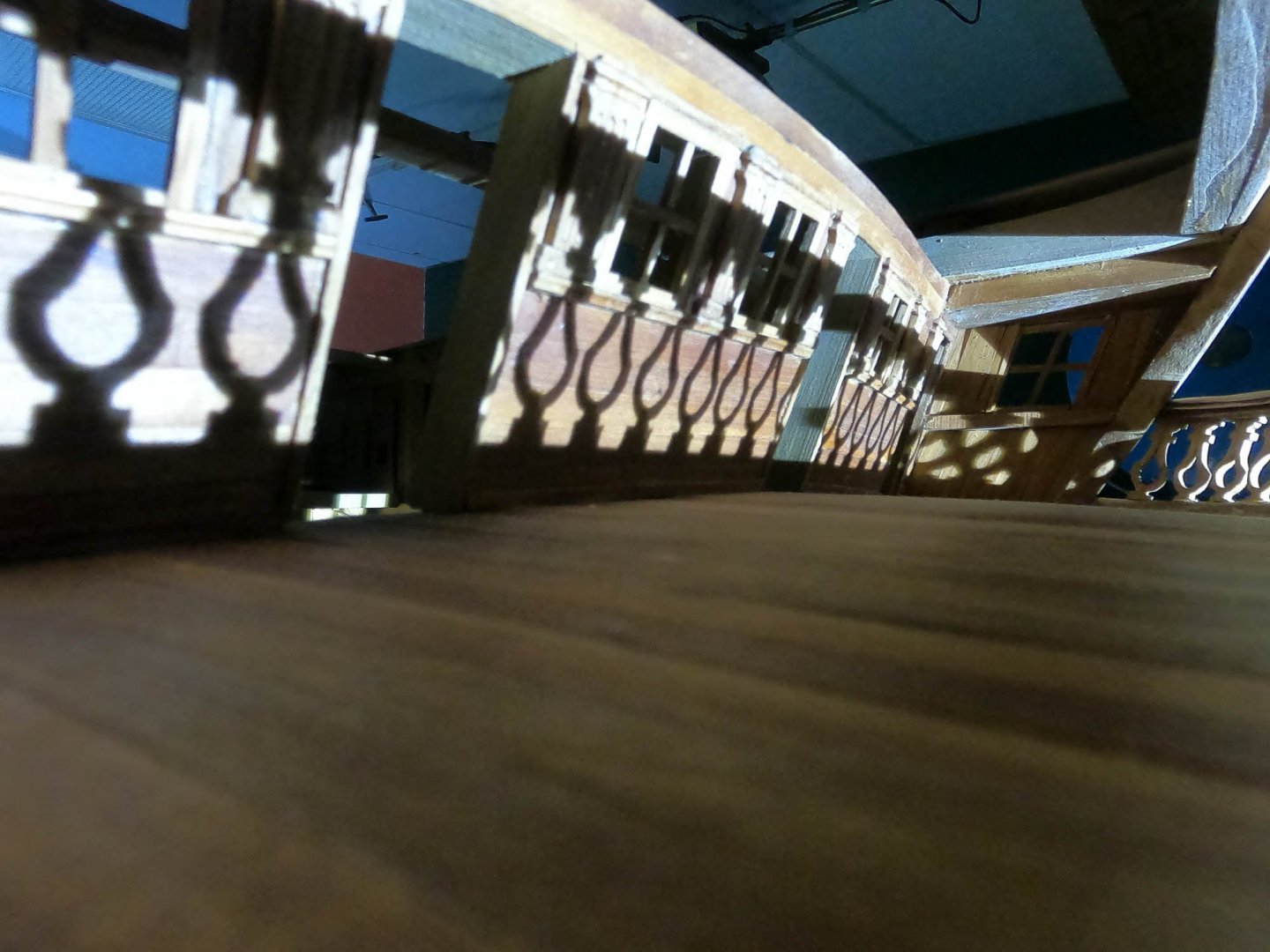

By example, when I use the Go pro inside a model ship, the camera rest anywhere it can stands well and the trigger is made by a phone. Inside, I never use a cable release. Mainly, I use Canon cameras. Canon delivers a program to control the camera at distance. There are also other programs which do it even better like ON1 photo raw, Capture one and so on and you can change many parameters directly from the Laptop. When taking a photo directly from the camera, it is hard to see the details of the photos because of the very small screen of the camera, it is easier to control the photos from the laptop screen or even better from a desktop computer. When I take photos during the construction, I hold the camera and try to adjust ISO as much as possible without going too far and increase the speed as fast as possible for the lens opening.

-

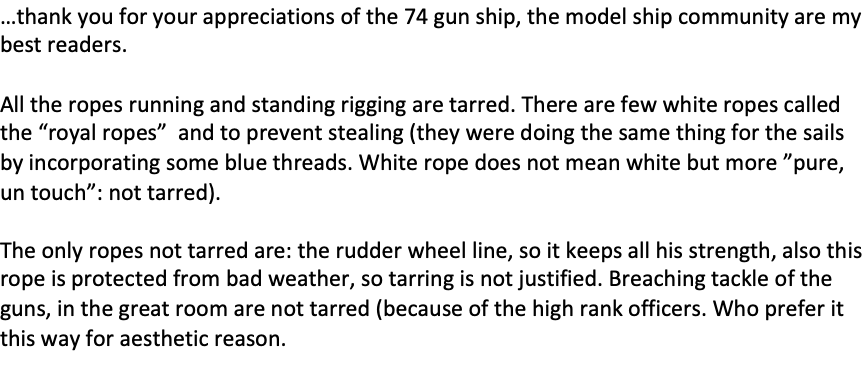

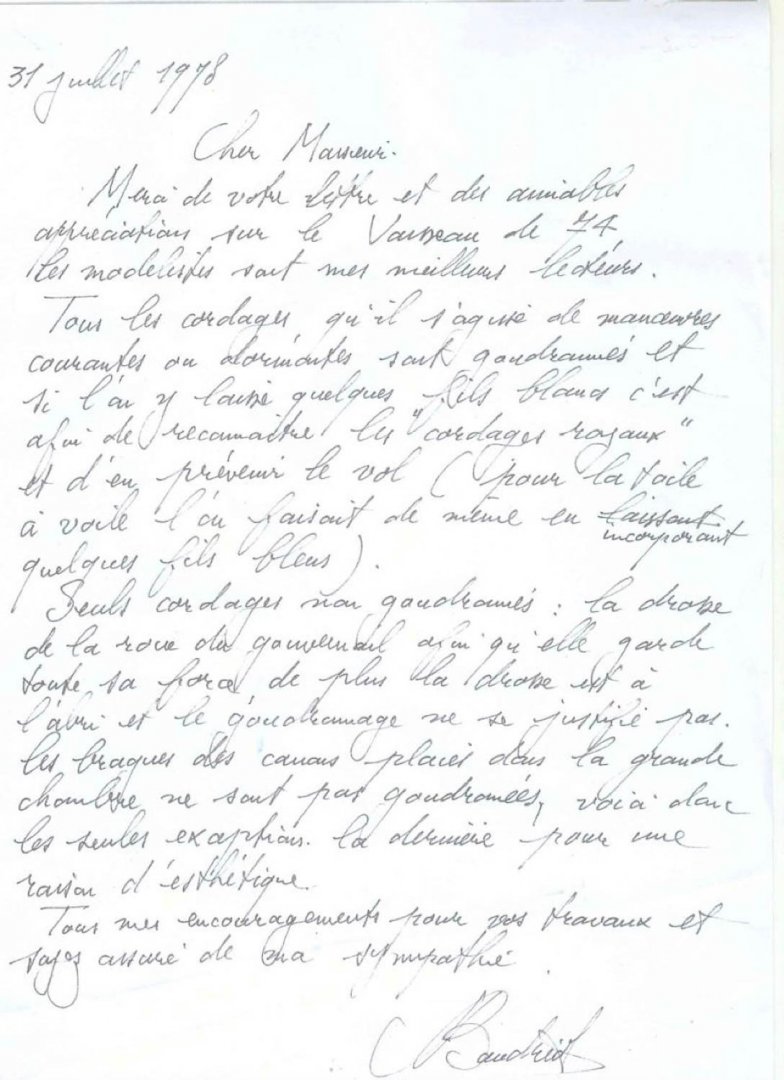

it goes about like this: (I guess there are also some pendants where it is important to keep the maximum strength so it does not break. If a tarred rope is let's say may be about 1/3 less strength than un tarred rope... does that mean that they had to slightly increase the rope diameter of ... few ropes?)

-

This is a subject which was rarely noted in books. I would guess, simply because it was clear in their mind that almost all the rigging was tarred with only few exceptions.

-

HMS VICTORY 1765 by albert - 1/48

Gaetan Bordeleau replied to albert's topic in - Build logs for subjects built 1751 - 1800

Hi Albert, thank you to show your good work. On the photo, you have 2 milling machine from Proxxon. Is the FF230 much better than the MF70, is there a big difference between these 2? -

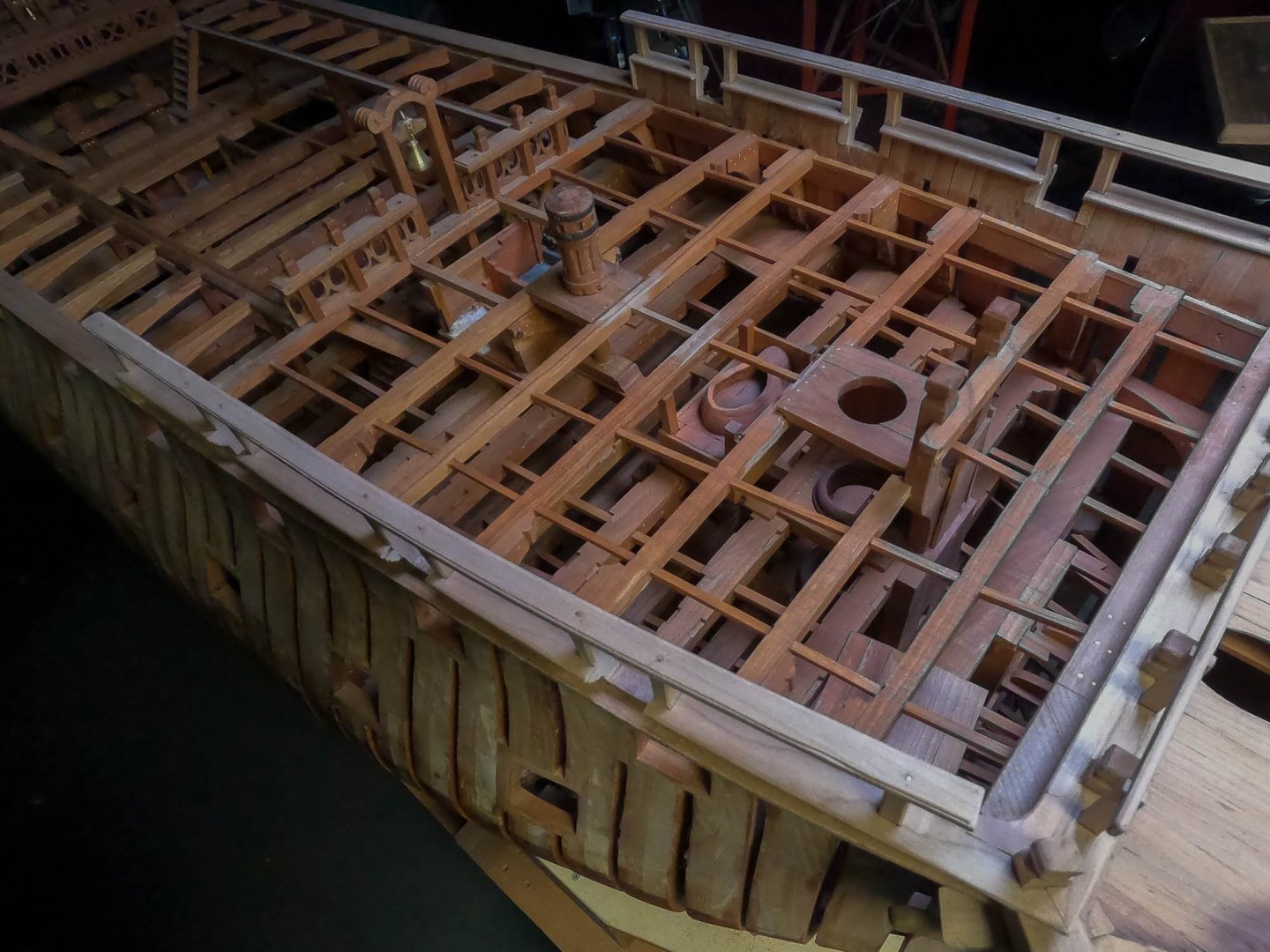

This morning, I wanted to test shooting from the top . The next working area will be the second deck, to add a few details and close that deck. Recently, Lightroom did a major step in his program. You can now select any part of the photos and work only on a part at the time modifying what you want. By example, if one part of the photo, from any size, is too dark, you can increase the light. It is now possible to do steps that were only possible in photoshop before. By example, you can change a background color in one easy step. I wonder what kinds of mathematical formulas are involved to achieve this. The only drawback, to use it you need to pay annual fee. It is not worth if you only take few photos every year, but it is acceptable if you take a lot of photos. It is a great tool to retouch the photos and also to organize the classification.

-

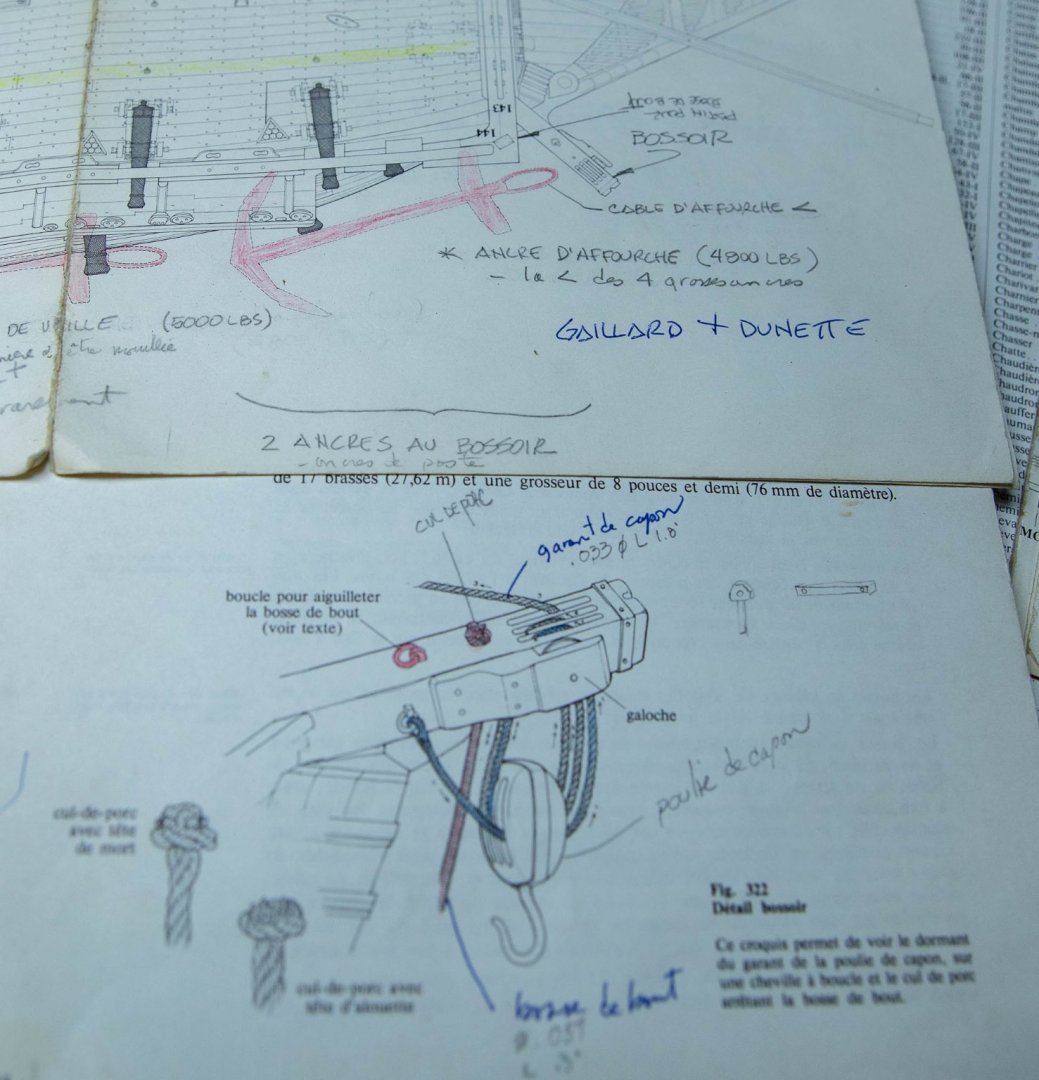

Here is an example why it can be interesting to build at a larger scale: When the anchor is lift on the ship there is a cable which is part of the cathead, the name is bosse de bout. This cable probably slip on an arched wood part named skate of the bosse de bout. It is also probably turned around the railing ounce or two and may be by having this skid, it slides easier? To know a clear answer, more research is needed or may be someone knows how.

-

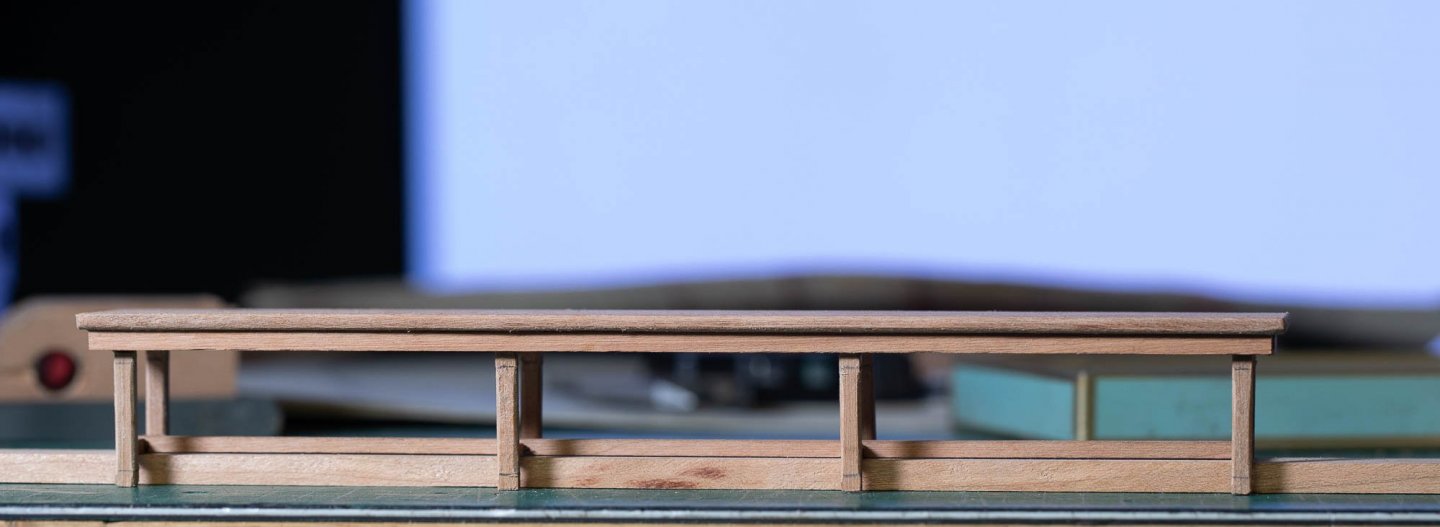

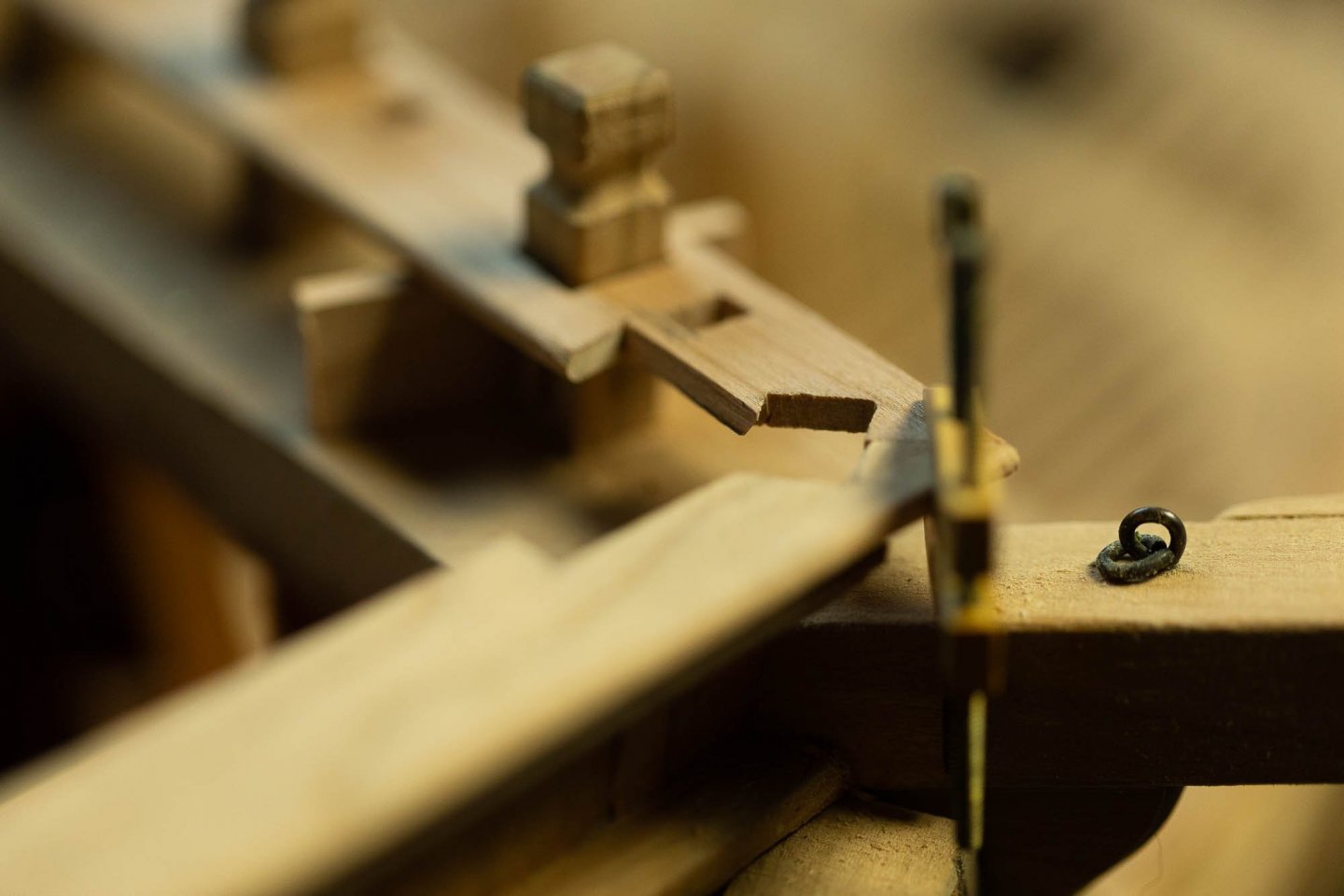

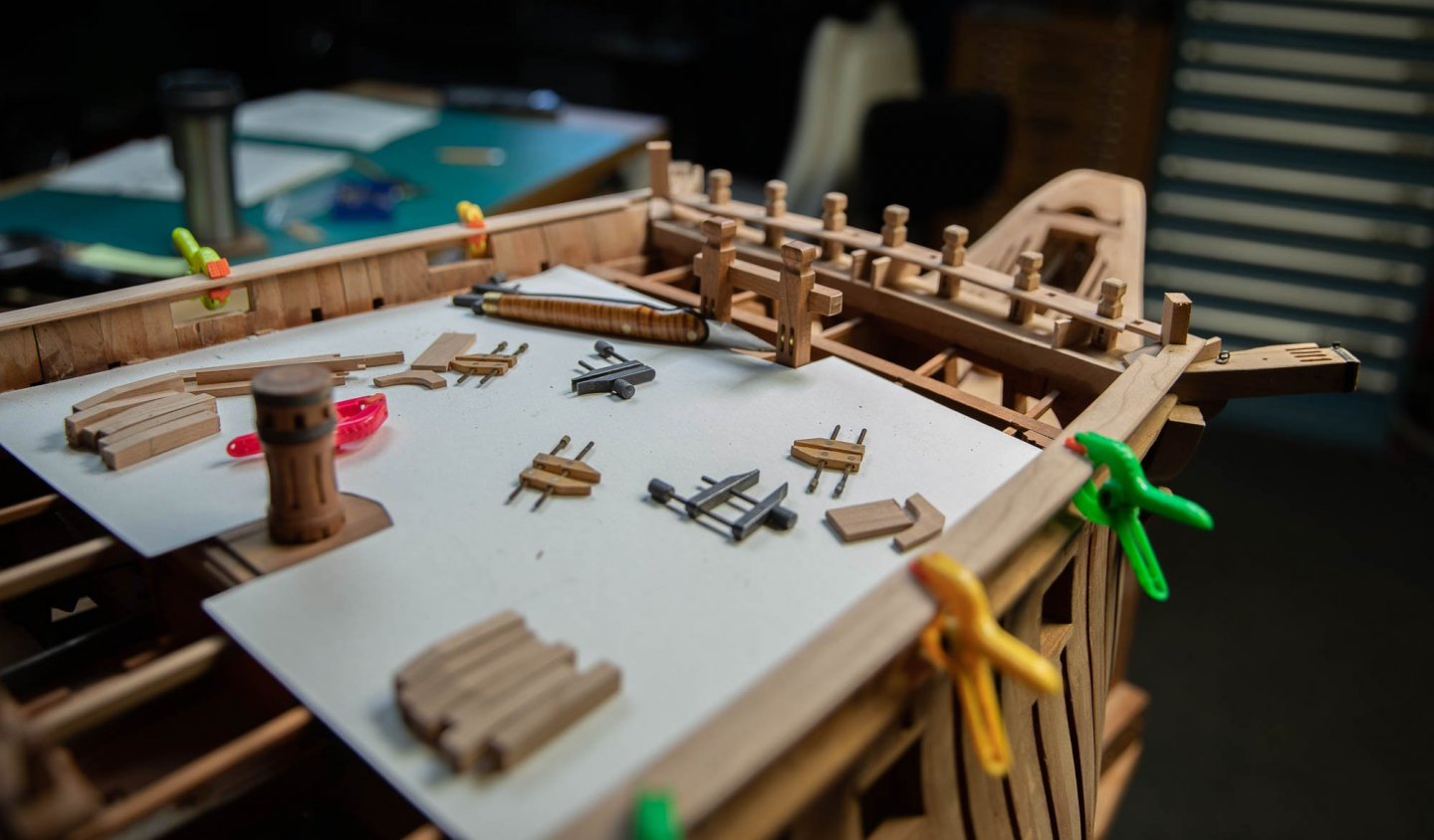

Stair railing during construction on the forecastle. What is the worst way to build the stairways? Glue the parts as they are done. Parts will be glued faster on the model but it will be harder to build other parts on the model itself. At the opposite, it is easier to build as much as possible without gluing. This way, a part can be remove as needed to be shape. Often, it will be easier to shape a part on the vise, simply because the vise will easily hold the part, something that the fingers cannot do very well, and the hands will be free to hold the tool to shape the part: at the good working angle and at the good height. Not in all the situations, but often a part of the fabrication is much easier done if the tool meets the part at the good angle and also at the good height where it is easier to perform a movement. 2 things are needed to achieve this: an electric height adjusting table. This is 1 of 2 important tools that everybody should have when possible. The other one is a vise. Choosing a vise looks like to be very easy to do.. This subject comes back occasionally in the tool section. The newcomer will usually buy a vise at a very low price. As in the learning of the model ship building, understanding what is a good tool often needs experimentation. When I was a beginner, I bought a hobby vise. With the wearing, the vise became harder and harder to squeeze tight the jaws. Also the angle adjustment had more and more trouble to hold the working position. It was not long that this tool became unusable. The second category of vise would be in the metal machining category. There is a company who made a good little one and this is Unimat. The problem with the milling vise, is that it is difficult to find a quality vise in the small sizes Finally, a third category of vise comes from the jewelry tool industry. The range is quite large. Unfortunately, there is a bad side, the price. In this category, the price can be as low as$20 for something simple and close to $1000 for an elaborate one. One of the main problem of the vise is to hold a part parallel to the table. The part has a tendency to be pushed out vertically, out of the vise. This is why a machinist will give the part a light hammer blow to seat well the part on the vise. This is also why the jaws need to have a way to stay well seated on the vise base. There are a lot of vises on the market but very few can really be called a good vise!

-

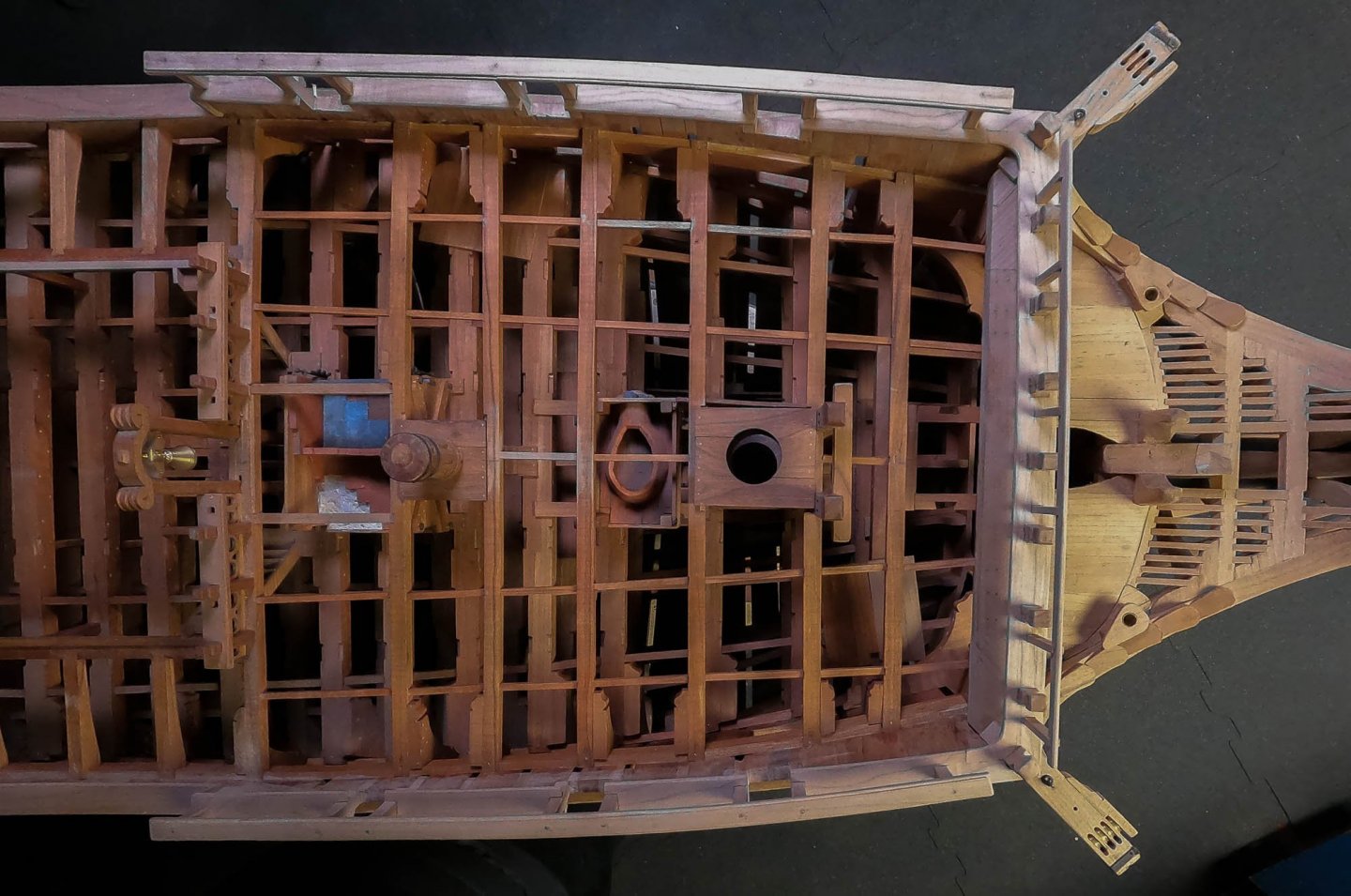

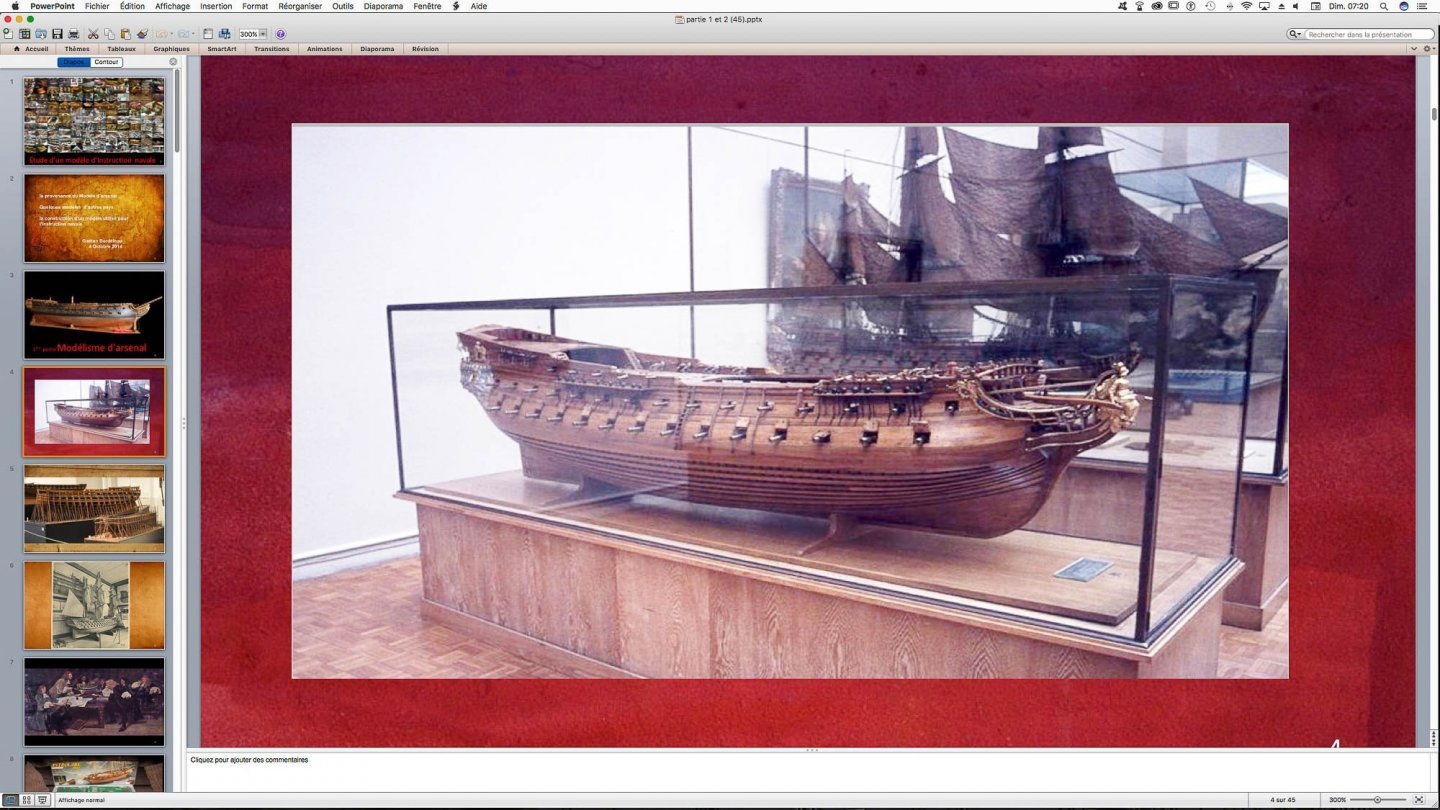

I did a log for 3 models: the first one a 74 guns. This log disappeared with MSW 1. The second one was a 64 guns: A third one, also in this forum, in construction, another 74 guns: I insert a photo of the first 74 guns: As Vaddoc said, edge bending is difficult. This easy way to solve the problem, is to cut the plank with the curve in it. It does require more wood, but the palnks are more stable this way. Rekon also did a model of the 64 guns at 1/24 scale on this forum: and there is a model of a 74 at the Maritime french museum" as in the last photo. Model ships were sometimes built at 1/24 scale to teach to the engineers the construction and also at 1/12 to easily show how the rigging was done.

-

I work around my 8 feet model ship with an electric micro motor! I see 4 main categories? Flex shaft removes dexterity Dremel are affordable and heavy Micro motors, electric, are the best choice, lightweight and performs and handles better than Dremel, and affordable Micro motor, brushless, can be as strong as Foredom with a shaft but more expensive.

-

You do not need a lathe, you need a block plane.

-

Before we can suggest something, you need to know what you will be turning. Instead to suggest you 1 brand of lathe, I would prefer to suggest to you a book about Metal lathe. Also compare different brands to see which one could suit your needs. Good reading

-

Why would you buy a wood lathe? A metal lathe would be much more versatile.

-

Variable speed dremels

Gaetan Bordeleau replied to Laggard's topic in Modeling tools and Workshop Equipment

Do any Foredom have a 0-50K rpm variable speed? yes -

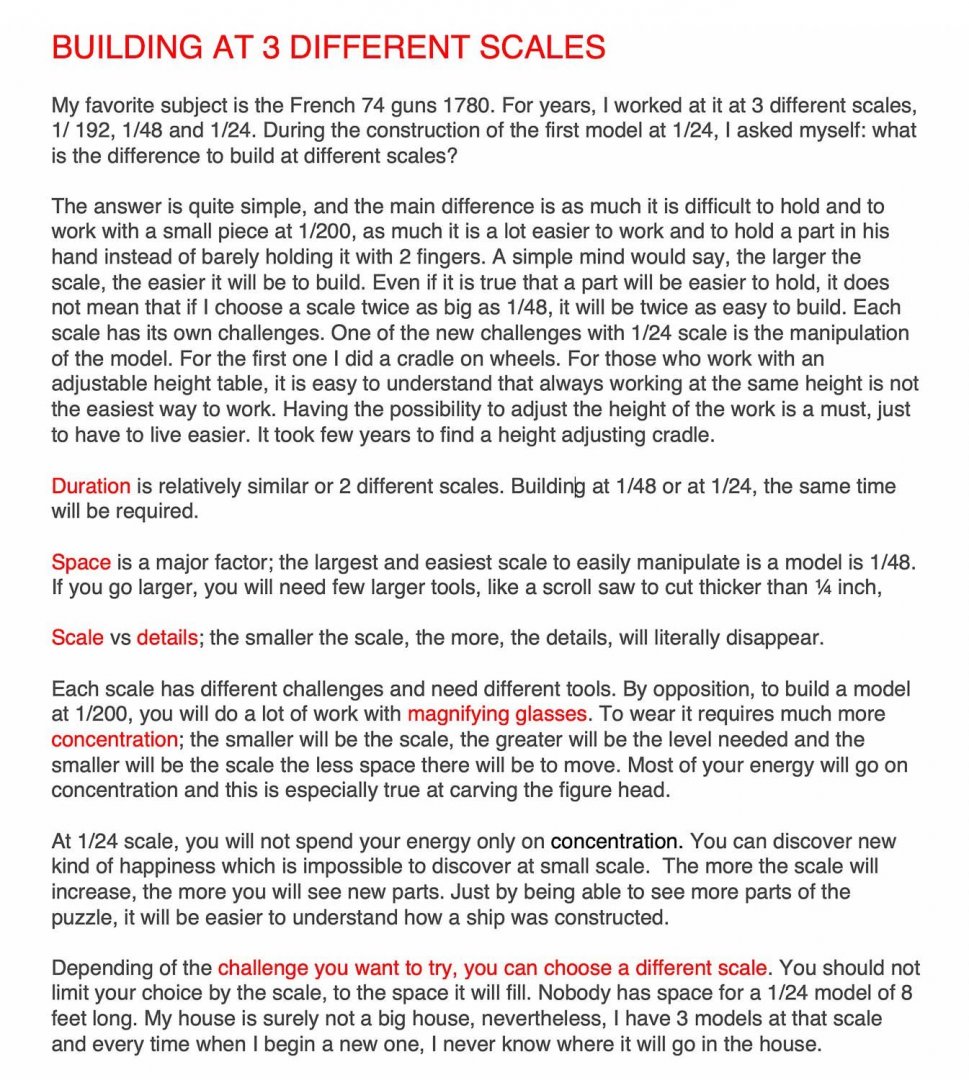

1/48 is the largest scale easy to handle in a room. This is why most of the models are built at this scale considering also the height when masts are installed. For the same reason, I chose 1/24, because it is the largest I can move in the workshop. If I wanted to add the mast, I would have to choose 1/36.

-

I wrote a few times about this subject: each scale has his own challenge. The smaller the scale, the more "visual aid" you will need to wear all the time. The larger the scale, the easier it will be to handle "with more fingers". To think that the larger means the easier to build is false. To build at 1/24 will require larger tools: like a larger saw bench, a larger scroll saw, larger files, etc. The smaller the scale, the more the details will disappear. Space will always be an issue; while you work and when you will have finished. If you try to find a spot in the house before to begin, you will not build it... but if you build one, you will find space. Actually, I am working on a third one at 1/24. Would I come back at 1/48, no. One of the interesting facts about working at this scale is that the comprehension of the wood ship construction is much easier simply because "you see the parts closer to their real size" and you see things that you could not see at 1/64 by example.

-

I saw this Jewelry tool dealer this morning for the first time. Jewelry tools are very useful for us the model ship makers. In the flex shaft and rotary category, to give an example, if you want to buy something much better than a Dremel; brushless are the best. https://jetsinc.com/categories/flex-shafts-and-rotary.html

About us

Modelshipworld - Advancing Ship Modeling through Research

SSL Secured

Your security is important for us so this Website is SSL-Secured

NRG Mailing Address

Nautical Research Guild

237 South Lincoln Street

Westmont IL, 60559-1917

Model Ship World ® and the MSW logo are Registered Trademarks, and belong to the Nautical Research Guild (United States Patent and Trademark Office: No. 6,929,264 & No. 6,929,274, registered Dec. 20, 2022)

Helpful Links

About the NRG

If you enjoy building ship models that are historically accurate as well as beautiful, then The Nautical Research Guild (NRG) is just right for you.

The Guild is a non-profit educational organization whose mission is to “Advance Ship Modeling Through Research”. We provide support to our members in their efforts to raise the quality of their model ships.

The Nautical Research Guild has published our world-renowned quarterly magazine, The Nautical Research Journal, since 1955. The pages of the Journal are full of articles by accomplished ship modelers who show you how they create those exquisite details on their models, and by maritime historians who show you the correct details to build. The Journal is available in both print and digital editions. Go to the NRG web site (www.thenrg.org) to download a complimentary digital copy of the Journal. The NRG also publishes plan sets, books and compilations of back issues of the Journal and the former Ships in Scale and Model Ship Builder magazines.